#Material Handling Motion Control System

Explore tagged Tumblr posts

Text

Material Handling Motion Control System Market: Global Industry Analysis, Size, Share, Trends and Forecast by 2032

Material handling motion control system is manufacturing technology that manages moving parts of equipment in a skillful manner to reduce manpower, minimize industrial hazards, and to maintain safety at workplace. Material handling control system cater to industries such oil & gas, food & beverages, aerospace & defense, automotive, semiconductor & electronics, metal & machinery manufacturing,…

0 notes

Text

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

[tfp] obsessed!optimus prime x human!reader

inspired by this very old ask about you giving opti diy crochet charms

cw: hardcore pinning, obsessive thoughts, optimus is bad with dealing with emotions

word count: 700

something small that I needed to get off my system <3

Digits glide over the soft yarn with calculated subtlety. A thumb slowly traces the indentations of the intricate patterns, acquainting itself with the texture of the interwoven chains and half-double stitches, magically linking together into a shape. A few motions are enough for him to memorize every dent and placement of the material, yet he does not cease his journey, still gently stroking the creation. After dozens of times, the tenderness gives way to adoration — he is aware of it, but cannot stop, incapable.

But he knows he should. Optimus uses this friendly gesture to feed the fire, burning ever fiercer with every movement of his thumb, taking advantage of your kindness to nurture the warped, unworthy-of-your-innocence feelings that slip further and further beyond control. He despises himself for it — oh, how he loathes himself — but has long since grown accustomed to self-hatred, his ever-present shadow at every turn. Hatred was familiar. The feeling of receiving gifts from you was a vibrant novelty he had yet to learn how to handle, for it terrified him with its rawness.

Crochet charms, as you called them. Everyone on Team Prime received a few, so he should not be assigning such immense significance to his own. Should simply be happy with the gift, accept it, and maybe glance at it occasionally, recalling your eyes gleaming with excitement like beads and your broad smile, radiating pure joy, as you handed your tiny creations to his massive servo. A star and a sunflower — both incredibly delightful, almost as much as your expression when you saw that he had accepted your present.

"Tomorrow, I can help attach them to your mirror in the alt mode. If you’d like to, of course" you told him, and though he longed for nothing more than to fall to his knees before you and beg you to do it now, the only thing he managed to utter was:

"I would be delighted."

But he cannot simply be "delighted". Cannot just set your creations aside and occupy himself with other things when a piece of you is so close to him. Cannot fall into indifference, seeing it as an affront to you. Wants to cherish the crumbs of attention you have given him, to savor this non-physical affection he is unworthy of but treasures more than the ability to sustain himself with energon. Wants to linger by the proof of your kindness for as long as he can, fully aware of his madness yet unable to put its source away.

His thumb moves to the sunflower, gently pressing into the material. A gift from you. You. He never asks for anything, demanding only the preservation of safety. Optimus doesn't seek glory, gold, or riches, for he has found them in you — and you are the most magnificent treasure he could have ever dreamed of. Yet you went a step further, crafting something with your own hands, dedicating your precious time to him. You called your gift modest, but in this, he cannot agree with you, for to him, it was everything. And soon, it would permanently become a part of him.

It is an exhilarating thought, but also a treacherous one, for he knows these are the last moments he will hold your creations in his servos. The final moments to touch, to encode the texture into his memory, to relish the sight of your affection woven into physical form. Wanting to make the most of it, he brings the crochet charms closer to his faceplate, pressing against the soft fabric. Closes his optics, sharpening the remaining senses, focusing entirely on the feeling of having a piece of you so close to him. Knows he is defiling your gifts, that he should have let them be long ago and forced himself to suppress his erratic emotions towards you, but he cannot, craving to draw every ounce of impure satisfaction from this moment.

He clings to the gifts more tightly. Just a little longer. A nanoklik, he tells himself — but he cannot bring himself to turn his helm away.

214 notes

·

View notes

Text

How do charr hands function? Here's my headcanon (with drawings!)

So I made this poll earlier today and I ended up making some sketches to explain how I headcanon charr hands and their supposedly retractable yet too big claws. The idea is that both the game and the books are partially right: claws can be big (not as big as the models), and they're semi-retractable (so fully-fluffy paws). [Disclaimer: I am bad at anatomical drawings and did not try to make them super accurate :')]

Basically charr fingers are made of three phalanges, but functionally they're just two, with the 2nd and 3rd being much shorter and sort of "merging" with the claw itself, which is mostly supported by the 3rd and starts very close to the knuckle between them. The palm is covered almost entirely by a skin pad/paw pad, which usually extends to the first phalanx of each finger, and the fingertips are covered by pads as well.

The claws are semi-retractile, though the exact range of motion depends on the individual's genetics (claw size and shape + hand anatomy) and preferences (how much they trim the claw). The ability to retract their claws is managed by specialized extra tendons and muscles in the hand's structure, and they can lock the claw in place or move it, even while the fingers are bent, though with some limitation at the extremes of movement. While the claw at rest will stay at a "safe" angle, the claw's bed can shift on the cartilage structure when pulled, sliding back into a "sheathed" position or be pushed outwards. [note: I was too scared to go too far with the "x-ray" sketches and probably the claws could go a bit further back in the finger lol]

Ancestrally, this system kept the claws from always digging into the ground and losing sharpness when running on all fours, while still allowing for extra grip when necessary (similar to cheetahs) and the use when fighting or taking down prey. During the evolutionary transition in which charr started walking upright most of the time and using tools, it lost some of its ancestral necessity and functionality. However, instead of turning into something vestigial, charr evolved the ability of controlling each claw's movement independently from the rest of the finger, allowing for greater precision, fine motor skills and dexterity.

The pad grants grip and softer manipulation of items, while the claw handles movements finer and more precise than the pad allows, and other races find it complex, fascinating or a bit freaky. Some say that charr are as dexterous than humans, if not more, which is quite an accomplishment for creatures with such big hands.

That said, variety is huge among charr. Some have stubby paws with big, wide claws, while others have long, slender fingers with narrow claws.

