#automotive programming tools

Explore tagged Tumblr posts

Text

Everyday challenges for Automotive Programming Tools include complicated vehicle systems, strict safety regulations, and quickening technological advancements. However, many of these issues can be successfully resolved with the correct tools and technologies at their disposal, improving results and workflows and ultimately making cars on the road safer and more dependable. Understanding the unique requirements of automotive programmers, we at Auto Key Pro provide tools and solutions that optimize development workflows and boost output.

#automotive programming tools#car key programming#mobile car key programming#car key programming tool#all car key programming tool#best car key programming tool#car key programming tools for sale#mobile key programming service#mobile car key reprogramming#locksmith car key programming#smart car key programming#car key programming service#car key programming locksmith near me#mobile car key programming near me

0 notes

Text

Top Facilities at PTTI That Help You Succeed in Automotive Repair Training

Philadelphia Technician Training Institute (PTTI) offers cutting-edge facilities that give students a competitive edge in the automotive repair field. From modern diagnostic tools to real-world lab settings, PTTI equips students with everything needed to master hands-on repair skills. The institute’s experienced instructors and career support services help students gain practical knowledge and confidence to enter the job market. Discover how PTTI’s learning environment supports your career goals and prepares you for success in the automotive industry. Whether you're just starting out or upskilling, PTTI provides the resources you need to thrive.

#automotive repair school Philadelphia#PTTI training facilities#hands-on mechanic training#auto technician lab equipment#career-focused trade school#mechanic certification program#enroll in auto repair school#trade school with workshops#auto repair course with tools#job-ready auto training#Automotive Repair

0 notes

Text

Ai Pixel Perfect Commercial information

to AI Pixel Perfect I recently had the opportunity to use the “AI Pixel Perfect” commercial production tool, and I must say it has significantly exceeded my expectations. As someone who regularly works with digital media, I have encountered a variety of tools designed to enhance images and streamline the production process. However, AI Pixel Perfect stands out due to its sophisticated features and user-friendly interface.

User Interface and Ease of Use One of the most impressive aspects of AI Pixel Perfect is its intuitive user interface. From the moment I started using the software, I found it incredibly easy to navigate. The design is clean and well-organised, making it straightforward to access the various tools and features. This is particularly beneficial for those who may not be as technologically savvy, as it reduces the learning curve and allows users to focus more on creativity rather than technical difficulties.

Advanced Features and Capabilities AI Pixel Perfect comes packed with advanced features that are essential for high-quality commercial production. The AI-driven algorithms ensure that images are enhanced with remarkable precision, correcting imperfections and optimising details in a way that feels almost magical. Whether it’s sharpening an image, adjusting colours, or removing background noise, the tool performs these tasks with a level of accuracy that I haven’t seen in other software. The ability to work with multiple file formats and the inclusion of batch processing further add to its utility, making it a versatile choice for professionals.

Time Efficiency and Productivity One of the most significant benefits of AI Pixel Perfect is the time it saves during production. The automation of many tedious processes means that I can complete projects much faster than before. For instance, the background removal tool, powered by AI, accurately isolates subjects from their backgrounds in seconds, which would have taken much longer if done manually. This efficiency not only speeds up my workflow but also allows me to take on more projects, ultimately boosting productivity.

Customer Support and Community I also found the customer support to be highly responsive and helpful. Whenever I encountered a challenge or had a question, the support team was quick to provide clear and concise answers. Additionally, the online community of users is quite active, offering tips, tutorials, and advice that can be incredibly useful for both beginners and experienced users. This supportive environment is a testament to the company’s commitment to ensuring that all users get the most out of their product.

Conclusion: A Game-Changer in Commercial Production In conclusion, AI Pixel Perfect is a game-changer in the world of commercial production. Its blend of advanced AI-driven features, ease of use, and time-saving capabilities makes it an invaluable tool for anyone involved in digital media production. Whether you are a seasoned professional or a newcomer to the field, AI Pixel Perfect offers the tools you need to create stunning, high-quality content with minimal effort. I highly recommend it to anyone looking to elevate their production game.

