#Magnetic belts

Text

Magnetic Separator Conveyor Belts Types

Magnetic Separator Conveyor Belts Types

Mgnetic separator conveyor belts move things from one place to another in factories. Some conveyor belts have magnets. The magnets take away pieces of metal that shouldn’t be there. This makes the product cleaner. It also stops metal from breaking machines further down the line. There are a few types of these magnetic separator conveyor belts. Each one…

View On WordPress

#Belt Drum Separator#Drum separators#hump magnets#In-line Magnets#industrial application#Industrial Magnetic Assemblies#industrial magnetic equipment#Magnet Design#magnetic attraction#Magnetic belts#Magnetic Circuits#magnetic components#Magnetic device#Magnetic drum separators#MAGNETIC field#magnetic field attraction#Magnetic Filters#Magnetic Filtration#magnetic filtration system#Magnetic Liquid traps#magnetic permeable sheets#Magnetic pulley separator#Magnetic Pulleys#Magnetic Separation#magnetic separation assemblies#magnetic separation equipment#magnetic separation systems#Magnetic Separator#Magnetic Separator Conveyors#Permanent magnet types

1 note

·

View note

Text

he's here....

#AAAAAAAAAAHHHH FUUCCCKK#he looks.... so amazing...#pics don't do him justice because he really looks so amazing in real life#I'm just blown away#actually have to sit down because I'm so giddy with excitement lol#he's so beautiful like#I love the way everything turned out#I forgot how big scale figures are too haha#his face is so handsome#and the blood looks really good especially on his clothes#he's so detailed and pretty#and all of his assembly is magnets so it's really easy to put together#I also like that he can be displayed without his base or the chair haha#like a big noodle stopper#there's so much detail on his clothing!!#all of the folds#the bottom of his shoes is detailed with blood#they included the back of his tie#the buttons on his shirt cuffs and the individual holes of his belt#his fingernails too#has aki's shirt always had a front pocket? lol#sigh... I want to spend the rest of the night staring at him#I'll take better pictures of him tomorrow when the lighting is better!!!#I want to make a detailed post about him#fighting the urge to bite him rn#aki <3

232 notes

·

View notes

Text

watching the Ancient Aliens episode of Buzzfeed Unsolved and pausing every two minutes to rant once they get to the Pyramids of Giza part bc I was one of those Egyptology kids and I will NOT stand for this fucking SLANDER

#''oh how did they align the pyramids with Orion's belt?'' THEY LOOKED AT THE SKY#navigation via stars was SO crucial in desert areas they were HUGE stargazers#I mean there's a reason a lot of stars have Arabic names#bc Arabic people named them using them to navigate#''how are they so well-preserved?'' it's a fucking DESERT#''they align with magnetic north'' MAGNETS EXIST IN NATURE#''the shapes are perfect'' MATH IS MATH. GEOMETRY IS GEOMETRY.#btw the first two ''examples'' in the video are also bullshit#but they aren't on a subject I read extensively about as a smol#and also Ryan didn't disrespect those cultures quite as much as the Ancient Egyptians#so I didn't have quite as strong reactions to it#anyways Shane is so based in that episode and Ryan is the wrongest he's ever been#the roommate and I kept ranting about how Wrong Ryan is being#Ghoul Boys#Buzzfeed Unsolved#speecher speaks

96 notes

·

View notes

Text

Max Gschwind, The Van Allen Belt, 1964

#hiyutekivigil#max gschwind#the van allen belt#magnetism#planetary science#astronomy#physics#stem#space#stem academia#academia#academia aesthetic#textbook

101 notes

·

View notes

Text

"Two University of Alaska Fairbanks scientists have discovered a new type of "whistler," an electromagnetic wave that carries a substantial amount of lightning energy to the Earth's magnetosphere. The research is published today in Science Advances."

"The wave carries lightning energy, which enters the ionosphere at low latitudes, to the magnetosphere. The energy is reflected upward by the ionosphere's lower boundary, at about 55 miles altitude, in the opposite hemisphere.

It was previously believed, the authors write, that lightning energy entering the ionosphere at low latitudes remained trapped in the ionosphere and therefore was not reaching the radiation belts. The belts are two layers of charged particles surrounding the planet and held in place by Earth's magnetic field."