Claws are still used as a natural weapon by many soldiers, but it's totally not uncommon for charr to file their claws down or keep them blunt, as there's a huge variety of reasons for not wanting sharp knives on one's fingers (job requirements, handling of delicate materials, safer interactions with cubs or creatures with softer skin, personal preference, etc), and some even keep their claws at different lengths for specific uses.

That said, claws can't be trimmed beyond the quick without bleeding or potential damage, and since it extends out of the sheath it's not possible for a charr to fully sheath their claws. Claws grow quite fast to make up for the daily wear and tear, so upkeep must be done regularly, as trimming too much might temporarily impact coordination. Declawing can happen during combat or following injury, and those affected might wear prosthetics/fake claws to make up for it.

#gw2 headcanons#gw2 charr#charr#my art#charr anatomy#gw2 lore rambling#btw hind paws and their claws are different and I have a whole other headcanon for the dewclaw with spur. and teeth number too#anyway everyone who draws charr hands does a great job at it so don't take this as gospel. I'm just trying to wrap my head around anatomy#but damn did I just really draw hands and fingers without despising them completely? O:#gotta keep telling myself that this isn't useless cuz I'm helping myself figure out stuff. the ocs drawings will be better now!#edit: since someone mentioned the term... I guess the claws are technically protractible as well? 🤔 oh well they still move lol

304 notes

·

View notes

Text

Clarification: Generative AI does not equal all AI

💭 "Artificial Intelligence"

AI is machine learning, deep learning, natural language processing, and more that I'm not smart enough to know. It can be extremely useful in many different fields and technologies. One of my information & emergency management courses described the usage of AI as being a "human centaur". Part human part machine; meaning AI can assist in all the things we already do and supplement our work by doing what we can't.

💭 Examples of AI Benefits

AI can help advance things in all sorts of fields, here are some examples:

Emergency Healthcare & Disaster Risk X

Disaster Response X

Crisis Resilience Management X

Medical Imaging Technology X

Commercial Flying X

Air Traffic Control X

Railroad Transportation X

Ship Transportation X

Geology X

Water Conservation X

Can AI technology be used maliciously? Yeh. Thats a matter of developing ethics and working to teach people how to see red flags just like people see red flags in already existing technology.

AI isn't evil. Its not the insane sentient shit that wants to kill us in movies. And it is not synonymous with generative AI.

💭 Generative AI

Generative AI does use these technologies, but it uses them unethically. Its scraps data from all art, all writing, all videos, all games, all audio anything it's developers give it access to WITHOUT PERMISSION, which is basically free reign over the internet. Sometimes with certain restrictions, often generative AI engineers—who CAN choose to exclude things—may exclude extremist sites or explicit materials usually using black lists.

AI can create images of real individuals without permission, including revenge porn. Create music using someones voice without their permission and then sell that music. It can spread disinformation faster than it can be fact checked, and create false evidence that our court systems are not ready to handle.

AI bros eat it up without question: "it makes art more accessible" , "it'll make entertainment production cheaper" , "its the future, evolve!!!"

💭 AI is not similar to human thinking

When faced with the argument "a human didn't make it" the come back is "AI learns based on already existing information, which is exactly what humans do when producing art! We ALSO learn from others and see thousands of other artworks"

Lets make something clear: generative AI isn't making anything original. It is true that human beings process all the information we come across. We observe that information, learn from it, process it then ADD our own understanding of the world, our unique lived experiences. Through that information collection, understanding, and our own personalities we then create new original things.

💭 Generative AI doesn't create things: it mimics things

Take an analogy:

Consider an infant unable to talk but old enough to engage with their caregivers, some point in between 6-8 months old.

Mom: a bird flaps its wings to fly!!! *makes a flapping motion with arm and hands*

Infant: *giggles and makes a flapping motion with arms and hands*

The infant does not understand what a bird is, what wings are, or the concept of flight. But she still fully mimicked the flapping of the hands and arms because her mother did it first to show her. She doesn't cognitively understand what on earth any of it means, but she was still able to do it.

In the same way, generative AI is the infant that copies what humans have done— mimicry. Without understanding anything about the works it has stolen.

Its not original, it doesn't have a world view, it doesn't understand emotions that go into the different work it is stealing, it's creations have no meaning, it doesn't have any motivation to create things it only does so because it was told to.

Why read a book someone isn't even bothered to write?

Related videos I find worth a watch

ChatGPT's Huge Problem by Kyle Hill (we don't understand how AI works)

Criticism of Shadiversity's "AI Love Letter" by DeviantRahll

AI Is Ruining the Internet by Drew Gooden

AI vs The Law by Legal Eagle (AI & US Copyright)

AI Voices by Tyler Chou (Short, flash warning)

Dead Internet Theory by Kyle Hill

-Dyslexia, not audio proof read-

#ai#anti ai#generative ai#art#writing#ai writing#wrote 95% of this prior to brain stopping sky rocketing#chatgpt#machine learning#youtube#technology#artificial intelligence#people complain about us being#luddite#but nah i dont find mimicking to be real creations#ai isnt the problem#ai is going to develop period#its going to be used period#doesn't mean we need to normalize and accept generative ai

72 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

The Importance of High-tech Rapid Prototyping

In the industrial industry, precision is not only desirable—it is essential. Consider a situation in which parts of a jet engine are even marginally machined incorrectly or misaligned. The repercussions can be disastrous and might cause the engine to fail in midair. Precision becomes the key to success in sectors like aerospace, automotive, and medical where safety and dependability are non-negotiable. Put simply, it's the capacity to manufacture parts or components that precisely conform to given dimensions, tolerances, and quality requirements. It takes state-of-the-art equipment, painstaking attention to detail, and highly competent operators to achieve this degree of accuracy. This is the sweet spot for Precision CNC Machining.

So how precisely can CNC machining accomplish such high precision levels?

Computerized Control: Advanced computer software is the brains of CNC machining, translating digital design requirements into exact motions and orders for the milling tools. This removes the possibility of human error and guarantees the highest level of precision in each cut, drill, and mill.

Superior Quality Equipment: Modern spindles, tools, and cutting implements that are designed to provide exact results are standard on CNC machines. These devices may operate at extremely tight tolerances, which are sometimes expressed in microns, guaranteeing an accurate reproduction of even the minutest features.

