#CFIA

Text

"The Canadian Food Inspection Agency (CFIA) is recalling Quebec-made cheese fondues under brand name “1001 Fondues” due to possible Listeria contamination.

The affected products were sold in Quebec, Ontario, British Columbia, Alberta and Nova Scotia[...]

The CFIA has a complete list of affected products including UPC codes, lot numbers and best before dates on its website."

Full article

Tagging: @politicsofcanada

#cdnpoli#canadian politics#canadian news#canada#canadian#food recall#product recall#canada product recall#canadian food inspection agency#CFIA

79 notes

·

View notes

Text

#photography#black and white#gif#music#horror#movie#movies#ilustracion#skate#halloween#flash gordon#cfilm#cfia#bad movies#teddy bear#ted bear

3 notes

·

View notes

Text

"Breaking: Avian Influenza Outbreak Detected in Nova Scotia Poultry Farm - Canadian Food Inspection Agency Takes Action" #BirdFluOutbreak #CFIA #PoultryIndustry #BiosecurityMeasures

“Breaking: Avian Influenza Outbreak Detected in Nova Scotia Poultry Farm – Canadian Food Inspection Agency Takes Action” #BirdFluOutbreak #CFIA #PoultryIndustry #BiosecurityMeasures

The Canadian Food Inspection Agency (CFIA) has confirmed an outbreak of avian influenza, commonly known as bird flu, at a poultry farm in Port Maitland, Nova Scotia. The virus was detected in turkeys on the farm, and…

View On WordPress

0 notes

Text

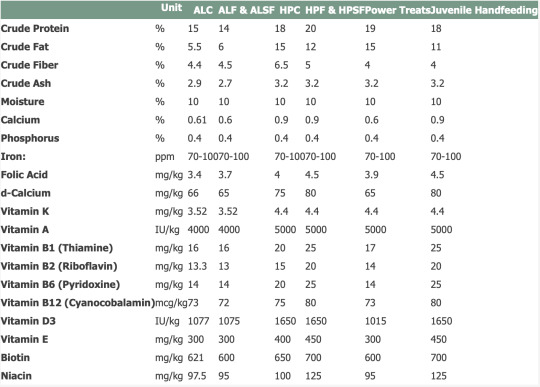

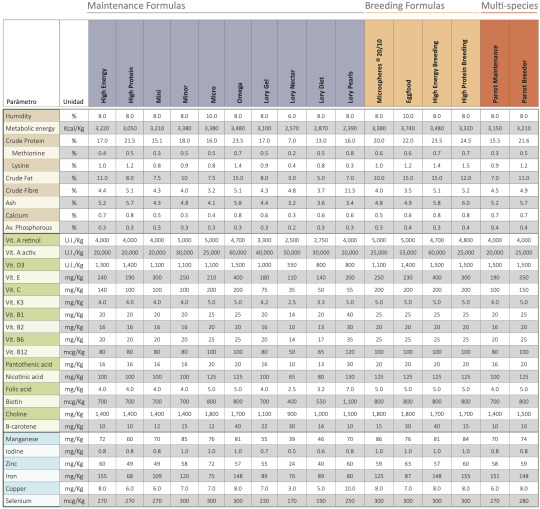

Transparency With Parrot Food Manufacturers

There's been a significant rise in the expectation of transparency between pet food manufacturers and the general public. Dog food manufacturers, for example; have AAFCO, feeding trials, and an array of nutrient digestibility charts, base nutrient expectations, and sanitary guidelines to follow which a lot of brands then openly share with the public. These standards help pet parents make more active choices in what they feed their pets, tailor their pets diet to meet their individual needs, trust that their food meets a base line of nutrition, and that the food was produced in a sanitary manner. The dog food industry is far from perfect and even these regulations have their flaws and the tests aren't without fault but it is a good base for us to compare to when we're trying to sort out what we want from other pet food manufacturers. In this case I'm focusing on parrot pellet manufacturers.

I had a few different goals heading in to this.

I wanted to see how transparent pellet manufacturers would be with sharing information that is common to ask dog food manufacturers (information is not confidential, revealing formulas, secrets, etc.)

The availability of nutrient analysis charts (breakdowns of how much of each nutrient is in their pellets)

What standards parrot food manufacturers held themselves to

If any feeding trials were performed on their pellets

And to preface this with my own bias, I am pro-pellet, I currently feed pellets.

Before we get too deep in to this let's break things down a bit.

As it stands there really aren't any regulating bodies above parrot food manufacturers as far as I could find. There doesn't seem to be much of any standards when it comes to their sanitization or product quality, the best you get is the FDA/ CFIA which basically just make sure a food isn't outright toxic. As it stands there haven't been enough studies done on parrot nutrition for there to be a governing body stating what the minimum nutrient requirements are for parrot food, we simply do not actually know what those requirements are yet so there cannot be a set standard for it. This unfortunately leaves us open to a lot of problems, if there's no nutritional requirements and no standardized testing then we're really just putting a lot of trust in to a company that wants to turn a profit. We're hoping that the food that says it's nutritionally complete is what it says with no evidence to show for it, and no science to confirm it.

So with that said no parrot food can actually claim to be "100% nutritionally complete", we do not know what nutritionally complete looks like for parrots, there is no science to back up those claims.

