#Aerospace material testing

Explore tagged Tumblr posts

Text

Why a 1000N Tensile Testing System is Essential for Quality Control

Why a 1000N Tensile Testing System is Essential for Quality Control Manufacturers and labs rely on 1000N tensile testing systems to verify material integrity before production. Whether you work with metals, polymers, textiles, or composites, this machine provides precise, repeatable measurements of tensile strength, elongation, and modulus—critical for quality assurance, R&D, and regulatory…

#1000N tensile testing machine#Aerospace material testing#ASTM/ISO compliant tensile tester#Material strength testing equipment#Medical device material validation#Packaging durability tester#Plastic film tensile strength test#Wire and cable tensile testing

0 notes

Text

🔥 Lateral Spread of Flame Test – Essential for Fire Safety Compliance 🔥

Fire safety is critical in industries such as construction, transportation, aviation, and marine. The ISO 5658 Lateral Spread of Flame Test is designed to measure how fire propagates across the surface of materials. This test ensures that materials used in high-risk environments meet global fire safety regulations.

🔥 What is the ISO 5658 Lateral Spread of Flame Test?

The ISO 5658 test evaluates the fire performance of materials by exposing them to a controlled flame. This test determines:

Flame Spread Rate: How quickly fire spreads across the material's surface.

Ignition Time: The time it takes for the material to catch fire.

Burning Behavior: The reaction of the material when exposed to direct flame.

Industries such as railway, aerospace, and construction require this test to ensure fire-resistant materials are used in buildings, trains, aircraft, and marine vessels.

🌍 Why Choose KDM Global for Fire Testing Equipment?

At KDM Global, we manufacture high-quality fire testing equipment, including the ISO 5658 Lateral Spread of Flame Test Apparatus. Our advanced testing solutions ensure:

Precision & Accuracy: Reliable data for material safety certification.

Compliance with ISO 5658 Standards: Meeting global fire testing requirements.

Robust & Durable Equipment: Built for long-term, high-performance testing.

🚆 Industries That Require Lateral Spread of Flame Testing

Various industries rely on the ISO 5658 test to assess the fire behavior of materials:

🏗️ Construction: Fire-resistant materials for safer buildings.

🚄 Railway: Ensuring compliance with railway safety regulations.

✈️ Aerospace: Testing aircraft cabin materials for fire resistance.

🚢 Marine: Ensuring ship interiors meet safety standards.

🔍 Get the Best Fire Testing Equipment from KDM Global!

Looking for the most reliable fire testing machines? KDM Global's ISO 5658 Lateral Spread of Flame Test Apparatus is designed to provide accurate results for your fire safety compliance needs.

🌐 Learn More About Our Product: ISO 5658 Lateral Spread of Flame Test Apparatus

📌 Visit Our Website: KDM Global

📞 Contact Us: +91 8218470498 | +91 7983475310

Ensure fire safety compliance with KDM Global’s high-precision fire testing equipment today! 🔥

#Lateral Spread of Flame Test#ISO 5658#Fire Testing Equipment#Flammability Testing Machine#Fire Safety Testing#Flame Spread Rate#Ignition Time#Fire Retardant Materials#Building Fire Safety#Railway Fire Testing#Aerospace Fire Standards#Marine Fire Safety#Fire Resistance Test#Construction Fire Safety#Aircraft Fire Safety#Ship Fire Safety#High-Performance Fire Testing#Fire Safety Compliance#Fire Testing Laboratory#KDM Global#Best Fire Testing Equipment Manufacturer#Flammability Test Apparatus#Fire Retardant Material Testing#Industrial Fire Testing#Fire Testing Machines#ISO Fire Testing Standards#Fire Spread Measurement#Material Ignition Test#Railway Fire Compliance#Aviation Fire Resistance

0 notes

Text

I still have no clue how Tumblr works but here's part 3

The third member to meet Danny is none other than our resident Demon brat.

It was rare that Damian could truly relax. In the league he had to constantly be the perfect heir, the perfect assassin. When his mother got him out it was just as hard when he had to compete with four adopted brothers, Gordon, Brown and the infamous Cassandra Cain.

It was difficult to find someone who could understand him and what he had been through and still put up with his bulshit. Damian was man enough to admit that his own attitude did not help him so when he found someone who would, whom he could let down his walls with, he grasped on with both hands.

"You seem to be thinking quite hard there Damian." A soft voice drew him from his thoughts. Damian looked her deep in her eyes freely let her peer at his thoughts. He knew she would not pry unless needed but he freely gave this.

"Just reminded myself how fortunate I was to have you." Damian admitted while they sat at their impromptu picnic.

It was rather rare for them to have dates in Gotham but today was a rare time where it was possible. The smog that always filled Gotham was almost completely absent today here in the forest at the edge of the Wayne property and perhaps most importantly, his father was off world with Cain and Grayson.

While most of the public believes Batman has a 'no metas allowed' rule, it was most certainly not true. What is true however is that his father is an overprotective idiot at times and would hover/spy onto their date.

"Dam-"

Whatever Raven was about to say was interrupted by a small sonic boom from just outside of the property that had both of them on their feet, their little picnic forgotten.

All too soon they found the source. A behemoth of a man was playing with a giant dog?

"Drop the stick boy!" The green beast dropped a log for want of a better word. "Good boy, wanna go again?" The beast gave a bark like artillery fire, tail waving like rotor blades. The man pick up the log and launched as though it was a javelin with a "Fetch Cujo!"

With one last artillery bark the beast bound after with great speed.

The man let out a deep sigh as he fell back into the shade of the nearby tree. "Man I wish I had more off days like this. Mhmmm, people? Hello there. Didn't think there would be people this far out. I'm Danny."

The man, Danny, waved as he lazily greeted them from where he lay on his bag in the shade. Danny lay so openly and without care that they could easily observe him.

Danny was very obviously a meta, his lazy smile with far too many sharp teeth, elfin ears and skin that was almost paler than Raven's. Most glaring was his height at seven and a half feet and shoulders nearly half as broad. (see Drake I can learn your freedom units)

"Damian" "Rachel" they introduced themselves.

