#magnetic filtration system

Text

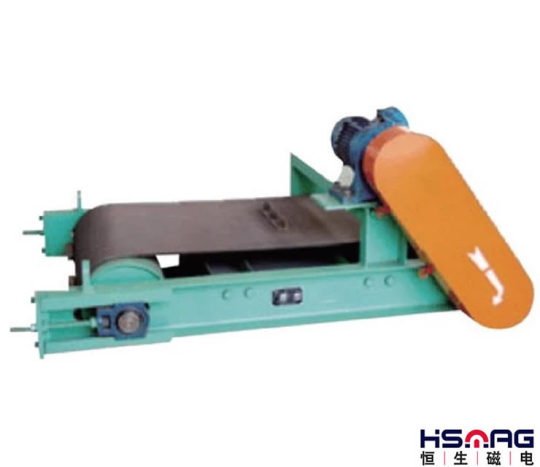

Magnetic Separator Conveyor Belts Types

Magnetic Separator Conveyor Belts Types

Mgnetic separator conveyor belts move things from one place to another in factories. Some conveyor belts have magnets. The magnets take away pieces of metal that shouldn’t be there. This makes the product cleaner. It also stops metal from breaking machines further down the line. There are a few types of these magnetic separator conveyor belts. Each one…

View On WordPress

#Belt Drum Separator#Drum separators#hump magnets#In-line Magnets#industrial application#Industrial Magnetic Assemblies#industrial magnetic equipment#Magnet Design#magnetic attraction#Magnetic belts#Magnetic Circuits#magnetic components#Magnetic device#Magnetic drum separators#MAGNETIC field#magnetic field attraction#Magnetic Filters#Magnetic Filtration#magnetic filtration system#Magnetic Liquid traps#magnetic permeable sheets#Magnetic pulley separator#Magnetic Pulleys#Magnetic Separation#magnetic separation assemblies#magnetic separation equipment#magnetic separation systems#Magnetic Separator#Magnetic Separator Conveyors#Permanent magnet types

1 note

·

View note

Text

catalyst filtration from the Autoclave

#Catalyst Filter System#catalyst filter#Catalyst filtration#Online Sampling System#gas liquid reaction with suspension solid liquid gas#Jacketed Reactor with Magnetic Seal#Limpeted Reactor with Magnetic Seal and internal coils#Limpeted Reactor with Mechanical Seal#Limpeted Reactor with Magnetic Seal and Plate Coils#Fitted with sintered candles#dispersion of gas in liquid#Keeping solids & gases in suspension while cooling liquids#catalyst filtration from the Autoclave#fire hazards in case of pyrophoric catalysts#Chemical reaction in viscous liquids and slurries

0 notes

Text

0 notes

Text

#Whole house water filtration#Pool water conditioner#Spa water treatment#Reduce evaporation in pool#Chlorine-free pool treatment#Chloramine removal#Salt water pool system#UV water treatment#Reverse osmosis water system#Water descaler#Ion exchange water softener#Magnetic water softener#Aqua water#Aqua Rev#Aqua Rev by HDC Products Inc.#Aqua Rev Water

0 notes

Text

See You Space Knight

Fill for @merlinmicrofic prompt ‘Shipwreck’ | Arthur&Gwen&Merlin | Teen | WC: 498

——

The cockpit is half-lost in a gray haze. Every inhale itches at Arthur’s throat, tasting of burnt hair and plastic.

The goddamn alarm finally cut off a few minutes ago, at least, though his ears have continued to ring.

“I thought the- cough- the one benefit of taking this miserable post was that it would be sa- cough- safer than combat,” he complains, futilely attempting to wave away the smoke. “Yet here we are, crashed on some fucking moon.”

Anywhere else in the galaxy, he might have expected a modicum of sympathy. But, of course, that’s too much to ask aboard the H.M.S. Emrys.

<If it’s such a hardship to captain a lowly research vessel—> The even, mechanical voice of the ship’s AI emanates from all sides, drowning Arthur in its contempt. <—Then why not put in for transfer? Surely someone with your lofty connections could net a command posting on one of those grand Dragon-class warships you admire so much.>

By now, Arthur has leveraged himself out of his seat despite the ache of his battered muscles. (Christ, he’s going to be one giant bruise by tomorrow.)

He scoffs. “Someone’s got to put up with you, don’t they?”

The ship is predictably unsatisfied with this argument. <I hear that charming Lt. Gwaine of the Lothian is up for promotion soon. Isn’t that right, Gwen?>

The Emrys’s engineer looks up from the open wall panel where she’s been crouched trying to reset the internal filtration system for the past quarter hour. She gives the nearest overhead camera a look.

“Leave me out of this, ship,” she says with faux-sternness and affection more transparent than the air they’re currently breathing.

Arthur barely resists the urge to roll his eyes. “You think an officer of Gwaine’s caliber would pass on the flagship of the Orkney fleet to captain a Merlin?”

Immediately, Guinevere bristles. “And what’s wrong with a Merlin, exactly, sir?”

He holds up his hands in an appeasing gesture. “Nothing, nothing.” When she doesn’t look convinced, he redirects: “Er, do you need some help with that?”

He’s pleased to see her soften at the offer.

“No, I’ve almost got it, Captain. But if you can move around alright now, could you maybe go see what’s taking Elyan and Percival so long? They went down to fetch the med kit and evac suits, but it’s been a while and they’re still not back.”

<Storage compartment door is jammed,> the ship reports, managing to sound amused. <Magnetic fasteners knocked out of alignment in the collision. Percival tried yanking on it and broke off the handle. He’s too embarrassed to come back up and tell you.>

“Oh, great.”

Arthur takes a deep breath and lets it out again.

He is going to go figure out how to open the stupid compartment. He is going to get them off this useless hunk of space rock as soon as possible.

And then, God willing, he is going to apply for a transfer.