So I set out and emailed every parrot pellet manufacturer I could think of and asked them the some questions.

"Does your company do feeding trials? If so, is that data available to the public anywhere?"

"Do you have a nutrient profile available?"

Feeding trials are very simply a test where you feed a set of animals exclusively one diet and then monitor them to see if the food is capable of providing the base essential nutrients needed to live. Usually they do blood work, urine and fecal alongside regular physical exams to monitor things like nutritional deficiency, ailments, and nutrient digestibility. This helps show that a food is capable of providing what the target animal needs to survive without causing health problems and provides vital information on what amount of vitamins/ minerals in the produced food are actually being digested and absorbed. These tests are common among well-known dog food companies and most are more than willing to share that data to give their consumers peace of mind with easy transparency.

And let me tell you I am beyond disappointed at what happened when I asked parrot food manufacturers the exact same thing.

TOPs: No nutrient profile listed on the website, does have a detailed breakdown of why every single ingredient was added though. Happily discloses that parrot nutritional science doesn't have all the data to claim any food as 100% nutritionally complete and advises for the feeding of fresh foods in addition to their food, didn't specify exactly how much of each to maintain optimal nutrition.

I emailed them three times and never got a response back from any of them.

Harrisons: Does say you can feed 20% vegetables by weight while the pellet should be 75%, has an easily available nutrient analysis on their website.

also emailed three times with no response back.

Caitec: no nutritional analysis listed on their main website, website did not state how they want their product to be fed, product packaging states that veggies should be a treat/ addition and lists the pellet as a "complete diet".

emailed three times with no response back.

Lafeber: Primarily promotes mixed seed and pellet formulas, doesn't state any risks of parrot's selective consumption (study on that problem), does promote the feeding of fresh produce in conjunction with their formulas at 20% of the diet, no nutrient analysis on their website.

emailed three times with no response back.

Zupreem (Compana Pet Brands): did respond back but they phrased their response in a way to dance around the subject, after some pushing they confirmed they do not do feeding trials. Encourages use of fresh foods with their formula, at least 60% pelleted diet recommended. Had an extremely small nutrient profile that just skipped over the important nutrient requirements like the Ca:Ph. I asked for a nutrient profile which they did not want to provide but were able to tell me that the naturals pellets have 0.59% calcium

Roudybush: Says fresh foods can be fed but "as a minor part of the diet", does say that science doesn't have enough information to make a product tailored to each species of bird, did make changes to their formula recently to remove menadione in favour of alfalfa due to it's potential toxicity. does seem to be evolving as science progresses. Ingredients list wasn't listed on the website, nor was a nutrient profile.

did not reply to any emails.

Tropican (HARI): I was hopeful for this one by the way their website boasts about their feeding trials and research. So so hopeful.

Talks about doing feeding trials openly on their website, recommends 70% pellet to 30% fresh foods (by caloric content not weight) but mentioned that their birds eat 100% pellets. Easily accessible albeit basic nutrient profile but it covers the main things.

After my email Mr. Hagen actually ended up calling me and what I was hoping would be a motivating call ended up being very hostile. Whenever I asked questions about data or results of a feeding trial I was immediately shut down, the topic was changed, I was interrupted mid-sentence over and over again. I was able to get small tidbits of info that were as vague as "we've fed multiple generations of birds on this food" and "we do annual weigh-ins". He would casually mention data from a study he had done but then dart away if I asked for the name of the study so I could read it later. It was an extremely off-putting phone call. Completely unwilling to say how many birds were in a trial, how many years the trial went on for, if there was bloodwork or nutrient digestibility charts, nothing at all. He also casually mentioned that once the birds are old enough they get sold to stores which was very unnerving to me.

So I guess they maybe do legitimate feeding trials but they will under no circumstances offer that data to the public? I don't know. They wouldn’t provide any published articles or data to actually prove that the trials exist and I will definitely not be contacting them again to find out. They suggested I was trying to steal their formula and lying about my identity. I'm not going to try to get a simple answer out of them again.

Mazuri: recommends 20% fresh foods 75% pellets, nutrient profile available on the website.

did not reply to any emails.

Pretty Bird: Does not do feeding trials, prompt to reply, at least knew what a feeding trial was. Couldn't find feeding recommendations on the website, no nutrient profile aside from the generic guaranteed analysis having a few add-ons but still skipping on the important nutrients you'd want to know about.

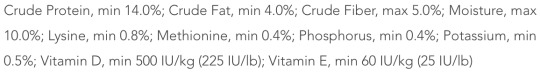

Kaytee: Did not know what a Feeding Trial was. Thought I wanted samples and offered me a coupon. I had to explain to this animal food manufacturer what a feeding trial was. Unsurprisingly they do not do feeding trials. Website had no listing of a nutrient analysis. Recommended 70-90% pellets to some fresh foods. In their own published article they went over how damaging seed diets are for parrots but then they also sell seed-only diets with the ingredients they were specifically bashing in their own article. When I asked for a nutrient profile this is what I was given:

"Nutrient levels are calculated based on ingredient data, feed compendium tables and direct diet analysis. Actual levels may vary slightly due to ingredient and analytical variation."