Consistency: The ability of CNC machining and High-tech Rapid Prototyping to manufacture similar components with little variance is one of its main advantages. A machine program that has been developed and tuned may be repeated endlessly with reliable outcomes. In fields where stability and dependability are critical, this degree of constancy is priceless.

Advanced Techniques: Multi-axis milling, turning, EDM (Electrical Discharge Machining), laser cutting, and other state-of-the-art methods are all included in CNC machining. With unmatched accuracy and efficiency, manufacturers can handle complicated geometries and materials thanks to these procedures.

Quality Assurance: CNC systems frequently include integrated quality control mechanisms including automated inspections, feedback loops, and real-time monitoring in addition to accurate machining. This reduces waste and rework by guaranteeing that any deviations from the intended standards are quickly identified and fixed. It is impossible to exaggerate the value of accuracy in production. Precision by Precision CNC Machining Manufacturer plays a crucial role in today's competitive economy, as it ensures everything from satisfying regulatory requirements and consumer expectations to assuring product performance and dependability.

Follow our Facebook and Twitter for more information about our product

#High-tech Rapid Prototyping#Precision CNC Machining#Precision CNC Machining Manufacturer#CNC Machining Manufacturer Company

2 notes

·

View notes

Text

Cargo handling has always been a time-consuming and unavoidable work, the emergence of AGV unmanned trucks, instead of people to complete the different states of the handling operation, greatly reduced people's labor intensity and improved the efficiency of the factory. The factory transportation robot system is based on a HandsFree robot and open source system, realizing the robot from map building, navigation, and motion control; it can autonomously and accurately complete the delivery of production materials under the operation scenario of human-machine mixing and provide the flexible flow of materials between production lines.

#innovation#mobile robot#agv#ultrasound#navigation#positioning#machine dreams#logistics#intelligent#warehousing#robotics#ugv#autonomous robot#higher education#market research#artificial intelligence (ai)#science and technology

3 notes

·

View notes

Text

A Hygienic and Convenient Solution for Nausea Management

Whether it’s motion sickness, morning sickness, post-surgery nausea, or the side effects of medication, vomiting is an unpleasant but sometimes unavoidable experience. In such moments, vomit bags offer a clean, safe, and practical solution for managing emesis—particularly in clinical, travel, and emergency settings.

What Are Vomit Bags?

Vomit bags, also known as emesis bags or sick bags, are disposable containers designed to catch and contain vomit. Typically made from durable plastic with a secure closure system, they help minimize mess, odor, and the risk of contamination.

These bags are commonly used in:

Hospitals and clinics

Emergency medical services (EMS)

Airplanes, buses, and cars

Schools and aged care facilities

Home care environments

Key Features

Leak-Proof Design High-quality vomit bags are made from durable, puncture-resistant plastic with a tightly sealed bottom to prevent leaks.

Secure Closure Most vomit bags feature a twist-and-lock or sealable ring closure, allowing for hygienic disposal and odor control.

Transparent or Graduated Markings Some models come with volume indicators to measure output—useful for medical monitoring.

Compact and Portable Lightweight and easy to carry, they fit into handbags, glove compartments, or first aid kits.

Benefits of Using Vomit Bags

Improved Hygiene Prevents spills and contact with vomit, reducing the risk of contamination and infection.

Odor Containment The sealing mechanism helps lock in unpleasant odors, making it more tolerable for users and caregivers.

Easy Disposal Designed for one-time use, vomit bags can be safely sealed and discarded without direct handling of contents.

Ideal for On-the-Go Use Compact and lightweight, vomit bags are especially useful while traveling or in emergencies.

Dignified and Discreet Offers a more respectful and clean solution for people experiencing nausea in public or clinical settings.

When to Use Vomit Bags

During travel (especially long road trips or air travel)

For patients post-surgery or undergoing chemotherapy

In pregnancy to manage morning sickness

For children and the elderly prone to sudden nausea

As part of an emergency or first aid kit

Types of Vomit Bags

Ring-sealed bags: With a rigid mouth ring for ease of use and secure closure.

Flat poly bags: Basic models for quick, low-cost usage.

Graduated emesis bags: With volume markings for clinical monitoring.

Biodegradable options: Eco-friendly alternatives made from compostable materials.

Conclusion

Vomit bags are a simple yet essential hygiene product that brings convenience, cleanliness, and comfort to situations where nausea and vomiting are involved. From hospitals to households, they are an indispensable tool for both caregivers and individuals managing health conditions.

0 notes

Text

Efficiency in Motion: Understanding Pneumatic Conveying Technology

In industries where bulk materials must be moved quickly, cleanly, and efficiently, pneumatic conveying systems have emerged as a preferred solution. These systems use air pressure or vacuum to transport powders, granules, and other dry bulk materials through pipelines—reducing manual handling and improving overall operational efficiency.Get more news about pneumatic conveying system,you can vist our website!

How Pneumatic Conveying Works

At its core, a pneumatic conveying system moves material through an enclosed pipeline using air as the conveying medium. Materials are either pushed using positive pressure (pressure conveying) or pulled using negative pressure (vacuum conveying). The choice between these two methods depends on the application, distance, and type of material.

The system comprises several components: an air mover (such as a blower or compressor), feed devices (like rotary valves), a convey line, and a receiving system that separates the material from the air. In some cases, additional equipment such as filters, cyclones, or airlocks may be installed for precise control and filtration.

Types of Pneumatic Conveying

There are generally three types of pneumatic conveying systems:

Dilute Phase Conveying: Material is suspended in the airstream and transported at high velocity. It’s suitable for light, non-abrasive materials.

Dense Phase Conveying: Material moves in a slug or plug form at a slower speed, ideal for fragile or abrasive materials to minimize degradation.

Semi-Dense Phase: Falls between the two, used for moderately abrasive materials with controlled airflow.

Each method offers distinct benefits and is chosen based on process requirements, energy consumption, material characteristics, and maintenance expectations.

