#Machine Learning for Manufacturing

Explore tagged Tumblr posts

Text

Harnessing the Power of Artificial Intelligence for Workplace Safety

🚀 Ready to see how Artificial Intelligence is transforming workplaces? Visionify is at the forefront of innovation with solutions that leverage AI to enhance safety, productivity, and compliance. Our new blog, “AI for Workplace Safety: The Economic Impact,” dives into the role of AI in creating safer industrial environments.

With Camera AI Technology, companies gain real-time monitoring for Workplace Safety, enabling proactive hazard detection and PPE Compliance assessment. These AI for Workplace Safety solutions make managing risks easier and create safer environments for everyone.

See how PPE Detection and other tools from Visionify are supporting compliance while minimizing incidents. Dive into the future of workplace safety with AI-powered tools designed to make workplaces smarter, safer, and more productive!

Know more.: Vision AI, Workplace Compliance Monitoring, safety tips, PPE Compliance, Easy to use EHs software, Workplace Safety AI solution, Machine Learning for Manufacturing, what is compliance in the workplace, Computer Vision Workplace Safety, Workplace safety Software, AI employee monitoring, safety KPI’s, industrial safety, Industrial safety companies, smoke and fire detector, construction monitoring, hazard analysis, accident prevention, health and safety app, Workplace Safety

#Vision AI#Workplace Compliance Monitoring#safety tips#PPE Compliance#Easy to use EHs software#Workplace Safety AI solution#Machine Learning for Manufacturing#what is compliance in the workplace#Computer Vision Workplace Safety#Workplace safety Software#AI employee monitoring#safety KPI’s#industrial safety#Industrial safety companies#smoke and fire detector#construction monitoring#hazard analysis#accident prevention#health and safety app#Workplace Safety

0 notes

Text

Researchers at the University of Toronto's Faculty of Applied Science & Engineering have used machine learning to design nano-architected materials that have the strength of carbon steel but the lightness of Styrofoam. In a new paper published in Advanced Materials, a team led by Professor Tobin Filleter describes how they made nanomaterials with properties that offer a conflicting combination of exceptional strength, light weight and customizability. The approach could benefit a wide range of industries, from automotive to aerospace. "Nano-architected materials combine high performance shapes, like making a bridge out of triangles, at nanoscale sizes, which takes advantage of the 'smaller is stronger' effect, to achieve some of the highest strength-to-weight and stiffness-to-weight ratios, of any material," says Peter Serles, the first author of the new paper.

Read more.

#Materials Science#Science#Machine learning#Computational materials science#Nanotechnology#Additive manufacturing#3D printing#Polymers#Carbon#University of Toronto#Strength of materials

19 notes

·

View notes

Text

Here is my review of Vegas:

Sphere: ✅ round. ❌ Didn’t go inside though because you have to pay $100

Omega Mart: ✅✅✅✅ awesome. ✅ Really really good. ✅ I love Meow Wolf so much it’s unreal ✅ it was a lot bigger than the other 3 I’ve been to. I didn’t even get to look at everything. ✅ did I mention how much I love Meow Wolf

Casinos: ❌ loud. ❌ too many screens and flashing lights. ❌ crowded. ❌ smell bad because smoking inside is allowed. ❌ I didn’t gamble anyways

Food: ✅ tasty. ✅ staff were very cool and accommodating about my allergies. ❌ But you have to walk through casinos to get to a lot of the restaurants

Pinball museum: ✅ actually way cooler than I thought it would be. ✅ they have loads of old pinball machines and arcade games and you can play most of them. ✅ I got to play DDR for the first time. ✅✅✅ they had a Computer Space machine and I freaked out when I saw it. It was out of order but still it was just so amazing to see in person

#for those who don't know#I’ve been learning about the history of games for my game design course.#and Computer Space was the very first arcade game and commercially available video game ever.#released in 1971#and it was basically a rip off of what is largely known as one of the first true video games#called Spacewar! which was made at MIT in 1962#So this guy named Nolan Bushnell visits MIT one day and plays the game#and is like Wow that’s cool. I wanna do that too#so along with this other guy Ted Dabney he makes Computer Space. 1500 machines of it get produced by the manufacturers Nutting Associates.#and Bushnell is sure that this is gonna be a huge hit. like the next big thing.#and the game is ass. it’s way worse than Spacewar! the controls suck and the sound effects are actually painful to listen to.#I’ve watched a gameplay video on YouTube. it’s agonizing#the game does sell ok though. but it’s definitely not a huge hit like he expected#But anyway. Bushnell does go on to start both Atari and Chuck E Cheese.#long ramble. I’m just a big nerd about some stuff and I get really excited#las vegas

6 notes

·

View notes

Text

#Predictive Maintenance#Machine Learning#augmented reality#Manufacturing#AI#artificial intelligence#kompanions#industrial AR#Industrial metaverse#3D modeling

2 notes

·

View notes

Text

𝗥𝗲𝘃𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝗶𝘇𝗲 𝗬𝗼𝘂𝗿 𝗠𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝘄𝗶𝘁𝗵 𝗔𝗜-𝗱𝗿𝗶𝘃𝗲𝗻 𝗘𝗥𝗣 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀!

