#Modbus Communication

Explore tagged Tumblr posts

Text

Modbus Communication

youtube

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#plc#SCADA#Drive#HMI#I/O#Modbus Communication#gateway#servo drive#drives#Youtube

0 notes

Text

Discover the top 5 reasons why RS-485 IoT Gateways are essential for efficient and reliable industrial automation systems. Boost performance today!

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

EtherNet/IP Plug In Module

For use with P2 and ECO only. Two Ethernet /IP ports 10/100Mbit half duplex operation. Supports DLR (Device Level Ring) and Linear network topology. CIP Parameter object support.

OPT-2-ETHNT-IN

The VFD Exchange

#invertek#drives#communication#protocol#ethernet#modbus#variablefrequencydrives#optidrive#vfd#acdrives#controls#electricmotor#frequency#voltage#amperage#torque#1phase#3phase#industrial#automation#manufacturing

0 notes

Text

Analog vs. Digital Meters: Understanding the Differences and Applications

In today’s increasingly connected and technologically advanced world, precise electrical measurement is critical for efficient power management and system monitoring. Two primary tools dominate the field of electrical measurement: analog meters and digital meters. While both serve the same fundamental purpose — measuring electrical quantities like voltage, current, and frequency — their technology, design, readability, and application differ significantly.

This article explores the key differences between analog and digital meters, their respective advantages, disadvantages, and common use cases to help you make an informed decision when selecting the right meter for your needs.

What Are Analog Meters?

Analog meters are traditional instruments that display measurement readings through a mechanical needle moving over a graduated scale. They have been widely used for decades in industries, commercial applications, and even residential setups.

Key Features of Analog Meters:

· Use of moving coil or iron vane mechanisms

· Continuous scale display

· Passive operation (no power required in many types)

· Simple, durable construction

Common Types:

· Analog Voltmeters

· Analog Ammeters

· Analog Frequency Meters

· Analog Power Factor Meters

Advantages of Analog Meters:

· Easy to interpret trends and fluctuations

· Cost-effective for basic applications

· Operate without auxiliary power

· Better tolerance to transient spikes and overloads

Limitations:

· Lower accuracy compared to digital meters

· Manual reading required

· Parallax error due to needle reading

· Limited data logging or interfacing capabilities

What Are Digital Meters?

Digital meters represent a more modern approach to electrical measurement. These devices convert analog signals into digital values, displaying results on an LCD or LED screen. They are widely used in automation, smart grids, and precision engineering environments.

Key Features of Digital Meters:

· High-resolution digital display

· Advanced microprocessor control

· MODBUS communication (RS-485 interface)

· Programmable settings and alarms

Common Types:

· Digital Voltmeters

· Digital Ammeters

· Digital Frequency Meters

· Digital Multifunction Meters (VAF, kWh, Power Factor, etc.)

Advantages of Digital Meters:

· High accuracy and readability

· Remote monitoring capabilities

· Compact and modern design

· Enhanced functionalities like data logging, alarms, and networking

Limitations:

· Higher initial cost

· Requires auxiliary power

· More complex installation in some cases

Applications of Analog and Digital Meters

Where Analog Meters Excel:

· Educational institutions for teaching fundamentals

· Industrial environments where ruggedness is key

· Backup or emergency systems where power is limited

· Low-budget installations

Where Digital Meters Lead:

· Smart panels and industrial automation

· Energy monitoring systems

· Commercial buildings and infrastructure

· Remote power distribution networks

Choosing the Right Meter: Factors to Consider

When deciding between analog and digital meters, consider the following:

1. Accuracy Requirements — For precision tasks, digital meters are the preferred choice.

2. Budget Constraints — Analog meters offer a cost-effective solution for basic needs.

3. Environment — Analog meters can be more tolerant in high-temperature or high-vibration areas.

4. Communication Needs — If integration with SCADA or monitoring systems is needed, go digital.

5. Data Analysis — For trend tracking and analytics, digital meters with memory and communication ports are ideal.

Enza Electric: Your Trusted Source for Analog and Digital Meters in the UAE

At Enza Electric, we provide a comprehensive range of analog and digital panel meters tailored to meet diverse electrical monitoring needs. Our digital meters support RS-485 MODBUS, enabling seamless integration into modern automation systems. Whether you’re looking for reliable analog meters for legacy systems or advanced digital meters for new installations, Enza Electric has the expertise and inventory to deliver.