Kaytee exact naturals cockatiel pellet:

"0.4% Calcium

0.2% Available Phosphorus (non-phytate P)

0.1% Magnesium

120 ppm Zinc

140 ppm Iron

700 IU/kg Vitamin D3"

and that's just extremely limited information. I'm glad they were willing to provide something but in comparison to some of the others it's just not a lot of data.

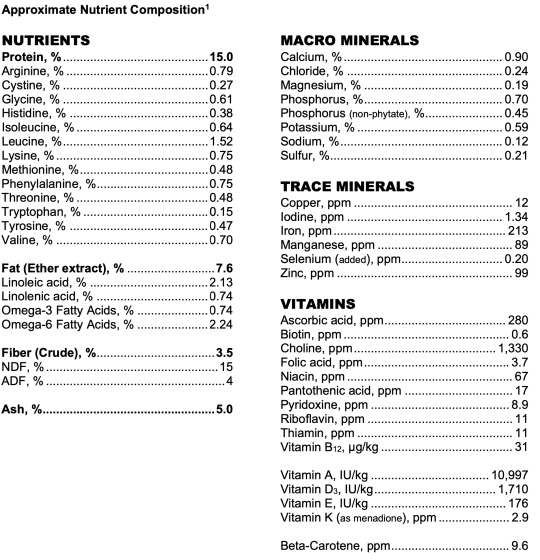

Psittacus: advises for the use of grit in parrots, recommends 100% pellets but says you can feed a minimum of 70% to make room for fresh foods. Their response to feeding trails was really vague: "our products have been evaluated and tested in our centre as well as collaborating centres. This information is for internal use and it is not published anywhere". Wouldn't say what tests were done or elaborate further than that in any way. I then inquired for a detailed nutrient analysis chart saying that Mia's calcium has been a bit of a struggle (since it has been), curious if their brand may have more calcium than the ones Im using now to help her out to which they replied with "our food contains the calcium levels appropriate for him/her". (you literally cannot say that, you haven't run tests on my bird, you haven't worked with my vet regarding my bird, you cannot guarantee a blanket statement like that.). They did offer me a link to this catalogue which has more detailed info on their pellets production and a more thorough nutrient analysis chart.

I am shocked by the responses I received. I am disappointed in parrot food manufacturers. I am frustrated with parrot food regulations.

I knew I wouldn't get much out of these emails since the standards for parrot food are so low but the amount of companies that just pretended not to get my emails or didn't even know what a feeding trial was is ridiculous. The amount of companies that were making claims that science can't back up, or making claims that science actually disagrees with is astounding.

The complete lack of transparency is terrifying.

#I am never doing this again#don’t ask questions to pet food companies they will try to throw you in jail#dude straight up was like WHAT WILL YOU DO WI THE THAT INFO YOURE NOT A VET???#HUH?????#feed my birds a diet that’s confirmed to be healthy for them……..#bring the data tm my vet and ask if this looks like a good option for my pets……#I will now be rethinking their diets entirely#thank you for coming to my ted talk#pellets#science

224 notes

·

View notes

Text

Cfiagender Pride Flag

Cfiaspec/cfia (cfiagender spectrum)/cfiaty/cfia or cisfiaspec/cisfiaty (cisfiagender/fiacis/fiacisgender): umbrella term for anyone on the "cis female" side of the viabinary-to-aptobinary spectrum.

Similar to cisera (cisgenderera/cisgendera/cisgendrera), cfeingender (cisfeingender)/CFEIN/cisfein and cfingender (CFIN) or cisfideospec/cfideospec. However, this flag includes anyone who fits both spectrums: cis* (ciaspec) and woman/female/girl/gal (fiaspec or wifgender), regardless of birth assignment (assigned gender/sex).

#mogai#mod ap#cfiaspec#ciagender#fiaspec#fiagender#cisfiaspec#cis#cisgender#cis woman#cisgender female#viabinary#aptobinary#binary#cisfemale#cisfem#cisfe#cisfeingender#cisfein#cfein#cfeingender#genderera

27 notes

·

View notes

Quote

[MFDS]韓国産ラーメンの欧州への輸出額、前年比約72%増加

グローバル輸出戦略担当官 2023-12-28

https://www.mfds.go.kr/brd/m_99/view.do?seq=47933

韓国産ラーメンの欧州への輸出額、前年比約72%増加

食品医薬品安全処は今年、食品輸出の非関税障壁を解消するため、国内輸出業界の現場の苦情を聴取し、海外の食品規制機関と協議するなど輸出支援に最善を尽くした結果、ラーメン(欧州地域)、牛肉含有食品(カナダ地域)の輸出額が前年比で少なくとも4,425万ドル以上増加し、輸出の活性化に寄与したと明らかにした。

今年の食品輸出の主な成果の一つは、代表的な国内食品である韓国産ラーメン(即席麺類)に対する欧州連合のエチレンオキシド*(Ethylene oxide、以下EO)管理強化措置の解除(’23.6.27)で、欧州連合へのラーメン輸出額が前年同期(1月~11月)比、約72%上昇(約4,400万ドル↑)**したことが分かった。