#bbc merlin#fic#my writing#does gwaine still flirt w/ ai!merlin? yes. yes he does#it’s a disembodied voice but it’s still a cutie

4 notes

·

View notes

Text

Water Softener Filter in Ireland

What is a Water Softener Filter?

A water softener filter is a device designed to remove or reduce the mineral content of hard water, turning it into soft water. The most commonly used water softeners use ion exchange technology in which sodium or potassium ions replace calcium and magnesium ions in the water. This process effectively reduces water hardness, preventing scale build-up and improving overall water quality.

Types of Water Softeners

Ion Exchange Based Salt Softeners: These are the most common and effective systems that use salt to exchange ions and remove water hardness. They are particularly suitable for homes that have faced serious hard water problems.

Magnetic and electronic softeners: These devices use magnetic or electronic fields to change the properties of minerals in the water, preventing the formation of limescale. They are less efficient than ion exchange systems, but require minimal maintenance.

Dual Tank water softeners: With two tanks, these systems provide a continuous supply of fresh water that allows one tank to be regenerated while the other is in use. They are ideal for large families with high water consumption.

Each type of water softener offers unique benefits, so it's essential to choose the one that best meets your family's needs.

Advantages of Installing a Water Softener Filter

Investing in a water softener filter offers many benefits beyond just improving water quality. Some of the key benefits include:

Appliance Life: By preventing limescale build-up, water softeners help extend the life of appliances such as washing machines, dishwashers and water heaters, helping to save money on repairs and replacements.

Improving the Quality of Water: Soft water is gentler on the skin and hair, improves the taste of drinking water, reduces soap scum and makes cleaning easier.

Increased Energy Efficiency: Appliances that use fresh water run more efficiently, resulting in lower energy consumption and utility bills.

Ecological: Water softeners reduce the need for harsh chemicals and detergents, contributing to a greener home.

Cost savings: Although the initial investment in a water softener system can be significant, the long-term savings in equipment maintenance, energy bills and cleaning products make it a cost-effective solution.

Improved Washing Results: Soft water improves the effectiveness of laundry detergents, resulting in cleaner and softer clothes.

Healthier Skin and Hair: Soft water is less irritating to skin and hair, helping to relieve dryness and irritation caused by hard water.

Choosing the Right Water Softener

When choosing a water softener for your home, consider the following factors:

Water Hardness Level: Start by determining the water hardness level with a test kit or a professional service like Euro Water Solutions.

Size of Home: The size of your home and daily water consumption will affect the type and capacity of the water softener you need.

System Type: Decide whether you prefer a salt, salt-free, magnetic or dual-reserve system based on your needs and preferences.

Maintenance Requirements: Some systems require regular salt refills or periodic maintenance, so consider the maintenance requirements of each option.

Euro Water Solutions offers expert advice and a range of high quality water filtration systems including water softeners filter suitable for Irish households. Their commitment to customer satisfaction ensures that you have the best solution for your home's water quality needs.

#water filtration systems ireland#water softener for home#water softeners ireland#water filters ireland#Water Softener Filter in Ireland

0 notes

Video

youtube

Cadmium-Injected Manganese Ferrite

Cadmium-injected manganese ferrite (CdMnFe₂O₄) is gaining attention in materials science for its promising applications in magnetic devices, energy storage systems, sensors, and environmental technologies. The compound represents an intersection of two key materials: manganese ferrite (MnFe₂O₄) and cadmium, combining their properties to offer novel functionalities. Below is an exploration of how this material could revolutionize various industries and fields.

Properties and Structure

Manganese ferrite is a well-known spinel ferrite that exhibits strong magnetic properties, making it an attractive material for magnetic storage, biomedical applications, and catalysis. Cadmium, when introduced into the manganese ferrite matrix, alters the magnetic, electronic, and optical properties, enhancing its utility in advanced applications.

Magnetic Properties: Cadmium-doped manganese ferrite can exhibit enhanced magnetic permeability and reduced coercivity. These properties make it more suitable for high-frequency applications such as transformers, inductors, and telecommunications equipment.

Electrical Conductivity: Cadmium injection also influences the electrical conductivity of manganese ferrite, enabling better performance in devices that rely on the control of charge carriers, such as semiconductors and spintronic devices.

Optical Characteristics: Incorporating cadmium can tailor the optical bandgap of manganese ferrite, opening possibilities for applications in optoelectronics, particularly in photovoltaics and photocatalysis.

Energy Storage: The ability of cadmium-injected manganese ferrite to operate at high frequencies and its tunable magnetic properties make it a potential candidate for energy storage systems, especially in supercapacitors and batteries. Enhanced ionic conductivity could improve the efficiency and lifespan of these devices.

Magnetic Data Storage: With advances in spintronics, materials with specific magnetic and electrical characteristics are essential. Cadmium doping in manganese ferrite could create more efficient magnetic data storage devices with lower energy consumption and higher data densities.

Environmental Applications: As a catalyst for water purification and air filtration, cadmium-injected manganese ferrite can break down pollutants more efficiently. Its enhanced surface area and reactive sites make it suitable for catalytic processes like Fenton reactions, helping address environmental challenges.

Biomedical Uses: Due to its biocompatibility, manganese ferrite has been studied for drug delivery and magnetic resonance imaging (MRI). Cadmium injection may offer further opportunities to enhance its contrast properties in MRI or improve its effectiveness in targeted drug delivery systems.

Sensors and Actuators: The material’s ability to respond to external stimuli, such as magnetic fields or pressure, makes it ideal for sensors and actuators in smart technologies and Internet of Things (IoT) devices.

More Info: physicistparticle.com

contact us : [email protected]

#youtube#sciencefather#cadmiuminjectedferrit#manganeseferrite#cdmndopedferrite#ferritenanomaterials#magneticmaterials#spinferrite#nanotechnology

0 notes

Text

Barium Sulfide Manufacturing Plant Project Report 2024: Industry trends and Plant Setup

Introduction

Barium sulfide is a chemical compound widely used in various industries, including manufacturing, agriculture, and environmental management. It is particularly valued in applications such as fluorescent lights, ceramics, and as a precursor for other barium compounds. Given its diverse applications and market demand, establishing a manufacturing plant for barium sulfide represents a strategic business opportunity. This Barium Sulfide Manufacturing Plant Project Report provides a comprehensive guide to setting up a barium sulfide manufacturing facility, covering market analysis, plant setup, production processes, and financial considerations.