We offer:

· Voltmeter, Ammeter, and Frequency meters in both analog and digital forms

· Multifunction VAF meters

· Panel meter sizes: 72x72mm and 96x96mm

· Customizable CT and PT ratios

Conclusion

Both analog and digital meters play important roles in today’s electrical systems. While analog meters offer simplicity and durability, digital meters bring precision, connectivity, and intelligence. Understanding their differences and applications is key to choosing the right tool for your project.

For expert guidance and high-quality meters, contact Enza Electric — one of the leading electrical measurement solution providers in the UAE.

#AnalogMeters#DigitalMeters#PanelMeters#ElectricalMeasurement#PowerMonitoring#ElectricalEngineering#EnergyMeters#IndustrialAutomation#MeteringSolutions#Instrumentation#electrical#switchgear#dubai#low voltage#uae

4 notes

·

View notes

Text

Top 5 Must-Have Accessories for Every Electrical Panel

An electrical panel is the nerve center of any low-voltage power distribution system — responsible for delivering electricity safely and efficiently to various circuits. While the breakers and busbars often take the spotlight, it’s the accessories that enhance functionality, safety, monitoring, and reliability. Whether you’re an OEM, panel builder, or facility manager, equipping your panels with the right accessories can make all the difference.

In this article, we explore the top 5 must-have accessories for every electrical panel, based on industry best practices and real-world applications.

1. Cable Ducts and Trunking Systems

Purpose:

Cable ducts (also called wiring ducts or trunking) are essential for organizing and routing internal panel wiring. They prevent clutter, minimize the risk of short circuits, and make future maintenance more manageable.

Key Benefits:

· Improved safety through wire separation and insulation

· Neat, professional layout that meets electrical standards

· Ease of troubleshooting during inspections or servicing

Common Types:

· Slotted PVC ducts

· Halogen-free wiring ducts (for safety-critical environments)

· Flexible ducts for tight corners

Pro tip: Always select ducts with sufficient space for future cable additions — typically 20–30% free space is recommended.

2. Terminal Blocks and Marking Systems

Purpose:

Terminal blocks serve as connection points between internal and external wiring, ensuring a secure and modular setup. Combined with proper marking systems, they allow clear identification of circuits and functions.

Key Benefits:

· Safe and reliable wire termination

· Clear labeling for faster diagnostics

· Scalable for expansions and upgrades

Essential Variants:

· Feed-through terminal blocks

· Grounding terminals

· Fuse terminal blocks

· DIN-rail mounted marking strips or markers

Tip: Use color-coded terminals and labels according to IEC or local wiring codes for better clarity.

3. Panel Meters and Monitoring Devices

Purpose:

Modern electrical panels are not just passive distribution points — they are smart monitoring stations. Panel meters and current monitoring devices help track voltage, current, frequency, and power consumption.

Key Benefits:

· Real-time data for preventive maintenance

· Improved energy efficiency

· Quick response to load imbalance or faults

Popular Options:

· Digital voltmeters and ammeters

· Multi-function energy analyzers

· Load monitoring relays

Advanced choice: Consider smart monitoring units with Modbus or Ethernet communication for integration with BMS or SCADA systems.

4. Control and Signaling Devices

Purpose:

Control and signaling accessories like push buttons, selector switches, and pilot lights are critical for human-machine interaction. They allow operators to control, signal, and monitor operations within or from the front of the panel.

Key Benefits:

· Improved operator control and feedback

· Quick visual status indication

· Enhanced safety through emergency stop functions

Must-Have Components:

· Illuminated push buttons (Start/Stop)

· Pilot lights (for voltage presence or fault status)

· Emergency stop buttons

· Audible buzzers for alerts

Best Practice: Use IP65-rated front-panel devices for industrial environments to ensure durability and resistance to dust and moisture.

5. Surge Protection Devices (SPD)

Purpose:

Electrical surges — whether from lightning or switching operations — can damage panel components or connected equipment. SPDs protect against transient over voltages.

Key Benefits:

· Prevents costly downtime and equipment failure

· Increases the lifespan of electronics and controls

· Meets compliance with IEC 61643 or UL 1449 standards

Selection Tips:

· Choose SPDs according to system voltage (230V/400V) and risk level

· Type 1 for external surge protection, Type 2 for internal panel protection

· Consider combined Type 1+2 for comprehensive safety

Smart move: Pair SPDs with monitoring modules to track surge counts and SPD health.

