#Printed Circuit Board (PCB) Design Market

Text

#Printed Circuit Board (PCB) Design Market#Printed Circuit Board (PCB) Design Market Trends#Printed Circuit Board (PCB) Design Market Growth#Printed Circuit Board (PCB) Design Market Industry#Printed Circuit Board (PCB) Design Market Research

0 notes

Text

Printed Circuit Boards (PCBs) Market Analysis, Key Players, Share Dynamic Demand and Consumption to 2032

The printed circuit boards (PCBs) market refers to the industry involved in the design, production, and sale of PCBs, which are essential components in electronic devices. PCBs provide a platform for interconnecting and supporting various electronic components, such as integrated circuits (ICs), resistors, capacitors, and connectors.

printed circuit board market size is expected to increase USD 3.60 billion by 2032 and Growth Rate from 2023 CAGR of 3.9% Forecast Period 2023 To 2032

Here are some key points about the PCBs market:

Market Size and Growth: The PCBs market has experienced significant growth in recent years. Factors driving this growth include the increasing demand for consumer electronics, telecommunications equipment, automotive electronics, industrial automation, and healthcare devices. The proliferation of smart devices, Internet of Things (IoT) applications, and advancements in technologies like 5G and artificial intelligence also contribute to the expanding PCBs market.

Types of PCBs: PCBs come in different types, including single-sided, double-sided, multi-layered, rigid, flexible, and rigid-flex PCBs. Each type has its specific applications and advantages. For instance, flexible PCBs are used in wearable devices and applications where flexibility and compactness are essential, while multi-layered PCBs are commonly found in complex electronic systems like smartphones and computers.

Manufacturing Process: PCB manufacturing involves several steps, including design, substrate selection, copper etching, solder mask application, and component assembly. The industry has seen advancements in manufacturing techniques such as surface-mount technology (SMT) and advanced packaging, enabling smaller and more complex PCB designs.

Market Players: The PCBs market is highly competitive, with numerous manufacturers operating globally. Some of the key players in the industry include Nippon Mektron Ltd., Unimicron Technology Corp., Zhen Ding Technology Holding Limited, Tripod Technology Corporation, Samsung Electro-Mechanics Co., Ltd., and TTM Technologies, Inc. These companies offer a wide range of PCB products and services to cater to different industries and customer requirements.

Regional Market: Asia-Pacific dominates the global PCBs market, primarily due to the presence of major electronics manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. These countries are known for their strong electronics industry, which drives the demand for PCBs. North America and Europe also contribute significantly to the market due to their established electronics and automotive sectors.

Emerging Trends: The PCBs market is influenced by several emerging trends. These include the miniaturization of electronic devices, the adoption of advanced materials and technologies for higher performance and reliability, the shift towards environmentally friendly and lead-free PCBs, and the growing demand for high-speed and high-frequency PCBs to support advanced applications.

It's worth noting that the PCBs market is subject to various factors, including technological advancements, regulatory requirements, supply chain dynamics, and customer demand. To obtain the most accurate and up-to-date information on the market, it's advisable to refer to industry reports, market research studies, and publications specific to the PCBs market.

I recommend referring to our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into the humidity sensors market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to the humidity sensors market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in the market.

Remember to look for recent reports to ensure you have the most current and relevant information.

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/reports/printed-circuit-boards-(pcbs)-market/901/

Market Segmentations:

Global Printed Circuit Boards (PCBs) Market: By Company

• AT&S

• Nippon Mektron

• Unimicron

• Samsung

• Dynamic Electronics

• Daeduck Electronics

• CMK Corporation

• Nan Ya PCB Co.

• TTM Technologies

• Shenzhen Kinwong Electronic

Global Printed Circuit Boards (PCBs) Market: By Type

• Single-sided

• Double-sided

• Multi-layer

Global Printed Circuit Boards (PCBs) Market: By Application

• Consumer Electronics

• Aerospace and Defense

• Automotive

• Healthcare

• Others

Global Printed Circuit Boards (PCBs) Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Printed Circuit Boards (PCBs) market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/printed-circuit-boards-(pcbs)-market/901/

Reasons to Purchase Printed Circuit Boards (PCBs) Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organization’s useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy development, and business planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/printed-circuit-boards-(pcbs)-market/901/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Printed Circuit Boards (PCBs) Market Analysis#Key Players#Share Dynamic Demand and Consumption to 2032#The printed circuit boards (PCBs) market refers to the industry involved in the design#production#and sale of PCBs#which are essential components in electronic devices. PCBs provide a platform for interconnecting and supporting various electronic compone#such as integrated circuits (ICs)#resistors#capacitors#and connectors.#printed circuit board market size is expected to increase USD 3.60 billion by 2032 and Growth Rate from 2023 CAGR of 3.9% Forecast Period#Here are some key points about the PCBs market:#1.#Market Size and Growth: The PCBs market has experienced significant growth in recent years. Factors driving this growth include the increas#telecommunications equipment#automotive electronics#industrial automation#and healthcare devices. The proliferation of smart devices#Internet of Things (IoT) applications#and advancements in technologies like 5G and artificial intelligence also contribute to the expanding PCBs market.#2.#Types of PCBs: PCBs come in different types#including single-sided#double-sided#multi-layered#rigid#flexible#and rigid-flex PCBs. Each type has its specific applications and advantages. For instance#flexible PCBs are used in wearable devices and applications where flexibility and compactness are essential

0 notes

Text

Advantages of Full Turnkey PCB Assembly Services

• Shorter Lead Time

As a fundamental form of electronic assembly, PCB assembly primarily contains three phases: PCB fabrication, components procurement and PCB assembly. Traditionally, you should quote and confirm design files with sales and engineers working for your PCB manufacturer, then components distributors and finally PCB assemblers. Such series of quotations and confirmations just need your time spent in contacting with different partners. If those partners are from different countries, you have to overcome some problems such as time zone, communication habits etc. Full-turnkey PCB assembly, however, is a highly-efficient form of electronic assembly. As soon as full-turnkey PCB assembly is determined, an overall assembly quotation and indispensible issues prohibiting smooth manufacturing will be raised so that three times of communication have been cut to one time with electronic assembly efficiency dramatically improved in Hitech Circuits Co., Limited.