"You two out on a date? It's one of my rare days off so I was planning one myself but unfortunately my girlfriend's dad needed help so she's out of town with him and her brother." Danny offered up freely. There was no hostile intent as far as Damian could tell. 'His intentions are true and there is no amniosity. His mind is well protected though.' Raven shared with telepathy.

"I take it your job is rather taxing?" Damian prodded.

Danny snorted "Nah man, I'm a university student, Aerospace engineering. The degree is kicking my ass but that's due to the amount of stuff I have to do. It's like they are afraid that I will have free time because I swear some of my projects and tests aren't for engineering.

Last week I had to write a chem exam and yesterday I had to submit a project that I'm pretty sure was a business model in disguise. If my luck holds out I might get a psych test next week. Ugh I'm already half dead, now their trying to get me to fully dead."

That was... concerning. It sounds like danny was possible rogue material and the university was trying their best to keep him from actually going rogue.

"So your taking a break and playing with you dog?" Raven asked.

"Yeah, Cujo is a sweetheart but it's hard to play with him here since people keep attacking him when he's in his large form." Danny explained as the dog bounded back without his stick. Worryingly there was a bit of blood on him. The dog had obviously been in a fight.

"Again buddy? Why can't they just leave you alone. Let's see what it's this time." Cujo dropped a finger on the ground with a very familiar green ring.

"He's a rescue I suppose but he was originally a guard dog and he was trained to disarm people when they attack him so I keep having to stash away guns and the like. With how crazy some people are I really should be prepared for things like this."

The ring seemed to sluggishly work it's way off of the finger before shooting straight for Danny.

"Daniel Fenton of -"Danny swiped the ring out of the air and held it in a tight grip. "Nah ah, I already have one green magic ring and I don't want a talking one on top of that!"

Danny rummaged through his bag before pulling out his thermos that smelled like coffee and chugged it like he was drakes long lost twin and managing to seal it into the thermos.

"There, I'll figure out what to do with that later."Sigh."well I guess we can talk at a later time but after that I'm heading home. Cujo shrink!"

The massive beast of a dog deflated like a balloon till it was the size of a small dog, happily trudging sfter it's owner as they hiked in the direction of Gotham.

With a glance to Raven, he confirmed that she was just as bewildered by the interaction as he was. Eventually they returned to their date, no use in letting odd encounters ruin their day, but Damian kept the name in the back of his head for now.

Later that night Damian found himself in the watchtower, going for the terminal so he could research this Daniel Fenton. He would have done this at home but Drake hogged the bat computer, nou doubt pinning after his coffee crush.

Along the way he found a small congregation of heroes trying to drown out Guy Gardner but also had to listen to his report as his hand was quite bandaged and missing a finger...

"On my patrol I nearly got Final destinationed by a flying log and then I got attacked by a green beast that wouldn't go down no matter what I thew at it. To make matters worse it was able to bite off my ring!" Guy complained incessantly.

Suddenly it made perfect sense why Danny was so upset but accepting of people attacking Cujo. How many times has this happened to him? How many times had the guy patched up his dogs wounds because people attacked him. How many of those time was it a hero who attacked Cujo? Damian could feel for both Danny and his dog.

"Sounds like you attacked a dog playing fetch and got upset when you couldn't hurt a dog for playing. Neutralizing an attacker's weapon is the bare basics of any guard dog's training." Damian found himself snapping at the man. Superman nodding along with him.

"Robin is right, while I am very concerned about you losing your ring, I am also concerned that you would attack a dog for playing fetch. I do the same with Crypto." Superman chastised Guy sternly.

#dc universe#dcu#dcxdp#dpxdc prompt#batman#cass x danny#danny phantom#tim drake#Mentioned#damian wayne#dc robin#robin#raven#cujo#dead silent

546 notes

·

View notes

Text

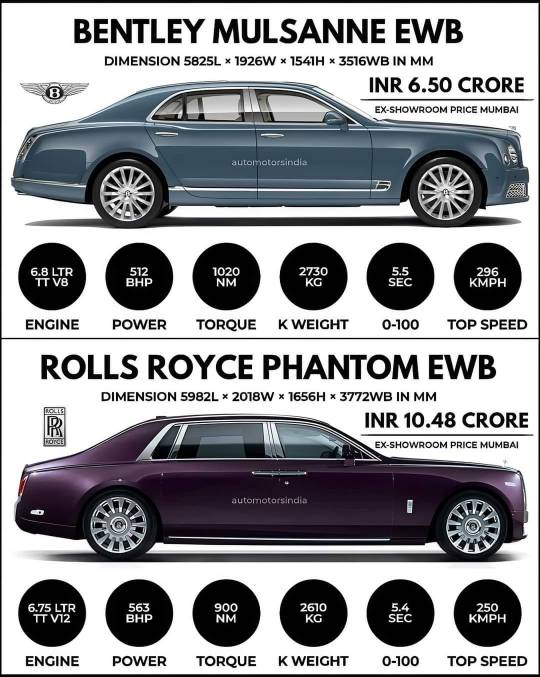

Here are ten more lesser-known facts about Bentley and Rolls-Royce:

1. Bentley's Le Mans Dominance: Bentley gained fame in the 1920s for winning the 24 Hours of Le Mans race multiple times, including a streak of four consecutive wins from 1927 to 1930.

2. Rolls-Royce's Silent Engine Test: Rolls-Royce famously tests their engines in a specially designed room called the "Silent Room" to ensure they operate silently and smoothly.

3. Bentley's Connection to W.O. Bentley: Bentley Motors was founded by Walter Owen Bentley, known as W.O. Bentley, in 1919. He was deeply involved in the design and engineering of Bentley cars until the company's acquisition by Rolls-Royce.

4. Rolls-Royce's Bespoke Options: Rolls-Royce offers extensive customization options for their cars, allowing customers to create truly bespoke vehicles tailored to their preferences, from materials to finishes.

