#Prototype Electronics Assembly

Explore tagged Tumblr posts

Text

Precision Prototype Electronics Assembly in Austin – EWME NPI Services

Bring your concepts to life with EWME’s expert prototype electronics assembly services in Austin. We specialize in fast, reliable prototyping and new product introduction (NPI) to accelerate your product development cycle. Our advanced capabilities ensure high-quality builds, quick turnarounds, and full support from design to production. Whether it’s a single prototype or a small batch, EWME delivers with precision. Visit our page to explore how we streamline your innovation journey.

#Prototype Electronics Assembly in Austin#Prototype Electronics Assembly#Prototype Electronics Assembly Austin

0 notes

Text

Newcastle Industries is a leading distributor of electronic connectors, specializing in aerospace and defense applications. With over 30 years of experience, they offer a wide range of high-quality connectors, accessories, and tools to meet the needs of manufacturers, assemblers, and repair facilities worldwide. Explore our full range at https://newcastleindustries.com/.

#Aerospace Electronics Connectors#Electronic Connectors Distributor#Custom Backshell Connectors#Military-Grade Electrical Contacts#Industrial Relay Suppliers#High-Performance Switch Assemblies#Precision Connector Insertions#Aerospace Connector Solutions#OEM Electrical Components#Custom Cable Assembly Services#Electronic Connector Prototyping#Delta Electronic authorized distributor#insertions and extraction tools

0 notes

Text

A close-up view of hands working on a microcircuit board, showcasing precision electronics engineering and prototyping. This image highlights the intricate process of assembling and testing electronic components, a key step in hardware design and development.

0 notes

Text

#electronic manufacturing services#electronics manufacturing companies#electronic manufacturers company#global business directory#assembled prototype#Testing and debugging

0 notes

Text

#pcb assembly services#circuit board assembly#printed circuit assembly#printed circuit board design#electronic pcb#pcb fabrication and assembly#pcb production#pcb design service#pcb fabrication#pcb electronic#oem electronics manufacturing#pcb prototype us