Disclaimer.Some of the links on this page are affiliate links, meaning, at no additional cost to you, we may earn a commission if you click through and make a purchase. We only recommend products and services we believe will add value to you. Your support helps keep this site running, allowing us to continue creating high-quality content and resources. Please conduct your own research before making any purchase decisions. Thank you for your support

It's 100%Real site not a fake,plz purchase this item my affiliate 🔗🙏

#business ideas#online tools#Online software#tools#automotive tools#writing tool#business news#business standard#business growth#startup#ecommerce#marketing#services#affiliate links#affiliate program#affiliate promotion#passive income

0 notes

Text

How to Install a Car Performance Chip

When it comes to enhancing your vehicle’s performance, one of the most effective and accessible upgrades is the installation of a car performance chip. This small but powerful device can significantly improve your car’s horsepower, torque, fuel efficiency, and even throttle response. In this detailed guide, we’ll walk you through how to install a car performance chip, ensuring that you can boost…

#aftermarket chips#auto mods#auto performance#auto upgrade#automotive chips#car DIY#car ECU#car ECU chip#car efficiency#car electronics#car engine#car enhancement#car improvement#car install#car installation#car modification#car optimization#car performance#car power#car tech#car tools#car tuning#car upgrade#chip installation#chip programming#chip tuning#chip upgrade#ECU chip#ECU installation#engine boost

0 notes

Text

What Kind of Tools Should I Use as a Beginner Software Developer

What Kind of Tools Should I Use as a Beginner Software Developer. Embarking on the journey as a novice in the realm of software development opens up a world filled with both excitement and challenges. The vast array of development tools available can be both thrilling and overwhelming, as each tool serves a unique purpose in the multifaceted process of building software. The significance of selecting the right set of tools cannot be overstated, as it plays a pivotal role in shaping your development experience. These tools are not mere accessories but powerful instruments that directly impact your productivity, facilitate seamless collaboration with others, and contribute to the overall quality of your code.

Read Full Content Here 👇👇

What Kind of Tools Should I Use as a Beginner Software Developer

#SoftwareDevelopment#CodingTools#IDE#VersionControl#Collaboration#CommandLine#TextEditors#DatabaseManagement#Documentation#TestingFrameworks#Containerization#ProjectManagement#ContinuousLearning#WebDevelopment#ProgrammingLanguages#automotive tools#programming tools

0 notes

Text

Top Tips for Aspiring Auto Technicians

If you’re passionate about cars and enjoy solving complex mechanical problems, a career as an auto technician might be perfect for you. Auto Technicians are the backbone of the automotive industry, ensuring vehicles run safely and efficiently. Here are some key tips to excel in this field

1. Invest in Quality Tools

A reliable set of tools is essential for any auto technician. Start with basic hand tools and gradually invest in advanced diagnostic equipment. High-quality tools not only last longer but also make your job easier and more efficient.

2. Stay Updated with Technology

Modern vehicles rely heavily on computerized systems. Enroll in training programs and stay informed about the latest automotive technologies to stay competitive in the industry.

3. Develop Problem-Solving Skills

Auto technicians often troubleshoot complex issues. Cultivate analytical skills and patience to diagnose and repair problems accurately.

4. Prioritize Customer Service

Clear communication and a friendly attitude can set you apart. Explain repairs to customers in simple terms and provide excellent service to build trust and loyalty.

5. Seek Certification

Certifications like ASE (Automotive Service Excellence) demonstrate your expertise and can open doors to better job opportunities.

By following these tips, you can build a rewarding career as an auto technician.

#auto technician#HTV#LTV#auto electrician#auto mechanical#radiator#autos#audi#bmw#chevrolet#classic car#lamborghini#luxury car#ferrari#ford#cars

9 notes

·

View notes

Text

Locksmith Sylmar: Reliable Mobile Locksmith Services in the USA

When you search for Locksmith Sylmar, you're likely looking for a fast, dependable solution for your lock and key needs. At CK LOCK, we specialize in offering a full suite of Sylmar locksmith services—from emergency lockouts and home lock changes to advanced commercial access control and automotive key programming.

Our Sylmar mobile locksmith team operates 24/7 across the USA, ready to assist in the field. Whether you’ve locked your keys in the car, need a new transponder key for your vehicle, or want high security deadbolts installed at your residence, CK LOCK has you covered. We also offer safe opening, mailbox lock repair, and emergency locksmith Sylmar services, delivering professional solutions fast.

Why CK LOCK Leads in Locksmith Sylmar Services

• Rapid response: Our mobile locksmith vans are strategically positioned for fast dispatch—typically arriving within 15–30 minutes for emergencies.