Final Thoughts

When designing or upgrading your electrical panel, these five accessory categories are not just optional — they’re essential. They improve safety, functionality, compliance, and operational efficiency. Whether you’re building panels for industrial, commercial, or residential applications, investing in high-quality accessories will yield long-term benefits.

At Daleel Trading, we supply trusted low-voltage switchgear accessories from leading brands like Civaux — ensuring your panels are equipped with components that meet international standards.

Ready to upgrade your panel accessories?

Contact us today to learn more about our product range or request a consultation with our technical team.

6 notes

·

View notes

Text

Smart Switchgear in 2025: What Electrical Engineers Need to Know

In the fast-evolving world of electrical infrastructure, smart switchgear is no longer a futuristic concept — it’s the new standard. As we move through 2025, the integration of intelligent systems into traditional switchgear is redefining how engineers design, monitor, and maintain power distribution networks.

This shift is particularly crucial for electrical engineers, who are at the heart of innovation in sectors like manufacturing, utilities, data centers, commercial construction, and renewable energy.

In this article, we’ll break down what smart switchgear means in 2025, the technologies behind it, its benefits, and what every electrical engineer should keep in mind.

What is Smart Switchgear?

Smart switchgear refers to traditional switchgear (devices used for controlling, protecting, and isolating electrical equipment) enhanced with digital technologies, sensors, and communication modules that allow:

Real-time monitoring

Predictive maintenance

Remote operation and control

Data-driven diagnostics and performance analytics

This transformation is powered by IoT (Internet of Things), AI, cloud computing, and edge devices, which work together to improve reliability, safety, and efficiency in electrical networks.

Key Innovations in Smart Switchgear (2025 Edition)

1. IoT Integration

Smart switchgear is equipped with intelligent sensors that collect data on temperature, current, voltage, humidity, and insulation. These sensors communicate wirelessly with central systems to provide real-time status and alerts.

2. AI-Based Predictive Maintenance

Instead of traditional scheduled inspections, AI algorithms can now predict component failure based on usage trends and environmental data. This helps avoid downtime and reduces maintenance costs.

3. Cloud Connectivity

Cloud platforms allow engineers to remotely access switchgear data from any location. With user-friendly dashboards, they can visualize key metrics, monitor health conditions, and set thresholds for automated alerts.

4. Cybersecurity Enhancements

As devices get connected to networks, cybersecurity becomes crucial. In 2025, smart switchgear is embedded with secure communication protocols, access control layers, and encrypted data streams to prevent unauthorized access.

5. Digital Twin Technology

Some manufacturers now offer a digital twin of the switchgear — a virtual replica that updates in real-time. Engineers can simulate fault conditions, test load responses, and plan future expansions without touching the physical system.

Benefits for Electrical Engineers

1. Operational Efficiency

Smart switchgear reduces manual inspections and allows remote diagnostics, leading to faster response times and reduced human error.

2. Enhanced Safety

Early detection of overload, arc flash risks, or abnormal temperatures enhances on-site safety, especially in high-voltage environments.

3. Data-Driven Decisions

Real-time analytics help engineers understand load patterns and optimize distribution for efficiency and cost savings.

4. Seamless Scalability

Modular smart systems allow for quick expansion of power infrastructure, particularly useful in growing industrial or smart city projects.

Applications Across Industries

Manufacturing Plants — Monitor energy use per production line

Data Centers — Ensure uninterrupted uptime and cooling load balance

Commercial Buildings — Integrate with BMS (Building Management Systems)

Renewable Energy Projects — Balance grid load from solar or wind sources

Oil & Gas Facilities — Improve safety and compliance through monitoring

What Engineers Need to Know Moving Forward

1. Stay Updated with IEC & IEEE Standards

Smart switchgear must comply with global standards. Engineers need to be familiar with updates related to IEC 62271, IEC 61850, and IEEE C37 series.

2. Learn Communication Protocols

Proficiency in Modbus, DNP3, IEC 61850, and OPC UA is essential to integrating and troubleshooting intelligent systems.