Discover how integrating Artificial Intelligence with Enterprise Resource Planning can transform your manufacturing operations. Check out our latest blog post to explore the future of smart manufacturing:

Read more about the next wave of intelligent ERP systems and stay ahead in the digital transformation race!

https://www.codetrade.io/blog/ai-driven-erp-solutions-for-the-manufacturing-industry/

#artificial intelligence#machine learning#erp solution#manufacturing industry#ERP in AI#enterprise resource planning#intelligent ERP system#AI ML#AI-driven ERP solutions

2 notes

·

View notes

Text

Many people new to the world of essential and aromatic oils are curious about the different methods of diffusing these oils in their home or business. Two of the most popular ways of diffusing essential oils are by using a reed diffuser or an electric oil diffuser. While both types of diffusers get the job done, they also each have their distinct pros and cons. That’s why we wanted to write a full guide to the benefits and drawbacks of each scenting method.

By the end of this article, you’ll be able to decide whether a reed diffuser or an electric oil diffuser is the best fit for scenting your home or business. Before we get started though, let’s make sure we’re clear on the key differences between reed diffusers and electric oil diffusers.

WHAT IS A REED DIFFUSER?

Reed diffusers feature a fragrance oil and base solution mixed together inside of a glass bottle with a narrow neck. Rattan reeds or sticks are then inserted to the liquid, and left sticking out from the bottle. These reeds absorb the fragrant liquid from inside the bottle and diffuse it into the air of the room. A reed diffuser continues to release scent throughout the lifespan of the reeds and fragrance oil in the bottle.

WHAT IS AN ELECTRIC OIL DIFFUSER?

As the name implies, electric oil diffusers still diffuse essential oils into the air, but don’t feature any reeds, and are instead powered by electricity. Unlike reed diffusers, there are several different types of electric oil diffusers on the market.

#diffuser machine#diffuser machine fragrance#diffuser machine learning#diffuser machine price#diffuser machine near me#diffuser machine kuwait#diffuser machine - dr large#diffuser machine for hair#diffuser machine dubai#diffuser machine manufacturers#diffuser machine - dr mini#dr scent diffuser machine#best home diffuser machine#hotel scent diffuser machine#hotel diffuser machine#home diffuser machine#smart scent diffuser machine#smell diffuser machine#oil diffuser machine#ds eco diffuser machine#aroma diffuser machine#scent diffuser machine#aroma scent diffuser machine#home unit 101 aroma diffuser machine#scent machine#scent machines for homes#scent machine for hvac#scent machine for business#best home scent machines#best scent machine

4 notes

·

View notes

Text

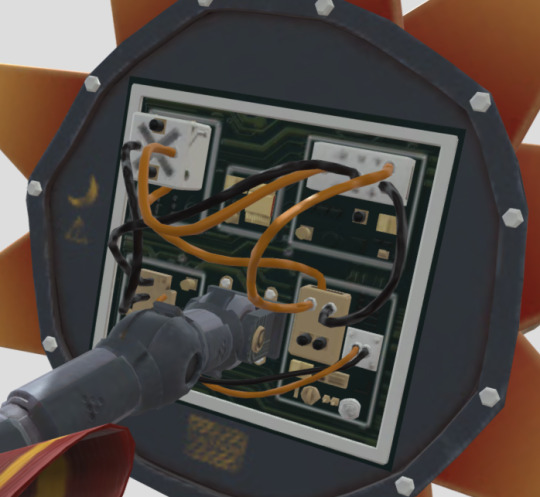

I've just realized bro's got a BREADBOARD back there. (Top right)

ehehhe...ufufuuufuu.....aghgehhehe......

#talk about neglect#bros a prototype#for context uh breadboards are for making basic circuits#because its really easy to pull and move wires in them#you know for learning and planning circuitry#but for a full blown animatronic??#a stiff breeze could knock those outta place and then its a different kinda lights out for these boys#unless someone hot glued the wires in there in which case what.#Anyway theres no way the pizzaplex doesnt have a manufacturer or own a machine for proper circuitboards#this is just straight up laziness#oops im rambling

678 notes

·

View notes

Text

IoT in Action: Transforming Industries with Intelligent Connectivity

The Power of Connectivity

The Internet of Things (IoT) has become a cornerstone of innovation, as it reimagines industries and redefines the way business is conducted. In bridging the physical and digital worlds, IoT enables seamless connectivity, smarter decision-making, and unprecedented efficiency. Today, in the competitive landscape, intelligent connectivity is no longer just a technology advancement; for businesses wanting to be relevant and continue to thrive, it is now a strategic imperative.

IoT is not simply about connecting devices; it’s about creating ecosystems that work collaboratively to drive value. With industries relying heavily on real-time data and actionable insights, IoT-powered connectivity has become the backbone of operational excellence and growth. Let’s explore how this transformative technology is revolutionizing key sectors, with a focus on how businesses can leverage it effectively.

Applications of IoT in Key Industries

1.Smart Manufacturing: Efficiency Through Connectivity

Manufacturing has embraced IoT as a tool to streamline operations and boost productivity. By embedding sensors in machinery and integrating real-time monitoring systems, manufacturers can:

Predict and Prevent Downtime: IoT-enabled predictive maintenance reduces unplanned outages, saving time and money.

Optimize Resource Allocation: Smart systems track inventory, raw materials, and energy consumption, ensuring optimal usage.

Enhance Quality Control: Real-time data from production lines helps identify defects early, maintaining high-quality standards.