"Review of plasma wave data from the Van Allen Probes showed that specularly reflected whistlers are a common magnetospheric phenomenon."

continue reading

#astronomy#space#earth#solar energy#earth atmosphere#magnetic field#electromagnetism#magnetism#energy#electricity#van allen belt#magnetosphere#wavelengths#lightning#atmospheric layers#plasma#protection#science

5 notes

·

View notes

Text

I still haven't tried beating the E4 btw I just finished level grinding my team in the daycare AND picking up extra rare candies and PP up with a Meowth squad but I'm Still not satisfied so I'm chasing type enhancing items with Thief. Because I'm a normal person

#i still need the spell tag twisted spoon sharp beak and black belt i think#im being extremely cautious yes#btw i caught articuno in seafoam islands so itd count as my encounter before anything else LMAO#might do the same with zapdos and hunt the magnet later 👍#bitch mantis

9 notes

·

View notes

Text

Since GDQ is almost over (and they were shown off on there) I’ll finally show these off! I made these child link and zelda dolls for GDQ!

Their arms and legs have wire so they can move and the ocarinas, navi, and the sword all have magnets in them as well as the belts and hands so they can be held!

It was really fun to figure out how to make each individual piece and how to sew them together

#the magnets were hard to do but fun!#zeldas necklace and belt buckle was difficult#i had to tatt the ruby for the necklace#crochet#ocarina of time#legend of zelda

4 notes

·

View notes

Text

I'm starting to make some more complicated levels for later in the game: larger turns, faster movements, more things to keep track of!

#gamedev#indiedev#gaming#indie games#golf#game physics#steam games#screenshotsaturday#magnetism#conveyor belt#fast

16 notes

·

View notes

Text

UGH Why do so many songs I want to sing require a huge amount of charisma to pull off.

#creepy? good. pathetic? good. awkward? good. murder? excellent.#confidence? magnetism? FUCK no.#I promised I'd sing a Gay Song if the anime lesbians won and it's looking like they actually might#and everything I can find that's in my vocal range (i.e. NOT TOO LOW) is a duet or is about 'women love me I'm an icon'#slash 'I'll steal your girl' which TO BE CLEAR I am in favor of these songs existing I think we need even more of them actually#but there is no way in HELL I could ever make something like that work it would be THEEEEE biggest joke in the universe#so there's nothing for me to comfortably sing ;-;#unless you count 'lacy' as a gay song which I go back and forth on#I GUESS I could do rem's sacrifice song in the musical but that song is HARD I do not think ANYBODY wants to hear me sing that lmao#I USED to be able to fully belt 'you oughta know' (of which there IS a gay Broadway Version) and that was my one (1) pop/karaoke song.#but I can't do that anymore.#I might be able to build it back up again but that would take. a while. it's not something I could toss out within the week of the poll#ending (if they win)#ugh why did I stop singing every day I don't know how to do anything anymore a;lsfkja;slfjadslfk#unhinged lady screams about music

4 notes

·

View notes

Text

ok everybody wish me luck in packing the day i move. (tomorrow)

#i packed my clothes and now im so tired. zzzz#i have so many miscallaneous stuff And also i don’t know where im going to put all my random tiny accessories my desk at my apartment is not#that big 😭 my two jeans my 3D printed skull my lego bat characters this tiny music box my playbills for wicked and hadestown#my copies of traitor and tyrant baru that are just my emotional support my atsv art book my. okay that was just a packing list thanks for#coming. my belts my earrings my rings my necklaces my um. lotion. my gamer heart magnet me and my roomie bought togetherhsxhdhdhj#esha.txt#well. at least it’s mostly all set up (same apt as last year) it’s just cleaning and all the clothes and food restocks

17 notes

·

View notes

Text

KIM PANTS.

#some shit#wearing themmmm...#i got a medium and its a tight medium but were good. dont need a belt.#the fabric is. very soft. did not expect that#long legs but not too long. im very short.#magnet pocket closings. nifty..#oh and. button fly. cause. as a gay person i always need to take longer going to the bathroom.#feeling for the various seams. lots of darts i think!#including! horizonal? at the knee?? fascinating...

6 notes

·

View notes

Text

Y’all, our “casual” cosplays for day two of TFCon look so good. I’m so happy. Wife is going as Chromedome and I’m Rewind.

