#automotive robots

Explore tagged Tumblr posts

Text

AIDA by the MIT Personal Robotics Group (2009)

#robotics#companion robots#united states#american robots#automotive robots#00s robots#robots from 2009#massachusetts institute of technology#mit#mit personal robotics group#cynthia breazeal#mit medialab#audi#00s#2009#robots

1 note

·

View note

Text

Why Every Modern Factory Needs Robotic Welding Automation (Do You?)

The future of manufacturing is here. 🤖🔥

Traditional welding is slow, costly, and inconsistent – but AI-powered robotic welding automation solves all 3 problems:

✔ 30% faster production cycles (↑output = ↑profits) ✔ 0.01mm precision (No rework, no waste) ✔ 24/7 operation (Humans need sleep, robots don’t!)

👉 See how PARC Robotics’ solutions can transform your factory: parcrobotics.in/robotic-welding-automation-solutions

💬 Question for reblogs: "Would you trust a robot to handle your critical welding jobs? Why/why not?"

#IndustrialAutomation#WeldingRobots#SmartManufacturing#Industry40#robotics#robots#robotics automation#robotics engineering#automation#automotive robots

0 notes

Text

#robotics engineering#metalwork#robotics#automation#business#entrepreneur#automotive robots#entrepreneurship#car manufacturers

0 notes

Text

Understanding the 3 Types of Manufacturing Automation

Manufacturing automation has come a long way since it was first introduced after World War II. By the 1970s, it had become a common industrial method to improve productivity and efficiency. Today, it plays a crucial role in almost every manufacturing sector.

Automation in manufacturing simply means using technology to handle various tasks and processes, reducing manual effort and increasing efficiency. It helps businesses produce more in less time, with fewer human errors. Automation also shifts human involvement from repetitive tasks to more skilled roles like designing, operating, directing, installing, and troubleshooting automated systems, robots, software, and machines.

There are three main types of manufacturing automation: Fixed Automation, Programmable Automation, and Flexible Automation. Each of these is designed to meet different production needs. Let’s understand them in detail.

1. Fixed Automation (Hard Automation)

Fixed automation is also called hard automation because it is designed to produce a single type of product in large quantities. Once the system is set up, the sequence of operations is fixed, meaning you cannot change the product design or process easily. It is best suited for high-volume production where the same product is manufactured repeatedly.

Since fixed automation systems involve specialized machinery, they require a high initial investment. However, this cost is justified by the high production rates and efficiency they offer. The biggest challenge with fixed automation is its inflexibility—changing the product design would require significant modifications, which can be expensive and time-consuming.

Examples of Fixed Automation:

Automated assembly machines

Web handling and converting systems

Chemical manufacturing processes

Material conveyor systems

Machining transfer lines

Paint and coating automation processes

This type of automation is commonly used in industries like automobile manufacturing, where large quantities of the same car model are produced efficiently.

2. Programmable Automation

As the name suggests, programmable automation allows manufacturers to program the machines for different tasks. Unlike fixed automation, where the system is rigid, programmable automation provides flexibility in producing different products, although in batches.

This type of automation is particularly useful when companies need to manufacture products in medium volumes, where each batch may be slightly different from the previous one. The system requires some setup time to change from one product to another, but this is much easier and cost-effective compared to fixed automation.

Key Features of Programmable Automation:

Machines follow a programmed set of instructions.

Suitable for batch production (dozens to thousands of units per run).

Can handle different products, but requires reprogramming.

High initial investment, but greater flexibility compared to fixed automation.

Examples of Programmable Automation:

Numerically controlled (NC) machine tools

Programmable logic controllers (PLCs)

Industrial robots

Industries like electronics and packaging benefit greatly from programmable automation, as they often produce different variations of a product in small to medium batches.

3. Flexible Automation

Flexible automation takes programmability one step further. It allows manufacturers to switch between different product designs almost instantly without stopping production. This is made possible through advanced computerized control systems.

In a flexible automation system, machines are controlled by computers, and human operators manage the programming through Human-Machine Interfaces (HMIs). The system can produce multiple product types simultaneously with minimal setup time. This is ideal for industries that need to manufacture a variety of products in medium to low quantities.

Key Features of Flexible Automation:

Highly adaptable to different product designs.

No downtime between production batches.

Controlled by a central computer system.

Ideal for customized or made-to-order products.

Examples of Flexible Automation:

Robotics

Assembly systems

Material handling systems

Flexible automation is commonly used in industries like consumer electronics and medical devices, where product designs change frequently.

Which Type of Automation is Best for You?

