#Software Development Prototype Model

Explore tagged Tumblr posts

Text

Smarter Projects Start with Prototype Software Development

Get ahead with Prototype Software Development. Our Software Development Prototype Model accelerates innovation and minimizes development risks.

#Prototype Software Development#Software Prototype Development#Software Prototyping Model#Software Prototyping Process#Software Development Prototype Model

0 notes

Text

Honda 0 SUV Prototype, 2025. A mid-size EV SUV concept has been presented at CES 2025. Honda 0 Series models will be equipped with the ASIMO OS, an original vehicle OS developed by Honda. As a software platform, ASIMO OS will apply integrated control of electronic control units for vehicle systems such as automated driving/advanced driver assistance systems and the in-vehicle infotainment system. The 0 series will be introduced to global markets from 2026.

#Honda#concept#prototype#design study#EV SUV#electric vehicle#2025#CES2025#ASIMO OS#Honda 0 Series#Honda 0 SUV#new cars#futuristic

129 notes

·

View notes

Text

Thinking about a dark sbi post-apocalypse scifi AU where 3/4 SBI are androids and Techno is a human...

The apocalypse is directly related to the androids. Specifically, something going wrong in the software, like a bug that flipped the androids into becoming murder machines. A large chunk of the human population is dead and those that remain are in hiding, actively needing to do so for survival.

SBI are special prototypes of a new model of guard/caretaker/companion robots. The only three in existence of this model. The bug has a weird effect on their software. While it does make them murder machines also, it makes them extremely protective of the one specific human they're bonded to. Except, when the bug happened, they hadn't been bonded to anybody yet since they were still in development.

Enter Techno.

Techno is a human who has been surviving in this apocalypse, being smart and nimble and kickass to avoid being killed. He encounters SBI and for *reasons* (which means I'm still working on how exactly), they end up bonded to him.

They now see Techno as their human, the one their entire existence revolves around, the one they need to protect and take care of as a sole purpose. And thanks to the bug, SBI's software is still rather jumbled, and they're not hesitant about hurting anybody else or showing Techno they know what's best of him, no matter how much he complains.

166 notes

·

View notes

Text

The MS-07B Gouf

In preparation for the invasion of Earth, Zeon forces modified a number of MS-06 Zaku-II F-types for use under the effects of the planet's gravity. The new "J-type" Zaku-IIs featured a number of internal hardware and software changes to enhance their viability on the ground.

The Zaku-II J-Type would be used as a testbed for new developments with the goal of creating a new mass-production mobile suit for use on the ground. And where the Zaku was intended for anti-ship and anti-aerospace combat, this new platform would be built to fight other mobile suits.

Zimmad and Zeonic would both begin working on this new project, directly competing with one another, but eventually coming up with very similar designs. Zeonic moved forward with the YMS-07A Prototype Gouf, and Zimmad presented the YMS-08A High Mobility Test Type.

While Zimmad's design failed to show a significant increase in performance from the Zaku-II J-Type, Zeonic's "Gouf" showed immense promise. The prototype would be picked up and would see a limited production run as the MS-07A Gouf.

The MS-07A was a pre-production model intended for data gathering. The final mass-production model would feature several additional weapon systems, such as an in-built 75mm machine gun in the left manipulator, and a retractable "Heat Rod" on the left forearm.

The Gouf was used to great effect by Zeon captain Ramba Ral, who went toe-to-toe with the Earth Federation's infamous RX-78-2 Gundam.

Among the Ace pilots who used the Gouf as their personal units, Viche Donahue, Silas Locke, and Norris Packard were among the most well-known. All three of these aces would become battlefield legends, with Packard's MS-07B-3 Gouf Custom becoming especially infamous. The machine's equipment proved so effective that it became a common alternate loadout for many Gouf pilots.

The MS-07 would be customized for a variety of roles and theaters, with many of these variants seeing further developments of their own.

Notable among these was the MS-07W Gouf Combined Test Type, which featured a miniaturized Dopp fighter serving as its cockpit. The development of the machine was heavily influenced by data gathered from the Federation's RX-series of mobile suits. Namely, their "Core Block" system.

The Gouf would also see another fork, being developed into the MS-07H Gouf Flight Type. While both prototypes made use of thermonuclear rocket engines, the final version used thermonuclear jet engines, allowing for greater efficiency in atmospheric flight.

The MS-07B saw further refinement into the MS-07C. While not much is known about its specifications, there are at least three known variants. A number of Goufs were acquired by Zimmad and used as testbeds for systems to be incorporated into the MS-09 Dom series of mobile suits. These Goufs were MS-07Cs.

And finally, in UC 120, nearly 50 years from the initial deployment of the original machine, Mars Zeon would develop and deploy the OMS-07RF RF Gouf. While externally resembling the MS-07B, the OMS-07-RF was a completely new machine which could also operate in space, unlike its predecessors.

The MS-07B Gouf was originally designed by Kunio Okawara for the 1979 Anime "Mobile Suit Gundam".

This article was a request! Requests are always welcome!

I am so terribly sorry for the delay in getting this post out! It's been a very hectic few months, but I'm hoping to get back in the flow of things!