* EO:米国・カナダで農産物などの燻蒸剤、殺菌剤として使用され、国別に残留基準設定・管理

** (‘22. 1~11月) 6千1百万ドル → ('23. 1~11月) 1億4百万ドルで前年比約4千4百万ドル増加 / (‘20) 4千5百万ドル → (‘21) 5900万ドル →(‘22) 6900万ドル →(‘23.11月) 1億400万ドル/(出典:Kati農食品輸出情報)

この成果は、韓国政府がEU保健食品安全総局(DG-SANTE)に代表団を派遣し、国内安全管理政策を説明し、強化措置解除を継続的に要請するなど、多角的な努力を通じて18ヶ月ぶりに規制を解消した事例である。

<欧州連合のエチレンオキシド強化措置に関する規定(’22年2月~)>

◆ Regulation(EU) 2021/2246:第3国から輸入される製品の一時的な管理強化措置で、韓国の輸出業者が欧州に即席麺類と栄養補助食品を輸出する際、公認試験・検査機関でエチレンオキシドの最大残留水準規定の遵守可否を証明できる試験・検査成績書と公式証明書*の発行を受けて提出するように規定

* 輸出国政府機関(食品安全管理)で輸出業者の申請により発行する書類で、公認試験・検査機関が発行した分析証明書に基づいて輸出しようとする製品がEU規定に準拠して生産されたことを証明する書類

次に食薬処は、欧州連合が今年新たに導入した複合食品に対する輸入規制強化措置に成功的に対応し、欧州連合に複合食品を輸出できる国の地位を維持した。

<欧州連合の複合食品輸入強化措置の内容(’23年~)>

◆ 2023年から動物性原料に対する動物用医薬品、残留農薬など残留物質の管理を強化するために、EUに輸出が可能な国を対象に原料の原産地、トレーサビリティなどに対する政府の管理方式を毎年評価する内容で輸入規制を強化

* 韓国は2021年5月、EUに複合食品を輸出できる国リストに初めて登載されたことにより、別途の規制なしにEU又はEUが輸入を許容した国(51カ国、’22.11月基準)の動物性原料を含む複合食品の輸出が可能だった。

食薬処は食品輸出業界の意見を反映して原産地、トレーサビリティなどに対する政府の管理方案などが含まれた評価資料を作成し欧州連合に提出した結果、欧州連合から今年3月に持続的な輸出が可能だと返信を受けた。

これにより、欧州連合で国内製造飲料類、菓子類、麺類、ソース類など複合食品の持続的な輸出が可能となり、今年、欧州に輸出された複合食品の輸出額は前年より4,560万ドル増加し1億8,780万ドル*と確認された。

* 複合食品の欧州輸出額(ドル):(’22)1億4,220万 →(’23.11)1億8,780万

最後に、カナダの食肉衛生検疫管理が強化され、中断されていた調味料、豚骨スープなどの牛肉含有食品が、今年4月から再びカナダに輸出できるようになった。

<カナダにおける牛肉含有食品の輸入強化措置の内容(’20年11月~)>

◆ カナダに輸出しようとする牛肉含有食品は、HACCP適用業者で生産し、家畜伝染病伝播の恐れがないように十分な熱処理(滅菌又は食肉中心部温度70℃30分以上処理)をしなければならず、カナダ産又はカナダへの輸入が許可された牛肉原料肉(米国産、オーストラリア産など)を使用する必要がある。

* これまで別途の規制なしにカナダへ牛肉含有食品を輸出可能

食薬処は輸出資格を維持するためにカナダ食品検査庁(CFIA, Canadian Food Inspection Agency)に輸入許可を継続的に要請し、韓国の食品安全管理制度と輸出管理体系資料を迅速に提出した結果、カナダ食品検査庁で国内食品製造業者3カ所に対して輸出を優先許容するという回答を受けた。

食薬処は2024年にもアジア・太平洋食品規制機関長協議体*(APFRAS、アプラス)を通じて食品安全のための国際協力と規制調和を主導し、現場で感じる輸出業界の困難に耳を傾け、より多くの国内企業と食品が世界市場に進出できるよう最善を尽くして支援する計画である。

2024-01-29 - 食品安全情報blog2

3 notes

·

View notes

Text

Food Safety Systems Recognition Arrangement

Canada and the U.S. have a Food Safety Systems Recognition Arrangement (FSSRA). The Foreign Supplier Verification Program (FSVP) provides modified requirements to U.S. importers of food covered under the FSSRA from manufacturers in good regulatory standing with the Canadian Food Inspection Agency (CFIA).

ITB HOLDINGS LLC

390 North Orange Avenue, Suite 2300

Orlando, FL 32801

United States

T: +1 855 389 7344

T: +1 855 510 2240

T: +44 800 610 1577

https://www.fda.itbhdg.com/product/fsvp/

2 notes

·

View notes

Note

You feed raw right? I'm looking into feeding half kibble half raw and just wondering what brand you use. I feel like you always research so thoroughly that I trust your opinion

I currently feed hungry hunter (sub brand of big country raw) and rotate proteins, they meet the AAFCO nutrient profiles, CFIA standards, are readily available at common stores which make stocking up way easier, are a well established brand, and have an extended feeding trial readily available which they happily provide the full research paper for upon request (which is quite rare for raw brands currently!)

It is not the Worlds Largest Feeding Trial Ever but that’s to be expected when raw is new and research takes time.