Industrial Applications and Advantages

Pneumatic conveying systems are widely used in industries such as food processing, chemicals, cement, pharmaceuticals, plastics, and power generation. For example, in the food industry, they transport flour, sugar, and spices while minimizing contamination. In cement plants, pneumatic systems handle fly ash or powdered limestone with precision and minimal dust emission.

Key benefits include:

Enclosed transfer: Reduces contamination and dust leakage, improving product quality and workplace safety.

Flexible routing: Pipes can be laid over long distances, through tight spaces, and around obstructions.

Automation-ready: Easily integrates with control systems for consistent performance and reduced labor.

Low maintenance: Fewer mechanical parts result in less wear and downtime compared to mechanical conveyors.

Challenges and Considerations

Despite their advantages, pneumatic systems require careful planning and design. Incorrect velocity or pressure may lead to material degradation or pipeline blockages. Abrasive materials can wear down piping over time, and energy consumption can be significant if the system is not properly optimized.

Proper system design involves understanding the material properties—such as particle size, density, moisture content, and abrasiveness—as well as the required throughput and conveying distance. Working with experienced engineers ensures a balance between cost, performance, and durability.

Innovations and Sustainability Trends

Modern pneumatic systems are evolving with digital controls, real-time monitoring, and energy-efficient blowers that reduce carbon footprints. Some systems now use nitrogen or other inert gases instead of air to handle highly reactive materials in chemical processing or pharmaceuticals.

Sustainability is also driving the development of quieter, cleaner, and recyclable system components. As industries aim to reduce environmental impact, pneumatic conveying systems continue to offer scalable, eco-conscious solutions.

Conclusion

Pneumatic conveying systems have become integral to modern industrial operations by offering a clean, efficient, and automated way to move bulk materials. Their versatility, coupled with continuous innovation, ensures they will remain a key technology in the pursuit of productivity, quality, and sustainability.

0 notes

Text

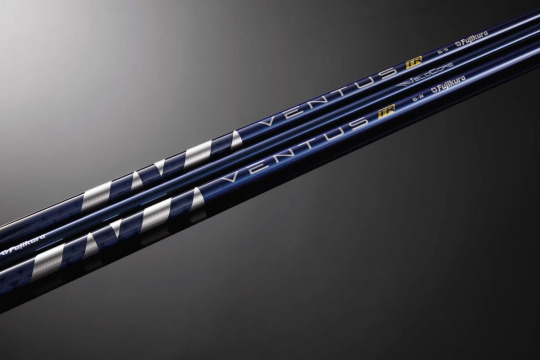

Unlocking Your Potential: A Comprehensive Guide to the Ventus TR Swing Speed Chart

For serious golfers, the quest for optimal performance often leads to the intricate world of golf shafts. Among the most revered names in shaft technology, Fujikura's Ventus line, particularly the Tour Rated (TR) series, stands out for its exceptional stability and feel. But with different profiles like Red, Blue, and Black, how do you know which Ventus TR shaft is the perfect match for your swing? The answer lies in understanding the Ventus TR swing speed chart and how it correlates with your unique swing characteristics.

This in-depth article, crafted for the discerning golfer, will demystify the Ventus TR series, analyze its swing speed recommendations, and guide you towards unlocking your maximum potential on the course.

The Science Behind Ventus TR: VeloCore Technology and Beyond

Before diving into swing speed specifics, it's crucial to appreciate the core technology that underpins the Ventus TR series: Fujikura's proprietary VeloCore Technology. This multi-material bias core construction, featuring full-length, ultra-high modulus Pitch 70 Ton Carbon Fiber (150% stronger and more stable than T1100g), is designed to stabilize the shaft wall and prevent ovaling and deformation, especially during the high-stress transition and impact phases of the swing.

The TR designation in the Ventus series introduces an additional layer of innovation: Spread Tow carbon fabric. This ultra-high modulus and lightweight composite woven material further stiffens the torque in the mid/handle section of the shaft. Fujikura's enso® analytics, a sophisticated 3D motion capture system, identified this area as a critical stress point during the swing, and the Spread Tow material effectively reduces shaft twist and ovalization by nearly 10% compared to the original Ventus Blue. The result is enhanced stability, consistency, and control without sacrificing feel.

Deconstructing the Ventus TR Family: Red, Blue, and Black

The Ventus TR series offers three distinct profiles, each engineered to cater to specific swing dynamics and desired ball flight characteristics:

1. Ventus TR Red: The Mid-High Launch & Mid-Low Spin Performer

Launch: Mid-High

Spin: Mid-Low

Feel: Smooth and easy launch

Ideal for: Golfers seeking maximized carry distance with a slightly higher ball flight. This shaft offers a balance of stability and launch, making it a great option for players who desire more airtime and easier loading of the shaft.

2. Ventus TR Blue: The Balanced Mid-Launch & Low Spin Option

Launch: Mid

Spin: Low

Feel: Powerful combination of stability and feel, maintaining an ultra-stiff tip section for superior control.

Ideal for: A wide range of golfers who prioritize a balanced flight with low spin for optimal total distance. The increased torsional stiffness in the TR Blue allows for more aggressive swings while still providing a smooth feel. It’s often considered the "Goldilocks" option for players who find the original Ventus Blue slightly too soft but the Ventus Black too rigid.

3. Ventus TR Black: The Low Launch & Ultra-Low Spin Powerhouse

Launch: Low

Spin: Ultra-Low

Feel: Exceptionally stable and precise, offering a penetrating ball flight.

Ideal for: Golfers with very fast, aggressive swing speeds and tempos who demand maximum control and minimal spin. The TR Black is designed to withstand the highest loads, promoting a powerful, piercing trajectory with significant roll.

The Ventus TR Swing Speed Chart: Finding Your Match

While a professional fitting is always recommended for precise optimization, understanding the general guidelines of the Ventus TR swing speed chart can provide a valuable starting point. These recommendations correlate typical driver swing speeds with the ideal Ventus TR profile and flex.

Here's a general breakdown, keeping in mind that individual tempo, transition, and desired ball flight also play significant roles:

Driver Swing Speed (MPH)

Recommended Ventus TR Profile

Recommended Flex Range

Characteristics & Benefits

Below 90 mph

Ventus TR Red

Regular (R) to Stiff (S)

Higher launch and spin to maximize carry distance. Smooth feel and easier to load, promoting better control for moderate swing speeds.