They were just supposed to be comfortable and easy to move around in but god they look great. Anyone that has ever been on a film set/knows how they function will immediately recognize what I’m doing with my utility belt too!!!! I’ll be walking around with my Minolta film camera and my Zoom H6 too to capture some “memories” in an 80’s way (from consenting cosplayers of course.)

#even my nylon straps look like magnetic tape or film reels#sosososososooooo happy#tempted to stick my dome and Dominus toy in my utility belt but I don’t want them hurt so best to leave them home#op text#tfcon 2022

4 notes

·

View notes

Text

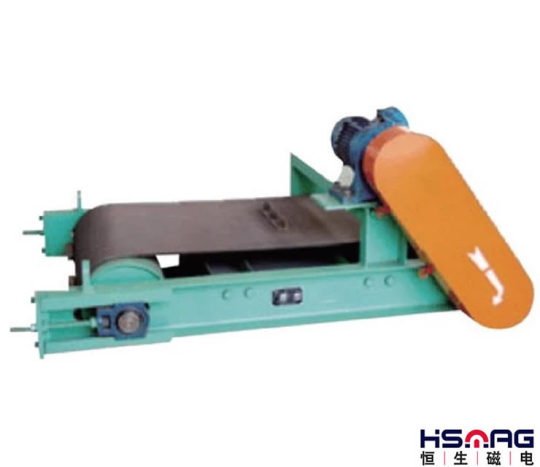

Quality Assurance Practices of Top Belt Type Magnetic Separator Manufacturers

Introduction Of Belt Type Magnetic Separator Manufacturers

In industries where material purity and contamination control are paramount, belt type magnetic separators play a crucial role. These separators are designed to remove ferrous contaminants from bulk materials, ensuring the quality and safety of products. Maintaining high-quality standards is essential for manufacturers to provide reliable and effective separators. The top belt type magnetic separator manufacturers employ rigorous quality assurance practices to ensure their products meet industry standards and deliver optimal performance. Here’s an in-depth look at these practices and how they contribute to the overall quality of magnetic separators.

1. Comprehensive Material Testing

Top belt type magnetic separator manufacturers begin their quality assurance process with rigorous material testing. The selection of raw materials is critical as they directly impact the durability and effectiveness of the separator. Manufacturers test the quality of materials like steel, magnets, and other components to ensure they meet specific standards for strength, resistance to corrosion, and magnetic performance. This testing helps in preventing issues such as material degradation and ensures that the separators will perform reliably in demanding industrial environments.

2. Precision Engineering and Design

Engineering precision is crucial for the effectiveness of belt type magnetic separators. Leading manufacturers invest in advanced design and engineering practices to ensure that each separator is built to exact specifications. Computer-aided design (CAD) and finite element analysis (FEA) are commonly used to create detailed models and simulations of separators. These tools allow manufacturers to identify potential design flaws and optimize performance before production begins. Precision engineering ensures that separators have the correct magnetic strength, belt speed, and configuration to effectively remove contaminants.

3. Strict Manufacturing Standards

Manufacturing processes are carefully monitored to maintain high-quality standards. Top manufacturers adhere to stringent quality control procedures throughout the production cycle. This includes:

In-Process Inspections: Regular inspections during the manufacturing process help identify and address any defects or deviations from specifications. This proactive approach ensures that issues are resolved before they affect the final product.

Welding and Fabrication Checks: Quality assurance practices involve inspecting welds and fabrications to ensure structural integrity and durability. Any inconsistencies are corrected to prevent future failures.

Assembly Procedures: Precise assembly techniques are employed to ensure that all components fit correctly and function as intended. This includes aligning magnetic elements, adjusting belt tension, and ensuring proper calibration.

4. Performance Testing

Performance testing is a critical aspect of quality assurance for belt type magnetic separators. After assembly, each separator undergoes thorough testing to verify its performance. This includes:

Magnetic Field Testing: Measuring the magnetic field strength and uniformity to ensure it meets the specified standards for effective contaminant removal.

Capacity and Efficiency Testing: Testing the separator’s capacity to handle different flow rates and materials, ensuring it operates efficiently under various conditions.

Operational Tests: Running the separator through simulated operational scenarios to assess its reliability and performance in real-world conditions.