• Lower Cost

Another advantage of full-turnkey PCB assembly service is overall cost reduction. Pack-up service is usually cheaper than separate ones as far as electronic assembly is concerned. At least, freight fee will be saved because you don’t need to get manufactured PCB boards and electronic components delivered to assembly workshop. Moreover, components procurement may get easy and customer-friendly because experienced electronic assemblers are usually able to provide reliable components with relatively low cost based on their long-term cooperation with parts manufacturers or distributors.

• Transparent Monitoring

When it comes to electronic assembly process, it’s significant yet difficult to monitor your products’ manufacturing stage as it is totally related with your products’ performance and time to market. Full-turnkey PCB assembly allows engineers at each stage to be aware of what they’ve accomplished and to better understand their status for better performance of final products.

Who Can Benefit Most From Our Turnkey PCB Assembly Services?

Now that full turnkey PCB assembly allows PCB designers to make better use of their time to focus more on PCB design, it works perfectly on companies striving for frequent upgrading and refreshing of products. They need to dig into deeper market by providing multiple creative electronic products and they strongly call for a steady and smooth electronic assembly process.

Turnkey printed circuit board assembly is also an ideal electronic assembly solution for small businesses or startup companies that want to bring smaller quantities of assembled PCBs to market without having to invest in or carry an extensive inventory. It also offers a more cost-effective, efficient means of assembling and testing PCB prototypes for new products. In addition, quick-turn PCB assembly service makes sense for any company that needs to receive their circuit boards with the shortest possible lead time.

4 notes

·

View notes

Text

3 Ways Full Turn Key PCB Manufacturing Services Streamline Production

In today's tech-driven landscape, the demand for swift, reliable, and top-notch electronic products is soaring. To meet this demand effectively, opting for full turnkey PCB (Printed Circuit Board) manufacturing services is imperative. These services offer a comprehensive solution, managing everything from conception to the final product.

Primarily, full turnkey services expedite the production process by consolidating multiple stages under one roof. This streamlined approach ensures a faster transition from design to production. Moreover, it guarantees quality control as the entire process is managed by a single entity, minimizing errors and ensuring consistency. Additionally, by eliminating the need to coordinate with multiple vendors, costs are reduced significantly.

Choosing a reputable printed circuit board fabrication company like Bay Area Circuits (BAC) for full turnkey PCB services ensures a hassle-free experience and top-notch results. With BAC's comprehensive package, businesses can stay ahead in today's competitive tech market.

Originally Published at- https://techplanet.today/post/3-ways-full-turn-key-pcb-manufacturing-services-streamline-production

0 notes

Text

Note the Various Benefits of Clone PCB

A clone PCB is a replicated version of an existing printed circuit board (PCB), designed to mimic the layout, components, and functionality of the original PCB. It serves purposes such as backup, legacy support, cost reduction, customization, or reverse engineering. However, creating clone PCBs must be done while considering legal and ethical considerations regarding intellectual property rights.

Sometimes, clone PCBs are created through reverse engineering processes to replicate the functionality of an existing PCB without access to its original design files or documentation. PCB (Printed Circuit Board) reverse engineering is the process of deconstructing and analyzing the design and functionality of a printed circuit board to understand its schematics, layout, and operation.

There are multifaceted benefits of clone PCBs:

Continuity and redundancy - Clone PCBs provide a safety net for businesses by ensuring continuity in production processes. In case the original PCB design becomes unavailable due to damage, loss, or obsolescence, having clone PCBs allows manufacturing to continue without disruptions. This redundancy is crucial for industries where downtime can result in substantial financial losses.

Legacy support and maintenance - Many industries rely on equipment or devices with legacy PCB designs that may no longer be supported by the original manufacturer. Clone PCBs enable the continued operation, maintenance, and repair of such equipment, extending its lifespan and maximizing return on investment. This is particularly important in sectors like aerospace, defense, automotive, and industrial manufacturing, where equipment longevity is paramount.

Cost optimization - Clone PCBs offer opportunities for cost optimization in several ways. By replicating the original PCB design using more readily available or cost-effective components, manufacturers can reduce production costs without sacrificing quality or performance. Additionally, economies of scale can be leveraged when producing clone PCBs in bulk, further driving down per-unit costs.

Flexibility and customization - Clone PCBs can be tailored to meet specific requirements or to incorporate improvements over the original design. Manufacturers can modify aspects such as component selection, layout, or functionality to optimize performance, enhance reliability, or adapt to evolving technological standards. This flexibility enables businesses to stay competitive and responsive to changing market demands.

Reverse engineering and innovation - Clone PCBs support innovation by facilitating reverse engineering efforts. Analyzing and replicating existing PCB designs allows engineers to gain insights into complex electronic systems, identify best practices, and develop new products or technologies based on proven designs. This process fosters creativity, knowledge transfer, and continuous improvement within the industry.

Intellectual property protection - While not directly a benefit, clone PCBs can also help protect intellectual property (IP) by offering a legal and authorized means for manufacturers to reproduce their own designs. This ensures that valuable innovations are safeguarded against unauthorized replication or counterfeiting, preserving the competitive advantage of original equipment manufacturers.