0 notes

Text

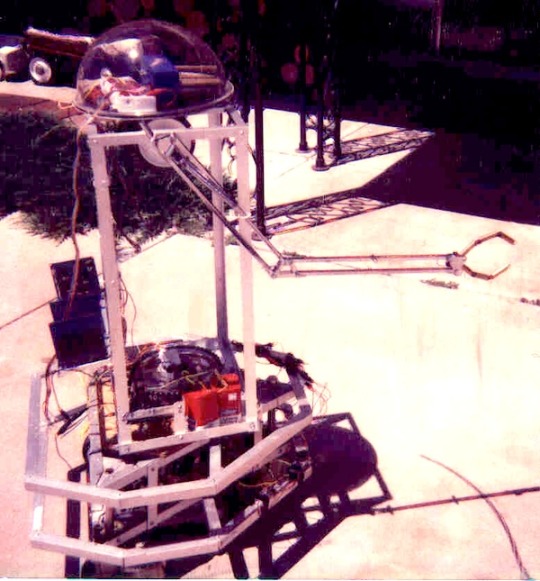

S.A.M by "Bill" (1978). "S.A.M (Short for "Sentient, Autonomous Mechanism" or "Smart Ass Machine", depending on his (and my) mood on a given day, was one of my first real robot projects, started in 1978 when I was around 15. His "brain" was a single-board Z-80 computer (the big square object in the middle of his "back" in this picture), with many bits of TTL I/O, a couple of serial ports, a bunch of counter-timers, and several D/A & A/D channels. The base was taken from the book "How to Build a Computer Controlled Robot" by Todd Loofbourrow - I had built the robot in the book, and had used my KIM-1 to control it. Later, I decided that just a little platform was kind of boring, so I added the upper torso shown here. The torso (mounted on a "lazy-susan" turntable bearing) is rotated by a heavy-duty gear motor driving a chain and sprocket assembly from a bicycle. The base is powered by two of the (apparently no longer available, which is sad) all-metal rubber-tired "motorized wheel" assemblies that Herbach & Rademan used to sell, with a large rubber-tired caster in front. The head platform (mounted on a small "lazy-susan" bearing) was originally rotated by a surplus gearbox from a Mattel "Big Trak" with some rubber-tired wheels mounted on the output shafts. This arrangement was later replaced by a small gear-head motor driving a large gear mounted to the center of the turntable. The device in the head with the tubes sticking out the front is a directional light tracking device. Each tube has a CDS photocell at the bottom, and is painted flat black inside. A comparator circuit tells the computer which direction the brightest light is coming from. This device could also tilt up and down with a small gear-head motor, to track light sources vertically. Most of the circuitry was installed on small plug-boards from Radio Shack, mounted in a card rack below the CPU card. This rack could be tipped back 90 degrees to facilitate easier access for testing. In addition to motor driver circuits, there was a "Sweet Talker" speech synthesizer board so he could talk. Power came from a large "gel-cell" marine battery (for powering trolling motors on boats), which was slung near the ground in the center of the base. Two 6V lantern batteries (later replaced by a 12V motorcycle battery) provided separate power for the electronics. All motors were isolated from the electronics via relays and/or opto-isolators. After these pictures were taken, a set of metal panels was installed on the "facets" of the base, with lever switches behind them for collision sensing. A Polaroid sonar range-finder was also added later. If you check out the other photos of S.A.M., you will notice an "arm" sticking out the front. This was a prototype made from an old swing-arm desk lamp and some "fingers" from a robot hand design using brass tubing, bicycle chain, and 1/16" steel cable to allow natural bending of each finger. It was later replaced with a much heavier duty aluminum framework arm operated by two 12VDC linear actuators." – My Home Robot Projects, by Bill.

25 notes

·

View notes

Text

SYNTAX x READER

Content: Fluff (i think)

Posted from my AO3 account to here

Enjoy :>

———————————————————————

It was not a good day, to say the least.

You had set your drink down on a bed of notes by mistake, so now there’s a ring of water decorating those rather important papers, your sparring match with Huntsman left you feeling more sore than usual, and your mood just wasn’t that great to begin with.

So now you’re stuck in Syntax’s room, having been sent to work on some printed circuit board assemblies with him. Not that that was bad, most of the time you loved working with someone who could match your intellect with computer and other electronic hardware.

It’s just for some reason you coudn’t get this stubborn LED to work properly.

Which was strange, to say the least. As this had never happened before, you struggling this badly over something so utterly simple. It was frustrating to you, so much so that the pen in your hand you were using for schematics was now brutality making contact with the table.

The pen nib was practically destroyed, but you kept going, finding a strange satisfaction in how it cracked under the pressure. But rather quickly Syntax notices this, looking over at you from his seat with an expression of slight concern and something akin to amusement.

“You’re lucky I didn’t like that pen.” He muses, getting up from his seat to walk over to you. His movements are swift and confident, like always, but you can already feel the snarky remark or joke coming any second now.

After a moment or two, you finally respond.

“Yeah, I really don’t like it either.”

He hums in acknowledgement, seemingly thinking about something. He can practically feel your bad temper right now, and he knows you’re rather fond of jokes. So he decides to take a small risk, doing something he’d normally never even think about, but to be fair, he’s also curious as to what your reaction could be if he finally says something other than a smug remark.

“You know, I just have to say… think of that poor pen’s feelings, hm? How would you feel if I banged you on the table like that?” A little smirk forms on his face, and he leans against your work station, supporting himself with a hand.

Your eyes widen slightly, and then a grin slowly begins to cover your face. “Do you want the ‘appropriate’ answer, or the ‘down horrendous’ answer?”

Now it’s his turn to stammer, seemingly caught off guard. Syntax had expected nothing short of a ‘shut up’ to his comment, so when you said that, it left him stumbling to calculate a response. You take notice of his current embarrassed expression, deciding to have a bit of fun with this now.

“Oh, c’mon. You really walked into that one. For someone so intelligent, I would’ve figured you’d have realized the double meaning there,” You lean back in your swivel chair, lightly tossing the broken pen onto the surface of the workstation.

He just huffs, picking himself and his dignity off of the metaphorical ground.

“Well, I didn’t know I was speaking with someone whose mind occupies the entire gutter!”

“You gotta admit, that was funny,” You laugh, smiling like a fool at his reaction. He’s not genuinely mad, you can tell, but it’s still very silly.

Syntax just sighs, rolling his eyes and feigning annoyance. “You’re lucky you’re decent with hardware, otherwise I would’ve kicked you out of here already.”

This time around, he’s more careful as to not say anything that could be turned into a sexual joke. It’s not like he doesn’t enjoy it, but it’s more interesting for the both of them if he puts up a fight. But you do glance over at the ridiculously stubborn LED from earlier, feeling a little bit down again with how you weren’t able to get it to function correctly.

