#Manufacturing Process Improvement

Explore tagged Tumblr posts

Text

IoT Solutions in Manufacturing Solutions by Mobiloitte

#Advanced Manufacturing Solutions#Manufacturing Innovation#Manufacturing Technology#Smart Manufacturing#Industrial Automation#Manufacturing Efficiency#Production Optimization#Digital Manufacturing#Manufacturing Industry Solutions#Robotics in Manufacturing#AI in Manufacturing#Manufacturing Process Improvement#IoT in Manufacturing#Manufacturing Software#Global Manufacturing Innovation#Advanced Production Techniques.

0 notes

Text

The Flashback shows us Chosen and Dark being destructive across the web, but it doesn’t really give any indication of why they did this. This leaves us to come up with probable reasons that might fit. It also leaves us to come up with probable reasons why Chosen changed his tune before Dark.

And there are a lot of those XD but while so many of us talk about why Chosen stopped, and what might’ve changed to motivate his shift, I haven’t seen as many suggesting that…maybe, from the start, they were being destructive for different reasons.

#animator vs animation#ava#ava tco#ava tdl#just thinking about how stress become normal and familiar for traumatized people#and how when they finally escape their hostile environment they aren’t used to peace and safety#so they’ll manufacture stress because not being stressed feels unnatural#also thinking about how processing of trauma can be delayed until circumstances have improved#thinking about a lot of things I can’t articulate rn#triggers and elimination/conquering of perceived threats and such

116 notes

·

View notes

Text

Occasionally we debate on illustrating random bits from our Discord PMs that we find really funny but then we remember that we're, like, the physical embodiment of the "ace that makes sex jokes" stereotype and phrases like "iterator dick discourse" would both be remarkably difficult to illustrate and probably require us drawing something at least somewhat NSFW (we do not particularly care to learn how to draw this)

#we speak#realistically it would just require more specific tinkering w what we choose to include but we still think the dickscourse is funny#it's the image of a bunch of ancient monks gathering around to very seriously debate decisions with the upcoming iterator project#and then the whiteboard is just like. “ITERATORS: dick or no?”#(vital context: we got hung up on the semantics of people giving their iterators actual genitals in smut)#(as the existence of that on the puppet implies that someone had to design and manufacture and ship that shit for the finished iterator)#(and the general aura of the ancients instantly catapults this to fucking hilarious because it implies job titles like “dick director”)#(and work emails about iterator pipe written in the exact same cadence as all of the ancient correspondence we see in-game)#we dont think a lot of people designing iterators really Get the sheer amount of semantics and construction and effort and PEOPLE#that go into a project of the iterator's scale#especially when hundreds of them have been constructed! theres gonna be a whole ass trail of design changes and iterations!#youre gonna have hundreds of years of iterators being designed and technology coming into fashion and out of fashion#and things being integrated and things becoming obsolete and things being more or less practical as time goes on!#you cant really say that All Iterators have a trait because the sheer scale and timeframe theyre built on means thats near impossible#our windows 95 writing computer has different construction and deeply different design to a laptop from 2023#despite them technically being the same type of technology#you expect tech developed hundreds of years apart to be The Same? absolutely not. theres gonna be eight trillion weird design quirks#accumulated both in the construction process and in the continued design refinement and improvement stage#...which is to say that you can and should write what u want but if youre gonna include pleasure inducing wires then we want like#a 40k word essay on how this got into the design how it wound up in future designs what function the wires perform that makes them Like Tha#and so on and so forth#we admire the confidence and ingenuity of the people who want to fuck the robots but we cannot get into their fantasies with good conscienc#we live in the same house as an engineer who manages largescale construction and we also know too much about designing technology#...we should segment these tags into a separate post or something. we've gone WAY off-topic.

8 notes

·

View notes

Text

🔄 Process Approach Across ISO & IATF Standards with 🚗 OEM Requirements in 2025

✅ Introduction: Why the Process Approach Matters in 2025 The process approach isn’t just a buzzword from ISO standards—it’s the engine behind operational excellence. As we step into 2025, OEMs (Original Equipment Manufacturers) demand more than compliance—they expect traceability, zero-defect culture, and real-time performance. In this guide, you’ll learn: 📌 How the process approach is defined��

View On WordPress

#5W2H model ISO#Automotive manufacturing#automotive quality system#clause 4.4 explained#EHS process compliance#energy management ISO 50001#environmental compliance ISO 14001#IATF 16949 process control#ISO digital integration#ISO standards 2025#lean manufacturing#occupational health ISO 45001#OEM compliance 2025#PFMEA process improvement#process approach ISO#process mapping ISO 9001#process ownership in QMS#quality management ISO 9001#risk-based thinking ISO#SIPOC diagram example#smart factory process control#Turtle diagram QMS

0 notes

Text

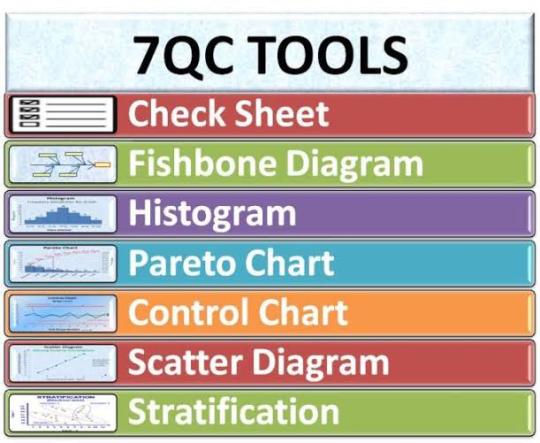

Improve Your Process Quality with These 7 QC Tools

In today’s competitive market, businesses must consistently deliver high-quality products and services. Whether you’re in manufacturing or service delivery, improving your processes is key to meeting customer expectations and reducing errors. That’s where the 7 QC (Quality Control) Tools come in.