0 notes

Text

Your leading PCB High Volume PCB Assembly supplier in China--Hitech Circuits

With 15 years of experience and high efficiency in PCB assembly and manufacturing, HITECH CIRCUITS is the perfect source for Big Batch PCB assembly on a limited budget. If you are looking for a large PCBA assembly within your budget, we will be your ideal choice. HITECH CIRCUITS has more than 15 years of experience in the OEM/PCBA manufacturing and assembly of printed circuit boards, advanced production technology and equipment, professional engineers and purchasing team to provide our partners with personalized and complete process solutions. HITECH CIRCUITS’s supply chain services deliver supply chain innovation on demand. We offer a bold, yet proven service solution designed to grow market share and profit. Our innovative approach to managing the supply chain offers a complete business model that delivers the talent and transformative tools necessary to create predictability, reliability, and responsiveness across your entire supply chain. Our practitioners are passionate about supply chains. We have spent a generation understanding, refining and building the best in intelligent supply chains. We provide talent on-demand with expertise in data analytics and strategic technologies that can help you predict, plan and respond more effectively.

Some designs require assemblies in small volume, maybe just prototypes, while others require them in high volume. At SMT house, High Volume, Large Volume, or Big Batch PCB Assembly always refers to printed board assembly projects with quantities more than 5K pieces. HitechPCB has the capability to offer high volume PCB assembly services to meet your requirements of high-quality, competitive price, on-time delivery and smooth communication in any manner of full turnkey, consigned and partial turnkey.

Also, if your business is involved in applications that require high-volume PCB assembly, the company to contact is HitechPCB, because we’re a complete turnkey solution for printed circuit boards assembly, we are ideally suited for bulk PCB assembly orders. Our state-of-the-art equipments, large facility and wide range of highly-qualified experts give us the capability of high-volume PCB assembly of up to 9,000,000.

We are also the perfect source if you’re looking for large-order PCB assembly on a budget. Because of our high level of efficiency and more than 10 years of experience with printed circuit board manufacturing and electronics assembly, we offer large printed circuit board orders at surprisingly competitive prices compared to other PCB manufacturers or PCB assembly companies.

Our large order PCB assembly process starts with a tested and practiced set of workflow guidelines for every phase of the process, from pre-order PCB design consultation with professional veteran engineers to PCB fabrication, components sourcing, PCB assembly, PCBA testing, PCBA inspection, PCBA packing and shipping all under the auspices of a highly-skilled production staff. You can be confident that no matter how many circuit boards you order, you will enjoy fast service, low prices and extremely high quality.

With our excellent after-sales service, 24 sales and technical support team, quick response service, we will be your best Big Batch PCB assembly manufacturer inChina. A wide variety of highly qualified experts.

Why choose Hitechpcba Big Batch PCB Assembly?

Compared to our competitors, Hitechpcba offers large printed circuit board orders at very competitive prices. The risky big batch PCB assembly process begins with a set of tried and tested workflow guidelines. From ordering PCB design to component procurement, manufacturing, testing, assembly, inspection, shipping and packaging. This is all under the guidance of our highly skilled production staff.

No matter how many boards you order, you'll love the fast response service, low cost, and surprisingly high quality.

Whether you are seeking for product designer, electrical engineer, system integrator, manufacturer, or big batch PCB manufacturing and assembly, low cost big batch PCB housing, electronic assembly services, Hitech Circuits PCB Assembly team will be your perfect choice for big batch PCB assembly plant in China.

0 notes

Text

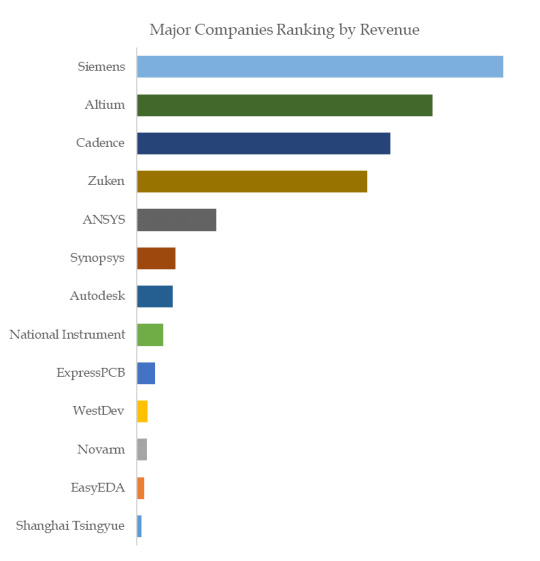

Global Top 5 Companies Accounted for 83% of total PCB Software market (QYResearch, 2021)

PCB design software aids electronic engineers in designing layouts for printed circuit boards. Engineers leverage the software to collaborate on the design process, pull previously used circuit board component designs from PCB libraries, and verify circuit schematic designs. PCB design software is most often used by engineering firms and teams that may be involved with product development. PCB design software is often implemented as a part of other design software systems such as product and machine design software and general-purpose CAD software.

The PCB Software industry can be broken down into several segments, On Premises, Cloud Based.

Across the world, the major players cover Siemens, Altium, etc.

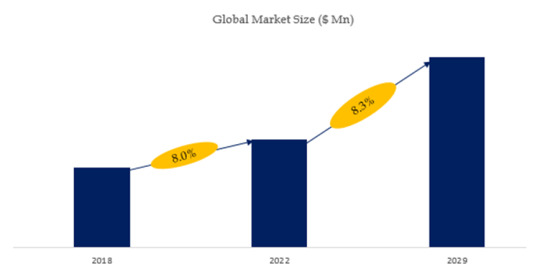

According to the new market research report “Global PCB Software Market Report 2023-2029”, published by QYResearch, the global PCB Software market size is projected to reach USD 1.82 billion by 2029, at a CAGR of 8.3% during the forecast period.