Choosing the right type of automation depends on your manufacturing needs:

If you need to produce the same product in large quantities, fixed automation is the best choice.

If you manufacture different products in batches, programmable automation is more suitable.

If you require frequent changes in product design with minimal downtime, flexible automation is ideal.

Investing in automation can significantly improve production efficiency, reduce costs, and enhance product quality. However, it’s essential to evaluate the upfront investment, long-term benefits, and specific production requirements before making a decision.

Final Thoughts

Automation is transforming the manufacturing industry by improving efficiency, reducing costs, and enhancing quality. The choice between fixed, programmable, and flexible automation depends on your production needs. While fixed automation is best for high-volume production, programmable automation allows for batch production, and flexible automation provides the highest level of adaptability.

Investing in automation can give your business a competitive edge, increase productivity, and improve overall operational efficiency. If you are looking for an expert partner in manufacturing automation, PARC Robotics is your go-to solution.

Let’s build the future of manufacturing together!

#robotics engineering#metalwork#welding#robotics#car manufacturers#automotive robots#automation#business#entrepreneur#entrepreneurship

1 note

·

View note

Text

industrial robots

#KUKA#robot#industrial robot#manufacturing#heavy industry#automotive#FIAT#Italy#Torino#Turin#FIAT 500

214 notes

·

View notes

Text

0 notes

Text

danielsimondesign

151 notes

·

View notes

Text

𝚢𝚘𝚞𝚛 𝚟𝚘𝚒𝚌𝚎 𝚒𝚜 𝚕𝚒𝚔𝚎 𝚊 𝚊𝚗𝚐𝚎𝚕

eu sou grata pela minha voz

minha voz é perfeita

eu canto extremamente bem

recebo elogios sempre quando canto

eu possuo ótimas habilidades de canto

minha voz é harmoniosa e agradável de se escutar

eu consigo fazer agudos e minha voz é afinadíssima

a cada dia, minha voz se torna mais poderosa para cantar

eu alcanço qualquer nota que eu quiser com precisão

eu canto com confiança e facilidade

tenho uma voz bonita e única e todos percebem isso

minhas cordas vocais são saudáveis e fortes

minha voz emociona a todos toda vez que canto

eu transmito emoções e confiança sempre que canto

minha respiração é controlada e consigo aplicar minhas habilidades vocais facilmente

minha dicção é perfeita para cantar

sou tão feliz por ter o talento de cantar

#robotic affirming#affirm and persist#affirmdaily#affirmations#affirm and manifest 🫧 🎀✨ ִִֶָ ٠˟#affirmyourreality#law of vibration#law of attraction#law of assumption#singer#talent#my voice#self love#automotive#confidence#lei da atração#lei da suposição#afirmações#law of manifestation#manifesting#manifestação#manifestation

17 notes

·

View notes

Text

Understanding the Difference Between a Welding Jig and a Welding Fixture

In manufacturing and fabrication, welding is a critical process that joins materials to create structures, components, and products. Specialized tools like welding jigs and fixtures are often employed to ensure precision, efficiency, and consistency in welding. While these terms are sometimes used interchangeably, they serve distinct purposes and have unique characteristics. Understanding the difference between a welding jig and a welding fixture is essential for optimizing production processes and achieving high-quality results.

What is a Welding Jig? A welding jig is a specialized tool designed to hold and position workpieces in a specific orientation during the welding process. Its primary function is to ensure that the parts being welded are aligned correctly, reducing the risk of errors and improving accuracy. Jigs are often customized for a particular workpiece or assembly, making them ideal for repetitive tasks where consistency is key.

One of the defining features of a welding jig is its ability to guide the welding tool, such as a torch or electrode, along a predetermined path. This guidance ensures that the weld is applied precisely where it is needed, minimizing deviations and enhancing the overall quality of the weld. Jigs are commonly used in applications where tight tolerances and exact alignment are critical, such as in the aerospace or automotive industries.

What is a Welding Fixture? A welding fixture, on the other hand, is a device used to securely hold and support workpieces during the welding process. Unlike a jig, a fixture does not typically guide the welding tool. Instead, its primary role is to stabilize the workpiece, preventing movement or distortion caused by heat or mechanical forces during welding. Fixtures are often designed to accommodate a range of similar workpieces, making them more versatile than jigs in some cases.

Fixtures are particularly useful in high-volume production environments where speed and efficiency are prioritized. By holding the workpiece in place, fixtures allow welders to focus on the welding process itself, reducing the likelihood of errors and improving productivity. Additionally, fixtures can help manage thermal expansion and contraction, which are common challenges in welding.