And of course my two get annual bloodwork to ensure they’re getting everything they need and we’ve never had an issue.

I’ve tried a few brands in the past

Primal raw- is well reviewed and quite popular (and pricey here) but Yoshi hated it because the frozen meats are squeezed in to shapes which makes the meat pretty dry. Freeze dried formulas she hated no matter what we used to rehydrate the meal with

Stella and chewy’s- again well reviewed well known and expensive. I only ever used the freeze dried as treats since they have some fun exotic flavours like goose and rabbit. It was fine but Yoshi just doesn’t love freeze dried as much. Their frozen formulas are also packed in to shapes which squeezes the juice out so picky dogs might not like it

Iron will raw- I honestly loved this one and so did Yo but it ended up being difficult for me to stock up on with only one company carrying it. Lots of unique flavour options like kangaroo! great bulk boxes and mixes. Just sold in satchels so they’re bloody and delicious to picky Yoshi. They didnt have as much research backing them as my current food choice

Instinct- another highly popular and expensive brand, only ever tried their freeze dried formulas and it was /fine/ but wasn’t a favourite and so enormously overpriced. Again frozen form is Patties and nuggets which lack Juiciness

Ofc I’m in Canada so idk what brands are really going to be available to you, key things are to look for current research from the brand, if they have reports on bacteria present in packing (raw brands should regularly be testing their packs to ensure salmonella, etc. aren’t present/// far below accepted measurements in their packs) and to talk to your vet.

Yes a lot of vets will be weary when you mention it- most of them are worried about cross contamination from poor prep work and bad formulations- but often when you explain that you are a knowledgeable human being wanting to do your best here they’re willing to work with you and help. Vets will know what brands have sent pets to their ER more than others, vets will know what brands have caused deficiencies for their clients in your area. They can help you figure out what foods are available around you that they Do recommend, and what ones they really hope you stay away from.

Raw isn’t nearly as scary as it can seem once you find the right brands to work with. Keep your area clean, don’t have anything in the fridge for more than 3 days MAX and when you thaw to portion it out ensure it’s only semi thawed- you should be cutting through it with force, not like jello, otherwise you’re letting bacteria develop before re freezing it.

3 notes

·

View notes

Text

Federal officials say a destructive insect that attacks and kills ash trees has been detected in Vancouver.

It is the first detection of the emerald ash borer or its larvae in British Columbia, and is outside of currently regulated areas for the insect, the Canadian Food Inspection Agency said Thursday.

The insects are a federally regulated pest in Canada and are known to be found in six provinces.

The CFIA says they are spreading to new areas through the movement of firewood and other ash products like logs, branches and wood chips. [...]

Continue Reading.

Tagging: @newsfromstolenland

140 notes

·

View notes

Video

youtube

Creating a Preventive Control Plan (PCP) under the SFCR

Contact our offices if you need assistance with your PCP plan. As of November 1st, 2022, the CFIA will start auditing all food sectors to ensure they are compliant with THE SFCR.

You can reach us at [email protected]

We look forward to hearing from you at your earliest convenience.

2 notes

·

View notes

Text

What resources and support are available to Canadian companies seeking ISO 22000 certification?

/ Uncategorized / By Factocert Mysore

Help for Businesses Seeking ISO 22000 Certification in Canada

ISO 22000 Certification in Canada : Food safety is critical within the everchanging world of food production and distribution. The ISO 22000 Certification in Canada , globally recognized, ensures safety across the supply chain. Numerous supports can guide Canadian businesses hoping to acquire this certification. Let’s take a closer look.

1. Government Aid Programs: In Canada, both federal and provincial governments give different aid programs. This helps businesses get the ISO 22000 Certification in Canada. These often include financial incentives and training resources. For instance, the Canadian Agricultural Partnership (CAP) gives funding and technical help to agri-businesses, supporting food safety actions like ISO 22000 Certification in Canada.

2. Industry Groups and Networks: Industry groups are key to aiding Canadian businesses working towards ISO 22000 Certification in Canada. These groups, like the Canadian Food Inspection Agency (CFIA) and the Canadian Federation of Agriculture (CFA), provide resources and training focused on food safety. Through them, businesses can learn best practices and get useful advice for achieving ISO 22000 Certification in Canada.

3. Consultancy Services: Specialized consultancy firms are often used by Canadian businesses seeking ISO 22000 Certification in Canada. These firms provide personalized help like gap assessments and staff training. By working with consultants, businesses can streamline the certification process and align with ISO 22000 Certification bodies in Canada requirements.

4. Training and Education Programs: Training programs are key to building internal capacity in food safety management. Various Canadian institutions offer courses to help understand ISO 22000 Certification in Canada standards. They teach about hazard analysis, food safety protocols, and more, equipping employees with the knowledge to support certification efforts.

5. Online Support and Tools: The digital era makes it easy to find online resources and tools to help businesses get ISO 22000 Certification in Canada. Websites, online communities, software solutions, and more provide useful information and streamline the certification process.

6. Collaboration with Peers: Collaborating with others in the industry can provide valuable insight for those seeking ISO 22000 Certification Audits in Canada. Exchanging experiences can offer practical advice and foster a sense of unity, helping to improve food safety practices.