5. Bentley's Continental GT Lineage: The Bentley Continental GT, launched in 2003, revived the Continental name which was previously used for Bentley's famous racing cars and luxury coupes in the 1950s.

6. Rolls-Royce's Parent Companies: BMW acquired the rights to the Rolls-Royce brand in 1998, leading to the formation of Rolls-Royce Motor Cars Ltd., while the original Rolls-Royce plc continued as an aerospace company.

7. Bentley's Crewe Headquarters: Bentley Motors is headquartered in Crewe, England, where all Bentley cars have been manufactured since 1946. Crewe is also known for its long tradition of luxury car production.

8. Rolls-Royce's Goodwood Factory: Rolls-Royce Motor Cars operates a state-of-the-art manufacturing plant in Goodwood, England, where every Rolls-Royce car is meticulously handcrafted by skilled artisans.

9. Bentley's Continental Flying Spur: The Bentley Continental Flying Spur, a luxurious four-door sedan, was first introduced in 2005 as a companion to the Continental GT coupe, sharing its platform and design ethos.

10. Rolls-Royce's Phantom Name: The Rolls-Royce Phantom nameplate has been in continuous use since 1925, making it one of the longest-standing models in automotive history and synonymous with luxury and prestige.

These additional facts further illustrate the deep heritage, craftsmanship, and unique characteristics that define Bentley and Rolls-Royce in the automotive industry.

44 notes

·

View notes

Text

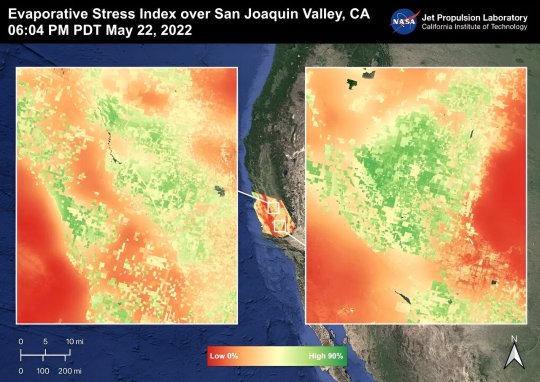

Research abounds at the International Space Station

At the International Space station, researchers are making strides in everything from Earth science to chemical properties. Here's what they're up to and why it matters.

Recently, researchers have found that eddies, or swirling wind patterns, increased moisture evaporation in an alfalfa field. A better understanding of the complex exchange of water and heat between the ground and atmosphere could improve remote sensing products and their use in agricultural water management.

The station's ECOSTRESS instrument takes high-resolution thermal infrared measurements of Earth's surface that provide data on changes in water availability, vegetation water stress, and agricultural water use. Researchers use observations from the USGS Landsat 8 and 9 satellites and ECOSTRESS to validate climate models and update data on Earth's surface energy (the amount of energy absorbed from the sun and radiated back into the atmosphere).

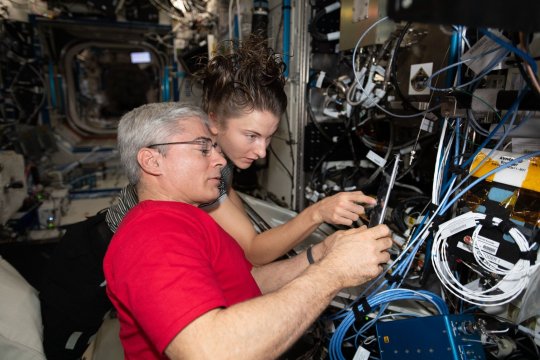

Properties of flow boiling

Researchers have identified various properties for flow boiling using n-perfleurohexane, a fluid used to cool electronics. A better understanding of this process can improve models for designing thermal cooling systems used in the electronics, energy, aerospace, and other industries.

Flow boiling, a method of thermal management, uses the heat generated by a device to boil a liquid, generating vapor bubbles that lift the heat from the surface. The Flow Boiling and Condensation Experiment (FBCE) tested a flow boiling method in microgravity, where the process is less efficient; in the absence of buoyancy, bubbles grow larger and remain near the surface.

A new radiation-resistant polymer

Researchers successfully manufactured a polymer of rare metals and other elements that showed high radiation resistance and has a suitable size and weight for use in space. This result provides knowledge that can support development of improved shielding for future spacecraft and extraterrestrial habitats.

The Roscosmos investigation Shielding Composite tested the absorbed radiation dose of two polymers during 225 days on the space station using monthly monitoring by the Pille-ISS investigation. The data showed that the material has high and stable radiation shielding characteristics. Protecting crew members and equipment from radiation is an important requirement for future long-duration space missions.

TOP IMAGE: The ECOSTRESS instrument on the International Space Station. Credit: NASA

CENTRE IMAGE: ECOSTRESS data shows evaporative stress in agricultural fields in California’s San Joaquin Valley. Credit: NASA

LOWER IMAGE: NASA astronauts Mark Vande Hei and Kayla Barron set up for the Flow Boiling and Condensation Experiment. Credit: NASA

11 notes

·

View notes

Text

The last time you dropped a favorite mug or sat on your glasses, you may have been too preoccupied to take much notice of the intricate pattern of cracks that appeared in the broken object. But capturing the formation of such patterns is the specialty of John Kolinski and his team at the Laboratory of Engineering Mechanics of Soft Interfaces (EMSI) in EPFL's School of Engineering. They aim to understand how cracks propagate in brittle solids, which is essential for developing and testing safe and cost-effective composite materials for use in construction, sports, and aerospace engineering. But traditional mechanics approaches to analyzing crack formation assume that cracks are planar -- i.e., that they form on the two-dimensional surface of a material. In fact, simple planar cracks are just the tip of the iceberg: most cracks -- like those in everyday brittle solids like glass -- propagate into three-dimensional networks of ridges and other complex features.

Read more.

#Materials Science#Science#Cracking#Materials failure#Brittleness#Materials characterization#Microscopy

19 notes

·

View notes

Text

Red Fountain Campus Facilities

Vanguard Campus Facilities

Tactical Combat Arenas

Varied arenas designed for tactical combat training and simulations.