Figure. Global PCB Software Market Size (US$ Million), 2018-2029

Figure. Global PCB Software Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of PCB Software include Siemens, Altium, Cadence, Zuken, ANSYS, Synopsys, Autodesk, National Instrument, ExpressPCB, WestDev, etc. In 2021, the global top five players had a share approximately 83.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Advanced Materials for Electronics is Projected to Grow at a 7.4% CAGR between 2022 and 2031

The Advanced Materials for Electronics Market is predicted to reach US$ 57.8 billion by 2031. According to market forecasts, the market is expected to grow at a CAGR of 7.4% through 2031.

Electronics that are printed and flexible continue to grow at a fast rate. Along the value chain, energy and resource efficiency can be significantly increased through new technological approaches to both production and product design.

Electronics are undergoing constant reorganization to meet changing consumer demands, which results in continuously evolving technologies, materials, and business models. Innovations in the technology industry have been stimulated by the growing need for miniaturized and improved capacity computers and networks, faster data transmission speeds, and most importantly, sustainable technologies.

For instance, a new high-speed broadband standard protocol for digital subscriber lines (DSL) was approved by the International Telecommunication Union (ITU) in December 2014. It is referred to as Gaits for local loops under 500 meters that support uploads and downloads at 150 Mb/s to 2 Gb/s. A local loop's length determines how fast Gaits can transmit data. It is mandatory in Gaits to have an asymmetry ratio of 90/10 to 50/50 between downstream and upstream

Download Sample Copy with Graphs & List of Figures: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85652

Market Segmentation

The advanced materials for electronics market can be segmented by service type, sourcing type, application, industry vertical, and region.

By Service Type

Design and Consulting

Integration and Implementation

Maintenance and Support

By Sourcing Type

In-house

Outsourced

By Application

Semiconductor Devices

Printed Circuit Boards (PCBs)

Display Panels

Batteries and Energy Storage

By Industry Vertical

Consumer Electronics

Automotive

Telecommunications

Healthcare

Energy and Power

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Regional Analysis

North America: Dominates the market due to the presence of major semiconductor companies and substantial investments in R&D.

Europe: Shows significant growth driven by the automotive sector, particularly in EVs.

Asia-Pacific: Expected to witness the fastest growth owing to the large consumer electronics market and manufacturing hub in countries like China, Japan, and South Korea.

Latin America and Middle East & Africa: Emerging markets with growing investments in technology infrastructure and renewable energy projects.

Market Drivers and Challenges

Drivers:

Technological Advancements: Innovations in semiconductor and nanotechnology drive the demand for advanced materials.

Growing Consumer Electronics Market: Increased adoption of smartphones, tablets, and wearable devices.

Electric Vehicles and Renewable Energy: Rising demand for EVs and renewable energy solutions, which require advanced battery materials and energy storage systems.

Challenges:

High Production Costs: The advanced materials often require complex and costly manufacturing processes.

Supply Chain Issues: Dependency on specific raw materials which might be geographically concentrated or scarce.

Regulatory Hurdles: Stringent environmental regulations regarding material production and disposal.

Market Trends

Miniaturization of Electronic Devices: Increasing demand for smaller, lighter, and more efficient electronic components.

Development of Flexible and Wearable Electronics: Surge in demand for materials that are flexible and can be integrated into wearable technology.

Sustainability: Focus on environmentally friendly materials and sustainable manufacturing processes.

Future Outlook

The future of the advanced materials for electronics market looks promising with continuous innovations and increasing integration of these materials in various high-tech applications. The push towards 5G technology, AI, and IoT will further amplify the demand for advanced electronic materials. Additionally, the evolution of the EV market and renewable energy solutions will continue to create substantial growth opportunities.

Key Market Study Points

Detailed analysis of market size and growth projections.

Comprehensive segmentation analysis to understand market dynamics.

Regional performance and growth prospects.

Identification of key market drivers, challenges, and trends.

Future outlook and strategic recommendations for market participants.

Competitive Landscape

The market is characterized by intense competition with several key players investing heavily in R&D to gain a competitive edge. Major companies include BASF SE, DowDuPont Inc., Samsung SDI, LG Chem, and 3M. These players focus on strategic partnerships, mergers, acquisitions, and new product developments to expand their market presence.

Buy this Premium Research Report | Immediate Delivery Available: https://www.transparencymarketresearch.com/checkout.php?rep_id=85652<ype=S

Recent Developments

BASF SE recently announced the development of a new line of conductive polymers for flexible electronics.

Samsung SDI expanded its production capacity for advanced battery materials to meet the growing demand from the EV market.

3M launched a new range of high-temperature resistant adhesives for semiconductor applications.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

The Rise of Drone PCB Technology in China: An Aerial Revolution

Over the last decade, China's drone industry has seen explosive growth, emerging as a global leader. At the heart of drone technology lies its intricate electronic systems, with Printed Circuit Boards (PCB) playing an indispensable role. China's advancements in drone PCB technology not only enhance the operational capabilities of drones but also position the country at the forefront of the aerial technology sector.

Key Developments in China's Drone PCB Technology

Drone PCBs in China have evolved significantly, driven by both demand and technological innovation. These circuit boards are designed to be lightweight yet robust, capable of withstanding various environmental challenges while maintaining functionality. The integration of high-density interconnect (HDI) technology is a notable advancement. HDI PCBs allow for finer lines and spaces, smaller vias, and higher connection pad densities, which are crucial for the miniaturization of drones and enhancement of their functionality.

Another significant advancement is the use of flexible PCBs. These are particularly beneficial for drones as they conform to the contours of uniquely shaped devices, reducing weight and improving reliability. Flex PCBs are integral in drones, facilitating complex connections between different sections of the drone without sacrificing performance.

Impact on Commercial and Military Applications

China's drone technology is not limited to consumer applications but extends to significant military and commercial uses. In commercial sectors, drones equipped with advanced PCBs are used for agricultural monitoring, aerial photography, and logistics. These drones require highly reliable PCBs to perform tasks such as real-time data processing, navigation, and autonomous operation.