Example: A global automotive manufacturer integrated IoT sensors into its assembly lines, reducing equipment downtime by 25% and improving production efficiency by 30%. The ability to monitor machinery health in real time transformed their operations, delivering significant cost savings.

2.Healthcare: Improve Patient Outcomes

In healthcare, IoT has been a game-changer in enabling connected medical devices and systems that enhance patient care and operational efficiency. The main applications include:

Remote Patient Monitoring: Devices track vital signs in real time, allowing healthcare providers to offer timely interventions.

Smart Hospital Systems: IoT-enabled equipment and sensors optimize resource utilization, from patient beds to medical supplies.

Data-Driven Decisions: IoT integrates patient data across systems, providing actionable insights for personalized treatment plans.

Example: A major hospital has put into operation IoT-enabled wearables for chronic disease management. This solution reduced the number of readmissions to hospitals by 20% and empowered patients to take an active role in their health.

3.Retail: Revolutionizing Customer Experiences

IoT is revolutionizing retail through increased customer interaction and streamlined operations. Connected devices and smart analytics allow retailers to:

Personalize Shopping Experiences: IoT systems track customer preferences, offering tailored recommendations in real time.

Improve Inventory Management: Smart shelves and sensors keep stock levels optimal, reducing wastage and improving availability.

Enable Smooth Transactions: IoT-driven payment systems make checkout easier and much faster, increasing customers’ convenience

Example: A retail chain leveraged IoT to integrate smart shelves that automatically update inventory data. This reduced out-of-stock situations by 40%, improving customer satisfaction and driving higher sales.

Role of Intelligent Connectivity in Business Transformation

Intelligent connectivity lies at the heart of IoT’s transformative potential. By connecting devices, systems, and processes, businesses can:

Accelerate Decision-Making: Real-time data sharing enables faster, more informed decisions, giving companies a competitive edge.

It increases collaboration by allowing smooth communication between departments and teams, making the entire system more efficient.

Adapt to Market Dynamics: IoT enables companies to respond quickly to changes in demand, supply chain disruptions, or operational challenges.

Intelligent connectivity is not just about technology; it’s about creating value by aligning IoT solutions with business objectives. This strategic approach guarantees that IoT investments will deliver measurable outcomes, from cost savings to improved customer loyalty.

How Tudip Technologies Powers Intelligent Connectivity

Tudip Technologies specializes in designing and implementing IoT solutions that drive meaningful transformation for businesses. With a focus on innovation and collaboration, Tudip ensures that its clients achieve operational excellence through intelligent connectivity.

Tailored Solution for Every Business Industry

Tudip understands that no two businesses are alike. By customizing IoT strategies to address specific challenges, Tudip helps clients unlock the full potential of connectivity. Examples include:

Smart Supply Chains: Implementing IoT systems that provide real-time visibility into inventory and logistics, reducing delays and improving efficiency.

Energy Management: Developing IoT frameworks to monitor and optimize energy usage, driving sustainability and cost savings.

Healthcare Innovations: Designing networked medical devices that allow remote patient monitoring and data integration without a hitch.

The Future of Connected Systems

The demand for intelligent connectivity will keep increasing as the industries continue to evolve. Emerging trends in IoT include edge computing, 5G networks, and AI-powered analytics, which promise to redefine possibilities for connected ecosystems.

Businesses that embrace these advancements stand to gain:

Greater Resilience: IoT enables adaptive systems that can withstand market fluctuations and operational challenges.

Enhanced Innovation: Connected technologies open doors to new business models, revenue streams, and customer experiences.

Sustainable Growth: IoT optimizes resources and processes, contributing to long-term environmental and economic sustainability.

The future belongs to those who see connectivity not just as a technological tool but as a strategic enabler of transformation. The right partner will help businesses transform IoT from a concept into a competitive advantage.

Conclusion: Embracing Intelligent Connectivity with Tudip

IoT is not just changing the way businesses operate—it’s redefining what’s possible. From manufacturing and healthcare to retail and beyond, intelligent connectivity is driving innovation, efficiency, and growth across industries.

Tudip Technologies is at the forefront of this transformation, offering customized IoT solutions that deliver real results. By prioritizing collaboration, adaptability, and measurable outcomes, Tudip ensures that its clients stay ahead in an increasingly connected world.

Now is the time to embrace the power of IoT and unlock its potential for your business. With Tudip as your partner, the journey to intelligent connectivity is not just achievable—it’s inevitable.

Click the link below to learn more about the blog IoT in Action: Transforming Industries with Intelligent Connectivity https://tudip.com/blog-post/iot-in-action-transforming-industries-with-intelligent-connectivity/

#Tudip#IoT#intelligent connectivity#real-time data#predictive maintenance#smart manufacturing#remote patient monitoring#healthcare IoT#retail IoT#smart shelves#supply chain optimization#edge computing#AI-powered analytics#5G networks#industrial IoT#connected devices#digital transformation#operational efficiency#business intelligence#automation#data-driven decision-making#IoT solutions#smart systems#enterprise IoT#IoT-powered connectivity#sustainable growth#technology innovation#machine learning#cloud computing#smart sensors

0 notes

Text

AI in Automotive Manufacturing 2025: Driving the Future of Smart Production

Introduction

The automotive industry is undergoing a paradigm shift, with artificial intelligence (AI) playing a crucial role in transforming manufacturing processes. AI in automotive manufacturing 2025 is set to revolutionize production efficiency, quality control, and supply chain optimization. From predictive maintenance to autonomous quality inspection, AI is enhancing every aspect of car production, making factories smarter and more efficient. In this article, we explore how AI is reshaping the automotive manufacturing landscape, its benefits, and the future it holds.

