#robotics 3dprinting 3ddesign 3dprinted

Explore tagged Tumblr posts

Video

instagram

How many times have you played this game when your internet went down?? - - Make sure to check out more cool projects from @David zindustries - - Posted @withregram • @davidzindustries Tristable compliant mechanism🔥 The process of designing compliant mechanism is actually very immature nowadays, I've use different simulating softwares, topology optimizers, Matlab implementations, etc... We have nothing basically😅 That's why intuition is the best way for us to make them, after a while you start understanding how flexures work and how to use them🧡 I haven't made it yet, but I'm really really close, maybe it's absolutely necessary to add a forth bistable mechanism although in theory 3 should be enough🤔 For more content: @davidzindustries . . . #3dprinting #3ddesign #engineer #industrial #arduino #tecnología #3dprints #industrialdesigner #productdesigner #mechanisms #3dprinters #3dmodels #invent #3ddruck #impresora3d #robotics (at Busan, South Korea) https://www.instagram.com/p/CEtw5RwjEiw/?igshid=wotaskeg6f0d

#3dprinting#3ddesign#engineer#industrial#arduino#tecnología#3dprints#industrialdesigner#productdesigner#mechanisms#3dprinters#3dmodels#invent#3ddruck#impresora3d#robotics

6 notes

·

View notes

Video

Gerçekten çok başarılı.🖍👌🏻🤖 . . . Daha iyi içerikler için 👉 @antalyamaker Sektörü takip etmek için 👉 @antalyamaker Bize destek olmak için 👉 @antalyamaker . . . Beğen, yorum yap, arkadaşların ile paylaş 😊 DM for credit or removal request (no copyright intended) All rights and credits reserved to the respective owner(s) #tag #friends #follow #instructable #arduino #drawing #robot #photo #robotikkodlama #robotik #robotikkodlamaantalya #3dprint #goodnight #3ddesign #3dtasarım #3dprinter #kodlama #3dbaskı #tinkercad #antalya #fritzing #students #course #robotics #engineering #electronic #technology #maker #antalyamaker #mhtrobotik (Robotik Kodlama Antalya) https://www.instagram.com/p/CGcTIr-Dlxp/?igshid=9hk2j9z3t1q2

#tag#friends#follow#instructable#arduino#drawing#robot#photo#robotikkodlama#robotik#robotikkodlamaantalya#3dprint#goodnight#3ddesign#3dtasarım#3dprinter#kodlama#3dbaskı#tinkercad#antalya#fritzing#students#course#robotics#engineering#electronic#technology#maker#antalyamaker#mhtrobotik

2 notes

·

View notes

Photo

So, what did those back of the envelope scribbles become? An enclosure for the NXT/EV3 breakout boards I can mount them in my builds and wire to a breadboard or microcontroller. The lid has the perfect click interference fit to the main enclosure body, first try! Math works my friends! #robotics #lego #nxt #ev3 #technic #3ddesign #3dprinting https://www.instagram.com/p/B9DC3jfpspM/?igshid=1d15zfofhoemn

1 note

·

View note

Photo

More work in progress. Photon blade • • #modibot #modibotsystem #indietoys #3ddesign #3dprinting #3dprinted #prototype #prototyping #characterdesign #character #stopmotion #diy #creativeplay #actionfigures #toystagram #robo #transformers #gundam #gunpla #robot #mech #mecha #kaiju #pacificrim (at San Francisco, California) https://www.instagram.com/p/B0lxhutHu8A/?igshid=13s4ms8dk4pmu

#modibot#modibotsystem#indietoys#3ddesign#3dprinting#3dprinted#prototype#prototyping#characterdesign#character#stopmotion#diy#creativeplay#actionfigures#toystagram#robo#transformers#gundam#gunpla#robot#mech#mecha#kaiju#pacificrim