These tools are simple yet powerful techniques that help you identify problems, analyze them, and find solutions for continuous improvement.

What Are the 7 QC Tools?

The 7 QC Tools are a set of problem-solving methods used widely in quality management and process improvement. Originating from Japan, these tools are easy to understand and apply—even if you don’t have a technical background.

Here are the 7 QC Tools:

Cause and Effect Diagram (Fishbone or Ishikawa Diagram)

Check Sheet

Control Chart

Histogram

Pareto Chart

Scatter Diagram

Flowchart (Process Diagram)

🔍 1. Cause and Effect Diagram (Fishbone Diagram)

Purpose: To identify root causes of a problem.

This tool helps teams brainstorm and categorize potential causes of a problem, showing how different factors (like manpower, machine, materials, methods) affect the outcome.

📌 Use when: You know the problem but not the reason behind it.

Example: High rejection in a production line — the diagram helps identify causes like machine calibration or operator error.

📝 2. Check Sheet

Purpose: To collect and organize data easily.

A check sheet is a simple form used to record the frequency of problems or defects. It helps in understanding where to focus improvement efforts.

📌 Use when: You need to collect real-time data on process issues.

Example: Tracking the number of defects per day or per machine.

📊 3. Control Chart

Purpose: To monitor process variation over time.

Control charts help you identify whether a process is stable or if there are abnormal variations that need attention.

📌 Use when: You want to control a process over time and ensure consistency.

Example: Monitoring the weight of a packaged product to stay within limits.

📈 4. Histogram

Purpose: To visualize the frequency of data.

Histograms show how data is distributed and help spot patterns, such as whether most defects fall within a certain range.

📌 Use when: You want to understand the distribution of a dataset.

Example: Measuring the delivery time of shipments and checking how consistent they are.

🎯 5. Pareto Chart

Purpose: To identify the most significant problems.

Based on the 80/20 rule (80% of problems come from 20% of causes), a Pareto chart helps you focus on the issues that have the biggest impact.

📌 Use when: You want to prioritize improvement efforts.

Example: Identifying that most customer complaints come from just two major issues.

🔗 6. Scatter Diagram

Purpose: To find relationships between two variables.

This diagram helps you determine if there's a correlation between two elements (e.g., machine speed and defect rate).

📌 Use when: You suspect that two variables are related.

Example: Analyzing if more training hours lead to fewer production errors.

🔄 7. Flowchart (Process Diagram)

Purpose: To visualize the steps in a process.

Flowcharts help understand how a process flows and where delays, defects, or confusion might occur.

📌 Use when: You want to document and improve a process.

Example: Mapping the customer complaint handling process to identify bottlenecks.

🚀 Why Use the 7 QC Tools?

The 7 QC Tools are popular for a reason—they’re simple, effective, and proven. Here’s why every business should use them:

✅ Easy to Use No complex software or technical skills needed—these tools are simple enough for anyone to understand and apply.

✅ Make Smarter Decisions They turn raw data into useful insights, helping you base decisions on facts instead of guesswork.

✅ Drive Continuous Improvement By identifying and fixing problems early, these tools help your team keep improving over time.

✅ Trusted Across Industries The 7 QC Tools are widely used in ISO 9001, Lean, Six Sigma, and other quality systems around the world.

✅ Save Time and Reduce Waste By targeting the real cause of issues, you reduce rework, improve efficiency, and save valuable resources.

🧠 How to Start Using the 7 QC Tools

Getting started with the 7 QC Tools is easier than you think. Follow these simple steps to improve your process quality:

Identify the Problem Start by clearly defining the issue you're facing. Be specific—whether it’s late deliveries, defects, or process delays.

Gather the Right Data Use tools like a Check Sheet or Flowchart to collect data and understand how the process works.

Find the Root Cause Use a Fishbone (Ishikawa) Diagram to dig deeper and identify the possible causes behind the problem.

Monitor Trends Over Time Use a Control Chart to see if the problem is consistent or just a one-time issue. A Histogram can help visualize data distribution.

Focus on What Matters Most Apply the Pareto Chart to find out which causes are having the biggest impact—so you can tackle them first.

Look for Relationships Use a Scatter Diagram to explore if two factors are connected—for example, training hours and error rate.

Take Action & Improve Once you understand the issue, take corrective actions. Then monitor the results and repeat the cycle for continuous improvement.

🏁 Final Thoughts

The 7 QC Tools are essential for any organization that wants to improve quality, reduce waste, and satisfy customers. Whether you’re in manufacturing, logistics, healthcare, or services—these tools can help you find problems and fix them faster.