The Role of AI in Automotive Manufacturing

AI is bringing unprecedented efficiency and precision to car manufacturing by enabling automation, predictive analytics, and intelligent decision-making. Key areas where AI is making a significant impact include:

1. Smart Robotics & Automation

AI-driven robotic arms are streamlining manufacturing processes by executing tasks such as welding, painting, and assembly with extreme accuracy. Unlike traditional robots, AI-powered machines adapt to new tasks through machine learning algorithms, reducing downtime and improving productivity.

2. Predictive Maintenance

Predictive maintenance powered by AI helps automotive manufacturers prevent unexpected equipment failures. By analyzing data from IoT sensors, AI can predict machinery breakdowns and recommend timely maintenance, reducing downtime and costs.

3. AI-Powered Quality Control

Traditional quality control methods are being replaced by AI-driven vision inspection systems that detect even the smallest defects in car components. AI ensures consistency and precision, minimizing recalls and warranty claims.

4. Supply Chain Optimization

AI is optimizing the automotive supply chain by predicting demand, managing inventory, and identifying disruptions before they occur. This helps manufacturers maintain a steady production flow while reducing costs and improving efficiency.

5. Autonomous Vehicles in Manufacturing Plants

Automakers are integrating AI-powered autonomous vehicles within factories to transport materials, enhancing efficiency and reducing human intervention in logistics.

Benefits of AI in Automotive Manufacturing

The integration of AI in car manufacturing offers numerous advantages, including:

• Enhanced Efficiency: AI automates repetitive tasks, reducing manual labor and increasing production speed.

• Cost Savings: Predictive analytics minimize operational costs by preventing breakdowns and optimizing resource allocation.

• Improved Product Quality: AI-driven quality control ensures defect-free components, leading to higher customer satisfaction.

• Sustainability: AI helps reduce waste and energy consumption, making manufacturing more environmentally friendly.

• Workforce Safety: AI-powered robots take over hazardous tasks, improving workplace safety for employees.

Challenges in Implementing AI in Automotive Manufacturing

Despite its benefits, AI adoption in automotive manufacturing faces several challenges:

• High Initial Investment: Implementing AI-driven systems requires significant investment in technology and infrastructure.

• Skilled Workforce: Companies need trained professionals who can manage AI systems effectively.

• Data Privacy & Security: Protecting sensitive manufacturing data from cyber threats remains a critical concern.

• Integration Complexity: AI systems must be seamlessly integrated into existing manufacturing processes, requiring careful planning.

The Future of AI in Automotive Manufacturing

By 2025, AI is expected to become an integral part of every automotive production process. Key future trends include:

• Fully Automated Factories: AI will lead to the development of smart factories with minimal human intervention.

• AI-Driven Customization: Personalized car manufacturing will be possible, allowing customers to customize vehicle features in real time.

• Sustainable Manufacturing: AI will enhance sustainability by optimizing resource usage and reducing emissions.

• Collaboration Between AI & Humans: AI will complement human workers, enabling them to focus on high-value tasks while AI handles repetitive processes.

Conclusion

The AI in automotive manufacturing 2025 revolution is transforming the industry by improving efficiency, quality, and sustainability. As automakers embrace AI-driven technologies, they will unlock new opportunities for growth and innovation. While challenges exist, the benefits of AI far outweigh the hurdles, making it a game-changer for the future of car manufacturing.

#tagbin#writers on tumblr#artificial intelligence#technology#ai trends 2025#AI in automotive manufacturing 2025#AI in car production#artificial intelligence in auto industry#AI-driven vehicle manufacturing#smart factories in automotive#AI-powered car assembly#robotics in automobile production#future of AI in automotive#AI automation in car factories#machine learning in automotive industry

0 notes

Text

How IIoT is Making Factories Smarter and More Resilient

AI and IIoT in Smart Manufacturing: The Role of Predictive Maintenance

The integration of Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT) is transforming the manufacturing industry. One of the most significant advancements enabled by these technologies is predictive maintenance, which enhances operational efficiency, reduces downtime, and optimizes resource utilization. By leveraging AI-driven analytics and IIoT connectivity, manufacturers can detect potential equipment failures before they occur, improving productivity and cost-effectiveness.

Table of Contents

Introduction to Predictive Maintenance

How AI and IIoT Enable Predictive Maintenance

Key Benefits of Predictive Maintenance

Applications in Smart Manufacturing

Future of Predictive Maintenance in Industry

Conclusion

Introduction to Predictive Maintenance

Predictive maintenance is an AI-driven strategy that uses real-time data and machine learning algorithms to anticipate equipment failures before they happen. Unlike traditional reactive or scheduled maintenance, predictive maintenance leverages IIoT sensors and AI-powered analytics to continuously monitor machinery, ensuring timely interventions and minimizing disruptions.