7. Certification Bodies and Accreditation Agencies: These organizations play a vital role by evaluating compliance with food safety standards. Their guidance helps businesses with the certification process, ensuring rigorous and credible results.

Conclusion:

Receiving ISO 22000 Certification in Canada is a key achievement for Canadian businesses committed to food safety. With these resources, they can get the help they need to navigate the certification process, enhance food safety practices, and prove their commitment to food excellence.

Why Factocert for ISO 22000 Certification in Canada

We provide the Best ISO 22000 Consultants in Canada who are knowledgeable and provide the best solution. And to know how to get ISO Certification in Canada. Kindly reach us at [email protected]. work according to ISO standards and help organizations implement ISO 22000 Certification in Canada with proper documentation.

For more information, visit ISO 22000 Certification in Canada.

Related links:

ISO Certification in Canada

ISO 9001 Certification in Canada

ISO 14001 Certification in Canada

ISO 45001 Certification in Canada

ISO 27001 Certification in Canada

ISO 22000 Certification in Canada

ISO 13485 Certification in Canada

CE Mark Certification in Canada

0 notes

Text

Listeria fears spur recall of T&T meat and vegetable products

Posted April 29, 2024 10:36 am

Updated April 29, 2024 11:40 am

1 min read

Image of one of the recalled products by T&T Kitchen.

Health Canada

Several meat and vegetable products from three brands are being recalled in Canada due to concerns over listeria contamination.

The Canadian Food Inspection Agency (CFIA) issued warnings on Saturday for T&T Kitchen, Kingwuu and Juewei brand items,…

View On WordPress

0 notes

Text

Apply now: https://canadianjobbank.org/administrative-assistant-163/

0 notes

Text

Chef WK, lead charcuterie specialist in Alberta Canada

Table of contents

1. Control Program Requirements for Fermented Meat Products

2. Facility and Equipment Requirements

3. Starter Culture

4. Chemical Acidification

5. Water Activity Critical Limits

6. Time and Temperature for Fermented Products

7. Fermentation Done at a Constant Temperature

8. Examples of Degree-hours at constant room temperatures

9. Fermentation Done at Different Temperatures

10. Fermentation done at Different temperatures

11. What happens if fermentation fails to hit critical limit?

12. E. coli and Salmonella Control in Fermented Sausages

13. Options for E. coli validation

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

Control Program Requirements for Fermented Meat Products

The producer must have a program in place to assess the incoming product. This program should outline specifications for the incoming ingredients. This may include criteria including receiving temperature, farm/ supplier, lot code or packed on date, species/cut etc.

2. Facility and Equipment Requirements

Equipment used in the fermentation process must be included in the operator's prerequisite control programs. These must include the following elements:

Temperature in the fermentation, drying and smoking chambers must be uniform and controlled to prevent any fluctuation that could impact on the safety of the final product.

Fermentation, drying and smoking chambers must be equipped with a shatter resistant indicating thermometer, (or equivalent), with graduations of 1°C or less. If mercury thermometers are used, their mercury columns must be free from separations. All thermometers must be located such that they can be easily read.

Fermentation and smoking chambers must be equipped with a recording thermometer for determining degree-hours calculations in a reliable manner. Recording thermometers are also preferable in drying and aging rooms but, in these rooms, it may be sufficient to read and record the temperatures 2 times a day.

Drying and aging rooms must be equipped with humidity recorders in order to prevent uncontrolled fluctuations of the relative humidity. The only alternative to an automatic humidity recorder in these rooms would be for the company to manually monitor and record ambient humidity twice a day (morning and afternoon) every day with a properly calibrated portable humidity recorder.

For routine monitoring, accurate measurement electronic pH meters (± 0.05 units) should be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument as well as recommended sample preparation and testing be followed.

When the aw of a product is a critical limit set out in the HACCP plan for a meat product, accurate measurement devices must be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument be followed.

3. Starter Culture

The operator must use a CFIA approved starter culture. This includes Freeze-dried commercially available culture as well as back-slopping (use of previously successful fermented meat used to inoculate a new batch). When performing back-slopping, the operator must have a control program in place to prevent the transmission of pathogens from when using the inoculum from a previous batch to initiate the fermentation process of a new batch. These must include:

The storage temperature must be maintained at 4°C or less and a pH of 5.3 or less.

Samples for microbiological analysis must be taken to ensure that the process is in line with the specifications.

The frequency of sampling is to be adjusted according to compliance to specifications.

Any batch of inoculum which has a pH greater than 5.3 must be analysed to detect at least Staphylococcus aureus. Only upon satisfactory results will this inoculum be permitted for use in back slopping.

This can be an expensive and a time exhaustive process and is generally avoided due to food safety concerns. AHS does not allow back-slopping.

[Chef WK was in communication with the U of A to get his method, a starter mix, studied.]

4. Chemical Acidification

If product is chemically acidified by addition of citric acid, glucono-delta-lactone or another chemical agent approved for this purpose, controls must be in place and records kept to ensure that a pH of 5.3 or lower is achieved by the end of the fermentation process. These acids are encapsulated in different coatings that melt at specific temperatures, which then release the powdered acids into the meat batter and directly chemically acidulate the protein.

Summer sausage is a very common chemically acidified product. The flavor profile tends to be monotone and lacking depth.

