#Electromagnets

Text

Milo: I do think the around-the-world journey that you're always talking about is a good idea, you know.

Doris: You think so? Some people may think it's a pipe dream.

Milo: Well, I'm not some people. If there's anyone who can do it, it's you.

24 notes

·

View notes

Text

Studying astrophysically relevant plasma physics

New Post has been published on https://thedigitalinsider.com/studying-astrophysically-relevant-plasma-physics/

Studying astrophysically relevant plasma physics

Thomas Varnish loves his hobbies — knitting, baking, pottery — it’s a long list. His latest interest is analog film photography. A picture with his mother and another with his boyfriend are just a few of Varnish’s favorites. “These moments of human connection are the ones I like,” he says.

Varnish’s love of capturing a fleeting moment on film translates to his research when he conducts laser interferometry on plasmas using off-the-shelf cameras. At the Department of Nuclear Science and Engineering, the third-year doctoral student studies various facets of astrophysically relevant fundamental plasma physics under the supervision of Professor Jack Hare.

It’s an area of research that Varnish arrived at organically.

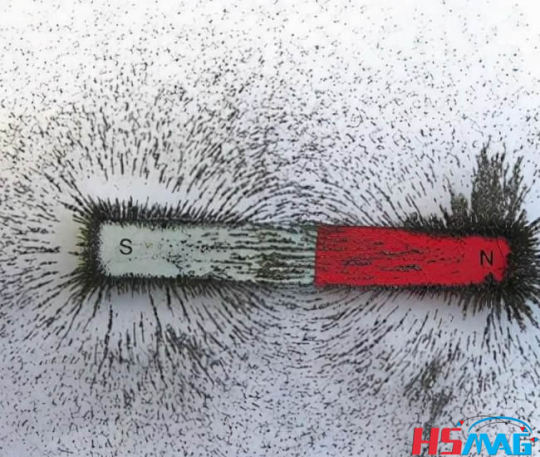

A childhood fueled by science

Growing up in Warwickshire, England, Varnish fell in love with lab experiments as a middle-schooler after joining the science club. He remembers graduating from the classic egg-drop experiment to tracking the trajectory of a catapult, and eventually building his own model electromagnetic launch system. It was a set of electromagnets and sensors spaced along a straight track that could accelerate magnets and shoot them out the end. Varnish demonstrated the system by using it to pop balloons. Later, in high school, being a part of the robotics club team got him building a team of robots to compete in RoboCup, an international robot soccer competition. Varnish also joined the astronomy club, which helped seed an interest in the adjacent field of astrophysics.

Varnish moved on to Imperial College London to study physics as an undergraduate but he was still shopping around for definitive research interests. Always a hands-on science student, Varnish decided to give astronomy instrumentation a whirl during a summer school session in Canada.

However, even this discipline didn’t quite seem to stick until he came upon a lab at Imperial conducting research in experimental astrophysics. Called MAGPIE (The Mega Ampere Generator for Plasma Implosion Experiments), the facility merged two of Varnish’s greatest loves: hands-on experiments and astrophysics. Varnish eventually completed an undergraduate research opportunity (UROP) project at MAGPIE under the guidance of Hare, his current advisor, who was then a postdoc at the MAGPIE lab at Imperial College.

Part of Varnish’s research for his master’s degree at Imperial involved stitching together observations from the retired Herschel Space Telescope to create the deepest far-infrared image ever made by the instrument. The research also used statistical techniques to understand the patterns of brightness distribution in the images and to trace them to specific combinations of galaxy occurrences. By studying patterns in the brightness of a patch of dark sky, Varnish could discern the population of galaxies in the region.

Move to MIT

Varnish followed Hare (and a dream of studying astrophysics) to MIT, where he primarily focuses on plasma in the context of astrophysical environments. He studies experimental pulsed-power-driven magnetic reconnection in the presence of a guide field.

Key to Varnish’s experiments is a pulsed-power facility, which is essentially a large capacitor capable of releasing a significant surge of current. The electricity passes through (and vaporizes) thin wires in a vacuum chamber to create a plasma. At MIT, the facility currently being built at the Plasma Science and Fusion Center (PSFC) by Hare’s group is called: PUFFIN (PUlser For Fundamental (Plasma Physics) INvestigations).