Market Analysis

Industry Overview

The global barium sulfide market is influenced by its various industrial applications. Barium sulfide is used in the production of barium pigments, which are essential in creating bright colors in ceramics and glass. It is also used in the manufacture of barium ferrites for magnets and in the treatment of wastewater to remove sulfate ions. The market for barium sulfide is expected to grow with increased industrial activities and advancements in technology.

Target Market

Manufacturers of Fluorescent Lights: Barium sulfide is used in the production of phosphors for fluorescent lamps.

Ceramic and Glass Manufacturers: The compound is used as a colorant and opacifier in ceramics and glass products.

Environmental and Water Treatment Facilities: Barium sulfide is utilized in processes for treating and purifying water.

Chemical Industry: Companies involved in the production of other barium compounds or chemicals may be key customers.

Competitive Landscape

The barium sulfide market is competitive, with several established players. Key competitors include chemical manufacturers specializing in barium compounds and companies in related industries. To stand out, focus on high-quality production, cost-efficiency, and strong customer relationships

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/barium-sulfide-manufacturing-plant-project-report/requestsample

Plant Setup

Location

Selecting the right location for your barium sulfide manufacturing plant is crucial:

Proximity to Raw Materials: Ensure access to barium carbonate and sulfur, the primary raw materials used in barium sulfide production.

Infrastructure: Choose a location with good infrastructure, including transportation links, utilities, and skilled labor.

Regulatory Environment: Opt for a location with favorable environmental and industrial regulations.

Facility Layout

A well-organized facility layout is essential for efficient operations:

Raw Material Storage: Secure storage for barium carbonate, sulfur, and other raw materials.

Production Area: Includes reactors for chemical reactions, filtration systems, and drying units.

Quality Control Lab: For testing and analyzing raw materials and finished products.

Packaging and Distribution: For packing the final product and preparing it for shipment.

Administrative Offices: For managing operations, compliance, and human resources.

Equipment and Technology

Invest in modern equipment and technology to ensure high-quality production:

Reactors: For conducting the chemical reactions required to produce barium sulfide.

Filtration Systems: For separating and purifying barium sulfide from the reaction mixture.

Drying Units: For drying the final product to obtain the desired physical form.

Quality Control Instruments: For analyzing the purity and quality of barium sulfide.

Production Process

Raw Materials

The primary raw materials for barium sulfide production are barium carbonate (BaCO₃) and sulfur (S). These materials are chemically reacted to produce barium sulfide.

Manufacturing Steps

Reaction: Barium carbonate and sulfur are combined in a high-temperature reactor to produce barium sulfide and carbon dioxide. The chemical reaction is as follows: BaCO3+S→BaS+CO2\text{BaCO}_3 + \text{S} \rightarrow \text{BaS} + \text{CO}_2BaCO3+S→BaS+CO2

Filtration: The reaction mixture is filtered to separate the barium sulfide from any remaining impurities or by-products.

Washing: The barium sulfide is washed to remove any residual reactants and impurities.

Drying: The washed barium sulfide is dried to obtain a fine powder or granules, depending on the required product form.

Packaging: The final product is packaged in suitable containers for distribution.

Quality Assurance

Implement stringent quality control measures:

Raw Material Testing: Ensure the quality of incoming barium carbonate and sulfur.

In-Process Monitoring: Regularly monitor the reaction parameters to maintain consistency and quality.

Final Product Testing: Conduct tests to verify the purity, particle size, and other properties of the barium sulfide.

Financial Considerations

Investment Requirements

Initial investments include costs for facility construction or leasing, purchasing equipment, and acquiring raw materials. Additional expenses cover licensing, regulatory compliance, and staffing.

Revenue Projections

Estimate revenue based on production capacity, market demand, and pricing strategies. Consider factors such as production costs, competitor pricing, and market potential.

Cost Management

Effective cost management involves:

Budgeting: Develop a detailed budget for plant setup and operations.

Efficiency: Implement cost-saving measures such as energy-efficient equipment and bulk purchasing of raw materials.

Monitoring: Regularly review financial performance and adjust strategies as needed.

FAQ

1. What is barium sulfide, and what are its main uses?

Barium sulfide is a chemical compound used in various applications, including the production of fluorescent lights, ceramics, and pigments. It is also used in water treatment processes and as a precursor for other barium compounds.

2. How long does it take to set up a barium sulfide manufacturing plant?

Setting up a barium sulfide manufacturing plant typically takes between 12 to 18 months. This includes facility construction or leasing, equipment installation, obtaining regulatory approvals, and training staff.

3. What are the primary challenges in manufacturing barium sulfide?

Challenges include ensuring consistent product quality, managing raw material supply, meeting environmental and safety regulations, and maintaining cost-efficiency in production.

4. How can I ensure quality control in barium sulfide production?

Implement comprehensive quality control measures, including testing raw materials, monitoring production processes, and conducting rigorous testing of the final product. Compliance with safety and industry standards is also crucial.

5. What environmental considerations should be addressed in this type of manufacturing plant?

Environmental considerations include managing chemical waste, reducing energy consumption, and ensuring compliance with environmental regulations. Implementing recycling practices and energy-efficient technologies can help mitigate environmental impact.

6. How can I differentiate my barium sulfide product from competitors?

Differentiate your product by focusing on high-quality manufacturing, competitive pricing, and excellent customer service. Building strong relationships with customers and suppliers can also provide a competitive edge.