Military drones, on the other hand, demand even more from their PCBs. They must operate under extreme conditions and often carry additional payloads such as communication hardware, sensors, and sometimes weaponry. The reliability of these PCBs is critical, as they must ensure the drone's performance in critical missions.

Challenges and Innovations

Despite these advancements, the drone PCB manufacturing sector in China faces several challenges. One of the primary concerns is the need for continual innovation to keep up with the rapidly evolving drone technologies. This requires constant research and development efforts to devise more efficient, durable, and smaller PCBs that fit the new generations of drones.

Another challenge is environmental sustainability. The PCB manufacturing process can be resource-intensive and environmentally taxing. Addressing these concerns, many Chinese PCB manufacturers are increasingly turning towards more sustainable manufacturing processes and materials, which not only reduce the environmental impact but also cater to the global demand for greener electronics.

Collaboration and Global Influence

China's drone PCB industry is not operating in isolation but is part of a larger global ecosystem. There is extensive collaboration between Chinese PCB manufacturers and global technology firms, enhancing the overall quality and capabilities of drone technologies. These collaborations help set international standards for drone PCBs, which, in turn, influence global market trends.

China's influence in the drone sector also extends to its role in setting global regulatory standards. As a leading market player, the policies and standards set in China have a cascading effect, influencing how drones are manufactured and used worldwide.

The Future of Drone PCBs in China

Looking forward, the future of drone PCBs in China is tied to the broader trends in technology such as AI and IoT. Integration of AI allows drones to perform more complex tasks autonomously, such as predictive maintenance and threat assessment in military applications. IoT integration, on the other hand, enables better connectivity and control, essential for managing fleets of drones used in logistics or agricultural monitoring.

Moreover, as 5G technology becomes more widespread, the capabilities of drones are expected to expand further. The ultra-low latency and high-speed connectivity offered by 5G will enhance the real-time data transmission abilities of drones, opening up new possibilities for their application.

Conclusion

China’s rapid advancements in drone PCB technology showcase its capacity to lead in high-tech industries. As the country continues to innovate and push the boundaries of what drones can achieve, the global impact of its developments will undoubtedly continue to grow. The integration of cutting-edge technologies into drone PCBs not only transforms the landscape of the drone industry but also sets the stage for the next era of aerial innovation.

0 notes

Text

Unveiling the Excellence of PCB Manufacturing in Toronto with Crimp Circuits

Introduction: In the bustling hub of technological innovation that is Toronto, Canada, Crimp Circuits stands as a beacon of excellence in the realm of PCB manufacturing. With a rich history spanning over four decades, Crimp Circuits has established itself as a leader in the industry, delivering cutting-edge solutions to clients across a diverse range of sectors. In this blog, we'll delve into the world of PCB manufacturing in Toronto and shed light on how Crimp Circuits continues to set the standard for excellence in the field.

A Legacy of Innovation: Since our inception, Crimp Circuits has been at the forefront of technological innovation, pushing the boundaries of what's possible in PCB manufacturing. Our state-of-the-art facility, located in the heart of Toronto, boasts advanced equipment, experienced personnel, and a commitment to excellence that sets us apart from the competition. From concept to completion, we pride ourselves on delivering superior PCB solutions that meet and exceed the expectations of our clients.

Precision Engineering and Design: At Crimp Circuits, precision is our watchword. Our team of skilled engineers and designers leverage the latest technology, including Eagle software, to create PCB designs that are optimized for performance, reliability, and efficiency. Whether it's a simple two-layer board or a complex multilayered design, we have the expertise and experience to bring your vision to life with unparalleled precision and accuracy.

Diverse Range of Offerings: Crimp Circuits offers a comprehensive suite of PCB manufacturing services to meet the diverse needs of our clients. From printed circuit board design and prototyping to full-scale production and assembly, we have the capabilities and resources to handle projects of any size or complexity. Whether you're a startup looking to bring a new product to market or a large corporation in need of high-volume production, Crimp Circuits has you covered.

Quality Assurance and Compliance: Quality is ingrained in everything we do at Crimp Circuits. We adhere to stringent quality control measures at every stage of the manufacturing process to ensure that our clients receive PCBs of the highest quality and reliability. Additionally, we maintain compliance with industry standards and regulations, giving our clients peace of mind knowing that their products meet all necessary requirements.

Customer-Centric Approach: At Crimp Circuits, we understand that our success is directly tied to the success of our clients. That's why we take a customer-centric approach to every project, prioritizing open communication, collaboration, and responsiveness. We work closely with our clients to understand their unique needs and requirements, ensuring that we deliver solutions that not only meet but exceed their expectations.

Conclusion: In conclusion, PCB manufacturing in Toronto is synonymous with excellence, innovation, and reliability, thanks to companies like Crimp Circuits. With our state-of-the-art facilities, experienced team, and commitment to quality, we continue to set the standard for PCB manufacturing in the region and beyond. Contact us today to learn more about how Crimp Circuits can meet your PCB manufacturing needs.For more details visit our website: www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Decoding PCBA Board Manufacture: A Roadmap to Efficient Production

PCBA (Printed Circuit Board Assembly) board manufacture stands as a pivotal stage in the journey from electronic concept to tangible product. This blog offers a detailed roadmap, guiding both novices and seasoned professionals through the multifaceted process of PCBA board manufacture.

The journey initiates with an elucidation of PCBA board components, ranging from basic resistors to intricate microprocessors. Understanding the role and compatibility of each component is paramount in crafting a functional and efficient board.

Subsequently, the blog navigates through the intricacies of PCB fabrication, encompassing design optimization, material selection, and fabrication techniques. Through insights into surface finishes, layer stackups, and trace routing, readers will grasp the fundamentals necessary for creating robust and reliable PCBs.