In a pulsed-power facility, tiny cylindrical arrays of extremely thin metal wires usually generate the plasma. Varnish’s experiments use an array in which graphite leads, the kind used in mechanical pencils, replace the wires. “Doing so gives us the right kind of plasma with the right kind of properties we’d like to study,” Varnish says. The solution is also easy to work with and “not as fiddly as some other methods.” A thicker post in the middle completes the array. A pulsed current traveling down the array vaporizes the thin wires into a plasma. The interactions between the current flowing through the plasma and the generated magnetic field pushes the plasma radially outward. “Each little array is like a little exploding bubble of magnetized plasma,” Varnish says. He studies the interaction between the plasma flows at the center of two adjacent arrays.

Studying plasma behavior

The plasma generated in these pulsed-power experiments is stable only for a few hundred nanoseconds, so diagnostics have to take advantage of an extremely short sampling window. Laser interferometry, which images plasma density, is Varnish’s favorite. In this technique, a camera takes a picture of a split laser beam, one arm of which encounters the plasma and one that doesn’t. The arm that hits the plasma produces an interference pattern when the two arms are recombined. Capturing the result with a camera allows researchers to infer the structure of the plasma flows.

Another diagnostic method involves placing tiny loops of metal wire in the plasma (called B-dots), which record how the magnetic field in the plasma changes in time. Yet another way to study plasma physics is using a technique called Faraday rotation, which measures the twisting of polarized light as it passes through a magnetic field. The net result is an “image map of magnetic fields, which is really quite incredible,” Varnish says.

These diagnostic techniques help Varnish research magnetic reconnection, the process by which plasma breaks and reforms magnetic fields. It’s all about energy redistribution, Varnish says, and is particularly relevant because it creates solar flares. Varnish studies how having not-perfectly-opposite magnetic field lines might affect the reconnection process.

Most research in plasma physics can be neatly explained by the principles of magnetohydrodynamics, but the phenomena observed in Varnish’s experiments need to be explained with additional theories. Using pulsed power enables studies over longer length scales and time periods than in other experiments, such as laser-driven ones. Varnish is looking forward to working on simulations and follow-up experiments on PUFFIN to study these phenomena under slightly different conditions, which might shed new light on the processes.

At the moment, Varnish’s focus is on programming the control systems for PUFFIN so he can get it up and running. Part of the diagnostics system involves ensuring that the facility will deliver the plasma-inducing currents needed and perform as expected.

Aiding LGBTQ+ efforts

When not working on PUFFIN or his experiments, Varnish serves as co-lead of an LGBTQ+ affinity group at the PSFC, which he set up with a fellow doctoral student. The group offers a safe space for LGBTQ+ scientists and meets for lunch about once a month. “It’s been a nice bit of community building, and I think it’s important to support other LGBTQ+ scientists and make everyone feel welcome, even if it’s just in small ways,” Varnish says, “It has definitely helped me to feel more comfortable knowing there’s a handful of fellow LGBTQ+ scientists at the center.”

Varnish has his hobbies going. One of his go-to bakes is a “rocky road,” a British chocolate bar that mixes chocolate, marshmallows, and graham crackers. His research interests, too, are a delicious concoction mixed together: “the intersection of plasma physics, laboratory astrophysics, astrophysics (the won’t-fit-in-a-lab kind), and instrumentation.”

#analog#approach#arm#Arrays#Astronomy#Astrophysics#Building#Cameras#Canada#college#Community#competition#Computer modeling#control systems#Dark#dark sky#diagnostics#easy#electricity#electromagnetic#electromagnets#energy#engineering#experimental#Explained#focus#Fundamental#Fusion#galaxies#Galaxy

2 notes

·

View notes

Text

Magnet Glossary

Magnet Glossary

A

Air Gap

An air gap is non-magnetic material present between a magnet and an attracted object or between two magnets attracting each other. It acts as a break in the magnetic circuit, weakening the magnetic hold. The air gap can be filled with air, wood, plastic, aluminum, paint, or any uneven surface. Refer to the ‘Pull-gap’ curve entry for a description of how pull strength…

#Alnico#aluminum nickel cobalt#Ceramic Magnets#Curie temperature#Electromagnets#Ferrite Magnets#ferromagnetic metal#magnet attraction#Magnet Knowledge#Magnet Maximum Operating Temperature#magnetic attraction#magnetic characteristics#Magnetic Field Strength#magnetic flux density#magnetic force#magnetic material#magnetic strength#magnetic suction#Magnetism#Magnets Manufacturer#NdFeB Magnet#NdFeB magnetic ring#NdFeB Ring Magnets#Neodymium iron boron#Permanent Magnet#Permanent Magnet Materials#samarium cobalt#strong magnet#super strong magnets

0 notes

Text

Elevating Efficiency in Steel Manufacturing with Circular Lifting Electromagnets

Introduction: In the bustling world of steel manufacturing, where efficiency and precision reign supreme, circular lifting electromagnets have proven to be indispensable. These powerful devices transform the way heavy steel plates and rods are handled, making operations not only quicker but also safer.