Start small. Pick one problem in your process, apply one or two tools, and see the improvement for yourself!

#7 QC Tools#Quality Control Tools#Process Improvement Techniques#Problem Solving in Manufacturing#Lean Tools for Quality#ISO 9001 Tools#Root Cause Analysis Tools

1 note

·

View note

Text

Expert Window, Door & Glass Installations in Peterborough | SafeGuard UK

Discover SafeGuard – Peterborough’s trusted experts in windows, doors, conservatories, and glass processing. With over 25 years of experience, we offer tailored installations and in-house manufacturing of PVCu, aluminium, and heritage glazing products. Quality service from start to finish.

#aluminium windows UK#aluminium doors UK#glass processing Peterborough#conservatories Peterborough#glazing experts UK#PVCu windows Peterborough#heritage glass units UK#bespoke glazing solutions#glass merchants Peterborough#double glazing Peterborough#Peterborough home improvements#SafeGuard Installations#UK glass manufacturers

1 note

·

View note

Text

Vertical Glue Mixer: Efficient and Uniform Adhesive Mixing for Plywood Manufacturing

In plywood production, efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this production is the Vertical Glue Mixer—a revolution in uniform adhesive mixing for better plywood bonding. If what you're searching for is an advanced glue mixing technology that maximizes productivity and reduces waste, this futuristic machine is a production-line essential.

Why a Vertical Glue Mixer?

A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood, ensuring a consistent glue spread on veneers. Unlike conventional mixers, a vertical mixer offers better blending, reduced glue wastage, and improved bonding strength, making it a preferred choice for modern plywood factories.

Key Benefits of a Vertical Glue Mixer

1. Superior Mixing Efficiency

Vertical design allows for complete and even blending of adhesives, which creates even viscosity and consistency across the batch. This produces improved plywood adhesion, minimizing defects in the finished product.

2. Economical Glue Use

Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality, resulting in extensive cost benefits in the long run.

3. Reduced Production Cycle Times

Using a high-speed mixing device, a vertical glue mixer reduces preparation time, enabling production cycles to be completed quickly and output to be maximized.

4. Minimal Maintenance & Longevity

Designed with robust parts and sophisticated automation, these mixers have negligible maintenance needs, making them a sound long-term investment for plywood production.

5. Eco-Friendly Operations

By minimizing glue waste and maximizing adhesive blending efficiency, a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.

Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

In selecting a Vertical Glue Mixer, there are important considerations to make:

✔️ Mixing Capacity – Select a machine in conformity with your volume of production.

✔️ Automation Features – Choose a model with easy-to-use controls for convenient operation.

✔️ Material Compatibility – Use one that can handle different adhesive types for general applications.

✔️ Manufacturer Reputation – Buy equipment from a reputable plywood machinery manufacturer for guaranteed quality.

A Vertical Glue Mixer is an important investment for plywood plant owners who want to improve efficiency, quality, and cost savings. By adopting this performance-intensive adhesive mixing system into your production process, you can achieve smooth operations, better plywood bonding, and increased profitability.

Want to find the ideal Vertical Glue Mixer for your plywood factory? Contact DNH Engineers a renowned manufacturer of plywood machinery and give your production a boost! Visit www.dnhengineers.com for more details.

#In plywood production#efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this#this futuristic machine is a production-line essential.#Why a Vertical Glue Mixer?#A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood#ensuring a consistent glue spread on veneers. Unlike conventional mixers#a vertical mixer offers better blending#reduced glue wastage#and improved bonding strength#making it a preferred choice for modern plywood factories.#Key Benefits of a Vertical Glue Mixer#1. Superior Mixing Efficiency#Vertical design allows for complete and even blending of adhesives#which creates even viscosity and consistency across the batch. This produces improved plywood adhesion#minimizing defects in the finished product.#2. Economical Glue Use#Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality#resulting in extensive cost benefits in the long run.#3. Reduced Production Cycle Times#Using a high-speed mixing device#a vertical glue mixer reduces preparation time#enabling production cycles to be completed quickly and output to be maximized.#4. Minimal Maintenance & Longevity#Designed with robust parts and sophisticated automation#these mixers have negligible maintenance needs#making them a sound long-term investment for plywood production.#5. Eco-Friendly Operations#By minimizing glue waste and maximizing adhesive blending efficiency#a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.#Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

0 notes

Text

Garage Door Installers in Pittsburgh, PA: Your Guide to Quality Installation Services

When it comes to home improvements, a new garage door can be one of the most impactful upgrades you can make. It not only enhances your home’s curb appeal but also boosts its functionality and security. If you're looking for a professional and reliable garage door installer in Pittsburgh, PA, you have plenty of options. However, selecting the right garage door installer can make a big difference in the quality of your installation and the long-term performance of your door.

In this article, we’ll guide you through the process of choosing the best garage door installer in Pittsburgh, PA, and explain what you can expect during the installation process. From selecting the right installer to understanding the installation procedure, we have you covered.

Why You Need Professional Garage Door Installers

Installing a new garage door is a significant investment, and ensuring that it’s done correctly is crucial for the safety, convenience, and security of your home. Here are some reasons why hiring a professional garage door installer is important:

Expertise and Experience: Garage doors are complex systems that require specialized knowledge and experience to install. From ensuring proper alignment to selecting the correct hardware, professional installers know the ins and outs of the process.