Related Reports

https://www.expertmarketresearch.com/reports/packaged-food-market

https://www.expertmarketresearch.com/reports/north-america-customer-journey-analytics-market

https://www.expertmarketresearch.com/reports/flexible-plastic-packaging-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

0 notes

Text

Common Problems with P&H Crane Parts and How to Solve Them

Understanding and addressing common issues with P&H crane parts is crucial for ensuring operational efficiency, safety, and longevity of equipment. This article aims to provide a comprehensive overview of frequently encountered problems with P&H crane components and offer practical solutions for addressing these challenges. Whether you're an experienced crane operator or new to the field, the insights provided here will serve as a valuable resource for maintaining optimal performance of your P&H crane equipment.

The Importance of Proactive Maintenance

Before we jump into specific problems, let's talk about why staying on top of your P&H crane parts is so crucial. Regular maintenance isn't just about keeping your crane running smoothly (though that's certainly important). It's about safety, efficiency, and avoiding costly downtime. As any reputable crane parts supplier will tell you, a well-maintained crane is a safe and productive crane.

Now, let's roll up our sleeves and look at some common issues you might encounter with your P&H crane parts:

1. Worn Wire Ropes: The Silent Strength Sapper

Wire ropes are the unsung heroes of your crane, but they're subject to wear and tear over time. Frayed or damaged wire ropes can compromise lifting capacity and pose serious safety risks. The key to addressing this issue is regular inspections. Check your wire ropes frequently for signs of wear, corrosion, or damage. Proper lubrication is also crucial – it reduces friction and extends the lifespan of your ropes.

Don't wait until it's too late to replace worn wire ropes. If you notice significant wear, it's time to contact your crane parts supplier for a replacement. As Mike Johnson, a veteran crane operator, puts it, "Wire ropes are critical P&H crane parts that require constant attention. I've seen operators try to squeeze extra life out of worn ropes, but it's just not worth the risk."

2. Hydraulic System Issues: When Power Meets Problems

Hydraulic systems are the muscles of your P&H crane, but they can develop leaks, lose pressure, or become contaminated over time. To keep your hydraulic system in top shape, make regular fluid checks a priority. Monitor hydraulic fluid levels and quality, and don't forget to inspect seals for leaks. If you find issues, replace the seals promptly.

Filtration maintenance is another crucial aspect of hydraulic system care. Keep those filters clean to prevent contamination. For complex hydraulic issues, don't hesitate to call in a specialist or consult your crane parts supplier. They have the expertise to diagnose and resolve tricky hydraulic problems.

3. Electrical System Glitches: When Wires Cross You

Electrical issues can range from minor annoyances to major operational problems. Faulty wiring, damaged controls, or malfunctioning sensors can all throw a wrench in your operations. Regular inspections are your first line of defense – check wiring and connections for signs of wear or damage.

Protecting electrical components from moisture and debris is crucial. If your crane uses computerized systems, ensure you're running the latest software versions. For persistent issues, bringing in an electrical specialist or consulting your crane parts supplier for advanced diagnostic tools can save you a lot of headaches down the line.

4. Structural Wear and Tear: The Framework of Reliability

Even the sturdiest P&H crane parts aren't immune to the effects of time and heavy use. Structural components can develop cracks, corrosion, or misalignment. Regular visual inspections of all structural components are essential, but sometimes issues can hide beneath the surface. That's where non-destructive testing methods like ultrasound or magnetic particle testing come in handy.

When it comes to structural issues, prompt action is crucial. Address any problems immediately – this isn't an area where you can afford to cut corners. And when replacement is necessary, always opt for high-quality P&H crane parts from a trusted crane parts supplier.

5. Brake System Failures: When Stopping Power Slips

Brake system issues can lead to dangerous situations. Worn brake pads, hydraulic problems, or mechanical failures can all compromise your crane's ability to stop safely. Make brake tests a regular part of your maintenance routine. Check brake pads for wear and replace them before they become dangerously thin.

Don't forget about the hydraulic systems supporting the brakes – they need to be in good condition too. When it comes to brakes, it's always better to err on the side of caution. If you're unsure about anything, consult a professional or your crane parts supplier.

6. Bearing Troubles: The Silent Operators

Bearings play a crucial role in various P&H crane parts, from the slewing ring to winch systems. Worn or damaged bearings can lead to increased friction, heat, and potential failure. Regular lubrication is key – keep those bearings well-greased according to manufacturer specifications.

Vibration analysis tools can be invaluable for detecting early signs of bearing wear. Also, keep an eye on bearing temperatures during operation – excessive heat can indicate problems. When bearings show signs of wear, don't delay in replacing them. Your crane parts supplier can help you find the right fit.

Preventative Maintenance: Your Best Defense

While knowing how to tackle these common problems is crucial, the best approach is to prevent them from occurring in the first place. Develop and adhere to a regular maintenance schedule for all your P&H crane parts. Keep detailed records of all maintenance activities, repairs, and part replacements – this information can be invaluable for spotting trends and preventing future issues.

Ensure all operators and maintenance staff are well-trained in identifying potential issues. Always source your P&H crane parts from a reputable crane parts supplier to ensure quality and compatibility. And don't forget to stay updated on the latest maintenance techniques and technologies for P&H cranes.

The Role of Your Crane Parts Supplier

Remember, you're not in this alone. A reliable crane parts supplier is more than just a vendor – they're a partner in keeping your P&H crane running smoothly and safely. Don't hesitate to reach out to them for advice, parts, or specialized services.

Sarah Thompson, a procurement specialist for a major construction firm, puts it well: "A good crane parts supplier doesn't just sell you parts. They provide expertise, help you troubleshoot issues, and ensure you're getting the right P&H crane parts for your specific needs."

Conclusion: Empowering Your Crane Operations

Understanding and addressing common problems with P&H crane parts is key to maintaining a safe, efficient, and productive operation. By staying proactive, addressing issues promptly, and partnering with a knowledgeable crane parts supplier, you can keep your P&H crane lifting strong for years to come.

Remember, every problem you solve and every maintenance task you complete isn't just about fixing a machine – it's about ensuring the safety of your team and the success of your projects. So here's to smooth operations, safe lifts, and cranes that keep on cranking!