5. Compliance with Industry Standards

Top belt type magnetic separator manufacturers ensure their products comply with relevant industry standards and regulations. This includes adherence to:

ISO Standards: Many manufacturers comply with International Organization for Standardization (ISO) standards, which outline requirements for quality management systems and product specifications.

CE Marking: For products sold in Europe, manufacturers ensure compliance with CE marking requirements, which indicate that the product meets European safety and performance standards.

Material Safety Standards: Compliance with standards related to the use of safe and non-toxic materials is also essential for manufacturers.

6. Continuous Improvement and Innovation

Quality assurance is not a one-time process but an ongoing commitment. Leading manufacturers continually seek ways to improve their products and processes. This involves:

Feedback and Analysis: Collecting feedback from customers and analyzing performance data to identify areas for improvement.

Research and Development: Investing in research and development (R&D) to innovate and enhance magnetic separator technology, incorporating the latest advancements and materials.

Training and Development: Providing ongoing training for staff to ensure they are knowledgeable about the latest quality standards and manufacturing techniques.

7. Comprehensive Documentation and Reporting

Maintaining thorough documentation is a key aspect of quality assurance. Manufacturers keep detailed records of material tests, design specifications, production processes, and performance tests. This documentation provides a traceable history of each product, which is essential for quality control and addressing any future issues. Additionally, manufacturers produce detailed reports that are reviewed regularly to ensure compliance with quality standards and identify opportunities for further improvement.

8. Customer Support and Service

Top manufacturers understand the importance of providing excellent customer support. Quality assurance extends beyond the production phase to include post-sale support. Manufacturers offer:

Installation Guidance: Assistance with the installation of separators to ensure they are set up correctly and function optimally.

Maintenance Services: Providing maintenance and repair services to address any issues that may arise during operation.

Technical Support: Offering technical support to help customers with troubleshooting and optimizing the performance of their separators.

Conclusion

Kumar Magnet Industries, a leading belt type magnetic separator manufacturers and roller type magnetic separator manufacturers, provides high-performance separators designed for effective contamination control and enhanced material processing in diverse industrial applications. Through comprehensive material testing, precision engineering, strict manufacturing standards, and continuous improvement efforts, manufacturers deliver separators that meet high quality and performance standards.

0 notes

Text

Electromagnetic Magnetic Cross Belt Separator

Electromagnetic Magnetic Cross Belt Separator

Electromagnetic Cross Belt & Inline Separators for High Performance and Hi Volume Separation requirements.

Ø IN-STOCK Ready to Ship Models: 30 to66″ Square Electros covers 85% applications while other sizes are available and manufactured as needed.

Ø Hi-Intensity Electromagnetic Separators – Exclusively vacuum impregnated coils for higher operating…

#Electro Overband Magnet#grate magnets#Industrial Magnetic Tools#magnet applications#Magnet Maker#Magnetic Application#Magnetic Cross Belt Separators#magnetic field#magnetic grate separators#magnetic hump#magnetic properties#Magnetic Separator#magnetic separators#magnetic tool moulds#Magnetic Tool Show#Magnetic Tools#magnetic traps#NdFeB Application#Overband Magnet#Overband Magnetic Separator#Permanent Cross Belt Magnet#Permanent Suspension Magnets#Self-clean Overband Magnet#Suspension Magnets

0 notes

Text

The Moon Landing Hoax Exposed: Did we go to space? (Documentary 2022)

youtube

The Moon Landing Hoax Exposed

#moon landing hoax#moon landing hoax exposed#july 20th 1969#buzz aldrin#neil armstrong#jfk#september 12 1962#youtube#marcus allen#nexus magazine#van allen radiation belt#magnetic storm#vacuum of space#micrometeorites#nasa#hadley rille#kaguya#apollo 11#manley p hall#secret socities#dwight eisenhower

0 notes

Text

#bussiness#industrial#Belt Conveyors in Hyderabad#Conveyor Belt Manufacturers in Hyderabad#Inclined Belt Conveyors in Hyderabad#Side Wall Cleated Belt Conveyors in Hyderabad#Modular Belt Conveyors in Hyderabad#Chain Conveyor Manufacturers in Hyderabad#Slat Conveyor in Hyderabad#Take Off Conveyors in Hyderabad#90 Degree Skate Wheel Roller Conveyors in Hyderabad#90 Degrees Magnetic Bed Slat Chain Conveyors in Hyderabad

1 note

·

View note