Environments mimic diverse terrains for realistic combat scenarios.

Leadership and Command Center

Dedicated space for strategic planning and leadership development.

Simulation rooms for command exercises and decision-making scenarios.

Freelance Operations Hub

Space designed for independent contracting simulations and diverse combat scenario training.

Rooms for role-play exercises in navigating solo contracts or team-based operations.

Squadron Collaboration Center:

Meeting space for students to form and strategize with their squads.

Equipped with planning boards, discussion areas, and team collaboration tools.

Military History Archives

Extensive collection of historical records and artifacts related to warfare and strategy.

Rooms for discussions and analyses on historical battles and strategies.

Field Operations Training Grounds

Outdoor areas equipped for survival tactics training and field operations simulations.

Includes obstacle courses and wilderness environments for practical survival exercises.

Arcane Campus Facilities

Enchantment Workshops

Workspaces dedicated to practicing and mastering enchantment techniques.

Areas for experimenting with various enchantments and spellcraft.

Magical Artifact Studios

Studios designed for creating and studying magical artifacts.

Workspaces with tools and materials for crafting and analyzing magical items.

Creature Conservation Habitats

Sanctuaries and habitats for mystical creatures, focusing on their preservation and ethical treatment.

Areas for students to observe and study the behavior of these creatures.

Grand Archives of Magic

Renowned repository containing ancient tomes, magical texts, and theoretical studies on magic.

Research areas for delving into magical theory and historical practices.

Elixir and Potion Brewing Laboratories

Integrated labs for alchemical experimentation, potion brewing, and magical elixir creation.

Equipped for hands-on exploration of alchemical processes and potion concoction.

Beast Taming and Riding Grounds

Specially designed grounds for students to practice beast taming and riding.

Various enclosures to safely interact with and learn to ride different mystical creatures.

Magical Lineage Chambers

Chambers dedicated to the study of noble lineages and their magical heritage.

Spaces for discussions and analyses on the magical significance of lineage connections.

TechForge Campus Facilities

Techno-Magic Integration Center

Central hub for merging technology and magic.

Advanced labs equipped for coding enchantments, spell-powered systems, and magical-technological fusion.

Techno-Magic Artificer's Workshop:

Specialized workspace for crafting and enhancing magical artifacts and tools.

Enchantment stations and forging areas for creating enchanted devices.

Aerospace Complex

High-tech laboratories dedicated to aerospace engineering and dimensional travel studies.

Simulated flight environments and testing areas for aircraft and dimensional travel prototypes.

Techno-Magic Innovation Hub

Collaborative space for cutting-edge research and innovation in techno-magic fusion.

Project rooms and brainstorming areas for interdisciplinary collaborations.

Techno-Magic Programming Center

State-of-the-art computing facilities for magical coding and program development.

Coding environments specialized for techno-magical integration and spell-driven systems.

Techno-Magic Prototype Hangar

Facility for prototyping and testing new techno-magic devices and vehicles.

Workspaces for students to build and refine their techno-magic creations.

___

Note:

I hope everyone had a good Christmas, or if you don't celebrate I hope this time of the year is treating you well. I took a few days to just be with my family. I want to get back into posting at least once a day, so I can just keep myself disciplined. This isn't what I wanted to post today, but I just needed to make sure I was posting something. I'm trying to build up the habit of not being worried about every single detail.

#winx headcanons#winx rewrite#winx club#winx#winx club headcanons#winx fanfic#winx club fanfiction#winx club fanfic#winx club headcanon#winx club rewrite#red fountain

28 notes

·

View notes

Text

Quantum computers:

leverage the principles of **quantum mechanics** (superposition, entanglement, and interference) to solve certain problems exponentially faster than classical computers. While still in early stages, they have transformative potential in multiple fields:

### **1. Cryptography & Cybersecurity**

- **Breaking Encryption**: Shor’s algorithm can factor large numbers quickly, threatening RSA and ECC encryption (forcing a shift to **post-quantum cryptography**).

- **Quantum-Safe Encryption**: Quantum Key Distribution (QKD) enables theoretically unhackable communication (e.g., BB84 protocol).

### **2. Drug Discovery & Material Science**

- **Molecular Simulation**: Modeling quantum interactions in molecules to accelerate drug design (e.g., protein folding, catalyst development).

- **New Materials**: Discovering superconductors, better batteries, or ultra-strong materials.

### **3. Optimization Problems**

- **Logistics & Supply Chains**: Solving complex routing (e.g., traveling salesman problem) for airlines, shipping, or traffic management.

- **Financial Modeling**: Portfolio optimization, risk analysis, and fraud detection.

### **4. Artificial Intelligence & Machine Learning**

- **Quantum Machine Learning (QML)**: Speeding up training for neural networks or solving complex pattern recognition tasks.

- **Faster Data Search**: Grover’s algorithm can search unsorted databases quadratically faster.

### **5. Quantum Chemistry**

- **Precision Chemistry**: Simulating chemical reactions at the quantum level for cleaner energy solutions (e.g., nitrogen fixation, carbon capture).

### **6. Climate & Weather Forecasting**

- **Climate Modeling**: Simulating atmospheric and oceanic systems with higher accuracy.

- **Energy Optimization**: Improving renewable energy grids or fusion reactor designs.

### **7. Quantum Simulations**

- **Fundamental Physics**: Testing theories in high-energy physics (e.g., quark-gluon plasma) or condensed matter systems.

### **8. Financial Services**

- **Option Pricing**: Monte Carlo simulations for derivatives pricing (quantum speedup).

- **Arbitrage Opportunities**: Detecting market inefficiencies faster.

### **9. Aerospace & Engineering**

- **Aerodynamic Design**: Optimizing aircraft shapes or rocket propulsion systems.

- **Quantum Sensors**: Ultra-precise navigation (e.g., GPS-free positioning).

### **10. Breakthroughs in Mathematics**

- **Solving Unsolved Problems**: Faster algorithms for algebraic geometry, topology, or number theory.