0 notes

Text

The Ultimate Guide to Oil and Air Filters for Your Car and Bike: Everything You Need to Know

Maintaining your vehicle in top condition is essential for ensuring its longevity and performance. One of the critical aspects of vehicle maintenance involves regular replacement of oil and air filters. Whether you own a car or a bike, understanding the importance of these filters and knowing how to choose the right ones is crucial. In this comprehensive guide, we’ll delve into everything you need to know about oil and air filters for your car and bike.

What Are Oil and Air Filters?

Oil and air filters are essential components in any vehicle, playing a vital role in keeping the engine clean and running smoothly.

Oil Filter

An oil filter removes contaminants from engine oil. Over time, oil accumulates dirt, debris, and other impurities that can damage the engine. A good oil filter traps these particles, ensuring that only clean oil circulates within the engine.

Air Filter

An air filter cleans the air entering the engine. Dust, pollen, and other particles can clog the engine if they aren’t filtered out. The air filter prevents this, allowing for better combustion and performance.

Types of Oil Filters

When it comes to choosing an oil filter for your car or bike, there are several types to consider:

1. Mechanical Filters

These use a paper or synthetic fiber material to trap contaminants. They are the most common type of oil filters.

2. Magnetic Filters

These contain a magnet that captures metallic particles in the oil. They are often used in conjunction with other types of filters.

3. Centrifugal Filters

These use centrifugal force to separate impurities from the oil. They are effective but more expensive and complex.

4. Sedimentation Filters

These rely on gravity to separate contaminants. Heavier particles settle at the bottom of the filter, while clean oil rises to the top.

Choosing the Right Oil Filter for Car

When selecting an oil filter for your car, consider the following:

Compatibility: Ensure the oil filter matches your car’s make and model. Using an incompatible filter can cause engine damage.

Quality: Opt for high-quality filters from reputable brands like Uno Minda. They offer reliable performance and longevity.

Type: Depending on your car’s requirements and your budget, choose the appropriate type of oil filter.

Reviews: Check user reviews and ratings to ensure the filter has a good reputation for reliability and performance.

Choosing the Right Oil Filter for Bike

Selecting an oil filter for your bike follows similar principles as choosing one for a car. Ensure compatibility, prioritize quality, and read reviews to make an informed decision. Uno Minda offers a range of bike oil filters designed to meet various requirements.

Types of Air Filters

Air filters also come in different types, each offering unique benefits:

1. Paper Filters

These are the most common and affordable type. They are effective but need frequent replacement.

2. Foam Filters

Foam filters are more durable and can be washed and reused. They offer better airflow but can be less effective at filtering fine particles.

3. Cotton Filters

These are high-performance filters often used in racing. They provide excellent filtration and airflow but are more expensive.

4. Synthetic Filters

Made from synthetic materials, these filters offer high efficiency and long life. They are a good balance between performance and cost.

Choosing the Right Air Filter for Car

Consider these factors when choosing an air filter for your car:

Compatibility: Ensure the filter is compatible with your car’s engine and air intake system.

Performance: High-performance filters, such as those from Uno Minda, offer better airflow and filtration, enhancing your car’s efficiency.

Maintenance: Determine how often the filter needs to be replaced or cleaned. Some filters require more frequent maintenance than others.

Cost: Balance cost with performance. Higher-end filters may be more expensive initially but can save money in the long run due to their durability and efficiency.

Choosing the Right Air Filter for Bike

When selecting an air filter for your bike, prioritize compatibility and performance. Uno Minda offers bike air filters that cater to various needs, ensuring your bike runs smoothly and efficiently.

Maintenance Tips for Oil and Air Filters

For Oil Filters:

Regular Replacement: Follow the manufacturer’s guidelines on how often to replace the oil filter. Typically, it should be replaced with every oil change.

Check for Leaks: After replacing the oil filter, check for any leaks to ensure it’s installed correctly.

Use High-Quality Oil: Using high-quality engine oil reduces the load on the oil filter, enhancing its longevity.

For Air Filters:

Regular Inspection: Inspect the air filter every few months, especially if you drive in dusty conditions.

Clean or Replace: Depending on the type of air filter, clean it or replace it as needed. Foam and cotton filters can often be washed and reused.

Check Seals: Ensure the air filter is properly sealed to prevent unfiltered air from entering the engine.

Benefits of Using High-Quality Filters

Using high-quality oil and air filters from reputable brands like Uno Minda offers several benefits:

Improved Engine Performance

Clean oil and air are crucial for optimal engine performance. High-quality filters ensure that your engine receives the clean oil and air it needs, enhancing power and efficiency.

Increased Engine Longevity

By effectively removing contaminants, high-quality filters prevent wear and tear on engine components, extending the life of your engine.

Better Fuel Efficiency

A clean air filter improves combustion efficiency, leading to better fuel economy. Similarly, clean oil reduces engine friction, further enhancing fuel efficiency.

Reduced Emissions

Clean oil and air contribute to more efficient combustion, resulting in lower emissions. This is better for the environment and can help your vehicle pass emissions tests.

Why Choose Uno Minda?

Uno Minda is a trusted name in the automotive industry, known for its high-quality filters. Here’s why you should consider Uno Minda for your oil and air filter needs:

Reliability: Uno Minda filters are designed to meet high standards of performance and reliability, ensuring your vehicle runs smoothly.

Variety: They offer a wide range of filters for different makes and models of cars and bikes, making it easy to find the right fit.

Innovation: Uno Minda continually invests in research and development, bringing innovative solutions to the market.

Customer Satisfaction: With a strong focus on customer satisfaction, Uno Minda products are well-reviewed and trusted by millions of users.

Conclusion

Maintaining your car or bike’s oil and air filters is essential for ensuring optimal performance and longevity. By choosing the right filters and following regular maintenance practices, you can keep your vehicle running smoothly and efficiently. Brands like https://unomindakart.com/ offer high-quality filters that provide reliable performance, making them an excellent choice for discerning vehicle owners. Remember, a well-maintained vehicle not only performs better but also saves you money in the long run by preventing costly repairs. So, take the time to invest in quality oil and air filters and enjoy the benefits of a well-maintained engine.