3. Understand Lifecycle Costing

Smart switchgear might have a higher upfront cost but offers significant savings in maintenance, energy efficiency, and downtime over its lifespan.

4. Collaborate with IT Teams

The line between electrical and IT is blurring. Engineers should work closely with cybersecurity and cloud teams for seamless, secure integration.

Conclusion

Smart switchgear is reshaping the way electrical systems are built and managed in 2025. For electrical engineers, embracing this innovation isn’t just an option — it’s a career necessity.

At Blitz Bahrain, we specialize in providing cutting-edge switchgear solutions built for the smart, digital future. Whether you’re an engineer designing the next big project or a facility manager looking to upgrade existing systems, we’re here to power your progress.

#switchgear#panel#manufacturer#bahrain25#electrical supplies#electrical equipment#electrical engineers#electrical

6 notes

·

View notes

Text

As Russia has tested every form of attack on Ukraine's civilians over the past decade, both digital and physical, it's often used winter as one of its weapons—launching cyberattacks on electric utilities to trigger December blackouts and ruthlessly bombing heating infrastructure. Now it appears Russia-based hackers last January tried yet another approach to leave Ukrainians in the cold: a specimen of malicious software that, for the first time, allowed hackers to reach directly into a Ukrainian heating utility, switching off heat and hot water to hundreds of buildings in the midst of a winter freeze.

Industrial cybersecurity firm Dragos on Tuesday revealed a newly discovered sample of Russia-linked malware that it believes was used in a cyberattack in late January to target a heating utility in Lviv, Ukraine, disabling service to 600 buildings for around 48 hours. The attack, in which the malware altered temperature readings to trick control systems into cooling the hot water running through buildings' pipes, marks the first confirmed case in which hackers have directly sabotaged a heating utility.

Dragos' report on the malware notes that the attack occurred at a moment when Lviv was experiencing its typical January freeze, close to the coldest time of the year in the region, and that “the civilian population had to endure sub-zero [Celsius] temperatures.” As Dragos analyst Kyle O'Meara puts it more bluntly: “It's a shitty thing for someone to turn off your heat in the middle of winter.”

The malware, which Dragos is calling FrostyGoop, represents one of less than 10 specimens of code ever discovered in the wild that's designed to interact directly with industrial control-system software with the aim of having physical effects. It's also the first malware ever discovered that attempts to carry out those effects by sending commands via Modbus, a commonly used and relatively insecure protocol designed for communicating with industrial technology.

Dragos first discovered the FrostyGoop malware in April after it was uploaded in several forms to an online malware scanning service—most likely the Google-owned scanning service and malware repository VirusTotal, though Dragos declined to confirm which service—perhaps by the malware's creators, in an attempt to test whether it was detected by antivirus systems. Working with Ukraine's Cyber Security Situation Center, a part of the country's SBU cybersecurity and intelligence agency, Dragos says it then learned that the malware had been used in the cyberattack that targeted a heating utility starting on January 22 in Lviv, the largest city in western Ukraine.

Dragos declined to name the victim utility, and in fact says it hasn't independently confirmed the the utility's name, since it only became aware of the targeting from the Ukrainian government. Dragos' description of the attack, however, closely matches reports of a heating outage at the Lvivteploenergo utility around the same time, which according to local media led to a loss of heating and hot water for close to 100,000 people.

Lviv mayor Andriy Sadovyi at the time called the event a “malfunction" in a post to the messaging service Telegram, but added, “there is a suspicion of external interference in the company's work system, this information is currently being checked.” A Lvivteploenergo statement on January 23 described the outage more conclusively as the “result of a hacker attack.”

Lvivteploenergo didn't respond to WIRED's request for comment, nor did the SBU. Ukraine's cybersecurity agency, the State Services for Special Communication and Information Protection, declined to comment.

In its breakdown of the heating utility attack, Dragos says that the FrostyGoop malware was used to target ENCO control devices—Modbus-enabled industrial monitoring tools sold by the Lithuanian firm Axis Industries—and change their temperature outputs to turn off the flow of hot water. Dragos says that the hackers had actually gained access to the network months before the attack, in April 2023, by exploiting a vulnerable MikroTik router as an entry point. They then set up their own VPN connection into the network, which connected back to IP addresses in Moscow.