#future#cyberpunk aesthetic#futuristic#futuristic city#cyberpunk artist#cyberpunk city#cyberpunkart#concept artist#digital art#digital artist#quantum computers#the future of quantum computers#futuristic theory

5 notes

·

View notes

Text

Titan: Don't Fuck With the Ocean

So this has been delayed, and everyone and their mother has already commented on this. We’re well past the virality mark on this topic. But whatever, I want to crack in and get this thing wrapped up anyways. For context, I study mechanical and manufacturing engineering. I’ve grown up around submarines with my dad being an engineer on US Navy subs, and I was able to ask him about this. I’ve also got a diving cert and enough experience living coastal to at least get me a knowledgeable respect for the ocean. Being 60 ft under should instill that, at least.

I will not make any comments on any of the other four victims. However, I reserve the right to be fully derogatory to the CEO who died in the submersible, Stockton Rush, for his disgusting flippancy towards safety in such a dangerous environment as 4,000m below sea level, for disregarding multiple warnings against the project, and for subjecting other passengers to this. I intended to start with my favorite source on this, but it looks like I’m beginning with spite. I claim that in engineering, if safety disregards don’t immediately boil your blood, you have to turn in your card. https://www.bbc.com/news/world-us-canada-65998914 “Titan sub CEO dismissed safety warnings as 'baseless cries', emails show” Some people may have seen the quote “At some point, safety just is pure waste,” Stockton told journalist David Pogue in an interview last year. “I mean, if you just want to be safe, don’t get out of bed. Don’t get in your car. Don’t do anything.” Stockton Rush has typed "We have heard the baseless cries of 'you are going to kill someone' way too often," he wrote. "I take this as a serious personal insult." *Frankly*, the response to this should very much not be personal insult, but a call to action. There is no reason to take this personally. “I have broken some rules to make this…The carbon fiber and titanium, there is a rule that you don’t do that. Well, I did.”

“At some point safety just is pure waste…I think I can do this just as safely by breaking the rules.”

“[The sub industry is] obscenely safe, because they have all these regulations…But it also hasn’t innovated or grown—because they have all these regulations.”

This is gruesomely hilarious when you remember the CEO isn’t the actual person running the stress tests, manufacturing it, checking materials charts and costs, calculating max tolerances, or anything else. He’s the little funny man with the money and the reputation who tells people do what he wants anyways. He has no right to play maverick when he is hardly doing any of the work, and especially when it involves other innocent people. While he has a bachelor’s in aerospace engineering, a very commendable thing to get, that’s not what he does hands on as the CEO, and aerospace does not directly translate to submersible understanding. You do not get to be flippant with other peoples’ lives. These comments would be bad enough for anything on the surface, or even in the sky. But again, the ocean is a completely different beast, where it is much more difficult for emergency services to reach people.

As well as this, I need to state the difference between submersible and submarine. If I don’t, I feel the entire US Navy breathe down my neck. It’s like boat vs ship. Submersible: needs to be supported by a vessel up top, not designed for long term deployments. Smol boy. Submarine: can be operated independently, can go on six month or so deployments. Big boy. Going forward, the primary difficulties of the ocean are first and foremost the atmospheres of pressure on the vehicle. The dangers of no breathing air in the ocean are of course, a major issue, but the pressure of the ocean will be what breaks this and makes that lack of air a huge issue. A submersible needs to be properly pressurized to withstand the changes and keep the passengers inside also safe. The ocean is also very difficult to reach communication through. https://www.hindawi.com/journals/wcmc/2019/6470359/, so the submersible losing connection isn’t entirely unsurprising. But other factors listed here lead to its delay.

#siege engineer#titan submersible#titan#oceangate#stockton rush#submarines#submersible#engineering#engineer#siege engineer talks#aerospace#oceangate submersible#titanic

74 notes

·

View notes

Text

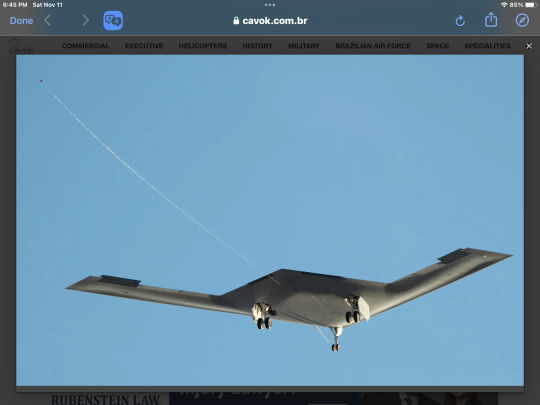

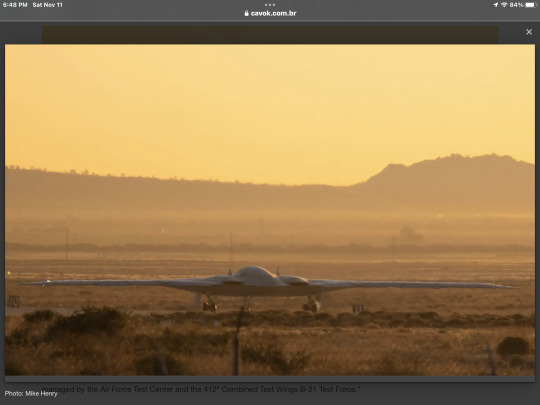

IMAGES: Fly the new USAF stealth bomber, the B-21 Raider

Fernando Valduga By Fernando Valduga 11/10/2023 - 15:14in Military

Photo: Matt Hartman

USAF's new B-21 “Raider” flying wing bomber made its first flight on Friday, the next step in the launch of a new fleet of nuclear-capable long-range stealth bombers built by Northrop Grumman.

The B-21 left the Northrop facility at U.S. Air Force Plant 42 in Palmdale, California, at sunrise on Friday at 6:51 a.m., offering the first improvised view of the new bomber that was developed under strict security.

The aircraft went to Edwards Air Base, California, where it will continue with the flight test phase with USAF. The flight lasted about 90 minutes.