Before you respond to the technician, your hands find themselves moving with a new idea. The LED is replaced with a newer red one, after turning off the power to the prototyping breadboard of course. Then you switch the button back on.

It begins emitting light, like the other one was supposed to do.

You celebrate for a split second before turning back to Syntax, a pleased expression on your face. The original light is between your thumb and index finger now, and then you place it to the side.

“It appears this one is a dud, didn’t these come in yesterday though?” You ask curiously, wanting to make sure you’re remembering things right.

He hums out an answer with a nod alongside it. “Yes, but the Queen insisted we go for more… nominal resources.”

You nod as well, feeling a little bit annoyed with such actions. The cheaper the materials, the harder it will be to do things, not to mention the risk of something malfunctioning. Then if, or rather when something goes wrong, them two will be the ones taking the blame for it.

“Well, that sucks,” You mutter, looking over at the burnt out LED, then to the functioning one.

“Nothing we can do about it,” The spider demon just sits back down in his chair, beginning to clean the area.

You do the same.

22 notes

·

View notes

Text

Why Choose East/west Manufacturing?

Below are The key reasons why choose East/West Manufacturing:

Experience

Our history and volume manufacturing expertise benefits projects of all sizes

Employees have an average of 15+ years industry experience

We leverage market leading Kanban and Lean Manufacturing strategies

Service

Hands on involvement in your project at all levels

Services tailored to your needs, use some or all of our capabilities

Central Texas owned and located

Quality

ISO 9001:2015, AS9100:2016, and ISO 13485:2016 Certified

Passed manufacturing audit with Met Laboratories

Accuracy — inspections at each step ensure high standards

Cycle time

You define the cycle time, we work with our suppliers to make it happen

On time delivery

Quick turns on expedited projects

Cost

Relationships and history with key suppliers help us lower your total cost per job

We continuously and actively seek cost reductions to pass the savings onto you

Our efficiencies lead to lower overhead and reduced cost

In summary, East/West Manufacturing Enterprises stands out as a reliable and experienced electronics contract manufacturing partner, offering high-quality services, flexibility, and a commitment to customer satisfaction.

#electronics contract manufacturing#east west manufacturing austin#Npi Electronics Manufacturing#Prototype Electronics Assembly

0 notes

Text

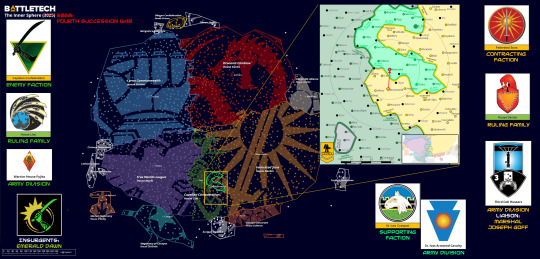

4th Succession War campaign report 1

Summary of the first of two games I ran for friends so far.

Preamble: an infographic I assembled from online assets to introduce the players to the setting.

-Map pic from gruese.de/innersphere - Excellent 3025 resource -Logos, Inset map from sarna.net BT wiki - You've probably heard of it already but if you haven't go there immediately it is the best -Emerald Dawn logo from Harebrained Schemes BattleTech, AFAIK this faction is apocryphal.

Disclaimer: I may have taken a few small liberties* with the specifics for convenience, but my players are pretty new so I feel confident nobody will call me out on them ;)

*sometimes also known as errors

TL;DR: You are mercs hired by team Yellow to help Teal fight off Green. Here's some money, now shoot those guys. Good merc.

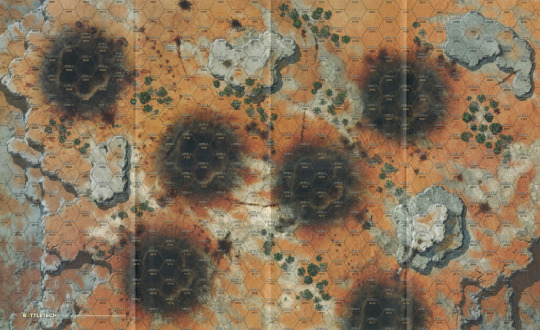

Mission 1: LZ Defense

Map: "Deployment Zone" from Tukayyid map pack Time limit: 10 turns to liftoff. Primary Objective: Defend dropship, at least 3/4 struts must survive. Secondary: Salvage prototype EW equipment.