90 - 105 mph

Ventus TR Blue

Regular (R) to Stiff (S)

Balanced mid-launch and low spin for controlled ball flight and good overall distance. Offers a blend of feel and stability for a wide range of golfers.

105 - 115 mph

Ventus TR Blue or TR Black

Stiff (S) to Extra Stiff (X)

At the lower end, TR Blue provides a stable, low-spin option. For more aggressive swings, TR Black offers superior stability and ultra-low spin for maximum distance and control.

Above 115 mph

Ventus TR Black

Extra Stiff (X) to Tour X (TX)

Unparalleled stability and control for extremely fast and aggressive swings. Produces a penetrating, low-spin trajectory for maximum distance and accuracy.

Important Considerations Beyond Swing Speed:

Tempo and Transition: Golfers with aggressive transitions (a quick change from backswing to downswing) often benefit from stiffer profiles, even if their peak swing speed isn't exceptionally high. The Ventus TR shafts are specifically designed to handle these higher stresses.

Ball Flight Desired: If you tend to hit the ball too high and with too much spin, a stiffer, lower-launching, and lower-spinning shaft like the TR Black or a heavier TR Blue might be beneficial. Conversely, if you struggle to get the ball in the air, a TR Red could provide the extra launch you need.

Feel: While data is crucial, personal feel is also vital. Some golfers prefer a "boardier" feel for maximum control, while others prefer a more active, responsive shaft. The Ventus TR series aims to provide enhanced stability without sacrificing the signature Ventus feel.

Tipping: For golfers on the cusp of a flex or seeking to fine-tune the shaft's performance, custom tipping (cutting a small amount off the tip of the shaft) can increase its stiffness and lower launch/spin. This is a common practice in professional fittings.

The Unbeatable Advantage of a Professional Fitting

While the Ventus TR swing speed chart provides excellent guidance, the nuances of your individual swing are best analyzed by a qualified club fitter. Using advanced launch monitors and their expertise, a fitter can precisely measure your:

Clubhead speed

Ball speed

Launch angle

Spin rate

Attack angle

Swing path

Tempo and transition

This comprehensive data, combined with your personal preferences and on-course tendencies, allows them to recommend the exact Ventus TR shaft model, flex, weight, and tipping that will optimize your performance. A properly fitted shaft ensures maximum energy transfer, tighter dispersion, and consistent ball striking, ultimately leading to lower scores.

Conclusion: Swing Smarter, Not Just Harder

The Fujikura Ventus TR series represents the pinnacle of golf shaft technology, offering unprecedented stability and control. By understanding the Ventus TR swing speed chart and the unique characteristics of the Red, Blue, and Black profiles, golfers can take a significant step towards optimizing their equipment. However, for truly maximizing your potential, investing in a professional club fitting remains the gold standard. With the right Ventus TR shaft in your hands, you'll gain the confidence to swing freely and unleash your best golf.

0 notes

Text

Troubleshooting Common Issues with Hydraulic Support Dollies

Hydraulic help dollies are integrated bits of equipment that have considerably transformed just how major equipment, cars, and industrial assets are moved and positioned in limited spaces. These units use hydraulic power to lift and maneuver big, cumbersome loads, lowering the need for guide job and improving security in workplaces. The flexibility and power of hydraulic dollies have created them a popular choice in industries such as for instance automotive, construction, aerospace, and heavy manufacturing. This informative article explores the style, operation, benefits, and purposes of hydraulic help dollies.

A hydraulic help dolly works on a not at all hard theory: hydraulic pressure is used to carry major objects with little physical effort. The dolly is typically built with hydraulic cylinders that produce the lifting force when operated via a pump. That allows the agent to maneuver significant products without requiring the usage of cranes or forklifts, particularly in environments with restricted space. Among the standout top features of hydraulic support dollies is their small style, making them well suited for maneuvering equipment in narrow corridors, small workshops, or confined areas.

The usefulness of those dollies is based on their ability to guide a wide selection of objects. Whether it's an automobile, commercial gear, or large devices, hydraulic support dollies may be tailored to take care of unique load dimensions and weights. Many of these dollies include variable tools, allowing consumers to raise things of different shapes and measurements securely. The Precisionsuppspänningslösningar can be quickly tuned to provide precise control over the raising method, making it easier to move objects slowly and gradually with their supposed location. This accuracy also reduces the chance of harm to sensitive and painful gear or structures.

One of the critical benefits of applying hydraulic support dollies could be the significant development in safety. Historically, moving major loads often included multiple individuals and harmful training practices that can result in accidents or injuries. Hydraulic dollies remove these dangers by letting anyone to lift and maneuver large gear with relative ease. Considering that the lifting is done hydraulically, the user is less apt to be subjected to stress, fatigue, or injury. Also, many hydraulic dollies are built with built-in protection functions, such as securing mechanisms and pressure comfort valves, which prevent accidents throughout operation.

Yet another significant advantage of hydraulic help dollies is their capacity to boost working efficiency. Because large goods may be transferred quickly and correctly with small manpower, downtime is paid off, and productivity increases. That is especially crucial in industries wherever time is just a important element, such as in the automotive business, where vehicle suppliers and fix stores use hydraulic dollies to move vehicles in creation lines or company bays.

Hydraulic support dollies may also be praised due to their durability. Constructed with powerful products such as for instance material and built with supreme quality hydraulic systems, these dollies are made to resist the rigors of daily used in challenging environments. Whether useful for moving structure equipment, heavy-duty cars, or aerospace components, they feature consistency and longevity, creating them a cost-effective investment for businesses.

To conclude, hydraulic support dollies have become an indispensable tool in various industries that require the motion and positioning of large loads. Their capability to carry and transfer big objects effortlessly, mixed with their safety functions, detail, and toughness, makes them an important advantage in contemporary workplaces. As industries continue to grow and the requirement for efficient substance handling raises, hydraulic help dollies will truly play a crucial position in simplifying and improving load-moving operations over the globe.