With the Cerberus callsign, the aircraft took off eastward with an F-16 companion plane after climbing about 500 feet. The landing gear was not collected, according to videos and photos that appeared on social networks.

TAP TITLE BAR TO VIEW VIDEO☝️

U.S. Air Force leaders did not disclose the first flight of the B-21, but about three dozen aviation enthusiasts and amateur photographers gathered around Plant 42 on Friday in the hope of seeing the bomber rise to the skies.

Photo: Mike Henry

The B-21, which carries the same "flying wing" format as its predecessor, the B-2, will be able to launch conventional and nuclear weapons around the world, using long-range and in-flight refueling capabilities.

The aircraft are projected to cost approximately $550 million each in 2010 dollars, or about $750 million in current inflation-adjusted dollars. However, the USAF kept other price information confidential, “which makes it difficult to validate the proposed cost,” the Congressional Research Service said in a 2021 report.

Photo: Mike Henry

The U.S. Air Force plans to buy at least 100 planes and start replacing the B-1 and B-2 bombers. The B-1 costs about US$ 60,000 per hour to operate and the B-2 costs about US$ 65,000 per hour, according to Pentagon data.

Ann Stefanek, USAF spokesperson, said: “The B-21 Raider is in flight tests. Flight tests are a critical step in the testing campaign managed by the Air Force Test Center and the 412ª Combined Test Wings B-21 Test Force."

Photo: Mike Henry

Six test aircraft are being produced now. They are being built on the same line, using the tools, processes and technicians that will build the production aircraft.

Northrop defeated a team composed of Boeing and Lockheed Martin when it won the 2015 contract to manufacture the bomber. Engine manufacturer Pratt & Whitney, Collins Aerospace, GKN Aerospace, BAE Systems and Spirit Aerosystems are among more than 400 suppliers in 40 states.

The B-21 was publicly presented in December 2022, but the expectation around its first flight had been growing for years.

In 2019, an important Air Force general suggested that the bomber could fly as early as December 2021, but the Force subsequently postponed this date to mid-2022. In early 2022, the USAF postponed even more until 2023.

The B-21 program is in the engineering and manufacturing development phase and the first aircraft will be delivered to Ellsworth Air Force Base in North Dakota.

Northrop is calling the plane a sixth-generation aircraft due to its ability to connect to other aircraft and easily integrate future weapons into its systems architecture.

The B-21 also features surface material with low observation, more durable and stealthy, which should require less maintenance and reduce operating costs and downtime.

Tags: Military AviationNorthrop Grumman B-21 RaiderUSAF - United States Air Force / U.S. Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

SAAB

Sweden will arm Gripen E fighters with anti-radar missiles

10/11/2023 - 18:00

DUBAI AIR SHOW

Russia will show the Il-76MD-90A and a line of civilian and combat helicopters at the Dubai Airshow

10/11/2023 - 17:00

MILITARY

Slovakia cancels military aid package to Ukraine

10/11/2023 - 14:00

MILITARY

Saab highlights Gripen E at a defense fair in Thailand

10/11/2023 - 09:00

The first Boeing T-7A Red Hawk, with the USAF test pilot Maj. Jonathan "Gremlin" Aronoff and Boeing test pilot Steve "Bull" Schmidt at the controls, arrive at Edwards Air Base on November 8, 2023 (Photo: U.S. Air Force / Todd Schannuth)

MILITARY

IMAGES: First T-7A Red Hawk arrives in Edwards to start the testing campaign with USAF

10/11/2023 - 08:10

MILITARY

Spain 'rejects' F-35 fighters and should focus on more Eurofighter Typhoons

09/11/2023 - 21:52

Client PortalClient PortalClient PortalClient PortalClient PortalClient PortalClient PortalClient PortalhomeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

26 notes

·

View notes

Text

What is a Foundry? Why It’s the Key to Chip Manufacturing

In the heart of the global electronics industry lies a quiet giant—the semiconductor foundry. While companies like Apple, NVIDIA, and Qualcomm design the chips that power your favorite devices, it's the foundries that physically bring those designs to life. But what exactly is a foundry, and why is it so critical to chip manufacturing?

What is a Semiconductor Foundry?

A semiconductor foundry, or simply "foundry," is a manufacturing facility that fabricates integrated circuits (ICs). These ICs, also known as microchips or chips, are the brains behind modern electronics—everything from smartphones and laptops to cars and industrial machinery.

Foundries specialize in manufacturing chips designed by other companies, a business model known as pure-play foundry. For example, TSMC (Taiwan Semiconductor Manufacturing Company) is the world’s largest and most advanced foundry, producing chips for tech giants without competing with them in design.

There are also IDMs (Integrated Device Manufacturers) like Intel, which both design and manufacture their own chips. However, the pure-play foundry model has become dominant due to the increasing complexity and cost of chip manufacturing.

The Role of a Foundry in Chip Manufacturing

Chip design is only half the equation. Once a design is finalized using software and simulations, it must be turned into physical silicon wafers through a meticulous and highly precise process involving:

Photolithography: Transferring microscopic circuit patterns onto silicon.

Etching and Deposition: Carving and layering materials to form transistors and interconnects.

Ion Implantation: Modifying electrical properties at the atomic level.

Packaging and Testing: Encasing chips and validating their performance.

This process takes place in ultra-clean, billion-dollar facilities where even a speck of dust can ruin a chip. Foundries provide the scale, expertise, and cleanroom environments necessary to execute this complex task at nanometer precision.

Why Foundries Are the Key to the Chip Industry

Enabling Innovation Through Specialization Foundries allow fabless companies (those that only design chips) to focus on innovation without the burden of operating expensive fabrication plants. This division of labor has accelerated technological progress.

Advanced Process Technology Leading foundries invest billions into R&D and process nodes (like 5nm, 3nm, or 2nm technology), pushing the boundaries of performance and power efficiency.

Scalability and Global Supply Foundries serve a wide range of industries: consumer electronics, automotive, medical, aerospace, and more. Their capacity and scalability make them vital to maintaining the global tech supply chain.