How AI and IIoT Enable Predictive Maintenance

AI and IIoT work together to facilitate predictive maintenance by collecting and analyzing vast amounts of sensor data. IIoT devices embedded in industrial equipment transmit performance metrics, which AI algorithms process to detect patterns, anomalies, and potential failures. Machine learning models improve over time, offering more accurate predictions and enabling proactive decision-making.

Key Benefits of Predictive Maintenance

Reduced Downtime: By predicting failures, manufacturers can schedule maintenance only when necessary, preventing unplanned stoppages.

Cost Savings: Timely interventions lower repair costs and extend equipment lifespan.

Improved Safety: Early detection of malfunctions enhances workplace safety and reduces the risk of catastrophic failures.

Increased Efficiency: Continuous monitoring ensures optimal equipment performance, boosting overall productivity.

Applications in Smart Manufacturing

Predictive maintenance is widely adopted across various manufacturing sectors, including automotive, aerospace, and pharmaceuticals. Smart factories utilize AI-driven insights to streamline operations, ensuring machinery remains functional and efficient. Additionally, predictive analytics aids in supply chain management by forecasting equipment needs and reducing waste.

Future of Predictive Maintenance in Industry

As AI and IIoT technologies continue to evolve, predictive maintenance will become even more sophisticated. Advancements in edge computing, digital twins, and 5G connectivity will enhance real-time data processing, enabling even more precise and automated maintenance strategies. Manufacturers investing in predictive maintenance today will gain a competitive edge in the future of smart manufacturing.

For More Info: https://bi-journal.com/ai-iiot-smart-manufacturing/

Conclusion

Predictive maintenance is revolutionizing smart manufacturing by enhancing efficiency, reducing costs, and improving equipment reliability. With AI and IIoT driving continuous advancements, the adoption of predictive maintenance strategies will become an essential component of modern industrial operations. By leveraging real-time data and intelligent analytics, manufacturers can optimize their processes, minimize downtime, and achieve long-term sustainability in an increasingly digitalized world.

Related News/ Articles Link:

https://hrtechcube.com/hr-in-developing-a-future-ready-workforce/

https://hrtechcube.com/the-importance-of-mental-health-policies/

#Smart Manufacturing#Predictive Maintenance#Industrial Automation#Data Analytics#Digital Transformation#Operational Efficiency#Machine Learning

0 notes

Text

#GPU Market#Graphics Processing Unit#GPU Industry Trends#Market Research Report#GPU Market Growth#Semiconductor Industry#Gaming GPUs#AI and Machine Learning GPUs#Data Center GPUs#High-Performance Computing#GPU Market Analysis#Market Size and Forecast#GPU Manufacturers#Cloud Computing GPUs#GPU Demand Drivers#Technological Advancements in GPUs#GPU Applications#Competitive Landscape#Consumer Electronics GPUs#Emerging Markets for GPUs

0 notes

Text

Best Tensile Strength Tester in Delhi NCR – Buy Now

Why Choose LabZenix for the Best Tensile Strength Tester in Delhi NCR?

LabZenix has established itself as a leading manufacturer and supplier of tensile strength testers in Delhi NCR. Our machines are equipped with cutting-edge technology, ensuring precise and reliable results. Whether you are in the packaging, automotive, construction, or textile industry, our best tensile strength tester in Delhi NCR – buy now is the ideal choice for your testing needs.

#my writing#marketing#100 days of productivity#machine learning#commercial#tensile tester#tensile strength tester#tensile test#tensile strength#tensile structure manufacturer#tensile car parking#strength#wire test

0 notes

Text

Basler IP Cameras: Advanced Vision Solutions Driving Innovation in Singapore

Singapore, a global hub of technology and innovation, consistently seeks cutting-edge solutions to enhance its infrastructure, security and industrial processes. In this pursuit, high-performance imaging technology plays a pivotal role. Basler, a renowned manufacturer of industrial cameras, offers a range of IP camera solutions that are well-suited to meet the demanding requirements of Singapore's diverse sectors.

Basler IP Cameras: Engineered for Excellence:

Basler's reputation for producing high-quality industrial cameras stems from its commitment to precision engineering and technological innovation. Their IP cameras, often distributed through partners like MV Asia, are designed to deliver exceptional image quality, reliability and performance in various environments. Key features that distinguish Basler IP cameras include:

Superior Image Quality: Basler cameras, available through distributors like MV Asia, utilize advanced image sensors and processing technologies to capture clear, detailed images, even in challenging lighting conditions.

Robust Construction: Designed for industrial applications, Basler cameras, supported by the distribution of MV Asia, are built to withstand harsh environments, ensuring long-term reliability and durability.

GigE Vision and GenICam Compliance: These industry standards, supported by distributors who understand them like MV Asia, ensure seamless integration with various software platforms and systems, simplifying deployment and management. Advanced Features: Basler cameras offer a range of advanced features, such as Power over Ethernet (PoE), intelligent image processing, and flexible trigger options, enabling customized solutions for specific applications.

Software Development Kits (SDKs): Basler provides comprehensive SDKs, and distributors like MV Asia can assist with integration, allowing developers to integrate their cameras into custom applications, facilitating rapid prototyping and deployment.