Despite that Russia connection, Dragos says it hasn't tied the heating utility intrusion to any known hacker group it tracks. Dragos noted in particular that it hasn't, for instance, tied the hacking to the usual suspects such as Kamacite or Electrum, Dragos' own internal names for groups more widely referred to collectively as Sandworm, a notorious unit of Russia's military intelligence agency, the GRU.

Dragos found that, while the hackers used their breach of the heating utility's network to send FrostyGoop's Modbus commands that targeted the ENCO devices and crippled the utility's service, the malware appears to have been hosted on the hackers' own computer, not on the victim's network. That means simple antivirus alone, rather than network monitoring and segmentation to protect vulnerable Modbus devices, likely won't prevent future use of the tool, warns Dragos analyst Mark “Magpie” Graham. “The fact that it can interact with devices remotely means it doesn't necessarily need to be deployed to a target environment,” Graham says. “You may potentially never see it in the environment, only its effects.”

While the ENCO devices in the Lviv heating utility were targeted from within the network, Dragos also warns that the earlier version of FrostyGoop it found was configured to target an ENCO device that was instead publicly accessible over the open internet. In its own scans, Dragos says it found at least 40 such ENCO devices that were similarly left vulnerable online. The company warns that there may in fact be tens of thousands of other Modbus-enabled devices connected to the internet that could potentially be targeted in the same way. “We think that FrostyGoop would be able to interact with a huge number of these devices, and we're in the process of conducting research to verify which devices would indeed be vulnerable,” Graham says.

While Dragos hasn't officially linked the Lviv attack to the Russian government, Graham himself doesn't shy away from describing the attack as a part of Russia's war against the country—a war that has brutally decimated Ukrainian critical infrastructure with bombs since 2022 and with cyberattacks starting far earlier, since 2014. He argues that the digital targeting of heating infrastructure in the midst of Ukraine's winter may actually be a sign that Ukrainians' increasing ability to shoot down Russian missiles has pushed Russia back to hacking-based sabotage, particularly in western Ukraine. “Cyber may actually be more efficient or likely to be successful towards a city over there, while kinetic weapons are maybe still successful at a closer range," Graham says. “They’re trying to use the full spectrum, the full gamut of available tools in the armory.”

Even as those tools evolve, though, Graham describes the hackers' goals in terms that have changed little in Russia's decade-long history of terrorizing its neighbor: psychological warfare aimed at undermining Ukraine's will to resist. “This is how you chip away at the will of the people,” says Graham. “It wasn’t aimed at disrupting the heating for all of winter. But enough to make people to think, is this the right move? Do we continue to fight?”

9 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

At OnlineUPSPrice.com, we bring you the most reliable and efficient power backup solutions to meet your critical power requirements. Among our top-selling products is the Emerson Vertiv 40 kVA UPS, a robust and high-performance uninterruptible power supply system designed to support demanding business environments. Whether you are running a data center, hospital, industrial facility, or IT infrastructure, this UPS ensures that your operations remain uninterrupted and protected from power disturbances.

Why Choose the Emerson Vertiv 40 kVA UPS?

The Emerson Vertiv 40 kVA UPS is engineered with advanced technology and unmatched reliability. As a part of the Vertiv (formerly Emerson Network Power) family, it offers best-in-class performance, superior efficiency, and excellent scalability. Below are some compelling reasons to choose this system:

1. High Efficiency and Performance

The 40 kVA UPS from Vertiv operates with high double-conversion efficiency, typically above 95%, ensuring energy savings and lower operating costs. It guarantees consistent and clean power delivery, even in areas prone to voltage fluctuations and frequent outages.

2. Advanced Power Protection

Equipped with online double-conversion technology, the Emerson Vertiv UPS ensures total isolation between the input and output power. It protects connected devices against surges, spikes, frequency variations, and power failures, making it ideal for mission-critical applications.

3. Scalability and Flexibility

One of the standout features of this UPS system is its modular and scalable architecture. As your power requirements grow, the system can be easily upgraded to handle higher loads, offering future-proof investment.

4. Compact Footprint

Despite its powerful capabilities, the Emerson Vertiv 40 kVA UPS features a compact design, allowing it to be installed in space-constrained environments without compromising performance.

5. Intelligent Monitoring and Management

The built-in LCD display and intelligent monitoring system allow for real-time diagnostics, fault reporting, and performance analysis. It also supports remote management via SNMP, Modbus, and other industry-standard communication protocols.