1 note

·

View note

Text

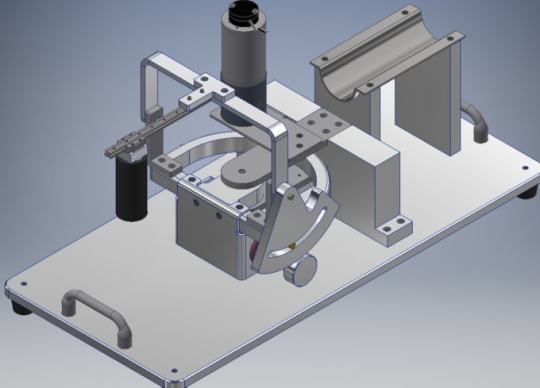

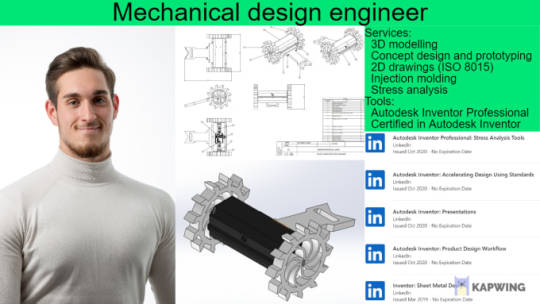

3D CAD Models

3D model are made by CAD drafting administrations that represent considerable authority in 3D Modeling. These organizations a larger number of times than most are in the mechanical drawing field since they manage mechanical parts that should be 3D demonstrated with extraordinary programming. Modeler's are presently beginning to utilize CAD programming that is amazingly comparative in a significant number manners. For example, you can make 3D dividers and entryway's by choosing which measurements you need and embeddings them into the CAD drafting programming. It will in a flash make a divider with a precise width, length, and stature.

Innovation is truly beginning to get on with regards to plan and planning 3D CAD models. You can really plan something on CAD like a stuff for example. Send the attracting record to an exceptional shop that has CNC machines made explicitly for machine parts, and have it made in a moment. This could be utilized for quite a few things like parts on the space transport, or shouldn't something be said about a bike outline. The impediments to 3D CAD models are essentially boundless. Anything the psyche can envision, can be planned with this CAD drafting apparatus, and nothing is far off. The lone thing keeping somebody away from planning any 3D CAD model they need is their creative mind.

Exclusively On Fiverr By verlorant

3D CAD displaying has assumed control throughout the times of the customary artists and his drafting table. With a variety of apparatuses at the fingertips of the CAD drafter the drafting board doesn't get an opportunity. Trust me however I'm not incredibly energized or anything, I really grew up utilizing one of these and that is the motivation behind why I'm in the drafting field now. Innovation with 3D CAD models is simply going to get further developed, and easy to understand over the long haul, and more refined plans will be delivered simultaneously. On the off chance that you might want to study CAD drafting administrations visit eLine Design. To know more visit the official website http://bit.ly/2YOeSXe

0 notes

Photo

Design of #Rainbowt goes on even during the night. I've designed the top plate made to mount an #Arduino. I've made also some tries for making a support for HC-SR04 #ultrasonic sensors. Now I'm printing 2 brackets for the top plate: one of them will hold the ultrasonic sensor. . . . . . . . . #3dprinting #3dprint #manufacturing #fablab #design #3ddesign #robotic #robotics #mechatronics #engineering #electronics #makersgonnamake #makers #makershed #printer #pla #tinkercad #fusion360 #autodesk #openscad #3dprinted https://www.instagram.com/p/CAi_4VdKH5X/?igshid=1nb6699gmycpf

#rainbowt#arduino#ultrasonic#3dprinting#3dprint#manufacturing#fablab#design#3ddesign#robotic#robotics#mechatronics#engineering#electronics#makersgonnamake#makers#makershed#printer#pla#tinkercad#fusion360#autodesk#openscad#3dprinted

0 notes

Video

instagram

From an idea to a finished project in a few days! 🤖 New video up on the YouTube channel of this 3D printed solder smoke extractor. Links to all files and materials in the video description. . . . #3dprinting #imadethis #autodeskfusion360 @autodesk #3dprintee #3dprint #electronics #autodesk #soldering #3ddesign #youtube #robot #diy #artstudio #makerspace

#soldering#3dprintee#electronics#3dprinting#imadethis#autodeskfusion360#autodesk#makerspace#3ddesign#robot#youtube#3dprint#diy#artstudio

2 notes

·

View notes

Video

instagram

This is definitely a program I have to try! It would be a lot of fun for our students too!! Posted @withrepost • @myminifactory 'Learn by making'! Want to learn robotics without taking out a student loan?! 👾🛠⛓ @almas_robotics obotics makes it easy to learn and easier to assemble ❌ No screws 💻 Learn coding 🖨 Test your 3d printing skills 🎛 Practice with programmable boards 🤖 Learn robotics like a Newbie and transform into a pro This Educational Robot Arm called "The M First." will teach you everything you need to know at your own pace in whatever environment you prefer! How cool is that?!? 🔧⚙️🧰 Design by @almas_robotics available on @myminifactory Have you used arduino? Tell us about your first experience in comment section!⬇️⬇️ link in bio @myminifactory Tag a friend who loves engineering ‼️ . #myminifactory #creativityfound #creativelifehappylife #3dprinting #3dprinted #impression3d #3dprint #3ddesigns #innovation #creativity #creativityfound #creativelifehappylife #3ddesigns #3dprint #3dmodel #3d #3dprinted #arduino #robotics #3deducation #roboticarm #mechatronics #3dprintedarm (at 부산 용호동 Lg메트로시티) https://www.instagram.com/p/B2X-xb2nP5P/?igshid=19jxujx5bjvss