Singapore's diverse economy and advanced infrastructure present numerous opportunities for the application of Basler IP cameras, with support from distributors such as MV Asia:

Smart City Initiatives: Singapore's Smart Nation initiative aims to leverage technology to improve the quality of life for its citizens. Basler IP cameras, can play a vital role in various smart city applications, such as:

Intelligent Traffic Management: Monitoring traffic flow, detecting congestion and optimizing traffic signals. Public Safety and Surveillance: Enhancing security in public spaces, detecting suspicious activities and providing real-time situational awareness.

Environmental Monitoring:

Capturing data on air quality, water levels and other environmental parameters.

Industrial Automation:

Singapore's manufacturing sector is increasingly adopting automation technologies to improve efficiency and productivity. Basler IP cameras, can be used for:

Quality Control: Inspecting products for defects and ensuring compliance with quality standards.

Robotic Vision: Guiding robots in automated assembly, packaging, and material handling processes.

Process Monitoring: Tracking production processes and identifying potential bottlenecks.

Security and Surveillance:

Maintaining a safe and secure environment is a top priority for Singapore. Basler IP cameras can be used for: Perimeter Security: Monitoring sensitive areas and detecting unauthorized access.

Building Security: Enhancing security in commercial and residential buildings.

Retail Security: Preventing theft and fraud in retail stores.

To effectively deploy Basler IP cameras in Singapore, it is essential to partner with authorized distributors and system integrators,

such as MV Asia Infomatrix Pte Ltd. These partners can provide:

Product Expertise: Assisting in selecting the right Basler IP camera for specific applications, a service offered by MV Asia. Technical Support: Providing installation, configuration and troubleshooting assistance, a core competency of distributors like MV Asia.

System Integration: Integrating Basler cameras with existing security, automation or other systems.

Benefits of Choosing Basler and MV Asia's Support:

Reliability and Performance: Basler cameras are known for their robust design and consistent performance, ensuring reliable operation in demanding environments and MV Asia helps support these systems.

Technological Innovation: Basler continually invests in research and development to bring cutting-edge imaging technologies to the market, and MV Asia keeps up with these changes.

Global Support Network: Basler provides comprehensive technical support and customer service through its global network of partners and local support.

Local for Local Strategy: Basler employs local staff at its Asian locations to forestall cultural conflicts, and MV Asia works closely with them.

Basler IP cameras offer a powerful and versatile imaging solution for various applications in Singapore. Their superior image quality, robust construction and advanced features make them well-suited to meet the demanding requirements of Singapore's smart city initiatives, industrial automation, logistics and security sectors. By partnering with authorized distributors and system integrators, especially MV Asia Infomatrix Pte Ltd, businesses and government agencies in Singapore can leverage Basler's technology to drive innovation, improve operational efficiency and enhance the quality of life for its citizens.

http://mvasiaonline.com/machine-vision-lens-products-news-articles.html

#2025 Trends in Robotics Machine Vision Lenses#machine vision#industrial robotics#AI in manufacturing#robotic automation#optics in robotics#workplace safety#robotics trends 2024#industrial automation#machine learning in robotics#sustainable manufacturing

0 notes

Text

Dynamic Balancing Machines by Suzuki Instruments: Precision and Efficiency in Manufacturing

In today’s fast-paced manufacturing landscape, the importance of precision and reliability cannot be overstated. Whether for automotive, aerospace, or other industries, maintaining the balance of rotating parts is critical to ensuring smooth operations, extended service life, and reduced wear and tear. This is where dynamic balancing machines play a vital role, and Suzuki Instruments stands out as a leading manufacturer of innovative balancing solutions. With a diverse range of machines like the Auto Correction Vertical Balancing Machine (Balance Tech VAC), Belt Driven Horizontal Balancing Machines (Model: HDCM), Horizontal Balancing Machines (Model: HDM), and Vertical Balancing Machines (Model: HDVM), Suzuki Instruments continues to set the standard in precision balancing technology.

The Importance of Dynamic Balancing in Manufacturing

Dynamic balancing involves adjusting rotating components to ensure that their mass is distributed evenly, thereby minimizing vibration and wear. Unbalanced rotating parts can lead to premature failure, noise, reduced efficiency, and even catastrophic machinery breakdowns. This is especially crucial in high-precision industries like automotive and aerospace, where even minor imbalances can have significant consequences. Dynamic balancing machines are designed to detect and correct these imbalances, ensuring the safety, reliability, and optimal performance of rotating components.

Suzuki Instruments’ Dynamic Balancing Solutions

1. Auto Correction Vertical Balancing Machine — Balance Tech VAC

The Balance Tech VAC is Suzuki Instruments’ state-of-the-art vertical balancing machine designed for automatic correction of imbalances in parts. The vertical balancing machine is ideal for components like rotors, shafts, and other similar parts that rotate on a vertical axis. What sets the Balance Tech VAC apart is its advanced auto-correction feature, which automatically adjusts the part during the balancing process, reducing the need for manual intervention. This not only saves time but also ensures precision, as the machine continuously monitors the part’s balance and makes real-time adjustments for the most accurate result.

KNOW MORE

2. Belt Driven Horizontal Balancing Machines — Model: HDCM

Suzuki’s HDCM model is a belt-driven horizontal balancing machine that offers precision and flexibility for balancing parts like flywheels, pulleys, and other horizontally rotating components. The belt-driven mechanism helps control the speed and accuracy of the balancing process, making it a reliable option for large-scale manufacturing. The HDCM model ensures that imbalances in components are detected and corrected efficiently, reducing vibration and preventing premature wear in machinery.