-Allied spheroid dropship (located in one of the scorched craters) is preparing to lift off but still needs more time to spin up the drives. A hostile lance unexpectedly appears nearby (map edge furthest from dropship) and attacks! The craft hull is well armored against mech-scale weapons, but the attackers are going for the exposed landing struts instead. Destruction of 2/4 struts (set their HP to a reasonable amount for the attacking force and make them immobile targets so they won't hold up long against a concerted effort) will prevent a safe liftoff and ground the dropship long enough for further Capellans to arrive, something the FedSuns forces cannot afford.

-3/4 of the attacking Lance are Emerald Dawn thugs (undisciplined, easily distracted from the struts by the players shooting at them), but the last one is a Raven in Liao colors (Have this pilot stand out by being more focused on the landing struts) equipped with a prototype Electronic Warfare suite, which is what prevented detection until the force was almost ontop of you. If you can control the field post-battle and salvage an intact EW system the Davions will pay extra for the chance to study it.

Hexes adjacent to the dropship on the last turn take a ton of damage+heat when it lifts off. The next hexes out take half that.

Optional Rule: "Shielding movement mode" Tactical Operations p.19 allows mechs to try to physically block the line of fire.

The players' results:

✅Primary: Diversion successful, dropship lifted off safely. One strut had moderate damage, another had light damage, but the players did a good job of juggling aggro so none were destroyed.

❌Secondary: EW equipment unrecoverable (Destroyed in Raven ammo detonation on the last turn!)

Enemy routed, battlefield controlled. 3 pilots captured (1 house military, 2 EmDaw). No viable mech salvage (CT destructions/Ammo dets) though a handful of weapons/heatsinks/jumpjets were salvaged.

I'm using the WP (Warchest Points) system in the new Mercs rulebook and I gotta say I like it, it's rather convenient. Their repair prices weren't granular enough for me though, I didn't think it should cost the same for a 1pt repair as a full repair (Tonnage amount in WP) so I houseruled: 1 armor = 1 WP 1 structure = 2 WP Component replacement = 3 WP per structure in component

Anyway it was a blast playing the OpFor and running this game.

#battle report#battletech#mechwarrior#scifi#tabletop wargaming#ttrpg#mecha#military#tabletop#role playing games#after action report#game master#gm#dungeon master#dm

2 notes

·

View notes

Text

Discover high-performance Aerospace Electronics Connectors engineered for precision and durability at Newcastle Industries. Explore our full range at https://newcastleindustries.com/.

#Aerospace Electronics Connectors#Electronic Connectors Distributor#Custom Backshell Connectors#Military-Grade Electrical Contacts#Industrial Relay Suppliers#High-Performance Switch Assemblies#Precision Connector Insertions#Aerospace Connector Solutions#OEM Electrical Components#Custom Cable Assembly Services#Electronic Connector Prototyping#Delta Electronic authorized distributor#insertions and extraction tools

0 notes

Note

Hello great wizard, Can you please expand on your quirk Assembly, I really like it it gives a various explainable methods to be useful, but it reminds me a lot of weld (they are similar in the sense of putting things together, while weld can redo these things). Would Assembly be able to put back buildings or other intricate things/or make buildings? Also keep up the good content, I love you're style of writing in which is cohesive and easily readable (as a non English speaker).

Thank you, I'm glad you find my work so comprehensive. Though as a general reminder: "Assembly" does not reshape or rebuild anything, It's only taking materials around it and crafting them to match whatever plans the user has gathered into something new. They need the specific materials and plans to have it work. "reshaping the area" was just hyperbole I used to make it sound cool.

So for training, the user should be trying to work with the Support Course or whatever equivalent they can get. Basically anywhere with people building lots of stuff and the user can read over the blueprints. It's one thing to read the instructions, it's another thing to see people build it. The user can then in turn practice building up stuff, ranging anything from small tools to more complex electronics. The Support students can then help teach the user about the various pieces and designs to help them expand their understanding. Plus it would be very helpful for the Support students who wouldn't have to waste as much time building their prototypes.

As the Quirk is so support oriented, it doesn't really have a lot of great Super Move options. Evolutions would come from more the user getting more skilled with the power. The size limit is a pretty hard cap, so it'd be a matter of the user understanding their materials more, the various designs the user could make from them, and even learning to improvise from whatever may be around them. The user could evolve that power to be able to work on multiple projects at a time and working faster to build them up. The bigger ones could see the user being able to undo the creations they make, letting them more easily reuse their parts for something else.