The narrative then transitions to the assembly phase, shedding light on component placement, soldering methodologies, and quality assurance protocols. From manual soldering to automated pick-and-place systems, readers will gain insight into the diverse assembly techniques and their respective advantages.

Moreover, the blog addresses the significance of thorough testing and inspection procedures to identify and rectify potential defects before the final product reaches the market. Topics such as in-circuit testing, functional testing, and quality control standards underscore the importance of delivering reliable and high-performance PCBAs.

In conclusion, "Decoding PCBA Board Manufacture" serves as a comprehensive guide for navigating the complexities of PCB assembly manufacturing. By leveraging the insights and best practices shared in this blog, electronics enthusiasts and industry professionals alike can streamline their manufacturing processes, ultimately fostering innovation and excellence in the realm of electronic design and production.

#pcb circuit#fr4 pcb#pcb factory#circuit board#led circuit board#flex pcb#pcb assembly#aluminum pcb#fpc#ems pcba

0 notes

Text

High-Speed Connector Market: Transforming Networks & Connectivity

The demand for digital services, and consequently data transmission, has witnessed explosive growth. As per IEA, since 2010, global internet traffic has expanded twenty-five-fold. This surge underpins the escalating need for high speed cable connectors, crucial for efficient data handling and transmission across various sectors. This growth is a direct response to the increasing need for robust connectivity solutions that can keep pace with the exponential growth of data generation and transmission. According to our report, the Global High Speed Connector Market is expected to grow significantly, driven by a CAGR of over 9.15% over 2024-2032.

High speed connectors also address compatibility issues with legacy systems, providing seamless integration that is essential for modernizing existing technology infrastructures. This capability is not only enhancing operational efficiencies but is also projected to boost market growth substantially in the near future.

Explore in detail about this market in our FREE sample

High Speed Connector Market: Spotlight on Key Products

Board-to-Cable Connectors

Among the various products, board-to-cable connectors witness significant traction due to their critical role in ensuring continuous and reliable connectivity in complex electronic assemblies. These connectors are particularly favored for their flexibility and durability, which are essential for applications involving frequent disconnection and reconnection.

Latest developments in board-to-cable connectors have showcased several innovations, particularly in terms of performance and application adaptability. Notably, in October 2023, Molex introduced the KickStart Connector System that combines low transmission loss and a compact design, making it the first Open Compute Project (OCP)-compliant solution of its kind.

Board-to-Board Connectors

Board-to-board connectors are also gaining prominence as they are vital for creating secure and efficient connections between printed circuit boards (PCBs) within a single device. This is increasingly important in compact electronic devices such as smartphones and tablets.

New innovations in board-to-board connectors have been noteworthy. For instance, in Market 2023, Hirose Electric introduced the IT14 Series, designed for telecommunications, supporting high-speed data transmission up to 112Gbps using PAM4 technology.

In the field of advanced automotive, board-to-board connectors play a crucial role. These connectors are essential for connecting multiple electronic control units (ECUs) within vehicles, which are central to the functionality of ADAS.

Connect with our experts for a simplified analysis!

USB Type-C: A Catalyst for High Speed Connector Evolution

The adoption of USB Type-C connectors has been a game-changer in the field of high-speed connectivity. Known for their reversibility and high-speed data transfer capabilities, USB Type-C connectors are becoming a standard in new devices, fueling further development and innovation in the high-speed connector market. Their versatility across various platforms and devices underscores the shift towards more universal, efficient connection solutions in technology hardware.

Trends and Investment Opportunities Ahead

Advancements in the high-speed connector market are focused on enhancing connector design to reduce electromagnetic interference and improve signal integrity. Innovations such as connectors supporting up to 400 Gbps are transforming data center operations with faster, more reliable cloud services.

Looking ahead, further developments are expected in nanotechnology and advanced materials science, promising more efficient connectivity solutions. This makes sectors like cloud computing and artificial intelligence particularly ripe for investment. Hence, monitoring these technological shifts is essential for businesses and investors to invest in high speed cable connect solutions.

Explore Our Latest Release for the 2024-2032 Market Analysis

FAQs

Q1) What advantages do high-speed connectors provide over traditional connectors?

High-speed connectors offer superior performance in terms of data transmission speed and reliability, which is critical for modern digital applications.

Q2) Can high-speed connectors be used with any device?

While high-speed connectors are versatile, compatibility with specific devices depends on the connector type and device specifications.

Q3) What are the future trends in the high-speed connector market?

Future trends include the development of connectors with higher speed capacities, enhanced durability, and improved EMI resistance, all crucial for the next generation of digital devices.

0 notes

Text

What is Electronic Design Automation (EDA)

Electronic Design Automation (EDA) technologies are critical in the fast-paced field of electronics, where innovation is the key to success and Understanding EDA is essential for students interested in pursuing careers in electrical engineering and industrial automation also we will dissect the complexity of Electronic Design Automation, investigating its relevance, applicability, and critical position in the specialized subject of Industrial Automation within Electrical Engineering schools.

What Is Electronic Design Automation (EDA)?

Electronic Design Automation refers to a category of software tools used for designing electronic systems such as integrated circuits and printed circuit boards. EDA tools facilitate the design, analysis, and simulation of electronic systems, ensuring efficiency and accuracy in the development process.

Significance Of EDA In Electrical Engineering

Streamlining the Design Process:

EDA tools streamline the design process by providing a virtual platform where engineers can create, test, and modify their designs This iterative process enhances creativity and innovation.

Cost Efficiency:

By identifying errors and optimizing designs before physical prototypes are created, EDA tools significantly reduce development costs, also this cost efficiency is paramount, especially in large-scale industrial projects.

Simulation and Analysis:

EDA tools enable engineers to simulate and analyze the behavior of electronic circuits under different conditions as well as this virtual testing ensures that the final product meets the required specifications and standards.