Proper Safety Measures: Garage doors are heavy and can be dangerous to handle without the right equipment and training. Professional installers have the tools and expertise to handle the job safely, preventing accidents and injuries.

Longevity and Performance: A poorly installed garage door can wear out quickly, leading to costly repairs and even potential security issues. Professional installation ensures that your door operates smoothly for years, minimizing the need for frequent repairs.

Time-Saving: Installation of a garage door can be time-consuming, especially if you lack experience. Hiring a professional installer ensures that the job is completed efficiently, saving you time and hassle.

Warranty Protection: Many garage door manufacturers offer warranties for products that are professionally installed. If you attempt a DIY installation, you may void the warranty, so professional installation is always the safest option.

Choosing the Right Garage Door Installer in Pittsburgh, PA

There are several garage door installers near me, each offering a range of services. To ensure you choose the best one for your needs, consider the following factors:

1. Experience and Reputation

Experience matters when it comes to garage door installation. A company with years of experience will have a proven track record of handling different types of doors and installations. Reputation is equally important. Look for companies with positive reviews and testimonials from previous customers. You can check online reviews, ask for references, or get recommendations from friends and neighbors who have had recent garage door installations.

2. Range of Services Offered

Garage door installers typically offer more than just installations. Many also provide repair and maintenance services. If you’re considering getting your door serviced in the future, it’s a good idea to choose a company that offers comprehensive services. Some common services to look for include:

Garage door repair (broken springs, faulty openers, etc.)

Garage door maintenance (tuning, lubricating, etc.)

Emergency repair services

Custom garage door design and installation

3. Licensing and Insurance

It’s important to choose a garage door installer who is licensed and insured. A licensed company ensures that they follow local building codes and regulations, while insurance protects you in case of accidents or property damage during the installation process. Always ask about licensing and insurance before hiring an installer.

4. Quality of Products

A good installer will use high-quality garage doors and parts from reputable manufacturers. Ask the installer about the materials and brands they work with to ensure that your new door is durable, secure, and energy-efficient. Whether you’re looking for a steel, wood, or custom door, quality products will ensure long-lasting performance.

5. Transparent Pricing

It’s essential to choose a garage door installer who offers transparent pricing with no hidden fees. The cost of a new garage door installation can vary depending on factors such as the type of door, materials, and labor. A good installer will provide a detailed estimate upfront and explain the cost breakdown so that you can make an informed decision.

6. Customer Service

When hiring a garage door installer, choose a company that values customer service. A reliable installer will communicate clearly, respond to inquiries promptly, and keep you updated throughout the installation process. Look for a company that offers a satisfaction guarantee, so you know they stand behind their work.

What to Expect During the Garage Door Installation Process

The process of installing a new garage door typically involves several steps. Here’s a general overview of what to expect during the installation process:

1. Consultation and Measurement

The first step in the installation process is usually a consultation where the installer assesses your needs and preferences. They will take accurate measurements of your garage opening to ensure a perfect fit. If you need help choosing a style or material, the installer can offer advice based on your budget and preferences.

2. Selection of the Door

Based on your consultation, the installer will help you choose the best garage door for your home. This may include selecting the material (steel, wood, aluminum, etc.), style (carriage house, contemporary, traditional), and color. They will also discuss additional features, such as insulation, windows, and custom designs.

3. Removal of the Old Door (if applicable)

If you’re replacing an existing door, the installer will remove the old door and its components. This includes detaching the old door from the opener and removing any old hardware. The installer will also dispose of the old door in an environmentally responsible manner.

4. Installation of the New Door

Once the old door is removed, the new door is carefully installed. This step involves assembling the door panels, installing the tracks, springs, and hardware, and ensuring everything is properly aligned. The installer will take extra care to ensure the door is balanced and functions smoothly.

5. Installation of the Opener (if applicable)

If you're also installing a new garage door opener, the installer will mount the opener unit, attach the door to the opener, and ensure proper operation. Modern openers come with additional features, such as smart technology, remote access, and battery backup, so the installer will ensure these features are properly set up.

6. Testing and Adjustments

After the door is installed, the installer will test its operation. They will check that the door opens and closes smoothly, and adjust the springs, opener, and sensors to ensure everything works correctly. They will also check for balance and make any necessary adjustments to prevent future issues.

7. Final Inspection and Cleanup

Once the installation is complete, the installer will conduct a final inspection to ensure everything is functioning correctly. They will also clean up the installation area, removing any debris or packaging materials. Some installers will walk you through the door’s features and provide maintenance tips.

Top Garage Door Installers in Pittsburgh, PA

Here are some of the top-rated garage door installers in Pittsburgh, PA:

1. A1 Garage Door Service

Known for their exceptional customer service, A1 Garage Door Service is a trusted name in Pittsburgh. They offer a wide range of services, including garage door installation, repairs, and maintenance. Their team of skilled technicians ensures fast, reliable service, and they offer same-day installations when needed.