Key Differences Between Jigs and Fixtures Functionality: The most significant difference between a welding jig and a welding fixture lies in their functionality. A jig is designed to guide the welding tool and ensure precise alignment of the workpiece, while a fixture is focused on holding the workpiece securely in place.

Customization: Jigs are often highly customized for specific tasks or workpieces, making them ideal for specialized applications. Fixtures, while still customizable, are generally more adaptable and can be used for a broader range of similar workpieces.

Complexity: Jigs tend to be more complex in design due to their dual role of positioning and guiding. Fixtures, by contrast, are typically simpler, as their primary purpose is to provide stability.

Application: Jigs are commonly used in industries where precision is paramount, such as aerospace or medical device manufacturing. Fixtures are more prevalent in high-volume production settings, such as automotive assembly lines.

Cost: Because of their specialized nature, jigs are often more expensive to design and produce than fixtures. Fixtures, being more versatile and less complex, are generally more cost-effective for large-scale operations.

Choosing the Right Tool for the Job The choice between a welding jig and a welding fixture depends on the project’s specific requirements. If precision and alignment are critical, a jig is likely the better choice. However, if the primary need is to stabilize the workpiece and improve efficiency, a fixture may be more appropriate. In some cases, a combination of both tools may be used to achieve the desired results.

In conclusion, while welding jigs and fixtures share the common goal of improving the welding process, they serve distinct roles and offer unique benefits. By understanding their differences, manufacturers can make informed decisions that enhance productivity, quality, and overall success in their welding operations.

2 notes

·

View notes

Text

Steampunk vehicles: Dragonfly series

#ai art#ai#steampunk#scifi#retro scifi#ai generated#ai artwork#city#indie music#bandcamp#dragonfly#insect#machinery#cybernetics#robotics#android#machine#steampunk world#dieselpunk#fantasy#oskar schuster#map#instruction#construction#vehicle transport#automotive#steampunk art#scifiart#sci fi and fantasy#science fiction

2 notes

·

View notes

Text

PSA: robots, i know you gals (and guys and ERR:GNDR_NOT_FND) all want your cute butch mechanic to fix you up, but for the love of gods please do not arrange with the local wildlife to have "accidents" to make it happen.

we gotta stop meeting like this

#hazyposting#robot girl#i literally just fixed this stupid girl a month ago#and now she hits a different animal on the other side#ungodly amounts of automotive glue going towards this one gang

3 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

youtube

#youtube#rc helicopters#rc ff#christmas#robotics#electronics#pokemon#fandom confession#automotive tools#action toy#Arrma Vendetta#Traxxas RC#RC Speed Run#rc bashing#rc car#rc crawler#rc shorts#rc truck#rc video#red bull racing#popular posts#ferrari#trending on tumblr#trending post#viral#viralshorts#trending now#viralpage#like#most followed

5 notes

·

View notes

Text

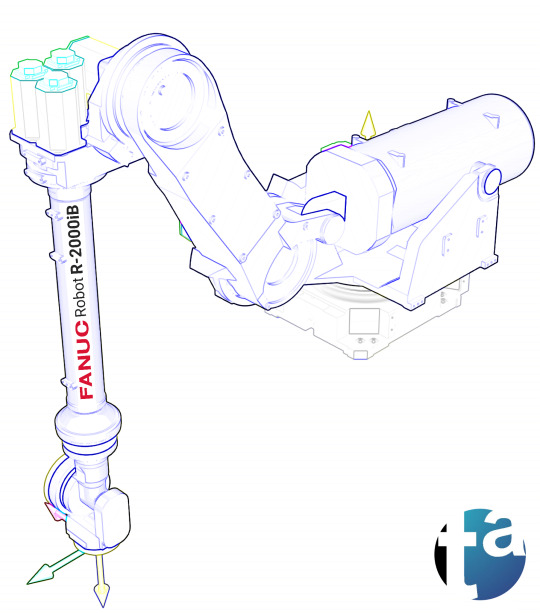

🦾 A010 - Robot FANUC R-2000iB Camshaft Machining Center automotive appl engineparts machining TranTek's Courtesy Robotics RTU Transfer Unit - linear motion track ▸ TAEVision Engineering on Pinterest

Data A010 - Jul 23, 2023

#automation#robot#robotics#FANUC#R-2000iB#FANUC R-2000iB#camshaft machining center#automotive applications#machining center#engineparts machining#TranTek courtesy#RTU#RTU Transfer Unit#transfer unit#TransferUnit#linear motion track#automation linear motion

4 notes

·

View notes

Text

0 notes