Something like what Awase carries around would be good examples, stuff like steel plates and pipes that can can be put together in various configurations for their needs and wouldn't need to take up too much space. I'm sure a competent user could train themselves to carry around various parts that can make into all kinds of things, like various circuits and wires to make electronics, but such a feat would require a lot of time and practice. They could also have something akin to Momo's dictionary, filled with various plans for stuff they can make with their resources in case their need a refresher. They could have larger trucks for disaster zones, building up relief tents for people. Oh, maybe they could go with a engineer or construction worker theme for their outfit.

9 notes

·

View notes

Text

South Korea will update its F-15K fighters

Fernando Valduga By Fernando Valduga 12/11/2023 - 17:00 in Military

Aerospace giant Boeing revealed plans for a comprehensive upgrade of the F-15K Slam Eagle fighters of the Air Force of the Republic of Korea (RoKAF).

According to Dong-A Ilbo, this transformation involves equipping the cockpit, radar and other components with state-of-the-art equipment to introduce an advanced variant.

Boeing representatives released ongoing discussions between the U.S. and South Korea during a meeting held on October 29 at the Boeing Mesa facility in Arizona. They highlighted the imminent change to a new model, integrating state-of-the-art technology throughout the front section of the aircraft, including the cockpit and radar systems.

Last year, during the 148ª meeting of the Defense Acquisition Program Administration, the South Korean military authorities ratified the fundamental strategy for the "F-15K Improvement Project". This strategy involves replacing the aircraft's mechanical radar with an EFSA radar and strengthening its electronic warfare capabilities. It is estimated that the project, scheduled to be executed from 2024 to 2034, requires a total investment of approximately US$ 2.62 billion.

The update initiative will focus on three main improvements: the installation of the AN/APG-82 radar, the strengthening of the cabin display features and the incorporation of the 'Eagle Passive/Active Warning and Survivability System' (EPAWS), a new electronic warfare set.

Rdar AESA AN/APG-82 from Raytheon.

Boeing officials anticipate that once the F-15K improvement is completed, the fighters will have an extended operational range and better performance, improving interoperability during joint U.S.-South Korea air operations.

EPAWS, a system also deployed in the latest variant of F-15 fighters operated by the U.S. Air Force, represents a crucial addition to South Korea's F-15K fleet.

TAP ARROW TO VIEW VIDEO 👇

youtube

South Korea has proposed the removal and replacement of the entire front section of the F-15K, which comprises the cabin and the front fuselage, due to its design that allows detachment between the cabin and the wings when necessary.

Robert Novotny, Director of Programs and Development of Boeing's F-15, pointed out that although there were considerations for partial component replacements, the research conducted by the Korean Institute of Defense Analysis (KIDA) defended the effectiveness of a complete replacement of the front section.

Novotny specified that the rear section of the F-15K, which undergoes proper maintenance, is not included in this update initiative.

In addition, Novotny emphasized the need for these improvements to keep up with the modernized opponents and stay ahead in the evolving scenario of air combat. He mentioned the ongoing collaboration with the Administration of the South Korean Defense Acquisition Program on related matters.

The F-15K improvement project means a substantial leap in South Korea's defense capabilities, demonstrating a commitment to technological advances and operational capacity in safeguarding the country's airspace.

Source: defence-blog

Tags: Military AviationBoeing F-15K Slam EagleROKAF - Republic of Korea Air Force/South Korea Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

First prototype of Turkey's KAAN fighter. (Photo: Cen Dogut)

MILITARY

Turkish manufacturer began assembling two more prototypes of the KAAN combat jet

11/12/2023 - 14:00

MILITARY

Russia plays reconnaissance drone against Ukrainian UAV hexacopter

11/12/2023 - 08:47

AERONAUTICAL ACCIDENTS

F-16 fighter accident in South Korea

12/11/2023 - 08:24

MILITARY

How did a Philippine attack jet manage to shoot down an F-22 in an air combat exercise?