#garage door installers near me#PA: Your Guide to Quality Installation Services#When it comes to home improvements#a new garage door can be one of the most impactful upgrades you can make. It not only enhances your home’s curb appeal but also boosts its#PA#you have plenty of options. However#selecting the right garage door installer can make a big difference in the quality of your installation and the long-term performance of yo#In this article#we’ll guide you through the process of choosing the best garage door installer in Pittsburgh#and explain what you can expect during the installation process. From selecting the right installer to understanding the installation proce#we have you covered.#Why You Need Professional Garage Door Installers#Installing a new garage door is a significant investment#and ensuring that it’s done correctly is crucial for the safety#convenience#and security of your home. Here are some reasons why hiring a professional garage door installer is important:#Expertise and Experience: Garage doors are complex systems that require specialized knowledge and experience to install. From ensuring prop#professional installers know the ins and outs of the process.Proper Safety Measures: Garage doors are heavy and can be dangerous to handle#preventing accidents and injuries.Longevity and Performance: A poorly installed garage door can wear out quickly#leading to costly repairs and even potential security issues. Professional installation ensures that your door operates smoothly for years#minimizing the need for frequent repairs.Time-Saving: Installation of a garage door can be time-consuming#especially if you lack experience. Hiring a professional installer ensures that the job is completed efficiently#saving you time and hassle.Warranty Protection: Many garage door manufacturers offer warranties for products that are professionally instal#you may void the warranty#so professional installation is always the safest option.#Choosing the Right Garage Door Installer in Pittsburgh#There are several garage door installers near me#each offering a range of services. To ensure you choose the best one for your needs#consider the following factors:#1. Experience and Reputation

0 notes

Text

Machine learning applications in semiconductor manufacturing

Machine Learning Applications in Semiconductor Manufacturing: Revolutionizing the Industry

The semiconductor industry is the backbone of modern technology, powering everything from smartphones and computers to autonomous vehicles and IoT devices. As the demand for faster, smaller, and more efficient chips grows, semiconductor manufacturers face increasing challenges in maintaining precision, reducing costs, and improving yields. Enter machine learning (ML)—a transformative technology that is revolutionizing semiconductor manufacturing. By leveraging ML, manufacturers can optimize processes, enhance quality control, and accelerate innovation. In this blog post, we’ll explore the key applications of machine learning in semiconductor manufacturing and how it is shaping the future of the industry.

Predictive Maintenance

Semiconductor manufacturing involves highly complex and expensive equipment, such as lithography machines and etchers. Unplanned downtime due to equipment failure can cost millions of dollars and disrupt production schedules. Machine learning enables predictive maintenance by analyzing sensor data from equipment to predict potential failures before they occur.

How It Works: ML algorithms process real-time data from sensors, such as temperature, vibration, and pressure, to identify patterns indicative of wear and tear. By predicting when a component is likely to fail, manufacturers can schedule maintenance proactively, minimizing downtime.

Impact: Predictive maintenance reduces equipment downtime, extends the lifespan of machinery, and lowers maintenance costs.

Defect Detection and Quality Control

Defects in semiconductor wafers can lead to significant yield losses. Traditional defect detection methods rely on manual inspection or rule-based systems, which are time-consuming and prone to errors. Machine learning, particularly computer vision, is transforming defect detection by automating and enhancing the process.

How It Works: ML models are trained on vast datasets of wafer images to identify defects such as scratches, particles, and pattern irregularities. Deep learning algorithms, such as convolutional neural networks (CNNs), excel at detecting even the smallest defects with high accuracy.

Impact: Automated defect detection improves yield rates, reduces waste, and ensures consistent product quality.

Process Optimization

Semiconductor manufacturing involves hundreds of intricate steps, each requiring precise control of parameters such as temperature, pressure, and chemical concentrations. Machine learning optimizes these processes by identifying the optimal settings for maximum efficiency and yield.

How It Works: ML algorithms analyze historical process data to identify correlations between input parameters and output quality. Techniques like reinforcement learning can dynamically adjust process parameters in real-time to achieve the desired outcomes.

Impact: Process optimization reduces material waste, improves yield, and enhances overall production efficiency.

Yield Prediction and Improvement

Yield—the percentage of functional chips produced from a wafer—is a critical metric in semiconductor manufacturing. Low yields can result from various factors, including process variations, equipment malfunctions, and environmental conditions. Machine learning helps predict and improve yields by analyzing complex datasets.

How It Works: ML models analyze data from multiple sources, including process parameters, equipment performance, and environmental conditions, to predict yield outcomes. By identifying the root causes of yield loss, manufacturers can implement targeted improvements.

Impact: Yield prediction enables proactive interventions, leading to higher productivity and profitability.

Supply Chain Optimization

The semiconductor supply chain is highly complex, involving multiple suppliers, manufacturers, and distributors. Delays or disruptions in the supply chain can have a cascading effect on production schedules. Machine learning optimizes supply chain operations by forecasting demand, managing inventory, and identifying potential bottlenecks.

How It Works: ML algorithms analyze historical sales data, market trends, and external factors (e.g., geopolitical events) to predict demand and optimize inventory levels. Predictive analytics also helps identify risks and mitigate disruptions.

Impact: Supply chain optimization reduces costs, minimizes delays, and ensures timely delivery of materials.