• Comprehensive offerings: From automotive locksmith Sylmar needs like key replacement and truck unlocking to residential locksmith tasks such as lock repair, rekeying, and installation.

• Commercial expertise: We handle master key systems, file cabinet and mailbox locks, biometric entry, panic bars, and access control upgrades for businesses.

• Cutting edge tech: We use the latest tools and non destructive techniques favored by top providers in Sylmar

Common Searches and Key Services

People searching Locksmith Sylmar often include phrases such as mobile locksmith Sylmar, auto locksmith Sylmar, commercial locksmith Sylmar, and emergency lockout Sylmar. Here’s how we answer those queries:

• Car lockout & transponder keys: Lost or broken car keys? Our emergency locksmith Sylmar vans carry cutting and programming gear to swiftly replace keys—no tow needed.

• Residential lockouts: Locked out of your home late at night? Our Sylmar locksmith services include 24/7 residential lockout, rekeying, and broken key extraction.

• Commercial access solutions: Businesses in Sylmar use our Sylmar mobile locksmith teams to install high security locks, keypad systems, filesafe locks, and emergency exit solutions

How CK LOCK Helps You

At CK LOCK, customer safety and satisfaction are our top priorities. When you choose us for Locksmith Sylmar needs:

1. Fast dispatch: We send a certified locksmith to your location nationwide—your emergency is our priority.

2. Transparent pricing: No hidden costs. You'll receive a clear quote before any work begins.

3. Professional care: Every technician is fully trained, insured, and equipped to handle locks without causing damage.

4. Latest locksmith technology: From keyless entry to high-security installations, we deploy modern tools to enhance security.

In Summary

When you type Locksmith Sylmar in your search bar, you deserve more than a quick fix—you deserve trust, skill, and speed. CK LOCK delivers that and more. Whether it's an emergency locksmith Sylmar call, a residential lock change, or commercial access control, we’re your one-stop Sylmar locksmith services team.

2 notes

·

View notes

Text

Why do my headlights keep going out?

The following is a systematic analysis and solution based on the problem of frequent headlight extinguishing of your vehicle:

I. Core fault causes 1. Circuit overload causes fuse to blow

Short circuit or overload: Damage to the insulation layer of the wiring harness (such as friction between the wiring harness and metal parts in the engine compartment) will cause a short circuit, or the modification of high-power LED bulbs (such as 100W) exceeds the original circuit design capacity.

Detection method: Use a multimeter to measure the resistance at both ends of the fuse. If it is close to 0Ω, there is a short circuit; if the resistance value is normal but the fuse blows repeatedly, it is necessary to check whether the load exceeds the standard.

2. Relay/switch aging failure

Relay contact adhesion: Long-term current shock causes contact oxidation, and the circuit cannot be disconnected normally, which may cause intermittent power outage of the headlight.

Carbonization of the combination switch: The internal contacts of the headlight switch form high resistance (>5Ω) due to arc erosion, resulting in voltage fluctuations that cause the light to flicker or go out.

3. Poor connector contact

Plug oxidation: When the headlight socket is damp, the metal contacts generate copper oxide (especially in rainy areas), the resistance increases to more than 10Ω, and the current transmission is unstable.

Wiring harness is not connected: The terminal is not tightened during maintenance or the vehicle vibration causes the connector to loosen (common in off-road vehicles), and the measured voltage fluctuation can reach ±3V.

4. Bulb and circuit compatibility issues

Poor quality LED modification: Non-automotive grade LED driver EMC is unqualified, generating high-frequency harmonics to interfere with BCM control signals.

Halogen filament breakage: After the filament is partially melted, it may be briefly overlapped, showing random extinguishing (typical symptoms at the end of life).

II. Diagnostic process and tools Step-by-step troubleshooting table: Step Operation Tool/parameter Normal value range 1 Check fuse specifications and blown state Visual inspection + multimeter Original rated current (usually 10-20A) 2 Measure headlight socket voltage (ignition switch ON) Digital multimeter 11.5-14.2V 3 Shake the wiring harness to observe light changes (simulate vibration interference) Manual test Voltage fluctuation should be <0.5V 4 Replace relay test Relay of the same model Contact resistance <0.1Ω 5 Read BCM fault code OBD-II diagnostic instrument (such as Autel) No U0100/U0155 code

III. Targeted solutions 1. Circuit protection upgrade

Replace slow-blow fuses (such as ATO series), which have a surge current resistance 300% higher than fast-blow fuses.