The Role of Electromagnets in Steel Manufacturing: Imagine a factory floor teeming with activity where the seamless movement of massive steel materials is crucial. The circular lifting electromagnet comes into play as a pivotal tool, capable of hoisting tons of steel with magnetic precision. This not only streamlines the workflow but also slashes operational costs and manual labor significantly.

How Circular Lifting Electromagnets Work: These specialized devices create a uniform magnetic field, ideal for handling ferrous materials like steel. The magnetic field is generated by an electric current passing through coils, enabling the electromagnet to attract and lift steel objects effortlessly. The operation is straightforward: activate the current to lift, and deactivate it to release the load, ensuring a smooth workflow on the factory floor.

Advantages of Using Circular Lifting Electromagnets:

Enhanced Operational Efficiency: Circular lifting magnets drastically cut down the time and effort needed for material handling. This increase in efficiency not only boosts production rates but also reduces downtime, enhancing overall profitability.

Improved Safety Measures: The safety of the workplace is paramount, especially in heavy industries like steel manufacturing. Lifting electromagnets ensure a secure grip on materials without the need for manual handling, minimizing the risk of workplace accidents and enhancing employee safety and morale.

Environmental Sustainability: By optimizing material handling and reducing energy consumption, circular electromagnets play a crucial role in promoting sustainable manufacturing practices. This contributes to lower carbon emissions and aligns with global environmental goals.

Reduced Labor Costs: The automation of lifting processes reduces the dependency on manual labor, which in turn lowers labor costs and optimizes resource allocation. The durability and low maintenance of electromagnets further ensure minimal operational disruptions.

Versatility in Applications: Circular lifting electromagnets are not just limited to lifting; they are versatile tools that can be integrated into various parts of the production line, from overhead cranes to specialized lifting equipment. This adaptability helps streamline processes and reduce bottlenecks.

Conclusion:

Circular lifting electromagnets are transforming the steel manufacturing industry by enhancing operational efficiency, safety, and sustainability. As the industry evolves, incorporating such innovative technologies is key to staying competitive and meeting the increasing global demand for steel.

For more insights into how circular lifting electromagnets can revolutionize your operations, visit Electro Flux today.

#Circular lifting electromagnets#lifting electromagnets#electromagnets#steel manufacturing#steel#steel industry

0 notes

Text

Working With Magnets in High or Low Temperatures

Working With Magnets in High or Low Temperatures

The ambient temperature surrounding your magnets during work impact their strength significantly, but each magnetic material is different. Which magnet works best in your conditions?

High or Low Temperatures | Get the Right Magnets for Your Application in High or Low Temperatures

Temperature and magnetic strength have a turbulent relationship.

Some…

View On WordPress

#Alnico magnets#Ceramic Ferrite Magnets#Ceramic magnets#electromagnets#ferrite magnets#General Questions#licensed neodymium magnets#magnet question#magnetic domains#neodymium iron boron#Neodymium magnets#permanent magnets#Protect Magnets#rare earth magnets#Rare Earths#Samarium Cobalt magnets#Stainless Steel Case Magnets#Stainless Steel Magnetic

0 notes

Text

Amazing The Global Strontium Carbonate Market Is Expected To Register A Considerable Growth By 2032: AMR

#Bone Health#Frit Manufacturing#Novel Nanoparticle#Fireworks Manufacturing#Pyrotechnics#Ceramics#Electromagnets