Advanced Process Control (APC)

Advanced Process Control (APC) is critical for maintaining consistency and precision in semiconductor manufacturing. Machine learning enhances APC by enabling real-time monitoring and control of manufacturing processes.

How It Works: ML models analyze real-time data from sensors and equipment to detect deviations from desired process parameters. They can automatically adjust settings to maintain optimal conditions, ensuring consistent product quality.

Impact: APC improves process stability, reduces variability, and enhances overall product quality.

Design Optimization

The design of semiconductor devices is becoming increasingly complex as manufacturers strive to pack more functionality into smaller chips. Machine learning accelerates the design process by optimizing chip layouts and predicting performance outcomes.

How It Works: ML algorithms analyze design data to identify patterns and optimize layouts for performance, power efficiency, and manufacturability. Generative design techniques can even create novel chip architectures that meet specific requirements.

Impact: Design optimization reduces time-to-market, lowers development costs, and enables the creation of more advanced chips.

Fault Diagnosis and Root Cause Analysis

When defects or failures occur, identifying the root cause can be challenging due to the complexity of semiconductor manufacturing processes. Machine learning simplifies fault diagnosis by analyzing vast amounts of data to pinpoint the source of problems.

How It Works: ML models analyze data from multiple stages of the manufacturing process to identify correlations between process parameters and defects. Techniques like decision trees and clustering help isolate the root cause of issues.

Impact: Faster fault diagnosis reduces downtime, improves yield, and enhances process reliability.

Energy Efficiency and Sustainability

Semiconductor manufacturing is energy-intensive, with significant environmental impacts. Machine learning helps reduce energy consumption and improve sustainability by optimizing resource usage.

How It Works: ML algorithms analyze energy consumption data to identify inefficiencies and recommend energy-saving measures. For example, they can optimize the operation of HVAC systems and reduce idle time for equipment.

Impact: Energy optimization lowers operational costs and reduces the environmental footprint of semiconductor manufacturing.

Accelerating Research and Development

The semiconductor industry is driven by continuous innovation, with new materials, processes, and technologies being developed regularly. Machine learning accelerates R&D by analyzing experimental data and predicting outcomes.

How It Works: ML models analyze data from experiments to identify promising materials, processes, or designs. They can also simulate the performance of new technologies, reducing the need for physical prototypes.

Impact: Faster R&D cycles enable manufacturers to bring cutting-edge technologies to market more quickly.

Challenges and Future Directions

While machine learning offers immense potential for semiconductor manufacturing, there are challenges to overcome. These include the need for high-quality data, the complexity of integrating ML into existing workflows, and the shortage of skilled professionals. However, as ML technologies continue to evolve, these challenges are being addressed through advancements in data collection, model interpretability, and workforce training.

Looking ahead, the integration of machine learning with other emerging technologies, such as the Internet of Things (IoT) and digital twins, will further enhance its impact on semiconductor manufacturing. By embracing ML, manufacturers can stay competitive in an increasingly demanding and fast-paced industry.

Conclusion

Machine learning is transforming semiconductor manufacturing by enabling predictive maintenance, defect detection, process optimization, and more. As the industry continues to evolve, ML will play an increasingly critical role in driving innovation, improving efficiency, and ensuring sustainability. By harnessing the power of machine learning, semiconductor manufacturers can overcome challenges, reduce costs, and deliver cutting-edge technologies that power the future.

This blog post provides a comprehensive overview of machine learning applications in semiconductor manufacturing. Let me know if you’d like to expand on any specific section or add more details!

#semiconductor manufacturing#Machine learning in semiconductor manufacturing#AI in semiconductor industry#Predictive maintenance in chip manufacturing#Defect detection in semiconductor wafers#Semiconductor process optimization#Yield prediction in semiconductor manufacturing#Advanced Process Control (APC) in semiconductors#Semiconductor supply chain optimization#Fault diagnosis in chip manufacturing#Energy efficiency in semiconductor production#Deep learning for semiconductor defects#Computer vision in wafer inspection#Reinforcement learning in semiconductor processes#Semiconductor yield improvement using AI#Smart manufacturing in semiconductors#AI-driven semiconductor design#Root cause analysis in chip manufacturing#Sustainable semiconductor manufacturing#IoT in semiconductor production#Digital twins in semiconductor manufacturing

0 notes

Text

Discover how generative AI solves manufacturing challenges: predictive maintenance, optimized design, quality control, and supply chain efficiency. Innovate your production today!

#AI-Driven Production Enhancements#Generative AI For Process Automation#AI In Manufacturing Intelligence#Generative AI For Manufacturing Improvement#AI In Industrial Efficiency#AI-Enhanced Manufacturing Workflows#Generative AI For Operational Excellence#AI In Production Management#AI-Driven Manufacturing Optimization#Generative AI For Supply Chain Resilience#AI In Process Innovation#AI In Manufacturing Performance#Generative AI For Manufacturing Analytics#AI In Production Quality#AI-Powered Factory Efficiency#Generative AI For Cost-Effective Manufacturing

0 notes

Text

Lean Manufacturing and Process Flow

What is it and how is it important? Lean manufacturing is a systematic approach to optimizing processes and minimizing waste in production. At its core, it emphasizes the continuous improvement of operations to enhance efficiency, quality, and safety. The principles of lean manufacturing, originating from the Toyota Production System (TPS), have been widely adopted across industries worldwide…

View On WordPress

0 notes

Text

Some great advancements come from modern machine controllers

Modern metal fabricating machine controllers have significantly impacted various aspects of the manufacturing process, including workflow, speed, efficiency, accuracy, and manageability. Here's how:

Workflow Improvement: Advanced controllers have software that allows for better planning and sequencing of jobs. This integration can streamline the workflow, reducing the time between design and production. Controllers with advanced user interfaces make it easier for operators to input data, understand machine status, and make quick adjustments, leading to a smoother production process. Operators have a number of options for job entry, such as from a CAD file automatically, manual iinput, or scanning from a paper job sheet.