5. Water Activity Critical Limits

The aw may be reduced by adding solutes (salt, sugar) or removing moisture.

Approximate minimum levels of aw (if considered alone) for the growth of:

molds: 0.61 to 0.96

yeasts: 0.62 to 0.90

bacteria: 0.86 to 0.97

Clostridium botulinum: 0.95 to 0.97

Clostridium perfringens: 0.95

Enterobacteriaceae: 0.94 to 0.97

Pseudomonas fluorescens: 0.97

Salmonella: 0.92 - 0.95

Staphylococcus aureus: 0.86

parasites: Trichinella spiralis will survive at an aw of 0.93 but is destroyed at an aw of 0.85 or less.

The above levels are based on the absence of other inhibitory effects such as nitrite, competitive growth, sub-optimum temperatures, etc., which may be present in meat products. In normal conditions, Staphylococcus aureus enterotoxins are not produced below aw 0.86, although in vacuum packed products this is unlikely below aw 0.89.

6. Time and Temperature for Fermented Products

Certain strains of the bacteria Staphylococcus aureus are capable of producing a highly heat stable toxin that causes illness in humans. Above a critical temperature of 15.6°C, Staphylococcus aureus multiplication and toxin production can take place. Once a pH of 5.3 is reached, Staphylococcus aureus multiplication and toxin production are stopped.

Degree-hours are the product of time as measured in hours at a particular temperature multiplied by the "degrees" measured in excess of 15.6°C (the critical temperature for growth of Staphylococcus aureus). Degree-hours are calculated for each temperature used in the process. The limitation of the number of degree-hours depends upon the highest temperature in the fermentation process prior to the time that a pH of 5.3 or less is attained.

The operator is encouraged to measure temperatures at the surface of the product. Where this is not possible, the operator should utilize fermentation room temperatures. The degree hour calculations are based on fermentation room temperatures. Temperature and humidity should be uniform throughout the fermentation room.

A process can be judged as acceptable provided the product consistently reaches a pH of 5.3 using:

fewer than 665 degree-hours when the highest fermentation temperature is less than 33°C;

fewer than 555 degree-hours when the highest fermentation temperature is between 33° and 37°C; and

fewer than 500 degree-hours when the highest fermentation temperature is greater than 37°C.

This means that as the temperature increases, the amount of time that you have available to reach 5.3 or under is shorter. The warmer the temperature, the sharper the log growth phase of bacteria, which equates to more overshoot in lactic acid production, faster.

8. Examples of Degree-hours at constant room temperatures

Example 1:

Fermentation room temperature is a constant 26°C. It takes 55 hours for the pH to reach 5.3.

Degrees above 15.6°C: 26°C - 15.6°C = 10.4°C

Hours to reach pH of 5.3: 55

Degree-hours calculation: (10.4°C) x (55) = 572 degree-hours

The corresponding degree-hours limit (less than 33°C) is 665 degree-hours.

Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

Example 2:

Fermentation room temperature is a constant 35°C. It takes 40 hours for the pH to reach 5.3.

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C

Hours to reach pH of 5.3: 40

Degree-hours calculation: (19.4°C) x (40) = 776 degree-hours

The corresponding degree-hours limit (between 33 and 37°C) is 555 degree-hours.

Conclusion: Example 2 does not meet the guideline because its degree-hours exceed the limit

9. Fermentation Done at Different Temperatures

When the fermentation takes place at various temperatures, each temperature step in the process is analyzed for the number of degree-hours it contributes. The degree-hours limit for the entire fermentation process is based on the highest temperature reached during fermentation.

Example 1:

It takes 35 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for second 10 hours and 35°C for the final 15 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C

Hours to reach pH of 5.3: 15

Degree-hours calculation: (19.4°C) x (15) = 291 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 291 = 519

The highest temperature reached = 35°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

10. Fermentation done at Different temperatures

Example 2:

It takes 38 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for the second 10 hours and 37°C for the final 18 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C

Hours to reach pH of 5.3: 10

Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 37°C - 15.6°C = 21.4°C

Hours to reach pH of 5.3: 18

Degree-hours calculation: (21.4°C) x (18) = 385.2 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 385.2 = 613.2

The highest temperature reached = 37°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)

Conclusion: Example 2 does not meet the guidelines because its degree-hours exceed the limit.

11. What happens if fermentation fails to hit critical limit?

What happens if the batch takes longer than degree-hours allows? For restaurant level production, it's always safer to discard the product. The toxin that Staph. Aureus produces is heat stable and cannot be cooked to deactivate. In large facilities that produce substantial batches, the operator must notify the CFIA of each case where degree-hours limits have been exceeded. Such lots must be held and samples of product submitted for microbiological laboratory examination after the drying period has been completed. Analyses should be done for Staphylococcus aureus and its enterotoxin, and for principal pathogens, such as E. coli O157:H7, Salmonella, and Clostridium botulinum and Listeria monocytogenes.

If the bacteriological evaluation proves that there are fewer than 104 Staphylococcus aureus per gram and that no enterotoxin or other pathogens are detected, then the product may be sold provided that it is labelled as requiring refrigeration.

In the case of a Staphylococcus aureus level higher than 104 per gram with no enterotoxin present the product may be used in the production of a cooked product but only if the heating process achieves full lethality applicable to the meat product.