Install ceramic insulation sleeves to protect the wiring harness in the engine compartment, which can withstand temperatures up to 1000℃.

2. Connection reliability optimization

Replace the original tin-plated plugs with gold-plated terminals, and the contact resistance is reduced to below 0.02Ω.

Apply conductive silicone grease (such as Dow Corning DC-4) in the socket to prevent oxidation and enhance sealing.

3. Control module reset

Perform a hard reset on the BCM: disconnect the negative pole of the battery for 10 minutes to clear the historical fault memory.

Update BCM firmware: Some models (such as Volkswagen after 2018) need to be upgraded to SW026 or above to fix the lighting control BUG.

Fourth, repair costs and suggestions Fault type Typical repair solution Cost range (RMB) Fuse/relay replacement Original spare parts + labor ¥80-200 Wiring harness repair Partial wiring + heat shrink tube insulation ¥300-600 BCM programming 4S shop special equipment matching ¥500-1,200 Full vehicle lighting system detection Diagnostic instrument + load test ¥200-400

Operation warning:

Do not use copper wire instead of fuse, which may cause the wiring harness to melt (case: a car owner caused a cabin fire).

LED modification requires simultaneous upgrade of the cooling system, and it is recommended to choose an integrated assembly with IP67 protection level.

If self-diagnosis fails, it is recommended to use an infrared thermal imager to scan the circuit (abnormal heating points are often the source of the fault), or contact a professional technician to perform oscilloscope waveform analysis (capture power ripple and relay control signals).

#led lights#car lights#led car light#youtube#led auto light#led light#led headlights#led headlight bulbs#ledlighting#young artist#car culture#race cars#classic cars#car#cars#coupe#suv#chevrolet#convertible#supercar#car light#headlight extinguishing#headlight bulb#headlight restoration#headlight#headlamp#car lamp#lamp#lighting#repair

2 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

Embrace a new era of automotive innovation with automotive programming tools. Precision, performance, and ease of use converge to redefine your automotive experience. Don't just drive – take control. Upgrade your toolkit with us and unlock the true potential of automotive programming. Your journey to automotive excellence begins here.

#automotive programming tools#car key programming#mobile car key programming#car key programming tool#all car key programming tool#best car key programming tool#car key programming tools for sale#mobile key programming service#mobile car key reprogramming#locksmith car key programming#smart car key programming#car key programming service#car key programming locksmith near me#mobile car key programming near me

0 notes

Text

The Power of Precision: Exploring the Benefits of PAUT in NDT

In the realm of industrial inspections, the demand for accuracy and efficiency has never been higher. Phased Array Ultrasonic Testing (PAUT) stands out as a revolutionary method that fulfills these requirements, offering unparalleled precision and speed. As an integral part of Non Destructive Testing, PAUT is widely used across various industries to ensure the integrity and reliability of critical components. Here, we delve into the intricacies of PAUT and its benefits.

PAUT is an advanced method of ultrasonic testing that uses multiple elements and electronic time delays to create beams of sound waves. These beams can be steered, focused, and scanned, providing detailed images of internal structures. Unlike conventional ultrasonic testing, which uses a single transducer to send and receive sound waves, PAUT employs an array of transducers. This allows for simultaneous collection of data from multiple angles, resulting in more comprehensive and accurate inspections.

As part of a broader suite of Non Destructive Testing Services, PAUT plays a crucial role in ensuring the safety and reliability of industrial components. Nondestructive testing (NDT) from RVS QUALITY CERTIFICATIONS PVT LTD encompasses various techniques used to evaluate the properties of a material, component, or system without causing damage. PAUT's advanced capabilities enhance the overall effectiveness of NDT services, providing detailed and reliable data that support maintenance and quality assurance programs.

Applications Across Industries

The versatility of PAUT makes it suitable for a wide range of applications. It is commonly used in the aerospace, automotive, and power generation industries for inspecting critical components such as welds, turbine blades, and composite materials. PAUT's ability to detect minute defects and irregularities ensures that even the smallest flaws are identified before they become critical issues. This level of precision is essential for maintaining safety and performance standards in high-stakes environments.