Applications of Emerson Vertiv 40 kVA UPS

This UPS system is suitable for a wide range of critical applications, including:

Data Centers: Ensures uninterrupted power to servers and networking equipment.

Healthcare Facilities: Supports diagnostic machines, ICU equipment, and essential medical systems.

Industrial Units: Protects automation and control systems from power disturbances.

Financial Institutions: Keeps banking servers and transaction systems always operational.

Telecom & IT: Maintains uptime for network operations and communication systems.

Technical Specifications at a Glance

Capacity: 40 kVA / 32 kW

Technology: Online Double Conversion (VFI)

Input Voltage Range: Wide input range to accommodate unstable grid conditions

Output Voltage: Pure sine wave output

Battery Configuration: External battery bank (customizable)

Efficiency: >95% in online mode

Display: LCD panel with key operating information

Communication Ports: RS-232, USB, SNMP, Modbus (optional)

Dimensions: Compact rack or tower model (varies by configuration)

Why Buy from OnlineUPSPrice.com?

At Online UPS Price, we specialize in providing top-notch power solutions at competitive prices. Here’s why customers trust us:

Genuine Products: We are authorized dealers of major UPS brands including Vertiv, APC, Eaton, and more.

Competitive Pricing: Get the best price for the Emerson Vertiv 40 kVA UPS without compromising on quality.

Expert Support: Our team of experts assists you in choosing the right UPS system tailored to your needs.

Installation & Service: We offer nationwide installation, AMC (Annual Maintenance Contracts), and 24/7 technical support.

Fast Delivery: We ensure timely delivery and hassle-free logistics across India.

Get the Best Deal on Emerson Vertiv 40 kVA UPS Today

Don’t let power failures disrupt your operations. Secure your business continuity with the Emerson Vertiv 40 kVA UPS from OnlineUPSPrice.com. Whether you need consultation, pricing, or installation assistance, our team is here to help.

Contact us today at https://onlineupsprice.com or call us for a free consultation and quotation. We promise the best value, expert advice, and top-notch after-sales service.

Keywords: Emerson Vertiv 40 kVA UPS, Vertiv UPS 40kVA price, Online UPS Price, Industrial UPS Systems, UPS for Data Centers, UPS for Hospitals, Online UPS Supplier India

1 note

·

View note

Text

Explosion proof Absolute Rotary Encoder with RS232 Modbus RTU Communication

Key features

Power-Off Memory: Maintains precise position data even during power outages, eliminating recalibration needs and ensuring consistent performance.

Absolute Multi-Turn Capability: Delivers accurate position data across numerous turns, making it suitable for intricate rotational tasks.

Mechanical Gear Counting: Uses sturdy mechanical gears for turn counting, eliminating the dependency on internal batteries and boosting reliability.

High Resolution: Offers up to 17-bit resolution with 0.07° accuracy for meticulous angle measurements.

Compact and Rugged Design: Features a minimal outer diameter of just 39mm and EX protection, making it resilient in harsh environments.

Data Interfaces: Equipped with RS232 connections and supports Modbus RTU, enabling seamless data integration and communication.

Visit https://briterencoder.com/product/explosionproof-absolute-rotary-encoder-with-rs232-modbus-rtu-communication/ for more.