10/12/2023 - 20:01

AIR SHOWS

Concert schedule of the main North American demonstration teams for 2024

10/12/2023 - 18:42

MILITARY

Belgium celebrates the presentation of its first F-35A

11/12/2023 - 08:17

11 notes

·

View notes

Text

SERIOUS Custom:

1951 Studebaker Woodie - Never Slow Down - StreetRodder

Body

Gray Baskerville accurately described Dennis Varni as "a hot rodder's hot rodder." Since buying a '31 Model A as a teenager in the late '50s, Dennis doesn't seem to have slowed down ever. He has amassed a phenomenal stable of collector cars, trucks, vintage race cars, and motorcycles of practically every type, including the '29 Model A roadster built by Boyd Coddington that was named America's Most Beautiful Roadster in 1992. He has participated in motorsports all over the world, including numerous trips to Mexico to race in the famous La Carrera Panamericana, to South Africa for the South African Rally Championship, and to the Bonneville Salt Flats, right here in the U.S., where he drove his Falconer L6-powered "Speed Nymph" streamliner just shy of 350 mph.

Dennis has more checks on his hot rodding bucket list than just about anybody we know. So did you really expect his latest street rod to be something ordinary?

Body Bottom

Any 1951 Studebaker woodie custom could be considered out of the ordinary (how many can you think of?), but Dennis, builder Curt Hill, and the people who had previously helped create this custom woodie, have taken the '51 to an extraordinary level.

This car was under construction when Dennis made the winning bid for it at the auction of the late Joe MacPherson's prized collection. The unfinished project had been started by Doug Carr of Woodn' Carr. It had already been transformed from a sedan to a fastback (based on Thom Taylor's design sketches) and was already a woodie. The top was chopped 2-1/2 inches, and the rear fenders were stretched 18 inches and treated to custom taillight lenses and bezels. The '37 Ford headlights were installed by Steve Davis, who had done some of the early fabrication on the car.

Such an unusual car deserved an equally unique engine. For a while, Dennis considered dropping in a Cadillac engine to create his own version of the Studillac, the Cadillac-powered Stude coupes custom-built in the mid '50s. Then he remembered the one-of-a-kind induction system he'd found at a swap meet decades ago. The mechanical fuel injection system, with wild-looking air bodies, was a prototype created by Propulsion Development Laboratories in the '50s. Everybody had seen it on the cover of Hot Rod magazine in 1959 and nobody had seen it since. The setup is finally in service, feeding a Ford 427 FE engine. Dan Brewer in Torrance, California, did the assembly on the engine and converted the PDL mechanical injection to work with a Hilborn electronic system hidden under the manifold. Edelbrock cylinder heads are topped with Edsel valve covers to replicate the look engine on Hot Rod's cover. The new combination produced 410 hp on the dyno. An adapter fits the Ford to a GM 700-R4 transmission. This is one of the rarest, most unusual engines you'll find in a hot rod, but Dennis is almost nonchalant about it. "Nobody puts Edsels in Studebakers," is what he said.

The interior was entrusted to Sid Chavers in Santa Clara, California. Chavers built custom bucket seats and covered them in tan leather with gray-toned fur inserts. No need to replace the '51 Studebaker dash, so Redline Gauge Works restored the appearance of the factory gauges and updated the internals. A reproduction '54 Stude steering wheel came from Shrock Brothers, which specializes in repro Studebaker parts. Lucky 7 Customs gave the wheel and column their wood grain paint. The perfect accessory to the interior is the set of vintage alligator-grain luggage in the rear deck area, which Dennis found in an antique store in Washington.

The end result is a genuinely unique custom that would probably hover around the top of most people's lists of great Studebakers, great woodies, and great customs.

3 notes

·

View notes

Text

Circuit Board, PCB assembly & electronics manufacturing service provider from China (hitechcircuits.com)

What is a prototype PCB assembly?

PCB prototyping is the experimentation pilot stage of the product which is to be mass produced at a later stage. This is more of an experiment which is done after the initial discussions and the design. This offers a pre-production analysis of the boards that are to be manufactured, reducing the possible number of errors in the PCB design. PCB prototypes help the manufacturer analyze the strengths as well as weak areas of their proposed circuit boards. Prototypes also serve as a reference point for future versions of the same product. At Hitechpcba, we handle PCB prototype assembly in quantities from one to hundred printed circuit boards.

We have acquired capabilities that enable us to serve our clients better. All these years, we have worked on many complex prototype PCB assembly projects, and we believe the following capabilities have helped us serve our clients better.

Prototype PCB Assembly Services: We specialize in the following prototype printed circuit board assembly services.

SMT: We can provide single-sided and double-sided surface mount PCB assemblies in different specifications.