0 notes

Text

About Eddy Current Recycling

About Eddy Current Recycling

Introduction

Eddy current recycling stands as an essential innovation in the domain of materials recovery and recycling. At its center, this advanced process utilizes the power of eddy currents – circulating currents induced in conductive materials exposed to a changing magnetic field. This can efficiently separate non-ferrous metals from mixed waste streams,…

View On WordPress

#eddy current devices#eddy current magnetic separator#Eddy Current Separator#Eddy currents#ferromagnetic#Magnet Attraction#Magnet Design#magnetic attraction#Magnetic Circuits#magnetic components#Magnetic device#MAGNETIC field#magnetic field attraction#Magnetic Filters#Magnetic Filtration#magnetic filtration system#magnetic flux density#Magnetic Liquid traps#magnetic permeable sheets#Magnetic Separator#Permanent Magnetic Filters

0 notes

Text

Research grade Proteins: Production and Scale-Up Challenges

Research-grade proteins are essential tools in the field of scientific discovery, serving as foundational elements in a variety of biological and medical research applications. These proteins, characterized by their high purity and consistency, enable researchers to conduct experiments with a high degree of reliability and reproducibility. Their use spans numerous disciplines, including biochemistry, molecular biology, pharmacology, and biotechnology.

The production of research-grade proteins involves several sophisticated techniques to ensure their purity and functionality. These techniques often include recombinant DNA technology, where genes encoding the desired proteins are inserted into expression systems such as bacteria, yeast, or mammalian cells. Once expressed, the proteins are purified using methods like affinity chromatography, ion exchange chromatography, and gel filtration. The goal is to obtain proteins free from contaminants and with the correct folding and post-translational modifications necessary for their activity.

Research-grade proteins play a crucial role in drug development and screening processes. They are used to study the binding affinities and specificities of potential therapeutic compounds, aiding in the identification of promising drug candidates. For instance, proteins such as enzymes, receptors, and ion channels are targeted by pharmaceutical companies to develop new medications for a variety of diseases. The high quality of research-grade proteins ensures that the data generated from these studies are accurate and reproducible, which is critical for the success of drug discovery programs.

In addition to drug development, research-grade proteins are vital for structural and functional studies. Techniques like X-ray crystallography, nuclear magnetic resonance (NMR) spectroscopy, and cryo-electron microscopy rely on high-quality proteins to determine their three-dimensional structures. Understanding protein structures at the atomic level provides insights into their mechanisms of action and interactions with other molecules, which is essential for advancing our knowledge of biological processes and developing targeted therapies.

The application of research-grade proteins in diagnostic assays is another area of significant impact. Proteins such as antibodies and antigens are used in various diagnostic tests, including enzyme-linked immunosorbent assays (ELISAs) and western blotting, to detect and quantify biomolecules in clinical samples. The accuracy and sensitivity of these tests depend on the quality of the proteins used.

Despite their importance, producing research-grade proteins presents challenges, including ensuring stability and functionality over time, and maintaining ethical and regulatory standards in their production. Nonetheless, ongoing advancements in protein engineering and purification technologies continue to enhance the availability and quality of research-grade proteins, driving forward scientific innovation and discovery.

0 notes

Text

Oil filtration systems

Optimizing Efficiency and Longevity: The Role of Oil Filtration Systems

In the realm of industrial machinery and automotive engines, oil filtration systems stand as unsung heroes, diligently safeguarding performance and durability. These systems play a critical role in maintaining the health of engines and equipment by effectively removing contaminants from lubricating oils. Let’s delve into the intricacies of oil filtration systems and their indispensable contributions.

Understanding Oil Filtration Systems:

Oil filtration systems are engineered to trap and remove particles, debris, and impurities that accumulate in lubricating oils during operation. These contaminants, if left unchecked, can cause abrasive wear, corrosion, and operational inefficiencies, ultimately leading to costly repairs and downtime.

Functionality and Components:

At the heart of an oil filtration system lies the filter element, designed with materials and structures tailored to capture particles of varying sizes. Modern systems often incorporate high-efficiency filters, magnetic separators, and centrifuges to ensure comprehensive purification of the oil. The filtration process may utilize depth filtration, surface filtration, or a combination of both methods to achieve optimal cleanliness levels.

Benefits of Effective Filtration:

The benefits of employing robust oil filtration systems are manifold. Firstly, they extend the lifespan of machinery and engines by minimizing wear on critical components such as bearings and pistons. Secondly, clean oil enhances operational efficiency by maintaining proper viscosity and thermal stability, thereby improving fuel economy and performance. Moreover, reduced contamination translates to lower maintenance costs and fewer unplanned shutdowns, contributing to overall operational reliability.

Applications Across Industries:

From heavy machinery in construction and mining to precision equipment in manufacturing and aerospace, oil filtration systems are indispensable across diverse industrial sectors. Automotive engines also rely heavily on oil filtration to ensure optimal performance and meet stringent emission standards.

Technological Advancements:

Advancements in filtration technology continue to drive improvements in efficiency and effectiveness. Innovations such as bypass filtration systems, electrostatic oil cleaners, and real-time monitoring sensors enhance the precision and reliability of oil purification processes, catering to the evolving needs of modern industrial applications.

Environmental and Economic Considerations:

Beyond operational benefits, effective oil filtration systems contribute to environmental sustainability by reducing waste oil disposal and minimizing the ecological footprint associated with manufacturing new oils. Economically, the upfront investment in quality filtration systems proves cost-effective in the long run, offering substantial returns through enhanced equipment longevity and performance.