Time-Saving:

In the competitive world of technology, time-to-market is crucial. EDA tools accelerate the design process, allowing engineers to meet tight deadlines without compromising on quality.

Applications of EDA:

Integrated Circuit (IC) Design:

EDA tools are extensively used in IC design, enabling engineers to create complex circuits with millions of transistors However, these circuits power various electronic devices, from smartphones to computers.

Printed Circuit Board (PCB) Design:

In PCB design, EDA tools assist engineers in creating the layout of electronic components on a board, So this layout is fundamental for the proper functioning of devices like laptops, televisions, and medical equipment.

FPGA (Field-Programmable Gate Array) Design:

FPGAs are versatile chips that can be programmed to perform specific tasks also EDA tools aid engineers in designing and programming FPGAs for applications in telecommunications, automotive, and aerospace industries.

Why Specialize In Industrial Automation?

Industrial Automation is the backbone of modern manufacturing processes specializing in this field, students gain expertise in automating industrial processes, leading to increased efficiency, reduced operational costs, and enhanced productivity.

Role of EDA in Industrial Automation:

In the Industrial Automation specialization program, students learn to leverage EDA tools to design electronic systems for automation, also students can understand how EDA contributes to the development of smart sensors, control systems, and robotic applications, essential components of modern industrial setups.

A strong grasp of Electronic Design Automation is essential in the ever-changing field of electrical engineering. EDA tools are the foundations of innovation, from envisioning complicated integrated circuits to optimizing PCB layouts and powering industrial automation. To make meaningful progress in the field of Industrial Automation, aspiring engineers must understand the complexities of EDA.

Students set the path for groundbreaking technological improvements by adopting the information and skills taught by EDA tools Remember that Electronic Design Automation is your passport to a future filled with invention, creativity, and endless possibilities as you start on your journey into the world of Electrical Engineering and Industrial Automation.

Arya College of Engineering & I.T. has a B.E. in Electronics & Communications Engineering (ECE) program is a cutting-edge, four-year undergraduate course meticulously designed in consultation with the electronics industry also with a focus on emerging technologies such as IoT, VLSI, and Embedded Systems, the curriculum provides a strong foundation in core electronics concepts while allowing students to specialize according to their interests.

The program offers invaluable experiential learning opportunities through collaborations with industry leaders like Nvidia and Texas Instruments, enabling students to work with state-of-the-art electronic training equipment, and a mandatory 6-month to 1-year industrial training stint and placement opportunities in Fortune 500 companies to ensure that graduates are not only academically adept but also industry-ready. The program equips students to pursue diverse career paths, from software analysis and network planning to research and development, in the rapidly evolving fields of electronics and communications.

Arya College of Engineering & I.T. ECE program stands as a beacon for aspiring engineers, providing a unique blend of theoretical knowledge and practical expertise. With a focus on hands-on learning, industry-oriented specializations, and world-class facilities, Arya prepares students to be the next generation of innovators and problem solvers. By choosing Arya, students embark on a transformative journey that not only hones their technical skills but also nurtures their entrepreneurial spirit, ensuring they are well-equipped to make a significant impact in the dynamic world of technology

Source: Click Here

#best btech college in jaipur#best engineering college in jaipur#best btech college in rajasthan#best private engineering college in jaipur#b tech electrical in jaipur#best engineering college in rajasthan#top engineering college in jaipur

0 notes

Text

The Role of Quick Turn PCB Fabrication in Prototype Development

In the tech world, time is invaluable, especially in product development. Quick turn PCB fabrication significantly accelerates the production of printed circuit boards (PCBs), reducing the process from weeks to mere days or hours. This rapid production is crucial for prototype development, enabling faster design, testing, and market entry.

Quick turn PCB fabrication is a game-changer, allowing businesses to stay competitive by swiftly testing and refining PCB layout designs. It also benefits small-scale manufacturers and hobbyists who need small quantities without the constraints of traditional minimum order requirements.

Importantly, this fast-paced process maintains high quality and precision, minimizing errors and rework. Quick turn PCB fabrication ensures that prototypes meet exact specifications, facilitating quick detection and correction of any issues.

Bay Area Circuits (BAC) exemplifies excellence in quick turn PCB fabrication, offering high-quality, precision-engineered PCBs with rapid turnaround times. Their advanced technology and skilled team ensure reliable and accurate results, making them a top choice for businesses seeking to accelerate their prototype development. Contact BAC for exceptional PCB fabrication services.

Originally Published at- https://bayareacircuits.blogspot.com/2024/05/the-role-of-quick-turn-pcb-fabrication.html

0 notes

Text

Insights of PCB Reverse Engineering Services Highlighting Its Benefits

PCB reverse engineering services or Printed Circuit boards have emerged as a crucial solution in the world of electronics. Essentially, it involves dissecting and analyzing the design and functionality of a PCB to reconstruct its schematics, layout, and components. This carefully designed process enables engineers to comprehend the intricacies of existing circuit boards without the aid of original documentation. While it may sound like a daunting task, SZOROD has made it easy for you! Delve into the world of PCB reverse engineering services including the benefits it offers that are substantial and multifaceted.

Unraveling Design Mysteries for Innovation

One of the primary advantages of our PCB reverse engineering services lies in its ability to create innovation. By unraveling the design mysteries of legacy PCBs or proprietary systems, our engineers gain invaluable insights into the underlying technology. This knowledge serves as a springboard for innovation, allowing us to develop enhanced versions of existing products or devise entirely new solutions based on proven designs. Whether it's optimizing performance, reducing costs, or adding new features, SZOROD empowers your businesses to stay competitive in dynamic markets.