KNOW MORE

3. Horizontal Balancing Machines — Model: HDM

The HDM model by Suzuki Instruments is another excellent option for balancing horizontally rotating parts. This machine is designed for components such as crankshafts, rotors, and other heavy-duty industrial parts. Horizontal balancing machines like the HDM are essential for preventing vibration and ensuring the smooth operation of machinery.

KNOW MORE

4. Vertical Balancing Machines — Model: HDVM

Vertical balancing machines are essential for balancing parts that rotate on a vertical axis. The HDVM model from Suzuki Instruments is engineered to deliver the same level of precision and reliability as other models in their lineup. These machines are typically used for balancing parts like rotor shafts and turbines.

KNOW MORE

In conclusion, Suzuki Instruments has firmly established itself as a leader in the dynamic balancing machine industry. Whether you need an auto-correction vertical balancing machine like the Balance Tech VAC, a belt-driven horizontal balancing machine like the HDCM, or a high-precision horizontal or vertical balancing machine like the HDM and HDVM models, Suzuki Instruments has a solution tailored to your needs. These machines are designed to provide the highest level of accuracy, reliability, and efficiency, making them indispensable tools in modern manufacturing processes. With Suzuki Instruments, manufacturers can ensure that their rotating components are perfectly balanced, improving performance, durability, and overall system reliability.

By choosing Suzuki Instruments for your dynamic balancing needs, you’re investing in precision engineering that keeps your machinery operating at its best, day in and day out.

0 notes

Text

Advanced robotics is transforming engineering by automating complex tasks with AI and machine learning. Industries like healthcare, manufacturing, and logistics benefit from intelligent machines that enhance efficiency and precision. Unlike traditional automation, AI-powered robots adapt, learn, and improve over time. At M.Kumarasamy College of Engineering (MKCE), students engage with cutting-edge robotics through hands-on projects. The institution’s labs foster innovation in autonomous systems and adaptive algorithms. Emerging trends like swarm robotics and soft robotics are revolutionizing automation. MKCE integrates interdisciplinary learning, merging robotics with AI and mechanical engineering. Industry partnerships ensure students gain real-world exposure to advanced technologies. The college also emphasizes sustainable robotics solutions for a greener future. As robotics continues to evolve, MKCE remains at the forefront of this transformative field.

To know more : https://mkce.ac.in/blog/advanced-robotics-as-the-next-frontier-in-engineering-automation/

#best engineering college in karur#top 10 colleges in tn#engineering college in karur#private college#engineering college#best engineering college#mkce college#mkce#libary#mkce.ac.in#Industrial Automation#Robotics in Manufacturing#Advanced Robotics#Engineering Automation#AI in Robotics#Robotics and Machine Learning#Autonomous Systems#AI-Powered Automation

0 notes

Text

Machine learning applications in semiconductor manufacturing

Machine Learning Applications in Semiconductor Manufacturing: Revolutionizing the Industry

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and computers to autonomous vehicles and IoT devices. As the demand for faster, smaller, and more efficient chips grows, semiconductor manufacturers face increasing challenges in maintaining precision, reducing costs, and improving yields. Enter machine learning (ML)—a transformative technology that is revolutionizing semiconductor manufacturing. By leveraging ML, manufacturers can optimize processes, enhance quality control, and accelerate innovation. In this blog post, we’ll explore the key applications of machine learning in semiconductor manufacturing and how it is shaping the future of the industry.

Predictive Maintenance

Semiconductor manufacturing involves highly complex and expensive equipment, such as lithography machines and etchers. Unplanned downtime due to equipment failure can cost millions of dollars and disrupt production schedules. Machine learning enables predictive maintenance by analyzing sensor data from equipment to predict potential failures before they occur.

How It Works: ML algorithms process real-time data from sensors, such as temperature, vibration, and pressure, to identify patterns indicative of wear and tear. By predicting when a component is likely to fail, manufacturers can schedule maintenance proactively, minimizing downtime.

Impact: Predictive maintenance reduces equipment downtime, extends the lifespan of machinery, and lowers maintenance costs.

Defect Detection and Quality Control

Defects in semiconductor wafers can lead to significant yield losses. Traditional defect detection methods rely on manual inspection or rule-based systems, which are time-consuming and prone to errors. Machine learning, particularly computer vision, is transforming defect detection by automating and enhancing the process.

How It Works: ML models are trained on vast datasets of wafer images to identify defects such as scratches, particles, and pattern irregularities. Deep learning algorithms, such as convolutional neural networks (CNNs), excel at detecting even the smallest defects with high accuracy.

Impact: Automated defect detection improves yield rates, reduces waste, and ensures consistent product quality.

Process Optimization

Semiconductor manufacturing involves hundreds of intricate steps, each requiring precise control of parameters such as temperature, pressure, and chemical concentrations. Machine learning optimizes these processes by identifying the optimal settings for maximum efficiency and yield.

How It Works: ML algorithms analyze historical process data to identify correlations between input parameters and output quality. Techniques like reinforcement learning can dynamically adjust process parameters in real-time to achieve the desired outcomes.

Impact: Process optimization reduces material waste, improves yield, and enhances overall production efficiency.