Increased Speed: Modern controllers have greater speed thanks to improved processing power and algorithms. This allows for faster execution of complex tasks and reduces the cycle time for each part. High-speed processing also enables machines to operate at higher speeds without compromising precision—in fact in many cases, precision is increased along with speed.

Enhanced Efficiency: These controllers often include features that optimize energy use and reduce waste. For example, predictive maintenance capabilities can forecast machine failures before they occur, minimizing downtime. The controller’s software can generate a plan to use multiple stations on a part with multiple bends, for example, allowing the setup to happen in one step instead of many. Or, if a laser cutter is cutting metal plate, it plans the job so that a the laser head moves to different cut areas to allow densely-cut areas to cool before the machine cuts nearby again.

Improved Accuracy: The precision of modern metal fabricating machines has significantly increased with the advent of sophisticated controllers. These systems can precisely control the movement of the machine, leading to higher-quality products with tighter tolerances. Advanced sensors and feedback systems ensure that the machine's performance aligns closely with the programmed specifications, reducing errors.

Better Manageability: Modern controllers are often part of larger networked systems that include data collection and analysis capabilities. This allows for better monitoring and management of the production process. Operators can track machine performance, predict maintenance needs, and optimize production schedules based on real-time data. Additionally, integration with other systems (like ERP or shop planning software) allows for better overall plant management and coordination.

Adaptability and Flexibility: Contemporary controllers enable machines to be more adaptable to different types of jobs. Quick setup changes and easy reprogramming allow for shorter runs of custom or specialized parts, making the production process more flexible to meet diverse customer demands. We live in an age of many short run jobs.

Safety Enhancements: Modern controllers also contribute to safer working environments. They can include safety features that prevent operator error and protect against machine malfunctions. Better precision and control also reduce the likelihood of accidents due to machine errors.

Connectivity and Smart Features: With the advent of Industry 4.0, these controllers are increasingly connected and smart. They can be integrated into a wider industrial network, allowing for remote monitoring and control, predictive maintenance, and enhanced data analytics.

Overall, the impact of modern metal fabricating machine controllers on the manufacturing landscape is profound, leading to more efficient, accurate, and flexible production processes. This technological evolution is a key driver in the industry's ongoing efforts to optimize productivity and quality.

#great advancements#modern machine controllers#metal fabricating machine#manufacturing process#including workflow#speed#efficiency#accuracy#manageability#Workflow Improvement#Increased Speed#Enhanced Efficiency#Improved Accuracy#Better Manageability#Adaptability and Flexibility#Safety Enhancements#Connectivity and Smart Features#remote monitoring

0 notes

Text

PDCA in IATF 16949: Beyond Compliance – A Practical Automotive Perspective

The PDCA (Plan-Do-Check-Act) cycle isn’t just a theoretical model in IATF 16949—it’s a discipline that drives defect prevention, customer satisfaction, and operational excellence. But too many suppliers stop at compliance, missing the real value: process maturity and zero-defect culture. Here’s how to truly live the PDCA cycle in an IATF 16949 environment. 🧩 1. PLAN: Go Beyond Quality—Integrate…

#Automotive QMS best practices#Automotive quality management#IATF 16949 continuous improvement#IATF 16949 corrective action#IATF 16949 implementation guide#IATF 16949 process approach#IATF compliance strategy#Lean manufacturing PDCA#PDCA audit preparation#PDCA cycle in manufacturing#PDCA for automotive suppliers#PDCA IATF 16949#PDCA in automotive industry#PDCA methodology in IATF#Plan Do Check Act IATF#Practical PDCA IATF examples#Quality improvement IATF 16949#Real-world PDCA application

0 notes

Text

Elevate Your Business with ERPNext Manufacturing Solutions

Introduction In today’s fast-paced business landscape, staying ahead of the curve is crucial. This is where ERPNext, coupled with the expertise of Sigzen Technologies, comes into play. Let’s delve into the myriad benefits and advantages that ERPNext can bring to your manufacturing business. Streamlined Operations ERPNext empowers your business with seamless integration across various departments.…

View On WordPress

#business growth#business optimization#Cost Control#Efficiency Optimization#ERPNext Manufacturing#ERPNextSolutions#Inventory Control#Lean Manufacturing#Manufacturing Excellence#Manufacturing Solutions#Process Improvement#Production Planning#Quality Assurance#Resource Management#Supply Chain Management#Technology Integration#Workflow Automation