0 notes

Text

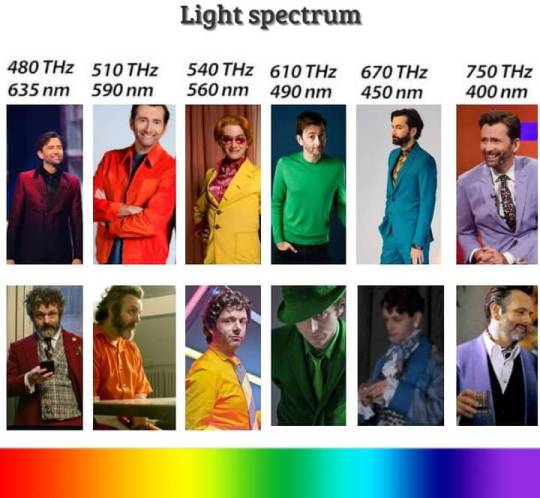

Agatataghaghhhhh

#good omens#david tennant#micheal sheen#light spectrum#waves#electromagnetic waves#crowley#aziraphale

2K notes

·

View notes

Text

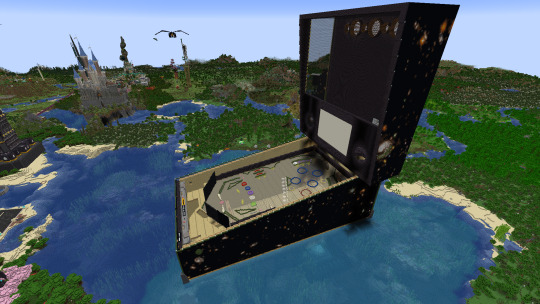

I just hit a huge milestone designing my giant pinball machine in Minecraft: the playfield is all laid out!

I'm calling the game Deep Field, and there's five primary objectives based on hitting different shots representing bands of the electromagnetic spectrum.

IR: rollover switches

Visible light: pop bumpers

UV: captive ball

X-rays: Drop targets

Gamma rays: spinner

Also, a kinetic sling disc to light locks for Pluto Multiball!

#hermitcraft#deep field#jwst#pinball#electromagnetic spectrum#xray#infrared#visible light#gamma rays#no radio or microwaves not a single luxury#joehillstsd#joehills#hermitcraft 9#joe hills#bobby mod

1K notes

·

View notes

Text

NORTLUCA ARMY! RISE!

#art#queer#idv#idv fool's gold#idv luca#idv hunter#idv norton#idv prospector#idv fanart#idv prisoner#identity v#identity v prisoner#identity v prospector#identity v fool's gold#fool’s gold#prisoner#nortluca#luca x norton#norton campbell#luca balsa#electromagnetism

198 notes

·

View notes

Text

ID: An illustration of Max and Sam sitting next to each other. Max has burn scars from a fire that exposes part of his skull, and a gaping hole in his chest. Sam also has burn scars that expose the opposite side of his skull, along with sparks of electricity fizzing around him and a huge lightning scar across his whole arm and hands. End ID.

do you think their hells are close to each other

#sam and max#sam and max freelance police#sam and max the devil's playhouse#sam and max spoilers#tdph spoilers#god help me idk what proper coverage for this kind of spoiler is#anyways sam has a lightning theme bc of the comment abt electromagnetism smile#thefinearts

144 notes

·

View notes

Text

Commission: Nora helping out Pyrrha

Some Electromagnetism goodness for folks! Hope y'all enjoy! If you'd like a comm too, i'm always open on here, twitter or discord under MamaLuigi2018!

139 notes

·

View notes

Text

Irene: Wait, what? How?

Lydia: Well, it all started when Margaret's boyfriend broke up with her. I always thought it was about time for her to lose him, he was a giant asshole. But, anyway, she feels kind of sad and humiliated. She wasn't even the one to dump him, and I think he left her indicating she wasn't good enough for him. So I said "babe, let's just go to Solar Coast and wash your troubles away". And she agreed. So...

Irene: Okay... But, just for your information, Milo has a small house, I don't think he'll be able to host everyone. Perhaps Eden-

Lydia: Pfft! Sister! Who do you think we are? Of course we booked a hotel. And Eden? I wouldn't even dare to bother Eden, she literally lives in the dorms and probably is dying for crumbs of privacy with her girlfriend. But that invitation to hang out together stands. You and your best friend, me and my best friend...

Irene: Oh, got it. Man, sometimes I wish I was as spontaneous as you. Don't tell anyone, but I've been freaking out about that trip since last month! Somehow it's... more anxiety-inducing than all of my previous meetings with Milo.

20 notes

·

View notes

Text

Engineers 3D print the electromagnets at the heart of many electronics - Technology Org

New Post has been published on https://thedigitalinsider.com/engineers-3d-print-the-electromagnets-at-the-heart-of-many-electronics-technology-org/

Engineers 3D print the electromagnets at the heart of many electronics - Technology Org

Imagine building an entire dialysis machine using nothing more than a 3D printer.