Efficiency and Accuracy Combined

One of the standout features of PAUT is its efficiency. The ability to steer and focus sound waves electronically means that inspections can be performed more quickly compared to traditional methods. This not only reduces downtime but also increases the number of inspections that can be completed within a given timeframe. Additionally, the detailed images produced by PAUT provide a clearer understanding of the inspected material's condition, allowing for more accurate assessments and decision-making.

Enhanced Tube Inspections

A specific area where PAUT excels is in Tube Inspection Services. Tubes, often found in heat exchangers and boilers, are prone to various types of degradation such as corrosion and cracking. PAUT's ability to inspect from multiple angles simultaneously makes it particularly effective for tube inspections. It can detect flaws that may be missed by conventional methods, ensuring that tubes are thoroughly evaluated for any signs of wear or damage. This comprehensive approach helps prevent failures and extends the lifespan of critical equipment.

Advancing with Technology

The continuous evolution of technology has significantly impacted PAUT. Advances in digital signal processing and software have improved the resolution and clarity of the images produced. Portable PAUT equipment from RVS QUALITY CERTIFICATIONS PVT LTD has made it possible to conduct inspections in challenging environments, further expanding its applicability. These technological advancements ensure that PAUT remains at the forefront of nondestructive testing techniques, providing industries with cutting-edge solutions for maintaining safety and quality.

In conclusion, PAUT is a powerful tool that combines precision and efficiency to deliver superior inspection results. Its ability to provide detailed images from multiple angles makes it invaluable for identifying defects and ensuring the integrity of critical components. As a key component of Non Destructive Testing, PAUT supports industries in maintaining high standards of safety and performance. Whether it's for welds, turbine blades, or Tube Inspection Service, PAUT continues to set the standard for advanced nondestructive testing methodologies.

5 notes

·

View notes

Text

Cars Key Services

Locksmiths do not only work for your homes and offices, or wherever there’s a jammed or malfunctioning lock within a building. There are, in fact, locksmiths that specialize in dealing with cars of all kinds. For instance, there are the automotive locksmith Atlanta who are of service to your for you your lost cay keys. These Cars Key Service have the necessary tools, equipment, and skills to get the job done. Knowing this, you should put to mind that lockouts and your need for key replacements is something that you should not worry much about as you have professionals willing to back you up on this particular need. Our service : *Transponder Key Programming *Opening Car Door *Car Remote Replacement *Auto Key Duplication *Car Unlocking *Replacement Auto Keys *Car Keys Locked in Car *Car Door Locks *Chip Key Programming *Locksmith For Car Door *Lost My Car Key *Car Lockout Service Car Key Service Georgia 18 Capitol Square SW, 30303 404-530-9684 all day 8:00AM - 11:00PM

30 % disscount of 2nd ignition key

http://carskeyservices.com/

#Transponder Key Programming#Opening Car Door#Car Remote Replacement#Auto Key Duplication#Car Unlocking#Replacement Auto Keys#Car Keys Locked in Car#Car Door Locks#Chip Key Programming#Locksmith For Car Door#Lost My Car Key#Car Lockout Service#Buick#Honda#Mitsubishi#Cadillac#Hyundai#Ford#Lexus#Nissan#Chevrolet#Jeep#Pontiac#Chrysler#Toyota#GMC#Kia#Subaru#Dodge#Land Rover

2 notes

·

View notes

Text

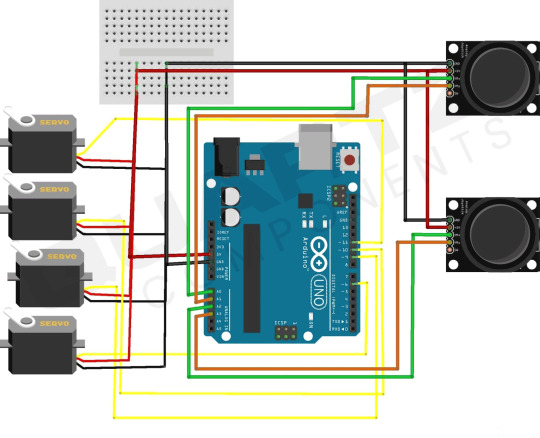

Build Robotic Arm Using Arduino

A robotic arm is a type of mechanical arm, usually programmable, that is designed to move materials, parts, tools, or specialized devices through various types of programmed motions for the purpose of manufacturing, assembly, testing, inspection, and other tasks. Robotic arms are widely used in a variety of industries, including automotive, aerospace, electronics, food processing, and pharmaceuticals.