0 notes

Text

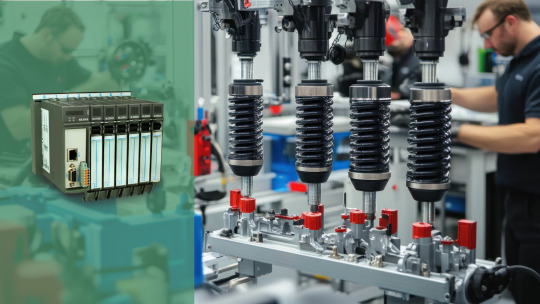

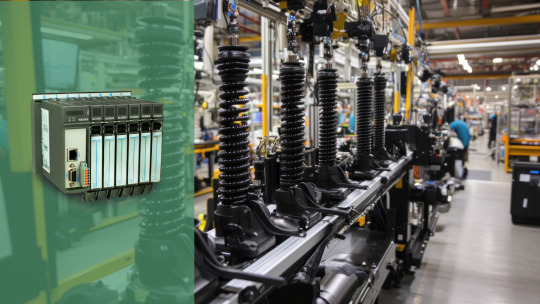

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

Other communication options are available in PowerFlex 525 AC Drives

The PowerFlex 525 AC Drives provide a variety of connection options in addition to typical EtherNet/IP connectivity to guarantee smooth integration with different industrial networks. These drives provide various networking setups by supporting optional dual-port EtherNet/IP, DeviceNet, and Modbus RTU protocols. Communication adapter modules allow them to interact with protocols including ControlNet, BACnet, and Profibus DP. Because of its adaptability, users may connect to various control systems without requiring significant hardware modifications, making the PowerFlex 525 perfect for a variety of automation scenarios. Easy configuration and connectivity are further improved by embedded Ethernet and built-in USB programming.

#automation#technology#tech#technical#AVEVA#PLC#HMI#SCADA#scada systems#industrial#industries#Allen Bradley#Rockwell Automation#Tech#Automotive

2 notes

·

View notes

Text

IoT gateways play a crucial role in smart technology ecosystems by aggregating and processing data from various devices, ensuring seamless communication and interoperability.

#RS 485 IoT Gateway Solutions#Industrial IoT Gateway Solutions#industrial iot gateway devices#IOT gateway devices#IIoT gateway devices#MQTT IoT gateway#iot gateway manufacturers#Top IoT gateway companies#IoT gateway company#iot gateway solutions#modbus gateway#rs485 gateway#rs485 protocol#modbus rs485#modbus communication protocol#rs485 iot gateway#modbus protocol#iot gateway

0 notes

Text

EtherNet/IP Module

ODVA compliant EtherNet/IP Modbus Translator Device. Compatible with all drive platforms: P2, E3 & Eco. Integrated network switch: simplifying network architecture. Compatible with RSLogix and CoDeSys PLCs.

OPT-2-ETHEG-IN

The VFD Exchange

#invertek#drives#communication#protocol#ethernet#modbus#variablefrequencydrives#optidrive#vfd#acdrives#controls#electricmotor#frequency#voltage#amperage#torque#1phase#3phase#industrial#automation#manufacturing

0 notes

Text

"SCADA & Communication Network" - Is it the backbone of industrial automation?

Without reliable communication channels and proper protocols, a SCADA system is simply useless

Do you really know how protocols like Modbus, DNP3, OPC actually work in practice?Discover more here: https://maxelectric.vn/scada-mang-truyen-thong-trong-cong-nghiep-a156.html

0 notes

Text

Introduction to CODESYS PLC: A Comprehensive Overview

CODESYS (Controller Development System) is a leading software platform for industrial automation, widely used for programming and configuring Programmable Logic Controllers (PLCs). Developed by the German company 3S-Smart Software Solutions, CODESYS PLC is a versatile, hardware-independent development environment that supports a broad range of industrial applications, from factory automation to process control and motion control systems. This article explores the key features, benefits, programming capabilities, and applications of CODESYS PLC, highlighting its significance in modern industrial automation.

What is CODESYS?

CODESYS is an integrated development environment (IDE) that adheres to the international standard IEC 61131-3, which defines programming languages for PLCs. This standard ensures that CODESYS is compatible with a wide variety of hardware platforms from different manufacturers, making it a flexible and scalable solution. The platform supports all five IEC 61131-3 programming languages: Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). Additionally, CODESYS extends support for object-oriented programming (OOP) with languages like Structured Text, enabling advanced programming techniques.

The CODESYS ecosystem includes not only the core IDE but also additional tools for visualization, simulation, debugging, and communication with field devices. It is used in industries such as manufacturing, energy, automotive, and building automation, offering a unified platform for developing complex automation solutions.

Key Features of CODESYS

IEC 61131-3 Compliance: CODESYS supports all standard PLC programming languages, allowing developers to choose the most suitable language for their application. This compliance ensures portability of code across different PLC hardware, reducing development time and costs.

Hardware Independence: CODESYS is compatible with over 1,000 devices from various manufacturers, including Siemens, Beckhoff, WAGO, and others. This flexibility allows engineers to write code once and deploy it on multiple platforms without significant modifications.

Integrated Visualization: CODESYS provides built-in tools for creating Human-Machine Interfaces (HMIs). Developers can design graphical user interfaces for operator panels, web-based visualizations, or mobile applications, all within the same environment.