Conclusion:

In conclusion, oil filtration systems are not mere accessories but essential components that safeguard the vitality of machinery and engines across industries. By investing in advanced filtration technologies and proactive maintenance practices, businesses can ensure prolonged equipment life, reduced downtime, and optimized operational efficiency. As industries continue to evolve, the role of oil filtration systems remains pivotal in shaping a sustainable and productive future.

In essence, these systems epitomize the adage that prevention is better than cure, preserving the heartbeats of mechanical giants and driving performance to new heights.

1 note

·

View note

Text

Centrifugal Pump Types Essential for Pharmaceutical Manufacturing

In the pharmaceutical industry, precision and dependability are key. In this industry, the centrifugal pump stands as one of the most critical components that ensure these standards are maintained. These pumps play an essential role in different processes, including liquid transfer to sustain sterile conditions. Differentiating between various types of industrial centrifugal pumps and their applications is helpful for experts when choosing suitable equipment.

In this blog, we discuss about types of centrifugal pumps used in the pharmaceutical industry, their examples, practical uses and the role of centrifugal pump manufacturers in India.

Overview of Centrifugal Pumps

Centrifugal Pumps are mechanical devices designed to move fluids by converting the kinetic energy from rotation into hydrodynamic energy. They are widely used in the pharmaceutical industry due to their high efficiency, reliability, and capability to handle various fluids like corrosive and viscous liquids.

Types Of Centrifugal Pumps In Pharmaceutical Industry

1. Single-Stage Centrifugal Pumps

Single-stage centrifugal pumps usually have one impeller and are typically employed in applications requiring minimum to medium pressure levels. They are simple, economical and best suited for moving liquids from one point to another.

Example: A single-stage centrifugal pump used by a pharmaceutical company for transferring purified water from a storage tank to the production line.

2. Multistage Centrifugal Pumps

These include several impellers which increase the fluid pressure at each stage. Such pumps are used where there is a need for high pressure as they could be applied in boiler feed systems or even high-pressure cleaning.

Example: In manufacturing sterile injectables, a multistage centrifugal pump ensures that there is a supply of highly pressurized water required during the cleaning and sterilization process.

3. Sanitary Centrifugal Pumps

Sanitary centrifugal pumps are designed with materials and finishes that prevent contamination, making them perfect for handling sensitive pharmaceutical products. They are easy to clean and meet stringent sanitary standards.

Example: A pharmaceutical company employs sanitary centrifugal pumps to transfer active pharmaceutical ingredients (APIs) in a sterile environment, ensuring product purity and compliance with regulatory standards.

4. Magnetic Drive Centrifugal Pumps

These centrifugal pumps eliminate the need for mechanical seals by using magnetic couplings to transfer torque. This makes them perfect for handling hazardous liquids or sensitive fluids because it reduces the chances of leaking and contamination.

Example: Magnetic drive centrifugal pumps are used by a pharmaceutical plant to handle volatile solvents required in pharmaceutical formulations to make them operate without any danger of leakage.

5. Self-Priming Centrifugal Pumps

Self-priming centrifugal pumps can re-prime themselves even if air enters the system. They are used in applications where the pump may need to start with an empty suction line.

Example: Self-priming centrifugal pumps are used by a pharmaceutical company during wastewater treatment operations where there may be different fluid levels that the pump must deal with.

Practical Applications of Centrifugal Pumps in the Pharmaceutical Industry

Fluid transfer: Movement of raw materials, intermediates, and finished products within the facility.

Cleaning systems: These provide necessary pressures for cleaning and sterilization systems.

Filtration processes: This involves circulating fluids through filtration systems to remove impurities.

Cooling systems: These ensure effective cooling of equipment as well as processes being undertaken.

Choosing The Right Centrifugal Pump

Among other factors, the selection of the proper type of centrifuge pump depends on certain fluid properties along with flow rate and pressure requirements coupled with environmental conditions unique to each application. Partnering with reputable centrifugal pump manufacturers in India, like Fristam Pumps, ensures access to high-quality, reliable equipment tailored to the pharmaceutical industry's needs.

Conclusion

Pharmaceutical processes must be optimized by understanding various types of centrifugal pumps and their applications. Depending on the requirements, each form may have several options including multi-stage, single-stage, magnetic drive or even sanitary pumps. By picking out the right category of industrial centrifugal pumps, pharmaceutical companies can ensure efficient, safe and reliable operations.

For top-quality centrifugal pumps manufacturer in India and expert guidance partner with Fristam Pumps, the leading name in industrial centrifugal pumps.

FAQs:

1) What are centrifugal pumps, and why are they used in the pharmaceutical industry?

Centrifugal pumps are mechanical devices that move fluids using rotational kinetic energy. They are used in the pharmaceutical industry for their efficiency, reliability, and ability to handle various fluids, ensuring precise and sterile processes.

2) What types of centrifugal pumps are commonly used in the pharmaceutical industry?

Common types of centrifugal pumps in the pharmaceutical industry include single-stage, multistage, sanitary, magnetic drive, and self-priming pumps.

3) What are the applications of centrifugal pumps in the pharmaceutical industry?

Centrifugal pumps in the pharmaceutical industry are used for fluid transfer, cleaning systems, filtration processes, and cooling systems.

4) What are the benefits of using centrifugal pumps in the pharmaceutical industry?

The benefits of using centrifugal pumps in the pharmaceutical industry include efficiency, reliability, precise fluid handling, and maintaining sterile conditions.

#centrifugal pumps#Pharmaceutical Industry#Pump Types#IndustrialPumps#PumpMaintenance#PharmaceuticalEquipment#PumpSelection

0 notes

Text

Guangdong Qeehua Industry Equipment Co., Ltd. is a high-tech enterprise based on the research and development of corrosion resistant chemical pumps. According to modern enterprise management standards, the company has established a scientific management system, with excellent manufacturing, quality management team.

In addition, QEEHUA PUMP also has a professional R & D team and sales engineer team, from project evaluation, scheme design, motor matching, mold development, injection molding, processing, assembly, testing, product inspection, packaging, logistics and transportation, truly realize the whole process of quality control.