#myminifactory#creativityfound#creativelifehappylife#3dprinting#3dprinted#impression3d#3dprint#3ddesigns#innovation#creativity#3dmodel#3d#arduino#robotics#3deducation#roboticarm#mechatronics#3dprintedarm

1 note

·

View note

Photo

Dirençlerle oluşturmuş bir sanat eseri.🕸🤖 . . . Daha iyi içerikler için 👉 @antalyamaker Sektörü takip etmek için 👉 @antalyamaker Bize destek olmak için 👉 @antalyamaker . . . Beğen, yorum yap, arkadaşların ile paylaş 😊 DM for credit or removal request (no copyright intended) All rights and credits reserved to the respective owner(s) #tag #friends #follow #instructable #robot #Arduino #spider #photo #robotikkodlama #robotik #robotikkodlamaantalya #3dprint #art #3ddesign #3dtasarım #3dprinter #kodlama #resistor #raspberrypi #antalya #arduinoproject #students #course #robotics #engineering #electronic #technology #maker #antalyamaker #mhtrobotik (Robotik Kodlama Antalya) https://www.instagram.com/p/CEC1eNNJDtc/?igshid=qthwc73pio2x

#tag#friends#follow#instructable#robot#arduino#spider#photo#robotikkodlama#robotik#robotikkodlamaantalya#3dprint#art#3ddesign#3dtasarım#3dprinter#kodlama#resistor#raspberrypi#antalya#arduinoproject#students#course#robotics#engineering#electronic#technology#maker#antalyamaker#mhtrobotik

1 note

·

View note

Text

Manually testing the delta robot mechanics. The next step is to mount the stepper motors and write some inverse kinematics code...

#3Dprinted #3dprinter #3dprint #3dprinting #3ddruck #3ddrucken #arduino #28byj48 #fusion360 #cad #caddesign #diy #diyelektronics #prusaprinters #prusai3 #prusai3mk3s #3ddesign #nodemcu #deltarobot #inversekinematics

#3dprinting#3dprinter#3dprint#3dprinted#3d printing#3d print#3d printer#prusai3mk3s#fusion360#3d druck#3d design#delta robot#nodemcu#diy arduino

3 notes

·

View notes

Photo

What’s a P.A.U.L.bot? You may have noticed that some of the tiers on my Patreon include a P.A.U.L.bot. So what exactly is a P.A.U.L.bot? Simply put it’s a little helper from my shop. The original design of the P.A.U.L.bot came from babanillustrations (twitch.tv/babanillustrations), and you can see an image of it on the header of the Patreon page. I’ve taken that image and created a 3-D version of the robot and we are now making toy versions of them as collectibles for you. Each month I’ll be creating a new version as either a 3D printable file for you or as a physical copy sent to your door. We have big plans for the P.A.U.L.bots, so be sure to start collecting them now. Link in bio. #paulpapedesigns #paulbot #twitch #patreon #design #3dprinting #3ddesign (at Paul Pape Designs) https://www.instagram.com/p/CPTtE4sN1S5/?utm_medium=tumblr

1 note

·

View note

Video

instagram

Day 2 Working on the body now, the head is now finished and I’m still using tinkercad

#art🎨 #art #drawing #sketch #illustration #daily #dailyart #b0nes_21 #conceptart #concept #characterdesign #character #artofinstagram #toy #robot #tinkercad #3d #design #workinprogress #wip #3dprinting #3ddesign (at New York, New York)

#3dprinting#dailyart#characterdesign#concept#3ddesign#robot#character#drawing#3d#wip#tinkercad#sketch#conceptart#art🎨#workinprogress#design#art#toy#daily#illustration#bones-21#artists on tumblr

13 notes

·

View notes

Video

youtube

Robotics Project: 3D Printed Arm Assembled!

0 notes

Text

Pulley & Belt Transmission

Admittedly, building a robot arm joint transmission is way more difficult than I expected. But where's the fun in a simple project? In my last post, I explained why a geared transmission doesn't work. This week I'll try a new approach.