Plated Through Hole: We offer plated through hole assembly with selective soldering.

Mixed Assemblies: We often work on projects involving mixed assemblies – through-hole and SMT and electromechanical assemblies.

PCBA Testing: All the PCBA functional testing is performed in-house. Over the years, we have invested in various test fixtures and equipment, which helps us ensure the quality of PCBA. Currently, we provide the following types of PCBA testing services:

Flying probe testing for PCB

Functional testing including system and board-level testing

General PCB Assembly Capabilities: Our general PCB assembly capabilities are not limited to these:

RoHS, leaded or lead free, clean and no chemistries

PCB components including various types of QFNs, BGAs, 0105, 0201, 0804, and press fit components in small quantities.

What are the benefits of a prototype PCB assembly?

Prototype PCB assembly comes with several advantages. These benefits play a major role in the facilitation of your PCB manufacturing. Some of these benefits include:

Detection of Flaws Early

With prototype PCB, you will easily detect whatever flaws are present during the product’s development stages. This will allow you to solve the issues thereby saving you some money if you had gone ahead to make the production having the flaws in them.

If you go ahead to make changes during the production, there may be a need for more technicalities, and this may be expensive.

Testing of Each Component

With a prototype, you will be able to test all your system’s elements individually before you go ahead to set it up. You should do this because it is important especially for very complex projects composed of several parts that are PCB based.

When you validate each of these components, you will be able to identify those areas having issues that you should look into. This is the only way the project can function the right way.

Reduction in Total Costs

Utilizing the prototype bare PCB for any of your projects could go a long way in reducing what you’ll have spent in total for the project. With prototyping, you will be able to notice those errors in your project and then make corrections before you start the real production.

As soon as these flaws have been checked and rectified, then you may continue with the manufacturing of your Printed circuit boards in large quantities, thereby saving you unnecessary costs.

High-Quality PCBs

Why prototyping your PCB is important is to help you test if your project will function effectively. When we talk of testing, it involves the identification of errors present and then rectifying and making corrections to them.

Therefore, the eventual PCB after the prototyping will be of high quality that surely meets standards set internationally.

Less Turnaround Time

With prototype PCB assembly, you will be able to reduce the total time used in producing your printed circuit board. While making use of prototype printed circuit boards, you’ll be able to see the errors and then make corrections before you start the actual production.

Therefore, the eventual prototype will be free of defects. This implies that your PCBs will be produced quickly by your manufacturer.

What are the different types of prototype PCB assembly services you offer?

With years of market presence and experience, we specializes in the following prototype PCB assembly services.

Plated through-hole (PTH): We can provide the through-hole assembly with selective soldering.

Surface mount technology (SMT): We offer single-sided as well as double-sided SMT board assemblies in varied specifications.

Mixed Assemblies: Our experts often work on projects involving both PTH and SMT assemblies.

What are the types of testing Hitechpcba use for prototype PCB assembly?

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

These techniques help us ensure the reliability and accuracy of the circuit boards. In addition to this, it ensures a long operational life of equipment, minimal production losses, streamlined processes, and much more.

What are the capabilities Hitechpcba offer for prototype PCB assemblies?

We specialize in offering IPC compliant, and quick turn PCB assemblies. We are very particular about our scheduled deliveries and timelines, and we deliver without compromising the quality. Our PCBA capabilities are not limited to these. Here are some capabilities we offer through prototype PCB assemblies.

RoHS compliance

Stringent testing procedures

Device encapsulation

Full turnkey, partial turnkey, and kitted/consigned services

Assemblies using Surface Mount (SMT), Thru-hole, Mixed Technology (SMT/Thru-hole), Single and double-sided SMT/PTH, Large parts on both sides, BGA on both sides.

Do you perform a component analysis for prototype PCB assemblies?

Yes, we check the quality and performance of components before mounting them on the circuit boards. This is because a malfunctioning component can affect the performance of the entire circuit board assembly and also pose risks.

What is your standard turnaround time for a prototype PCB assembly?

Our turnaround time for standard applications is two weeks. This timeframe varies depending on the complexity of the applications. However, we are committed to offering quick turnaround times without compromising on quality, functionality, and accuracy, which offers our client a competitive advantage and reduced time to market. You can also request any emergency assistance or queries related to any type of PCB assembly. Our experts will assist you in all possible ways.

How is the cost of prototype PCB assembly estimated?