Geopolitical and Economic Importance Countries now consider foundries as strategic assets, essential for national security and economic resilience. Supply chain disruptions in recent years have spotlighted their critical role.

Conclusion

Foundries are the unsung heroes of the digital era. While designers craft the vision for future chips, it’s the foundries that make those visions a reality with unmatched precision and scale. As chip demands surge across AI, IoT, and 5G, the importance of foundries in the semiconductor ecosystem will only grow.

Whether you're holding a smartphone or driving a smart vehicle, chances are a chip built in a foundry is powering the experience—quietly but powerfully behind the scenes.

3 notes

·

View notes

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

9 notes

·

View notes

Text

Green and Eco-Friendly Blasting Media: Current Development, Trends, and Future Challenges

——An In-Depth Industry Analysis for Manufacturing Managers and Environmental Engineers

Introduction: The Revolution of Blasting Technology in the Era of Environmental Transformation

As global environmental regulations tighten (e.g., EU REACH, U.S. EPA standards) and the ESG (Environmental, Social, Governance) concept gains traction, the manufacturing industry is increasingly demanding sustainable surface treatment technologies. Traditional blasting media, such as silica sand and steel grit, are under scrutiny due to dust pollution, high energy consumption, and health risks. In contrast, green and eco-friendly blasting media are emerging as a core breakthrough for industry transformation. This article combines the latest market data and technological trends to analyze the current development and future challenges in this field, providing strategic insights for decision-makers.

I. Market Status: Policy-Driven Growth and Technological Advancements

1. Market Size and Growth Potential

According to Grand View Research, the global blasting media market reached $5.2 billion in 2023, with the share of eco-friendly media rising from 12% in 2018 to 28% in 2023, achieving a compound annual growth rate (CAGR) of 9.7%. By 2030, the market share of green media is expected to exceed 45%, with the Asia-Pacific region (especially China and India) becoming a growth engine due to manufacturing upgrade demands.

2. Mainstream Eco-Friendly Media Types

Plant-Based Materials (walnut shells, corn cobs): Biodegradable, low dust emission (70% less than silica sand), suitable for precision parts.

Synthetic Ceramic Particles (alumina, silicon carbide): High hardness, reusable 5-8 times, reducing long-term costs.

Ice/Dry Ice: Zero-residue technology, with over 40% penetration in the aerospace sector.

Recycled Glass Beads: Made from waste glass, reducing carbon emissions by 65% compared to traditional processes.

3. Policy and Industry Standards Driving Adoption

The EU Circular Economy Action Plan aims to increase industrial waste recycling to 70% by 2030.

China’s 14th Five-Year Plan tightens blasting dust emission limits to 10mg/m³ (previously 20mg/m³).

Automotive giants (e.g., Toyota, Volkswagen) have incorporated "green blasting certification" into supply chain standards.

II. Technological Advantages and Business Value: Why Choose Green Media?

1. Environmental Benefits

Dust Control: Plant-based media reduce dust concentration to <2mg/m³ (compared to 15-20mg/m³ for silica sand), lowering the risk of silicosis.

Carbon Reduction: Each ton of recycled glass beads reduces CO₂ emissions by 1.2 tons compared to new steel grit.

Waste Management: 95% of synthetic ceramic media can be recycled, reducing landfill costs.

2. Economic Breakthroughs

Lower Lifecycle Costs: In the automotive industry, switching to ice media reduced annual maintenance costs by 18% per production line (source: Frost & Sullivan).

Improved Efficiency: High-precision ceramic particles increase blasting speed by 30% and reduce rework rates.

III. Future Challenges: Technological Bottlenecks and Industry Collaboration

1. Technical Pain Points

Material Limitations: Plant-based media have low hardness (Mohs 2-3), making them unsuitable for hard substrates like high-strength steel.

Cost Barriers: Green media prices remain 20-50% higher than traditional materials, hindering adoption by SMEs.

Lack of Recycling Systems: Only 35% of global companies have media recycling equipment, relying on third-party processing.

2. Industry Collaboration Challenges

Lack of Standardization: Differing definitions of "eco-friendly media" across countries create barriers to cross-border procurement.

Insufficient R&D Investment: SMEs lack funding for new material testing (single certification costs exceed $50,000).

IV. Solutions: Innovation and Ecosystem Building

1. Technological Breakthrough Paths

Composite Material Development: For example, "bio-resin + ceramic" hybrid media balancing hardness and biodegradability.

Smart Blasting Equipment: AI algorithms optimize media usage, reducing waste.

Cryogenic Plasma Technology: A zero-media alternative to physical blasting (currently in the lab stage).

2. Industry Ecosystem Recommendations

Policy Subsidies: Governments should offer tax credits for green media procurement (e.g., U.S. IRA Act).

Industry Alliances: Establish cross-company recycling networks to share regeneration facilities.

Customer Education: Use Life Cycle Assessment (LCA) reports to quantify long-term benefits and boost decision-maker confidence.

V. Conclusion: Green Blasting—A Must for Sustainable Manufacturing

Eco-friendly blasting media are not just a compliance requirement but a strategic choice for cost reduction, efficiency improvement, and brand value enhancement. To overcome the dual challenges of technological evolution and market education, innovation, policy coordination, and industry collaboration are essential to transition this field from an "optional solution" to an "industry standard."

Keywords: Green blasting media, eco-friendly surface treatment, sustainable manufacturing, blasting technology trends, industrial carbon neutrality, ESG compliance

Data Sources: Grand View Research, Frost & Sullivan, European Environment Agency, China Ministry of Ecology and Environment. Further Reading:

2024 Global Surface Treatment Technology White Paper

Pathways to Carbon Neutrality in Manufacturing: Starting with Blasting Processes

2 notes

·

View notes

Note

Hal. Do you get bullied by the other more mutated McCoys?👁️👁️

"Bullied? Well, it's not like they're pushing me in the sandbox and stealing my lollipop like we're schoolchildren. They also don't tend to accost me with childish taunts...No, they ignore me."