QEEHUA PUMP core products include acid and alkali resistant magnetic pump, centrifugal pump, vertical pump, precision filter, etc., widely used in electroplating, hardware, PCB, medical, solar energy, semiconductor, coating and other industries of chemical liquid circulation, filtration, transportation, can also be used for waste gas & wastewater treatment.

QEEHUA PUMP will adhere to the mission of “Make the world love Chinese pumps”, and will continue to develop a series of safer, more energy efficient and more efficient chemical pump products. With the experience and strength of QEEHUA PUMP, we can ensure the success of every chemical pump project for our customers. We look forward to your cooperation.

0 notes

Text

Aqua Bead Filters: The Ultimate Solution Filter For Pond Pump System

Filtration is essential to keeping pond water healthy and clear. Filters help remove debris, prevent clogs, reduce algae growth and provide oxygen to underwater plants. Select a filter whose capacity matches that of your Filter For Pond Pump volume, taking into account any fish stocking levels or adding a model if necessary.

Pump

▸Introduction to Pond Pumps: Filter For Pond Pump are recirculating pumps used for powering waterfalls and fountains as well as filtering the water in garden ponds, as well as filtering it. Pond Pumps are integral in maintaining healthy fish & wildlife in the garden pond; running 24/7 to filter the water and regularly cleaning out pre-filters is required to do this effectively. However, clear water does not necessarily signify healthy fish; regular testing of your water quality as well as seeking advice if your fish seem lethargic are essential components to good pond maintenance.

▸Capturing Debris for Clear Water: Filter For Pond Pump come equipped with mechanical, chemical and biological filtration systems for maximum clarity of water in your pond. Filter pads capture large debris as well as smaller particles before passing over bio-balls to biologically filter out debris – creating the clearest water possible for your aquatic habitat. Some filters even come equipped with built-in skimmer for easy surface debris removal.

▸Chemically Compatible Materials for Increased Resistance: Some of the latest models feature chemically compatible materials to increase resistance against harmful substances found in liquids that need to be pumped, and an air gap between their motor and pump chamber to minimize heat transfer as well as noise and vibrations.

▸Choosing the Right Pond Pump: Your choice of Filter For Pond Pump will depend on the size and purpose of your pond. Magnetic drive pumps are generally more durable and energy efficient; however they don’t lift water to heights beyond 2m. Direct Drive pumps may provide better water lift at greater head heights but don’t offer as much efficiency in energy savings as magnetic drive pumps do.

Pre-Filter

▸Introduction to Pre-Filters: Pre-filters, also referred to as sediment filters, remove dirt, sand, rust, silt and other large suspended particles from water before it enters your primary filtration system. By doing so they protect it from becoming clogged up while providing cleaner and higher quality water for your home.

▸Pre-Filters for Private Well Owners: Homeowners with private wells use pre-filters to capture iron and debris that enters their water system from their well, protecting equipment and avoiding costly service calls to their home.

▸Pre-filters, also referred to as catch all filters: Are constructed from materials like polypropylene that can easily be washed – ideal for homes with pets and those suffering from respiratory conditions as they capture large particles such as hair, dust and lint.

Biological Filter

▸Breaking Down Organic Pollutants: Biological Filter For Pond Pump use beneficial bacteria to break down organic pollutants in the water, providing an effective means of purification. They work best when combined with mechanical and pre-filters for an integrated filtering system.

▸Ensuring Adequate Oxygen Supply: Installing a biological Filter For Pond Pump requires careful consideration to ensure it’s placed appropriately in your water feature and receiving adequate oxygen. Furthermore, its pump should be powerful enough to push nutrient-rich water through it as without this action, the bacteria would quickly consume all their oxygen supply and die.

▸The Power of Billions of Bacteria in Biological Filtration: To be effective, biological Filter For Pond Pump requires billions of bacteria working together to cleanse the water. Since bacteria attach themselves to surfaces like filter media, rocks, or gravel, surface area is a crucial component in this process – thus justifying why ponds with gravel on their bottom are preferable over those without.

▸Removing Nitrates for Clean and Clear Water: After bacteria have broken down harmful nutrients, they will convert them to nitrates for consumption by aquatic plants and algae during their growth processes. De-nitrification then removes them from the pond through anaerobic areas without oxygen; an integral part of keeping your water clean and clear.

UV Clarifier

▸Addressing the Issue of Green Water: Green murky water can be the bane of every water garden owner’s existence. Green water is caused by single-celled algae settling to the bottom and can occur even with an effectively balanced ecosystem pond system.

▸Reduced Maintenance and Crystal-Clear Water: A UV clarifier works to eliminate green water by killing off algae before it can form blooms that stain the water’s surface and result in green streaks. This solution is great for ponds predisposed to green water or those looking to reduce maintenance while still having crystal-clear waters.

▸UV Clarifiers as Sterilizers, Not Filters: Though commonly mistaken as filters, UV clarifiers should actually be seen as sterilizers rather than filters. UV lights work by killing any undesirable organisms. For optimum performance and increased lifespan of the light itself it is advised that an appropriate amount of wattage be chosen according to your pond size.

▸Size Options for Pond UV Clarifiers: There are various sizes of UV clarifiers to choose from when it comes to pond UV clarifiers, and you can either purchase standalone units or ones as part of a Filter/UV combo package. It is essential that the flow rate of your pump matches up with that recommended by the UV unit’s manufacturer; usually this information can be found either within their product description or directly on it.

Why Choose Aqua Bead!

In terms of pond pump filtration systems, Aqua Bead by Filter is head and shoulders above the competition. Aqua Bead by Filter is highly recommended for pond owners for multiple reasons. The helpful bacteria that inhabit the huge surface area created by these beads efficiently break down hazardous elements and keep the water clear. The second reason is that filters work so well and last so long. Their filtration performance remains ideal even when subjected to heavy water flows. Plus, you won’t have to spend as much time Aqua Bead cleaning and maintaining your pond when you use Aqua Bead filters.

1 note

·

View note