0 notes

Text

Indoor vs. Outdoor Lighting Installation: What You Should Know

Lighting plays a significant role in determining how a space appears and feels. Whether you're upgrading your home or designing a new space, selecting the proper lighting is crucial. However, many homeowners become confused when trying to distinguish between indoor and outdoor lighting. They are not the same. Each has its own design, purpose, and technical needs. So, understanding their differences can save you time, money, and future problems.

In this blog, we'll help you understand the key differences between indoor and outdoor lighting installation. We'll also discuss the benefits of using lighting installation services and why hiring professional lighting installation services in British Columbia is a smart move.

Why Lighting Installation Matters

Lighting does more than brighten up your home. It adds beauty, safety, and energy savings. Good lighting improves your mood and highlights your home's best features.

On the other hand, poor lighting can cause eye strain, reduce a home's value, and increase energy bills. That's why it's essential to choose and install lighting correctly.

Indoor Lighting Installation

Indoor lighting is more than just light bulbs. It's about layers of light, control, and comfort. Here are a few essential types of indoor lighting:

1. Ambient Lighting

This is the primary source of light in a room. It includes ceiling-mounted fixtures, chandeliers, and recessed lights. It sets the tone for your living space.

2. Task Lighting

This lighting helps you perform specific tasks, such as reading or cooking. Examples include desk lamps, under-cabinet lights, and pendant lights.

3. Accent Lighting

This type highlights artwork, furniture, or architectural details. It's often used for mood or design purposes.

Indoor Lighting Considerations

Wiring: Usually built into the wall or ceiling.

Safety: Less exposure to moisture, but must still meet codes.

Bulbs: LED, incandescent, and fluorescent options.

Control: Often connected to innovative systems or dimmers.

Utilizing lighting installation services ensures that all these elements work in harmony. Experts know how to balance light and create the perfect atmosphere.

Outdoor Lighting Installation

Outdoor lighting serves a different purpose. It needs to handle weather, darkness, and safety concerns.

1. Security Lighting

Motion-sensor lights and floodlights help keep your home safe and secure. They deter burglars and light up dark areas.

2. Landscape Lighting

These lights highlight trees, paths, gardens, and water features. They make your home look beautiful at night.

3. Entry and Porch Lighting

These lights welcome guests and help you find your keys. They are also crucial for safety.

Outdoor Lighting Considerations

Weatherproofing: Fixtures must resist rain, wind, and sun.

Voltage: Outdoor systems often utilize low voltage for safety purposes.

Durability: Materials must be rust-proof and strong.

Placement: Avoid dark spots and light pollution.

For best results, many homeowners choose professional professional lighting installation services in British Columbia. Outdoor wiring and design require special tools and knowledge.

Key Differences: Indoor vs. Outdoor Lighting

Indoor and outdoor lighting serve different purposes and are designed with unique requirements in mind. Indoor lighting focuses on comfort, aesthetics, and functionality. It typically includes ambient lighting for overall brightness, task lighting for specific activities like reading or cooking, and accent lighting to highlight artwork or architectural features. Indoor fixtures are usually lightweight, stylish, and protected from weather conditions.

On the other hand, outdoor lighting is meant to enhance safety, security, and curb appeal. It includes options like motion-sensor lights, floodlights, porch lights, and landscape lighting. These fixtures must withstand harsh weather, use weatherproof and rust-resistant materials, and often run on low voltage or solar power for added safety.

While indoor lighting enhances the mood and usability of interior spaces, outdoor lighting focuses on visibility, protection, and exterior beautification. Due to these differences, installation methods and product choices also vary significantly, making lighting installation services essential for a professional and lasting setup.

Benefits of Hiring Professional Services

Lighting might seem simple, but it's not. Poor installation can lead to fire hazards, flickering lights, or higher energy bills.

Here's why hiring professional lighting installation services in British Columbia is a good idea:

1. Safety First

Experts are familiar with the latest codes and adhere to all safety standards. They use the right materials and check every wire.

2. Saves time

There is no need to guess or redo the work. Professionals finish the job quickly and correctly.

3. Custom Design

They create lighting plans that fit your home and lifestyle.

4. Energy Savings

LEDs, dimmers, and timers can all save power. Pros know how to set them up for best results.

5. Long-lasting Results

High-quality work means fewer repairs and replacements in the future.

Mistakes to Avoid

Whether you're going DIY or hiring help, avoid these common lighting mistakes:

Over-lighting: Excessive lighting can be harsh and wasteful of energy.

Wrong fixtures: Using indoor lights outside can be dangerous.

Poor placement: Lights should enhance, not distract.

Skipping permits: Some electrical work needs approval.

Ignoring controls: Dimmers, sensors, and timers make life easier.

To avoid these problems, always consider using lighting installation services. A trained eye can spot issues before they become costly repairs.

Lighting Trends to Consider

Want to add style as well as function? Here are a few lighting trends worth looking into:

1. Smart Lighting

Control your lights from your phone or voice assistant. Great for indoor and outdoor use.

2. Energy-Efficient LEDs

Long-lasting and cool to the touch, LEDs are the top choice today.

3. Solar Outdoor Lights

Easy to install and environmentally friendly.

4. Layered Indoor Lighting

Combining task, ambient, and accent lighting makes your home shine.

If you want the latest technology and design, consider professional lighting installation services in British Columbia.

Choosing the Right Installer

Not all contractors are the same. Here are tips for finding the right lighting expert:

Check reviews

Ask for licenses and insurance.

Look at past work

Get a written quote

Discuss your goals and style.

Choosing experienced lighting installation services ensures your home is safe and stunning.

Final Thoughts

Indoor and outdoor lighting serve different roles, have distinct needs, and pose other risks. Trying to do it all yourself may cause more harm than good. Utilizing professional lighting installation services in British Columbia provides you with peace of mind. You'll receive expert advice, optimal placement, and reliable results. So whether you're lighting your living room or backyard, make a wise choice. Go with trusted lighting installation services to brighten up your space the right way.

#lighting installation services#lighting installation#professional lighting installation#electrical services

0 notes

Text

What is a Manual Gyroscopic Mixer Machine?