"It's not like I'm the only McCoy who's not grown blue fur (or any other color fur for that matter)... but I'm definitely in the minority."

"It mainly lies in the fact that I'm not a biologist, a chemist, an MD, a geneticist, a biomedical engineer...or a fucking aerospace engineer. I don't have a wall full of BS degrees. I have dual BAs in Fashion Design Technology: Menswear and Womenswear from London College of Fashion. "

"I haven't saved the world with a cure for deadly viruses, or halted deadly microbots from destroying people from the inside out, or stopped alien race from taking over earth...and when they...we...are a prideful bunch, being a well-known fashion designer does not rank high in terms of achievements in their eyes."

"But they don't know that I dabble in biological and chemical engineering to create many of my designs. I have created new biosynthetic materials... I just choose to hire a small team of scientists to properly test and patent them. Being a scientist would peak the interest of certain parties that I don't want knocking on my door... I left that life long ago."

"They also don't know the experience of watching a nine-year-old girl cry with joy when she finally puts on a set of clothes that her skin won't melt off of her body. Or the man who was unable to touch anyone because of the strong electrical current running through his body suddenly be able to hug his family for the first time in decades without wearing rubber gloves...or fire departments worldwide now relying on thinner, less cumbersome material that has the same/better protections as their old, heavy layers which allows them to save lives more easily? I could go on..."

"The point is, they view me as beneath them because they don't even bother to see past the optical lenses of the microscope jammed against their eyes."

#the mccoyverse#hank mccoy#ask us anything!#beast xmen#Most McCoy's do not take him seriously even though he's no less intelligent#but he also uses their underestimations to his advantage

3 notes

·

View notes

Text

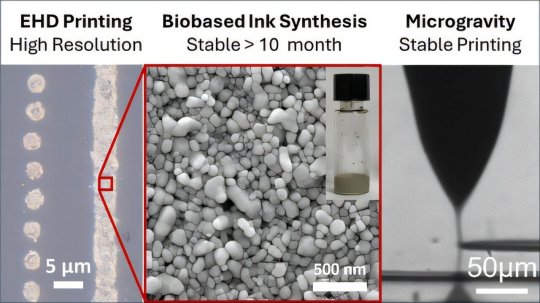

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

6 notes

·

View notes

Text

Songshun Steel Rod Supplier: Provides Various High Quality Steel Rods

Steel rod is a common rod-shaped steel material made of metal materials, it is widely used in machinery, ships, construction, engineering, manufacturing and other fields. Steel rods are one of the indispensable materials in the steel market and are in high demand, so steel rod suppliers play a pivotal role in the steel market. Songshun Steel, as a high-quality steel rod supplier in China, can provide various high-quality steel rod materials to the world. It not only has rich varieties and sufficient inventory, but also ensures that the quality, service, price, etc. can satisfy you. This article will introduce the steel rods and advantages provided by Songshun steel rod supplier.

Steel Rod Types Songshun Steel, as a steel rod supplier with a wide range of steel materials, provides steel bar materials of various materials. Our steel rod types are as follows:

(1) Classified by process, it can be divided into hot-rolled, forged and cold-drawn steel bars; (2) Classified by material, steel rods can be divided into alloy steel rods, Ordinary carbon steel rods, stainless steel rods, tool steel rods, high-speed steel rods, aluminum alloy rods, synthetic fiber steel rods, etc.; (3)Classified by shape, it can be divided into solid steel rods, round steel rods, square steel rods, hexagonal steel rods, wire rods, etc.

Steel Rod Properties High quality steel rod supplier, offering a wide range of high performance steel rods. As a reliable steel rod supplier in China, Songshun Steel provides steel rods with the following properties:

Excellent wear resistance, corrosion resistance and high temperature resistance Better electrical and thermal conductivity High strength and rigidity Good solderability and stability Good plasticity and toughness

Uses Of Steel Rods As a professional steel rod supplier, we have an in-depth understanding of steel rods and clearly understand the purposes for which our customers purchase steel rods. Below are some of our customers’ applications for steel rods in various fields.

Construction field: Steel rods are often used to reinforce concrete structures, and are also used to support structures such as beams, columns, bridges, and columns.

Automobile manufacturing field: Steel rods are used to manufacture various engine parts, rods, brake calipers, exhaust pipes, connectors, support columns, door beams, roof frames, etc.

In the manufacturing of electronic and electrical equipment, steel rods are often used to make wires for electromagnetic coils, transformers and generators. They are also used as heat-conducting elements in air conditioners, refrigerators, and other appliances, among other things.

In the manufacturing field, it is often used to manufacture various mechanical parts, tools, cutters, drill bits, planers, etc.

In addition to the above fields, steel rods are also used in aerospace, energy and power transmission, oil and gas industry, shipbuilding, chemical and heavy industry, home furnishing and decoration, etc.

Steel Rod Supplier In addition to the above points, as a high-quality and reliable steel rod supplier, Songshun can not only provide a variety of high-performance, multi-purpose and types of steel rods, but also has advantages in quality, professionalism, service, price, etc.

We ensure the quality of steel rods, provide various testing services, provide products in strict accordance with international production standards and customer requirements, and provide steel rods with the best performance and quality to customers.

Songshun has an experienced team that studies various steel rod materials and provides customers with one-stop solutions and technical support.

Whether it is processing, pre-sales or after-sales service, we are professional and can ensure that your project is completed smoothly and perfectly.

Competitive prices, abundant inventory, and ability to deliver on time.

Understand industry policies, market demand, international trade, etc., and be able to make reasonable strategies to adjust industrial structure, optimize product quality, improve operational efficiency, and promote innovative development according to market changes in a timely manner.

Adhere to the path of sustainable development, adhere to the goal of achieving win-win development with customers, adhere to treating every customer with sincerity, adhere to customer-centeredness, and meet customer needs.

In summary, Songshun Steel can become a reliable steel rod supplier, not only providing high-quality steel rod materials, but also having other advantages. In the future, we are committed to becoming your preferred steel rod supplier, constantly moving forward, and providing you with better steel products.

2 notes

·

View notes