Caption:MIT researchers modified a multi-material 3D printer so it could produce three-dimensional solenoids in one step by layering ultrathin coils of three different materials. It prints a U.S. quarter-sized solenoid as a spiral by layering material around the soft magnetic core, with thicker conductive layers separated by thin insulating layers.

Illustration by the researchers

This could not only reduce costs and eliminate manufacturing waste, but also since this machine could be produced outside a factory, people with limited resources or those who live in remote areas may be able to access this medical device more easily.

While multiple hurdles must be overcome to develop electronic devices that are entirely 3D printed, a team at MIT has taken an important step in this direction by demonstrating fully 3D-printed, three-dimensional solenoids.

Solenoids, electromagnets formed by a coil of wire wrapped around a magnetic core, are a fundamental building block of many electronics, from dialysis machines and respirators to washing machines and dishwashers.

The researchers modified a multimaterial 3D printer so it could print compact, magnetic-cored solenoids in one step. This eliminates defects that might be introduced during post-assembly processes.

This customized printer, which could utilize higher-performing materials than typical commercial printers, enabled the researchers to produce solenoids that could withstand twice as much electric current and generate a magnetic field that was three times larger than other 3D-printed devices.

In addition to making electronics cheaper on Earth, this printing hardware could be particularly useful in space exploration. For example, instead of shipping replacement electronic parts to a base on Mars, which could take years and cost millions of dollars, one could send a signal containing files for the 3D printer, says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories (MTL).

“There is no reason to make capable hardware in only a few centers of manufacturing when the need is global. Instead of trying to ship hardware all over the world, can we empower people in distant places to make it themselves? Additive manufacturing can play a tremendous role in terms of democratizing these technologies,” adds Velásquez-García, the senior author of a new paper on the 3D printed solenoids that appears in the journal Virtual and Physical Prototyping.

He is joined on the paper by lead author Jorge Cañada, an electrical engineering and computer science graduate student; and Hyeonseok Kim, a mechanical engineering graduate student.

Additive advantages

A solenoid generates a magnetic field when an electrical current is passed through it. When someone rings a doorbell, for instance, electric current flows through a solenoid, which generates a magnetic field that moves an iron rod so it strikes a chime.

Integrating solenoids onto electrical circuits manufactured in a clean room poses significant challenges, as they have very different form factors and are made using incompatible processes that require post assembly. Consequently, researchers have investigated making solenoids utilizing many of the same processes that make semiconductor chips. But these techniques limit the size and shape of solenoids, which hampers performance.

With additive manufacturing, one can produce devices that are practically any size and shape. However, this presents its own challenges, since making a solenoid involves coiling thin layers made from multiple materials that may not all be compatible with one machine.

To overcome these challenges, the researchers needed to modify a commercial extrusion 3D printer.

Extrusion printing fabricates objects one layer at a time by squirting material through a nozzle. Typically, a printer uses one type of material feedstock, often spools of filament.

“Some people in the field look down on them because they are simple and don’t have a lot of bells and whistles, but extrusion is one of very few methods that allows you to do multimaterial, monolithic printing,” says Velásquez-García.

This is key, since the solenoids are produced by precisely layering three different materials — a dielectric material that serves as an insulator, a conductive material that forms the electric coil, and a soft magnetic material that makes up the core.

The team selected a printer with four nozzles — one dedicated to each material to prevent cross-contamination. They needed four extruders because they tried two soft magnetic materials, one based on a biodegradable thermoplastic and the other based on nylon.

Printing with pellets

They retrofitted the printer so one nozzle could extrude pellets, rather than filament. The soft magnetic nylon, which is made from a pliable polymer studded with metallic microparticles, is virtually impossible to produce as a filament. Yet this nylon material offers far better performance than filament-based alternatives.

Using the conductive material also posed challenges, since it would start melting and jam the nozzle. The researchers found that adding ventilation to cool the material prevented this. They also built a new spool holder for the conductive filament that was closer to the nozzle, reducing friction that could damage the thin strands.

Even with the team’s modifications, the customized hardware cost about $4,000, so this technique could be employed by others at a lower cost than other approaches, adds Velásquez-García.

The modified hardware prints a U.S. quarter-sized solenoid as a spiral by layering material around the soft magnetic core, with thicker conductive layers separated by thin insulating layers.