Fieldbus and Communication Support: The platform supports a wide range of industrial communication protocols, such as Modbus, CANopen, EtherCAT, PROFINET, and OPC UA. This ensures seamless integration with sensors, actuators, and other devices in an automation system.

Simulation and Debugging: CODESYS includes a powerful simulation mode that allows developers to test their programs without physical hardware. The debugging tools enable real-time monitoring, breakpoints, and variable tracing, streamlining the development process.

Scalability and Modularity: From small embedded systems to large distributed control systems, CODESYS is highly scalable. Its modular architecture allows developers to add libraries, function blocks, and extensions as needed.

Safety and Security: CODESYS supports safety programming according to standards like IEC 61508 (SIL 2/3), making it suitable for safety-critical applications. It also includes features for secure communication and user authentication to protect against cyber threats.

Programming with CODESYS

CODESYS offers a flexible programming environment that caters to both novice and experienced developers. The five IEC 61131-3 languages provide diverse options:

Ladder Diagram (LD): Ideal for electrical engineers familiar with relay logic, LD resembles electrical circuit diagrams and is widely used for simple control tasks.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, making it intuitive for designing complex systems.

Structured Text (ST): A high-level, text-based language similar to Pascal or C, suitable for algorithmic and mathematical operations.

Instruction List (IL): A low-level, assembly-like language for precise control, though less commonly used today.

Sequential Function Chart (SFC): Used for sequential control processes, SFC is ideal for applications requiring step-by-step execution, such as batch processing.

In addition to these, CODESYS supports object-oriented programming, allowing developers to create reusable code through classes, methods, and inheritance. This is particularly useful for large-scale projects where modularity and maintainability are critical.

Benefits of Using CODESYS

Cost Efficiency: By supporting multiple hardware platforms, CODESYS eliminates the need for proprietary software tied to specific vendors, reducing licensing and development costs.

Flexibility: Developers can work in their preferred programming language and deploy code on various devices, enhancing project flexibility.

Community and Ecosystem: CODESYS has a large user base and an active community, with extensive documentation, libraries, and third-party tools available through the CODESYS Store.

Rapid Development: The integrated environment, combined with simulation and debugging tools, accelerates development and testing cycles.

Global Adoption: CODESYS is used worldwide, ensuring that skills learned in the platform are transferable across industries and regions.

Applications of CODESYS PLC

CODESYS is employed in a wide range of industries, including:

Manufacturing: Controlling assembly lines, robotic systems, and CNC machines.

Energy: Managing renewable energy systems, such as wind turbines and solar plants, as well as traditional power distribution networks.

Building Automation: Integrating HVAC, lighting, and security systems for smart buildings.

Automotive: Controlling production lines and testing equipment in automotive manufacturing.

Process Control: Managing chemical plants, water treatment facilities, and food processing systems.

Getting Started with CODESYS

To begin using CODESYS, developers can download the free CODESYS Development System from the official website. The software is compatible with Windows and supports a variety of PLC hardware. Beginners can start with the extensive documentation and tutorials available online, while advanced users can explore the CODESYS Store for additional libraries and add-ons.

A typical workflow involves:

Installing the CODESYS IDE.

Selecting a target PLC and configuring the hardware.

Writing the program using one or more IEC 61131-3 languages.

Simulating the program to test functionality.

Deploying the code to the PLC and monitoring its performance.

Challenges and Considerations

While CODESYS is a powerful platform, there are some considerations:

Learning Curve: For beginners, mastering all five programming languages and the IDE’s features can take time.

Hardware Dependency: Although CODESYS is hardware-independent, specific PLCs may require proprietary drivers or configurations.

Licensing: While the core IDE is free, certain add-ons, libraries, or runtime licenses may incur costs, depending on the application.

Conclusion

CODESYS PLC by Servotechinc is a cornerstone of modern industrial automation, offering a robust, flexible, and scalable platform for PLC programming. Its adherence to IEC 61131-3, support for multiple programming languages, and extensive feature set make it a preferred choice for engineers worldwide. Whether you’re developing a small control system or a complex, distributed automation solution, CODESYS provides the tools to streamline development and ensure reliable performance. As industries continue to embrace digital transformation, CODESYS remains at the forefront, empowering automation professionals to build the systems of the future.

0 notes