In the case where Staphylococcus aureus enterotoxin is detected in the product the product must be destroyed.

12. E. coli and Salmonella Control in Fermented Sausages

Business' that manufacture fermented sausages are required to control for verotoxinogenic E. coli including E. coli O157:H7 and Salmonella when they make this type of product. This includes:

establishments which use beef as an ingredient in a dry or semi-dry fermented meat sausage;

establishments which store or handle uncooked beef on site;

Establishments which do not use beef and do not obtain meat ingredients from establishments which handle beef are not currently required to use one of the five options for the control of E. coli O157:H7 in dry/semi-dry fermented sausages.

Any processed RTE product containing beef or processed in a facility that also processed beef, must be subjected to a heat treatment step to control E. coli O157:H7. Heating to an internal temperature of 71°C for 15 seconds or other treatment to achieve a 5D reduction is necessary. This is a CFIA requirement and is not negotiable.

Uncooked air dried products produced as RTE, must meet shelf stable requirements as detailed for Fermented-Dry products.

13. Options for E. coli validation

Without lab testing, the two main methods of validation are with heat treating by either low temp and a long duration, or various hotter processing temperatures for a shorter timeframe.

A challenge study to validate a process can take 1 year and over $100,000!

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

The aw and pH values are critical in the control of pathogens as well as to ensure shelf-stability in all semi-dry and dry fermented meat products. Each batch must be tested for aw and/or pH in order to verify that the critical limits are met.

Although aw measurement is mandatory only for shelf stable products, it is strongly recommended that the producer determine the aw values achieved for each product type they manufacture and for each product. Once this has been established, frequent regular checks should be made to ensure consistency. In the U.S., they rely on moisture to protein ratio and have set targets. This lab-tested value is a direct correlation of the % water to % meat protein and not aw. This gives more consistency to common names. For example, to legally call a product "jerky" it must have a MPR of 0.75:1 or lower.

Remember your ABCs:

Always be compliant.

-AND-

Documentation or it didn't happen.

(tags)

Charcuterie,Fermented Meat,Food Safety,Starter Culture,Chemical Acidification,Water Activity,Fermentation Process,Degree-Hours Method,Foodborne Pathogens,Meat Processing Guidelines,Chef WK Alberta Canada,Food Industry Standards,pH Critical Limits,Thermal Processing,Food Preservation,Food Microbiology,Sausage Fermentation,Charcuterie Expertise,Fermented Meats ,Food Safety Standards,Food Processing Guidelines,Starter Cultures,Chemical Acidification,Water Activity (a_w),Critical Limits,Degree-Hours Method,Foodborne Pathogens,Meat Processing Equipment,Processing Facility Requirements,Hazard Analysis and Critical Control Points (HACCP),Food Preservation Techniques,Temperature Control,Pathogen Reduction,Food Industry Compliance,Documentation Practices,Heat Treatment,pH Control,Food Stability,Consistency in Production,Microbial Testing,Real-time Monitoring,Process Validation,Regulatory Requirements,Verotoxigenic E. coli,Lethality Standards,Product Labelling,Spoilage Prevention,Enterotoxin Detection,Shelf-Stable Products,Moisture to Protein Ratio (MPR)

#Charcuterie#Fermented Meat#Food Safety#Starter Culture#Chemical Acidification#Water Activity#Fermentation Process#Degree-Hours#Meat Processing Guidelines#Thermal Processing#Food Preservation#Food Microbiology#Sausage Fermentation#Starter Cultures#Critical Limits#Meat Processing#Food Preservation Techniques#Temperature Control#Pathogen Reduction#Food Industry#Heat Treatment#pH Control#Food Stability#Microbial Testing#Real-time Monitoring#Process Validation#Spoilage Prevention#Enterotoxin Detection#Shelf-Stable Products#Moisture to Protein Ratio (MPR)

1 note

·

View note

Text

Yield10 Bioscience News: E3902 Camelina Receives Regulatory Clearance in Canada

Key Information:

The Canadian Food Inspection Agency (CFIA) has determined that Yield10 Bioscience’s E3902 Camelina is not classified as a Plant with Novel Trait (PNT).

This determination exempts E3902 Camelina from pre-market notification requirements under Part V of the Seeds Regulations, though it is still subject to other Seeds Act regulations.

E3902, a genetically edited variety of…

View On WordPress

0 notes

Text

Agnès Pannier-Runacher, ministre déléguée auprès du ministre de l’Agriculture et de la Souveraineté alimentaire, s'est rendu en Ille-et-Vilaine (35), jeudi 14 mars 2024. Elle a débuté son déplacement par la visite de la 27ème édition du Carrefour des fournisseurs de l’industrie agroalimentaire (CFIA 2024) à Rennes.

Elle a poursuivi, l’après-midi, par la visite d’une exploitation agricole lors d’une séquence dédiée aux enjeux de réduction de l’usage et de la dangerosité des produits phytosanitaires, dans le cadre de la stratégie « Ecophyto 2030 » qui vise à diminuer de moitié l’utilisation de pesticides à l’horizon 2030 par rapport à la période 2015-2017.

Photos Cheick Saidou/agriculture.gouv.fr

0 notes