PCBA costing varies based on the different factors, such as PCBA parts, type of materials to be used, order quantity, and much more. We can also offer quotes and customization options once you share the detailed requirement with us.

We focus on quality and customer satisfaction over anything else. This has helped us build a long list of happy and satisfied customers. So, if you wish to partner with a manufacturer of prototype PCB assembly in China, then don’t hesitate to reach us. Our experts will assist you through all the phases of the prototype PCB assembly process. We look forward to making your experience with us better and memorable.

How to choose prototype pcb assembly manufacturer?

Our pcb prototype assembly service includes the sourcing of components. This allows you to concentrate on what you do best: layout design. We have a dedicated sourcing staff that coordinates with multiple suppliers and distributors to purchase electronic parts as per client requirements, and our staff completes these purchasing particulars in a most efficient manner. We have advanced processes for optimal selection of packaging (cut tape, tube, bulk, etc.) to reduce the total cost. Furthermore, we are capable of cross-referencing parts and even locating hard-to-find and obsolete parts. Customers can be rest assured that when Hitech Circuits substitutes components that they are high quality: we only use the electronic component numbers and manufacturers specified in the BOM. We will not modify your original layout design. Part substitutions take place only with your permission.

The final pcb prototype assembly service cost includes assembly labor charges, bare circuit board rates, and part costs. We understand the importance of prompt delivery. The sooner the components are sourced, the sooner we can begin circuit board fabrication. We thoroughly evaluate engineering inquiries and concerns related to the related parts with our clients before commencing circuit board assembly. The average time taken for pcb manufacturing assembly is about two weeks, which can be further reduced if there are no hard-to-locate components or documentation mistakes.

We have specialized experts to deliver fast turnarounds for prototype circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components.

Anyone interested in electronics and electronic circuit boards needs to understand the various stages of developing and producing a printed circuit board. It can come in handy when you are seeking a top prototype smt assembly provider. The various production stages of printed circuit boards entail design, prototyping (prototype PCB development and rapid prototyping pcb assembly), and PCB high volume production. Different entities will always seek part of the whole production process depending on their electronic circuit board needs.

However, this article seeks to help you understand everything about prototype PCB assembly, a fundamental aspect of the PCB production process.

Rapid prototyping pcb assembly represents a fundamental phase of the printed circuit production process. It is also inferred as PCBA prototype assembly, SMT or surface-mount technology PCB prototype, PCB sample assembly, etc. From these alternative names, the meaning of prototype assembly regarding printed circuit boards becomes apparent. So what is assembly prototype?

PCB prototype assembly service is a fast prototype printed circuit board assembly primarily used to test fresh or new electronic designs. Consequently, it assists with checking and ensuring quality assurance of the PCB. For instance, it verifies that no bug exists in the test PCB, updates the design, and finds bugs. In most instances, prototype assembly of an electronic project will require two or three iterations to ensure everything is perfect.

Why Choose Hitech Circuits PCB Assembly for Your Prototype PCB Assembly Projects?

There are several PCB manufacturers specializing in prototype PCB assembly services. However, Hitech Circuits stands out owing to the following:

1.Strong Supply Chain: Over the years, we have built strong supply chain relationships in the industry, which helps us fulfill the requirements of turnkey prototype assembly services easily.

2.Fastest Turnaround Times: Our engineering expertise coupled with our understanding of industry requirements and a well-equipped facility enables us to assure the fastest turnaround times of 24-48 hours.

3.Reliability: All the printed circuit boards that we produce are IPC compliant, which helps us assure reliability.

4.Competitive Pricing and Quick Quote: Our supply chain relationships enable us to assure competitive prices. The cost of the PCB prototype assembly will be made available within 24-48 hours.

2 notes

·

View notes

Text

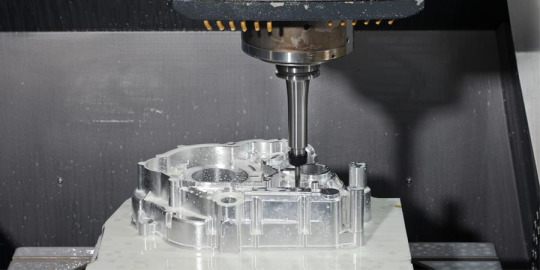

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#electronics#cleanenergy#industry#manufacturing#renewableenergy#quality#technology#EMS#Electronic Manufacturing Services#Indian EMS#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India

2 notes

·

View notes