As hinted in my last post, I'll give a timing belt and pulley transmission a go. The added benefit of using transmission pulleys in stead of gears is that I'm able to 3D print them. Since the force will be distributed over 50% of the pulley teeth, 3D printed pulleys should be able to handle the necessary torque.

I printed a small prototype to see if 3D printed pulleys would work, and although GT2 pulleys are on the limit of what is printable with a 0.5mm nozzle, they work absolutely fine. Just make sure the belt tension is sufficient.

So after my prototype had proven the possibilities of 3D printed pulleys I started working on a full fledged transmission.

The small (bought) pulleys I use are 20 teeth, so by using 80 teeth large (3D printed) pulleys, there is a 1:4 speed reduction. Since I aim for a 1:16 speed reduction, I needed to put two 1:4 reductions in series.

The "packaging" of the transmission matches the 60mm diameter pipe I'll be using fo the robot arm body.

After a few hours ... days ... of Fusion 360, the render looked extremely promising!

Of course, I need to do some real world testing before I can say anything about the accuracy, speed and torque. So fire up the Lulzbot, feed it some FormFutura HDglass, and start the printing!

Since the Lulzbot Mini has a print bed of 150x150 mm, the joint is built up by three separate pieces. Not only does this allow me to overcome the size limit, but it also helps in preserving strength and print quality by alternating the print orientation.

The 3D-printed body is provided with ball bearings which accommodates the 5mm and 8mm shafts. As a shaft, I simply use some hex head bolts. Bolts aren't precisely sized, but are very convenient to attach to a 3D printed part. Together with the ball bearing, the bolts seem to do their job.

I initially expected that I needed to add belt tensioners, but by calculation the needed pulley distance, I was able to get a perfect belt tension.

In the photo below, the large pulley on the main shaft only has one set screw. It turns out this wasn't sufficient, so I ended up redesigning this pulley to accommodate two 3mm setscrews.

The main shaft (bolt) will be attached to the matching joint part. this part might eventually get a redesign, but for now it will be used to temporarily mount a piece of 60mm pipe.

To make the test setup look a bit more impressive, I sticked an old joint prototype in the end of the pipe (and used some black electrical tape to keep it in place).

So there you have it. The one axis prototype of my robot arm. I can't wait to give it a test spin! So without further ado, I present you the first results:

youtube

It works wonders! The accuracy is impressive, there is no backlash and the torque is much higher than I expected. As a matter of fact, I wasn't able to stall the motor. The first point of failure where the slipping setscrews of the pulley. I managed to solve this, by flattening the bolt on the position of the setscrews. I'll do some actual torque tests as soon as I've manages to mount the joint in a proper way (in stead of the electrical tape).

The video also shows the acceleration and deceleration of the joint. This is not due to a spin up or spin down of the motor, but programmatically generated by the AccelStepper motor library I use. This is fully configurable (as well as the maximum speed).

The next steps on the to-do lists are properly mounting the joint and designing some nice covers to hide the pulleys and belts. But more important: getting real time absolute position feedback by using an encoder. Stay tuned!

Let me know what you think about this design in the comments down below!

#robot#robotics#engeneering#3dprinting#3ddesign#fusion360#formfutura#hdglass#lulzbot#stepper#nema17#accelstepper#arduino#video#prototype#pulley#belt#gt2#transmission#joint

4 notes

·

View notes

Photo

Finished to print the bracket for Micromotors E192 #gearmotor. It's *perfect*. I shared the STL file on #thingiverse: see my last post on my #blog: https://www.settorezero.com . . . . . . . #robotic #robot #engineer #engineering #3dprinting #3dprinter #3dprint #3ddesign #3dmodeling #tinkercad #openscad #onshape #electronics #developer #motor #automation #engine #coder https://www.instagram.com/p/BtJa4UDncH0/?utm_source=ig_tumblr_share&igshid=rbrps6boy3mb

#gearmotor#thingiverse#blog#robotic#robot#engineer#engineering#3dprinting#3dprinter#3dprint#3ddesign#3dmodeling#tinkercad#openscad#onshape#electronics#developer#motor#automation#engine#coder

0 notes

Photo

3D Printable Iris mechanism-3DP2BLROD10A Iris mechanism or taiji mechanism designed for 3d print. There are 2 leaves. Then you rotate the "Drive Part"or the middle plate, the center hole can open or close gradually. The center hole is diameter 10mm, the outer size is diameter 36mm and thickness is 8.2mm. #mechanical design #mechanicaliris #irisdiaphragm #irismechanism #shutter #3dprint #3dmodel #3ddesign #taiji #robotic

0 notes