COMPONENTS REQUIRED

Robotic Arm Kit

Arduino Board (UNO)

USB –A to micro-USB cable

Servo motor

Dual Axis XY Joystick Module

Connecting wires

Software Required

Arduino IDE

Circuit Diagram

youtube

41 notes

·

View notes

Text

the letterbox series ; chapter zero - the beginning

genre: time travel au, fluff, angst

warning: mentions of death

word count: 685

a/n: welcome to the first installment of the letterbox series! this is actually a rewrite from my previous blog, so if you've seen this before... no you didn't ( 。 •̀ ᴖ •́ 。)

taglist: @deoboyznet @winterchimez @mars101 @cloverdaisies @uwu0clock

series masterlist

Time travelers, you only hear about them in books and movies, right? Well, let me see if I can change your mind. My grandfather, a time traveler and an avid mechanic who worked on the side as a product developer. However, all this stopped when his wife passed due to an unknown disease early into their marriage.

His world suddenly crumbled and in his manic state, he decided to spend the rest of his life building a machine to travel back in time to relive the moments they shared together over and over again.

I never got to meet my grandmother, but that never stopped my grandfather from telling me all about her. Grandmother was a true dreamer; someone who always saw the best in people and never gave up. She worked as a mechanic as well, so that was how they met.

It was the summer right before his 16th birthday where grandfather got his first job at the local mechanics shop downtown. His uncle needed some extra hands, so he recruited him saying how he would be able to do the “dirty work” he so desired for.

While on a particularly busy day at the auto shop, his uncle calls for backup aka my grandmother. She was the talk of the town; young, drop dead gorgeous, smart and a fast learner. As soon as she stepped foot in the shop, it was as if the heavens opened up and the heavenly choirs above began singing.

Grandfather told me of how awestruck he was that he dropped his tools all over the ground leading everyone to stare at him as he sheepishly began picking up his tools. His coworkers were at a standstill, but luckily, well maybe not, grandmother took it upon herself to help the visibly flustered man.

Countless hours of hard work and elbow grease later, he eventually made his way into university, studying as an engineer specializing in automotives. While in university, he discovered that my grandmother was admitted in the same program, but specializing in product design. The two shared the stress and anxiety of exams while simultaneously building upon their undeniable connection.

My grandfather finally grew the courage to ask her out after their second year of university. They were known around campus as the power couple, everyone wanted to be them, while also rooting for their relationship.

Flash forward two years later, the couple graduated with degrees in engineering. It was then that grandfather finally proposed to her. He was nervous she would reject him, so he made sure to wear his lucky watch. Thankfully, she said yes and the couple was married by the same fall.

Now getting into why my grandfather decided to time travel, it was often a touchy subject for him, but one nonetheless he cherished. Grandmother grew ill in their second year of marriage and passed the same year. I had never known my grandfather be depressed, he was always cheery according to my mother.

He decided to quit his job to devote his time to building what I know now was a time machine. He spent years studying quantum physics and the concept of time travel. Grandfather, once being the talk of campus, was now the talk of the town– but not in a positive light.

He was often criticized for wanting to bring back old memories, people would tell him how insane he sounded and how he was nothing more than just a lunatic, but he never gave up. Using his engineering background, he traveled great lengths to acquire rare materials.

6 years had now passed and many failed creations later, the perfect machine was developed. Unfortunately my grandfather could not return, being stuck in the same timeline as when he first met my grandmother. Before he left, he wrote a letter to my mother. He said to never forget where you came from and to travel wherever your heart takes you. He signed off his letter by telling us to not worry about him, that he would be spending the rest of his life with the love of his life.