Explore the Manual Gyroscopic Mixer Machine, its design, and how it improves mixing efficiency. Perfect for professionals seeking reliable mixing solutions.Mexico Phoenix Mixer.

If you've ever wondered how thick liquids, like paint or ink, get that flawlessly lump-free consistency, it's likely due in large part to a gyroscopic mixer. However, what is a manual gyroscopic mixing machine, and why is it so popular among small businesses?

Definition and Basic Function

A sophisticated tool called a gyroscopic mixer is used to evenly mix thick liquids in their original containers. To prevent air bubbles and promote consistency, these mixers rotate the material in a dual-axis pattern, in contrast to traditional stirrers.

The Concept of Gyroscopic Motion

Consider how a planet orbits the sun by rotating on its axis. Gyroscopic mixers operate in precisely this manner, whirling around two axes at the same time to guarantee 360° mixing coverage.

The concepts of rotational dynamics and angular momentum underlie the intriguing physical phenomenon known as gyroscopic motion. From bicycle stability to spacecraft navigation, it is essential to many scientific, engineering, and technical applications.

Dual-Axis Rotation

Dual-axis motion, in which the container rotates and spins concurrently, is a feature of manual gyroscopic mixers. As a result, even the most difficult materials are thoroughly blended in a vortex-like movement.

The ability of an object or system to spin independently around two perpendicular axes, usually known as the X-axis and Y-axis, is known as dual-axis rotation. This idea is frequently utilized to describe and regulate two-dimensional movement in the fields of physics, engineering, robotics, aerospace, and consumer electronics.

Manual Operation Mechanism

The mixing process is manually initiated by a lever or handle, which activates the machine's rotational motion. There's no need for complicated electronics—just a little elbow grease!

A manual operation mechanism refers to a system or device that is controlled and operated by human effort rather than powered by electricity, hydraulics, or automation. These mechanisms convert manual input (such as turning, tugging, pushing, or cranking) into mechanical motion to perform specific tasks.

Comparison with Automatic Models

Manual gyroscopic mixers are mechanically driven, which makes them perfect for locations with erratic power supplies or for operations on a tight budget, whereas automatic versions rely on motors and computerized timers.

Gyroscopic motion is frequently contrasted to automatic models, which are sensor-driven, software-controlled systems that can mimic, enhance, or replace mechanical gyroscopic behavior. This is particularly true in the fields of engineering and contemporary technology. The following contrasts automatic

What Is Gyroscopic Motion?

Gyroscopic motion refers to the behavior of a spinning object (often called a gyroscope) that tends to maintain its orientation due to the conservation of angular momentum. When an external force attempts to change the direction of the spinning axis, the gyroscope reacts in a way that defies intuitive expectations — this response is known as precession.

Key Features of Manual Gyroscopic Mixers

Compact Design

They’re space-saving, making them perfect for small workshops or retail paint stores.

Energy Efficiency

Because they’re manually operated, they consume zero electricity, contributing to low operational costs.

Versatility with Various Can Sizes

Models like the one from Phoenix Mixer can accommodate 1 to 20-liter containers, with adjustable clamps.

Ease of Maintenance

Fewer parts mean fewer things that can go wrong—making maintenance a breeze.

We were able to produce paint mixtures of superior quality while saving electricity thanks to the Phoenix manual gyroscopic mixer.small, dependable, and low-maintenance. Nothing more was possible.

For small to medium-sized businesses that require effective, reliable mixing without the expense of automated solutions, a manual gyroscopic mixer machine is an excellent option. Whether you work in chemical blending, paint manufacturing, or cosmetics, this equipment does the job quickly and easily.

Visit :https://mx.phoenixmixer.com/manual-mixer.php

Contact: +91 9145240124

0 notes

Text

Powering Industry with Precision Gear Solutions

The Role of Gearboxes in Modern Industry

In the intricate world of industrial machinery, where precision and efficiency drive progress, gearboxes stand as unsung heroes. These mechanical marvels transmit power and control motion, enabling everything from conveyor belts in Manchester factories to heavy-duty cranes in construction sites. The worm gearbox is a standout in this realm, renowned for its compact design and ability to deliver high torque at low speeds. Its unique configuration, featuring a worm screw meshing with a gear, allows for significant speed reduction, making it ideal for applications requiring controlled, powerful movement. Industries across the UK rely on this technology to ensure smooth operations, from packaging plants to automated assembly lines.

The worm gearbox excels in scenarios where space is limited and reliability is paramount. Its self-locking feature, which prevents back-driving in many configurations, adds a layer of safety, particularly in lifting equipment or material handling systems. This characteristic, combined with its ability to handle high shock loads, makes it a preferred choice for rugged environments. In the UK’s diverse industrial landscape, where machinery must perform consistently under demanding conditions, this gearbox provides a robust solution that balances performance with durability.

Advantages of Helical Gear Technology

While worm systems dominate in specific applications, the helical gear reducer offers distinct advantages that make it a versatile option across industries. Characterized by angled teeth that engage gradually, this reducer delivers smoother and quieter operation compared to other gear types. Its design allows for higher efficiency, often exceeding 90%, which translates to energy savings in high-power applications like wind turbines or automotive manufacturing. In regions like Somerset, where sustainable practices are gaining traction, the energy efficiency of this reducer aligns with efforts to reduce operational costs and environmental impact.

The helical gear reducer is engineered to handle substantial loads with minimal wear, thanks to the increased contact area between its teeth. This durability ensures a longer service life, reducing maintenance costs for businesses operating heavy machinery. Its ability to operate at various angles and configurations makes it adaptable to complex setups, such as those found in steel mills or food processing plants. For UK industries seeking precision and longevity, this reducer provides a reliable solution that enhances productivity while maintaining operational stability.

Applications Across Diverse Sectors

The worm gearbox finds its niche in applications requiring precise control and high torque. In conveyor systems, it ensures steady movement of goods, from lightweight packages to heavy industrial components. Its compact footprint makes it ideal for automated machinery in tight spaces, such as bottling lines or textile production facilities. The gearbox’s ability to maintain consistent output under varying loads is particularly valuable in agriculture, where equipment like grain elevators or irrigation systems demands reliable performance. In the UK’s agricultural heartlands, this technology supports efficient operations, helping farmers meet growing demands.