Precisely controlling the process is of paramount importance because each material prints at a different temperature. Depositing one on top of another at the wrong time might cause the materials to smear.

Because their machine could print with a more effective soft magnetic material, the solenoids achieved higher performance than other 3D-printed devices.

The printing method enabled them to build a three-dimensional device comprising eight layers, with coils of conductive and insulating material stacked around the core like a spiral staircase. Multiple layers increase the number of coils in the solenoid, which improves the amplification of the magnetic field.

Due to the added precision of the modified printer, they could make solenoids that were about 33 percent smaller than other 3D-printed versions. More coils in a smaller area also boosts amplification.

In the end, their solenoids could produce a magnetic field that was about three times larger than what other 3D-printed devices can achieve.

“We were not the first people to be able to make inductors that are 3D-printed, but we were the first ones to make them three-dimensional, and that greatly amplifies the kinds of values you can generate. And that translates into being able to satisfy a wider range of applications,” he says.

For instance, while these solenoids can’t generate as much magnetic field as those made with traditional fabrication techniques, they could be used as power convertors in small sensors or actuators in soft robots.

Moving forward, the researchers are looking to continue enhancing their performance.

For one, they could try using alternate materials that might have better properties. They are also exploring additional modifications that could more precisely control the temperature at which each material is deposited, reducing defects.

Written by Adam Zewe

Source: Massachusetts Institute of Technology

You can offer your link to a page which is relevant to the topic of this post.

#000#3d#3D printers#additive manufacturing#applications#biodegradable#Building#chips#computer#Computer Science#contamination#devices#direction#earth#electromagnets#electronic#electronic devices#Electronics#employed#engineering#engineers#Fabrication#form#Forms#friction#Fundamental#Global#Hardware#heart#illustration

0 notes

Text

Neodymium Magnet Glossary

Neodymium Magnet Glossary

Welcome to our comprehensive glossary of neodymium magnets. As a leading supplier of high-quality magnets, we understand the importance of having a solid grasp of magnet terminology.

Whether you’re an industry professional, a hobbyist, or simply curious about the fascinating world of magnets, our glossary is designed to provide you with clear and concise definitions of…

#Alnico#aluminum nickel cobalt#Ceramic Magnets#Curie temperature#Electromagnets#Ferrite Magnets#ferromagnetic metal#magnet attraction#Magnet Knowledge#Magnet Maximum Operating Temperature#magnetic attraction#magnetic characteristics#Magnetic Field Strength#magnetic flux density#magnetic force#magnetic material#magnetic strength#magnetic suction#Magnetism#Magnets Manufacturer#NdFeB Magnet#NdFeB magnetic ring#NdFeB Ring Magnets#Neodymium iron boron#Permanent Magnet#Permanent Magnet Materials#samarium cobalt#strong magnet#super strong magnets

0 notes

Text

them making magnets

#silly warframes. that's not how you make magnets#did you just said alchemy exists in wf universe?#welp screw physics then cold plus electricity is magnetic yeah whatever you said just ignore electromagnetism all you like#gauss prime is very unhappy#okay enough nerdy tags#i just spent a fuck ton of plat on them so at least im gonna do something to commemorate those ~200p i just forfeited#im not gonna do the lineart and rendering properly i already did that with their normal versions and i don't wanna go through that again#call me lazy or something#also i like their normal version a LOT more than their prime version. probably gonna swap to their normal skin like how i did with rhino#their normal ver looks sillier and more huggable what can i say#warframe#warframe frost#warframe frost prime#warframe volt#warframe volt prime#my art

72 notes

·

View notes

Text

If a magnet keeps doing work, will its magnetism be weakened or even disappear?

If a magnet keeps doing work, will its magnetism be weakened or even disappear?

If a magnet keeps doing work, will its magnetism be weakened or even disappear?

There are many misconceptions about magnets and how they are magnetic.

Since the magnetism of a magnet is invisible and intangible, it will be more abstract in the eyes of many people, and it is difficult to reflect it intuitively.

First of all, whether a magnet does work or not is not directly related to its own…

View On WordPress

#electromagnetism#electromagnets#electrons#Explaining Magnetism#ferromagnetic material#ferromagnetism#Ferromagnets#magnetic domains#magnetic induction#magnetic materials#Magnetic objects#Magnetics#Magnetics technology#magnetism#Making Magnets#Measuring Magnets#permanent magnetic materials#permanent magnets#powerful magnets#regular magnets#small magnets

0 notes