Facilitating Legacy Product Support and Maintenance

In today's technological landscape, obsolescence is a constant challenge, particularly for legacy products. PCB reverse engineering services by SZOROD offer a lifeline in such scenarios by enabling the recreation of obsolete or discontinued circuit boards. This not only ensures continuity in product support but also extends the lifespan of your valuable assets, which ultimately saves time and resources in the long run.

Enhancing Supply Chain Flexibility and Resilience

The global supply chain is susceptible to various disruptions, ranging from component shortages to geopolitical tensions. In such volatile environments, having alternatives is paramount for business continuity. Our PCB reverse engineering services provide a strategic advantage by offering an alternative source for critical components or assemblies. By our reverse engineering PCBs, you can mitigate supply chain risks, reduce dependency on single suppliers, and maintain production continuity even in the face of unforeseen challenges.

Enabling Intellectual Property Protection and Compliance

Protecting intellectual property (IP) is a top priority for companies across industries. In an interconnected world, safeguarding proprietary designs can be challenging, especially when outsourcing manufacturing or collaborating with third-party vendors. SZOROD’s PCB reverse engineering services play a pivotal role in IP protection by enabling your company to assess the security of its designs and detect any potential vulnerabilities. Also, our reverse engineering can aid in ensuring compliance with industry standards and regulations, thus mitigating legal risks and liabilities.

Driving Cost-Efficiency and Time Savings

Last but not least, our PCB reverse engineering services offer significant cost-efficiency and time-saving benefits. Instead of starting from scratch, which involves extensive research, prototyping, and testing, our services will allow your company to leverage existing designs as a foundation. This streamlined approach reduces development cycles, accelerates time-to-market, and ultimately lowers overall project costs.

1 note

·

View note

Text

Sapphire Nitro+ B650I: Wi-Fi 6, DDR5 Support in AM5 Board

AM5 motherboards

Sapphire’s Nitro+ B650I AM5 motherboard astonished many PC enthusiasts, who know them for their high-performance graphics cards. This Mini-ITX board is a good choice for individuals who want a compact, powerful Ryzen 7000 series PC at a low price.

A Powerhouse Compact in Size

The Sapphire Nitro+ B650I is designed to conform to the requirements of the Mini-ITX form factor, with each side measuring around 170 millimeters. It’s perfect for SFF PCs, which save space and look clean. Though small, the board has several features.

Ryzen 7000 Support and AM5 Socket

With its AMD AM5 socket at its core, the Sapphire Nitro+ B650I can run the newest Ryzen 7000 series CPUs, including those with the Zen 4 architecture. This guarantees that customers can have the most potent AMD CPUs on the market right now. Furthermore, the board may even support Zen 5 CPUs in the future with BIOS upgrades, providing some futureproofing.

Cooling and the Distribution of Power

An 8-layer printed circuit board (PCB) and an 8+2 phase digital power delivery system are both featured on the motherboard. By combining this design with 70A Dr. MOS power stages, it is possible to deliver sufficient power for even the most demanding Ryzen 7000 central processing units. During load, the Voltage Regulator Module (VRM) is effectively cooled by a heatsink that is specifically designed for that purpose, which ensures excellent thermal performance.

Memory as well as storage

With its two DDR5 DIMM ports, the Nitro+ B650I can support memory speeds of up to an incredible 6000 MT/s . This enables users to benefit from DDR5 memory’s high bandwidth capabilities, which are essential for jobs like gaming and video development.

With two M.2 slots that support the PCIe Gen 4 x4 interface, the board offers ample capacity for storage. Because of this, users can install��fast NVMe SSDs for lightning-quick application loading and boot times. Four SATA III ports are also available for attaching conventional hard drives and other SATA-based devices.

Provisions for Connectivity

The compact design of the Nitro+ B650I is prioritised, but connectivity is not sacrificed. For dependable wireless internet access and peripheral device connectivity, the board has built-in Wi-Fi 6 and Bluetooth. Not only that, but a typical Gigabit Ethernet connector guarantees a reliable wired connection capability.

Both aesthetics and design

Although aesthetics may not be the primary consideration for a motherboard designed for a low budget, Sapphire hasn’t ignored this issue entirely. The sleek black PCB of the Nitro+ B650I has silver accents. Furthermore, it comes with two RGB headers, which offers users the ability to personalize their construction by incorporating the lighting effects of their choice.

Accessibility and Cost

At approximately 1,689 Yuan (or $233 USD) in pricing, the Sapphire Nitro+ B650I looks to be exclusively available in China as of April 2024. While some people may find the limited availability to be a negative, a more widespread distribution is ideally in the works.

In conclusion, a low-cost contender for SFF Ryzen 7000 builds

Budget-conscious builders wishing to build a powerful SFF PC with AMD Ryzen 7000 series processors can consider the Sapphire Nitro+ B650I. The reasonable pricing and good feature set make up for the lack of PCIe Gen 5 capability in some higher-end AM5 motherboards. If the Sapphire Nitro+ B650I becomes available in your region, consider it for a tiny but powerful Ryzen 7000 system.

Some Additional Things to Consider

In light of the fact that it is now only available in a restricted capacity, it is essential to keep in mind that user reviews and benchmarks may be rare. Furthermore, despite the fact that the motherboard is equipped with a powerful power delivery system, the extent of the overclocking headroom may be restricted in comparison to premium AM5 motherboards.

In general, the Sapphire Nitro+ B650I carves out a specific area in the market for AM5 motherboards by providing a cost-effective alternative for constructing a powerful small form factor personal computer that is equipped with the most recent generation of AMD CPUs. With its emphasis on cost and basic functionalities, it is designed to appeal to a particular subset of builders and has the potential to be a fruitful introduction for Sapphire into the market for motherboards.

Read more on govindhtech.com

#AMDmotherboards#amdryzen700series#ddr5dimm#nitro#shappire#shappirenitro#news#technology#technews#technologynews#technologytrends

0 notes