Conversely, the helical gear reducer shines in high-speed, high-power applications. Its efficiency and strength make it a staple in industries like mining, where it drives heavy-duty equipment such as crushers and conveyors. In renewable energy, these reducers are critical components in wind turbine drivetrains, ensuring optimal power transfer from blades to generators. Their versatility extends to marine applications, where they power winches and propulsion systems with precision. Across the UK, from coastal ports to inland industrial estates, this reducer supports critical operations with unmatched reliability.

Choosing the Right Gearbox Solution

Selecting between a worm gearbox and a helical gear reducer depends on the specific needs of the application. For tasks requiring high torque and compact design, the worm system is often the preferred choice. Its simplicity and cost-effectiveness make it accessible for small to medium-sized enterprises, while its robustness suits heavy-duty tasks. However, its lower efficiency, typically around 70-85%, may prompt businesses with high-energy demands to consider alternatives. Regular maintenance, such as proper lubrication, is essential to maximize its lifespan and performance.

For applications prioritizing efficiency and speed, the helical gear reducer is the go-to option. Its higher initial cost is offset by reduced energy consumption and longer operational life, making it a strategic investment for large-scale operations. The choice also depends on environmental factors, such as noise levels or operating temperatures, where the helical system’s quieter performance gives it an edge. In the UK, where industries balance cost with sustainability, consulting with gearbox specialists ensures the right fit for each project, optimizing performance and longevity.

The Future of Gearbox Technology in the UK

The demand for advanced gear solutions like the worm gearbox and helical gear reducer is set to grow as UK industries embrace automation and sustainability. Innovations in materials, such as lightweight composites and advanced alloys, are enhancing gearbox durability while reducing weight. Smart technologies, including sensors for real-time performance monitoring, are being integrated to predict maintenance needs and improve efficiency. These advancements align with the UK’s push toward Industry 4.0, where interconnected systems drive productivity.

The accessibility of these technologies is increasing, with UK suppliers offering tailored solutions for businesses of all sizes. Online platforms and local distributors provide detailed specifications and expert guidance, ensuring industries from Manchester to Somerset can access cutting-edge gearboxes. As the UK continues to innovate, the worm gearbox and helical gear reducer will remain integral to powering progress, delivering the precision and reliability that modern machinery demands.

0 notes

Text

Top Feeder Vibrator Motors in India: Features, Benefits, and Industry Trends

Top Feeder Vibrator Motors in India: Features, Benefits, and Industry Trends

In industries like mining, construction, and food processing, Feeder Vibrator Motors in India play a crucial role in material handling and automation. These motors ensure smooth and consistent material flow, enhancing efficiency and productivity. If you’re searching for high-quality Feeder Vibrator Motor manufacturers in India, this guide will help you explore the best options, features, and industry trends.

What Are Feeder Vibrator Motors?

Feeder Vibrator Motors are specialized electric motors designed to create vibratory motion in feeders, screens, and conveyors. Their purpose is to facilitate the movement of bulk materials with minimal manual intervention, ensuring uniform material distribution and preventing clogging.

Key Features of Feeder Vibrator Motors

High Durability: Built to withstand extreme industrial conditions.

Energy Efficiency: Designed to consume less power while delivering high performance.

Compact Design: Space-saving yet powerful for various industrial applications.

Low Maintenance: Engineered for longevity and minimal downtime.

Customizable Configurations: Available in different sizes and power ratings to meet specific requirements.

Top Feeder Vibrator Motor Manufacturers in India

When it comes to finding the best Feeder Vibrator Motor manufacturers in India, reliability and performance are key. Here are some of the leading manufacturers:

1. JK Industries – Industry Leader in Vibratory Motors

JK Industries is best Feeder Vibrator Motor manufacturer in India, offering high-quality motors that meet global standards. Their motors are known for:

Superior build quality and long-lasting performance.

Wide range of power options to cater to different industries.

Compliance with industrial safety standards.

2. Other Notable Manufacturers

Company A – Specializes in cost-effective feeder vibrator motors.

Company B – Offers customized vibratory motor solutions.

Company C – Known for high-speed, precision-controlled motors.

Each of these manufacturers provides unique solutions tailored to industry-specific needs.

Benefits of Using High-Quality Feeder Vibrator Motors

Investing in a reliable Feeder Vibrator Motor in India ensures multiple operational benefits:

1. Enhanced Efficiency

By automating material movement, these motors reduce manual effort and optimize production workflows.

2. Reduced Maintenance Costs

High-quality motors require less maintenance, reducing long-term operational costs.

3. Improved Material Flow

Feeder vibrator motors prevent clogging and ensure a steady material flow, essential in industries like mining and construction.

4. Energy Savings

Modern motors are designed for minimal energy consumption, leading to lower electricity bills.

Latest Industry Trends in Feeder Vibrator Motors

The demand for Feeder Vibrator Motors in India is growing due to advancements in automation and material handling systems. Here are some key trends:

1. Smart Vibration Control Systems

Modern vibratory motors now feature advanced control systems that allow real-time monitoring and adjustments for optimal performance.

2. Sustainable and Energy-Efficient Designs

Manufacturers are focusing on eco-friendly, energy-efficient motors to reduce carbon footprints.

3. Increased Demand in Mining and Recycling

Industries like mining and recycling are heavily investing in high-performance feeder vibrator motors to enhance productivity.

4. Customization for Specific Applications

Companies now offer customizable options to suit industry-specific needs, from food processing to pharmaceuticals.

Why JK Industries is the Best Choice

When choosing a Feeder Vibrator Motor in India, quality, efficiency, and reliability matter. JK Industries is best Feeder Vibrator Motor manufacturer in India for several reasons:

Proven Track Record: Years of experience in delivering high-performance vibratory motors.

Cutting-Edge Technology: Use of advanced materials and innovative design.

Customer-Centric Approach: Providing customized solutions to meet diverse industrial needs.

0 notes