#hyungseos-cafe#deoboyznet#ube iced coffee with almond milk brown sugar syrup and tapioca#series: the letterbox series#the boyz blubs#the boyz series#the boyz scenarios#the boyz au#the boyz sangyeon#the boyz jacob#the boyz younghoon#the boyz hyunjae#the boyz juyeon#the boyz kevin#the boyz chanhee#the boyz changmin#the boyz haknyeon#the boyz sunwoo#the boyz eric#the boyz#cw: death

9 notes

·

View notes

Text

CADOpt Technologies: Premium PTC Partner & Top Value-Added Reseller In India

In the fast-evolving landscape of digital design and engineering, having a reliable partner for computer-aided design (CAD) solutions is crucial. CADOpt Technologies has emerged as a beacon of excellence in this domain, establishing itself as a premium PTC partner and one of the top value-added resellers in India. This article delves into the myriad ways CADOpt Technologies stands out, offering insights into their services, solutions, and customer-centric approach.

Comprehensive Solutions Offered by CADOpt Technologies

CAD Software Solutions

One of the core offerings of CADOpt Technologies is their suite of CAD software solutions. These tools are designed to enhance productivity, improve design accuracy, and streamline the engineering process. Some of the key software solutions provided include:

Creo: A robust 3D CAD software that supports product design and development from concept to manufacturing.

Windchill: A product lifecycle management (PLM) solution that facilitates collaboration and data management across the product development lifecycle.

ThingWorx: An industrial Internet of Things (IoT) platform that enables smart, connected operations and products.

Training and Support Services

Understanding that software is only as good as the people using it, CADOpt Technologies places a strong emphasis on training and support. They offer comprehensive training programs tailored to different user levels, ensuring that clients can fully harness the power of their CAD tools. Additionally, their dedicated support team is always on hand to assist with any technical issues, providing timely and effective solutions.

Customization and Integration

Every business has unique needs, and CADOpt Technologies excels in offering customized solutions. They work closely with clients to understand their specific requirements and tailor their CAD tools accordingly. Moreover, their expertise in software integration ensures seamless incorporation of CAD solutions into existing workflows, enhancing overall efficiency.

Why CADOpt Technologies is a Top Value-Added Reseller

Industry Expertise

One of the key factors that set CADOpt Technologies apart is their deep industry expertise. They have a team of seasoned professionals with extensive experience in various sectors, including automotive, aerospace, consumer goods, and industrial equipment. This diverse expertise enables them to provide insights and solutions that are precisely aligned with industry-specific challenges and opportunities.

Customer-Centric Approach

At the heart of CADOpt Technologies' success is their unwavering commitment to customer satisfaction. They adopt a consultative approach, working closely with clients to understand their goals and challenges. This collaborative mindset ensures that the solutions provided are not only effective but also add significant value to the client's business.

Strong After-Sales Support

After-sales support is a critical aspect of any technology partnership, and CADOpt Technologies excels in this regard. Their dedicated support team provides ongoing assistance, ensuring that clients can maximize the benefits of their CAD solutions. From troubleshooting technical issues to providing regular updates and maintenance, CADOpt Technologies is committed to long-term client success.

The Future of CADOpt Technologies

Innovation and Growth

Looking ahead, CADOpt Technologies is poised for continued growth and innovation. They are constantly exploring new technologies and trends to stay ahead of the curve. Their ongoing investment in research and development ensures that they can offer cutting-edge solutions that meet the evolving needs of their clients.

Expansion Plans

CADOpt Technologies has ambitious plans for expansion, both geographically and in terms of service offerings. They aim to extend their footprint across India and beyond, bringing their world-class CAD solutions to a broader audience. Additionally, they are exploring new verticals and industries, leveraging their expertise to drive digital transformation in various sectors.

Conclusion

CADOpt Technologies stands out as a premium PTC partner and top value-added reseller in India, thanks to their innovative solutions, exceptional customer service, and deep industry expertise. Their comprehensive suite of CAD software, coupled with their commitment to customization, training, and support, makes them a trusted partner for businesses seeking to enhance their design and engineering capabilities. As they continue to grow and innovate, CADOpt Technologies is set to play a pivotal role in shaping the future of the CAD industry in India and beyond. For more information on CADOpt Technologies and their offerings, visit their official website or contact their support team for personalized assistance.

#CADOptTechnologies#PTCPartner#CADSolutions#ValueAddedReseller#IndiaTech#CreoSoftware#WindchillPLM#ThingWorxIoT#EngineeringExcellence#DigitalTransformation#TechInnovation#CustomerSupport#CADTraining#IndustryExpertise#ProductDesign#EngineeringSoftware#CADIntegration#TechGrowth#InnovationInCAD#FutureOfDesign#TechResellerIndia

2 notes

·

View notes