0 notes

Text

What are 7 QC Tools? 7 QC Tools: The Foundation of Quality Management

In the realm of quality management, the 7 Quality Control (QC) tools, also known as the 7 Basic Tools of Quality, serve as the bedrock for analyzing and improving processes. These powerful tools, developed by Dr. Kaoru Ishikawa, are indispensable for identifying issues, making informed decisions, and enhancing overall quality. This article delves into the details of the 7 QC tools, their…

View On WordPress

#7 QC Tools#Business Excellence#Cause-and-Effect Diagrams#Check Sheets#Continuous Improvement#Control Charts#Cost Savings#Customer Satisfaction#data analysis#Data-Driven#Decision Making#Defect Concentration Diagrams#Flowcharts#Healthcare#Histograms#Manufacturing#Operational Excellence#Pareto Charts#Problem Identification#Process Improvement#Process Stability#Quality Control#Quality Management#Root Cause Analysis#Service Sector#Versatile Solutions

0 notes

Text

"Sodium-ion batteries for electric vehicles and energy storage are moving toward the mainstream. Wider use of these batteries could lead to lower costs, less fire risk and less need for lithium, cobalt and nickel.

On Nov. 18, CATL, the world’s largest battery manufacturer, announced its second-generation sodium-ion battery, mass production of which would begin in 2027. The China-based company said the new battery has an energy density of 200 watt-hours per kilogram, which is an increase from 160 watt-hours per kilogram for the previous generation that launched in 2021. Higher energy density in an EV battery translates into more driving range.

On Nov. 21, a consortium of seven U.S. national laboratories announced a new initiative in which they would spend $50 million to foster collaboration to accelerate the development of sodium-ion batteries. The partnership is led by Argonne National Laboratory in the Chicago area.

The two announcements are part of a larger shift as governments, researchers and companies look for alternatives to lithium-ion batteries, the dominant technology for EVs and energy storage.

For now, there are no passenger cars or trucks sold in the United States that use sodium-ion batteries. Some sodium-ion models are available in China and countries that import vehicles from China.

“The reason we’re pursuing this is very simple,” said Venkat Srinivasan, a battery scientist at Argonne and the director of the new collaboration. “It’s because the huge demand in lithium-ion batteries has meant that we have a supply-chain constraint.

“We have a problem with cobalt. We have a problem with nickel,” he said, naming two of the metals often used in lithium-ion batteries.

Cobalt, nickel and lithium carry a variety of concerns, including the environmental damage of mining. [Note: Which is massive, and so are the human rights issues associated with lithium mining, which involves horrible conditions and is exacerbating conflict and civil wars in the Democratic Republic of Congo.] ...

In contrast, a sodium-ion battery relies on an element—sodium—that you can find in table salt and ocean water...

Also, a sodium-ion battery has much lower risk of fire. When lithium-ion batteries sustain damage, it can lead to “thermal runaway,” which triggers a dangerous and toxic fire.

The process of manufacturing sodium-ion batteries is similar to that of lithium-ion batteries, or at least similar enough that companies can shift existing assembly lines without having to spend heavily on retooling.

But sodium-ion batteries have some disadvantages. The big one is low energy density compared to lithium-ion. As a result, an EV running on a sodium-ion battery will go fewer miles per charge than a lithium-ion battery of the same size...

The national labs’ initiative has a five-year timeline, with a goal of developing sodium-ion batteries with energy densities that match or exceed those of today’s iron phosphate-based lithium-ion batteries. Researchers would do this by finding various efficiencies in design and materials.

The project is happening alongside the labs’ ongoing work to develop and improve other kinds of batteries.

Lithium-ion batteries dominate today’s market...

However, sodium-ion battery production is growing, and is projected to reach 140 gigawatt-hours by 2030, about 13 times its current level, according to Benchmark. Lithium-ion production also is projected to nearly triple by 2030.

“The key market driver for sodium-ion batteries is their potential to be cost competitive with lithium-ion batteries,” said Catherine Peake, an analyst for Benchmark...

Most of the push by battery companies to build sodium-ion systems is happening in China, but some of it is happening in other markets, including a plan by California-based Natron Energy to open its first large plant in Rocky Mount, North Carolina. Natron made its announcement about the $1.4 billion project in August and has not given a timeline for when the plant would be online.

Meanwhile, researchers and companies continue working on other battery technologies.

I asked Srinivasan how sodium-ion batteries fit into this larger picture. He said sodium-ion will likely gain market share over the next few years as an alternative to lithium-ion batteries.

Near the end of the decade, solid-state batteries will begin to become available, which would allow for higher energy densities and longer driving ranges. Solid-state batteries use a solid electrolyte instead of a liquid or gel. The electrolyte is the substance through which ions move as they go from side to side during charging and discharging.

The technologies can coexist in the market, Srinivasan said.

He thinks solid-state batteries will initially be most common in high-end models and popular with people who want the longest possible ranges.

He expects that sodium-ion batteries will be more common in low-cost EVs for people who live in cities or suburbs and don’t place a high premium on driving range.

“It will not be a fringe player,” he said, about sodium-ion. “It will actually be a fast-growing segment.”"

-via Inside Climate News, December 6, 2024

#ev#electric vehicles#sodium ion#lithium#lithium battery#lithium ion batteries#lithium mining#mining#cars#good news#hope

817 notes

·

View notes