Yield Prediction and Improvement

Yield—the percentage of functional chips produced from a wafer—is a critical metric in semiconductor manufacturing. Low yields can result from various factors, including process variations, equipment malfunctions, and environmental conditions. Machine learning helps predict and improve yields by analyzing complex datasets.

How It Works: ML models analyze data from multiple sources, including process parameters, equipment performance, and environmental conditions, to predict yield outcomes. By identifying the root causes of yield loss, manufacturers can implement targeted improvements.

Impact: Yield prediction enables proactive interventions, leading to higher productivity and profitability.

Supply Chain Optimization

The semiconductor supply chain is highly complex, involving multiple suppliers, manufacturers, and distributors. Delays or disruptions in the supply chain can have a cascading effect on production schedules. Machine learning optimizes supply chain operations by forecasting demand, managing inventory, and identifying potential bottlenecks.

How It Works: ML algorithms analyze historical sales data, market trends, and external factors (e.g., geopolitical events) to predict demand and optimize inventory levels. Predictive analytics also helps identify risks and mitigate disruptions.

Impact: Supply chain optimization reduces costs, minimizes delays, and ensures timely delivery of materials.

Advanced Process Control (APC)

Advanced Process Control (APC) is critical for maintaining consistency and precision in semiconductor manufacturing. Machine learning enhances APC by enabling real-time monitoring and control of manufacturing processes.

How It Works: ML models analyze real-time data from sensors and equipment to detect deviations from desired process parameters. They can automatically adjust settings to maintain optimal conditions, ensuring consistent product quality.

Impact: APC improves process stability, reduces variability, and enhances overall product quality.

Design Optimization

The design of semiconductor devices is becoming increasingly complex as manufacturers strive to pack more functionality into smaller chips. Machine learning accelerates the design process by optimizing chip layouts and predicting performance outcomes.

How It Works: ML algorithms analyze design data to identify patterns and optimize layouts for performance, power efficiency, and manufacturability. Generative design techniques can even create novel chip architectures that meet specific requirements.

Impact: Design optimization reduces time-to-market, lowers development costs, and enables the creation of more advanced chips.

Fault Diagnosis and Root Cause Analysis

When defects or failures occur, identifying the root cause can be challenging due to the complexity of semiconductor manufacturing processes. Machine learning simplifies fault diagnosis by analyzing vast amounts of data to pinpoint the source of problems.

How It Works: ML models analyze data from multiple stages of the manufacturing process to identify correlations between process parameters and defects. Techniques like decision trees and clustering help isolate the root cause of issues.

Impact: Faster fault diagnosis reduces downtime, improves yield, and enhances process reliability.

Energy Efficiency and Sustainability

Semiconductor manufacturing is energy-intensive, with significant environmental impacts. Machine learning helps reduce energy consumption and improve sustainability by optimizing resource usage.

How It Works: ML algorithms analyze energy consumption data to identify inefficiencies and recommend energy-saving measures. For example, they can optimize the operation of HVAC systems and reduce idle time for equipment.

Impact: Energy optimization lowers operational costs and reduces the environmental footprint of semiconductor manufacturing.

Accelerating Research and Development

The semiconductor industry is driven by continuous innovation, with new materials, processes, and technologies being developed regularly. Machine learning accelerates R&D by analyzing experimental data and predicting outcomes.

How It Works: ML models analyze data from experiments to identify promising materials, processes, or designs. They can also simulate the performance of new technologies, reducing the need for physical prototypes.

Impact: Faster R&D cycles enable manufacturers to bring cutting-edge technologies to market more quickly.

Challenges and Future Directions

While machine learning offers immense potential for semiconductor manufacturing, there are challenges to overcome. These include the need for high-quality data, the complexity of integrating ML into existing workflows, and the shortage of skilled professionals. However, as ML technologies continue to evolve, these challenges are being addressed through advancements in data collection, model interpretability, and workforce training.

Looking ahead, the integration of machine learning with other emerging technologies, such as the Internet of Things (IoT) and digital twins, will further enhance its impact on semiconductor manufacturing. By embracing ML, manufacturers can stay competitive in an increasingly demanding and fast-paced industry.

Conclusion

Machine learning is transforming semiconductor manufacturing by enabling predictive maintenance, defect detection, process optimization, and more. As the industry continues to evolve, ML will play an increasingly critical role in driving innovation, improving efficiency, and ensuring sustainability. By harnessing the power of machine learning, semiconductor manufacturers can overcome challenges, reduce costs, and deliver cutting-edge technologies that power the future.

This blog post provides a comprehensive overview of machine learning applications in semiconductor manufacturing. Let me know if you’d like to expand on any specific section or add more details!

#semiconductor manufacturing#Machine learning in semiconductor manufacturing#AI in semiconductor industry#Predictive maintenance in chip manufacturing#Defect detection in semiconductor wafers#Semiconductor process optimization#Yield prediction in semiconductor manufacturing#Advanced Process Control (APC) in semiconductors#Semiconductor supply chain optimization#Fault diagnosis in chip manufacturing#Energy efficiency in semiconductor production#Deep learning for semiconductor defects#Computer vision in wafer inspection#Reinforcement learning in semiconductor processes#Semiconductor yield improvement using AI#Smart manufacturing in semiconductors#AI-driven semiconductor design#Root cause analysis in chip manufacturing#Sustainable semiconductor manufacturing#IoT in semiconductor production#Digital twins in semiconductor manufacturing

0 notes