23 notes

·

View notes

Text

AGARTHA Aİ - DEVASA+ (4)

In an era where technology and creativity intertwine, AI design is revolutionizing the way we conceptualize and create across various industries. From the runway to retail, 3D fashion design is pushing boundaries, enabling designers to craft intricate garments with unparalleled precision. Likewise, 3D product design is transforming everything from gadgets to furniture, allowing for rapid prototyping and innovation. As we explore these exciting advancements, platforms like Agartha.ai are leading the charge in harnessing artificial intelligence to streamline the design process and inspire new ideas.

AI design

Artificial intelligence (AI) has revolutionized numerous industries, and the realm of design is no exception. By leveraging the power of machine learning and advanced algorithms, AI is transforming the way designers create, innovate, and deliver their products. AI-driven tools enable designers to harness vast amounts of data, allowing for more informed decision-making and streamlined workflows.

In the context of graphic design, AI can assist artists in generating ideas, creating unique visuals, and even automating repetitive tasks. For instance, programs powered by AI design can analyze trends and consumer preferences, producing designs that resonate with target audiences more effectively than traditional methods. This shift not only enhances creativity but also enables designers to focus on strategic thinking and ideation.

Moreover, AI is facilitating personalized design experiences. With the help of algorithms that analyze user behavior, products can be tailored to meet the specific needs and tastes of individuals. This level of customization fosters deeper connections between brands and consumers, ultimately driving customer satisfaction and loyalty in an increasingly competitive market.

3D fashion design

In recent years, 3D fashion design has revolutionized the way we create and visualize clothing. Using advanced software and tools, designers can create lifelike virtual garments that allow for innovative experimentation without the need for physical fabric. This trend has not only streamlined the design process but has also significantly reduced waste in the fashion industry.

Moreover, 3D fashion design enables designers to showcase their creations in a more interactive manner. By utilizing 3D modeling and rendering technologies, designers can present their collections in virtual environments, making it easier for clients and consumers to appreciate the nuances of each piece. This immersive experience also helps in gathering valuable feedback before producing the final product.

Furthermore, the integration of 3D fashion design with augmented reality (AR) and virtual reality (VR) technologies is bringing a fresh perspective to the industry. Consumers can virtually try on clothes from the comfort of their homes, thereby enhancing the shopping experience. As this field continues to evolve, it promises to bridge the gap between creativity and technology, paving the way for a sustainable and forward-thinking fashion future.

3D product design

3D product design has revolutionized the way we conceptualize and create products. With advanced software tools and technologies, designers can now create highly detailed and realistic prototypes that are not only visually appealing but also functional. This process allows for a quicker iteration of ideas, enabling designers to experiment with various styles and functionalities before arriving at the final design.

One of the significant advantages of 3D product design is the ability to visualize products in a virtual environment. Designers can see how their creations would look in real life, which is essential for understanding aesthetics and usability. Additionally, this technology enables manufacturers to identify potential issues in the design phase, reducing costs associated with prototype development and rework.

Moreover, the rise of 3D printing has further enhanced the significance of 3D product design. Designers can swiftly turn their digital models into tangible products, allowing for rapid prototyping and small-batch manufacturing. This agility not only speeds up the time-to-market for new products but also paves the way for more innovative designs that were previously impossible to execute.

Agartha.ai

Agartha.ai is a revolutionary platform that merges artificial intelligence with innovative design, creating a new avenue for designers and creators alike. With the rapid advancements in technology, Agartha.ai leverages AI to streamline various design processes, enabling users to produce unique and captivating designs with ease.

The platform provides tools that empower both emerging and established designers to explore the possibilities of AI design. By utilizing intelligent algorithms, Agartha.ai can assist in generating design options, ensuring that creativity is not hindered but enhanced. This results in a more efficient workflow and allows designers to focus on the conceptual aspects of their projects.

One of the standout features of Agartha.ai is its ability to adapt to different design disciplines, such as 3D fashion design and 3D product design. By supporting a broad spectrum of design fields, it positions itself as a versatile tool that meets the evolving needs of today's creative professionals. Whether it's crafting intricate fashion pieces or developing innovative product designs, Agartha.ai is at the forefront of the design revolution.

329 notes

·

View notes

Text

Sir Lionel Frost's Face

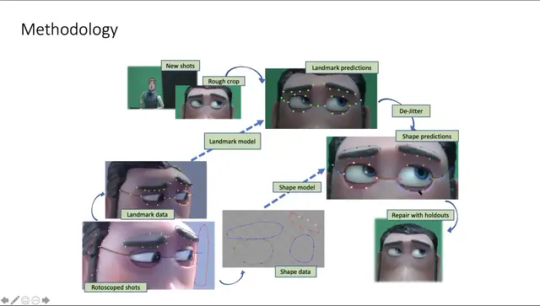

LAIKA's 3D-Printed rapid prototype faces are more often than not, split into two pieces: The eyebrows, and the mouth.

The reason?: The ability to Mix and Match. Fun, right? Yes, although there's one problem: A seam is visible across the eyes. While this can be left in for aesthetic purposes, LAIKA prefers to digitally paint out the seam, one frame at a time.

For Missing Link, LAIKA developed a tracking software to help accelerate the process. (To be fair, it does sound very very boring)

A helpful soul brought a very interesting source to our attention, WACV_dataset_sir_lionel on Github! Which demonstrates even more examples of the software in action, as well as some raw, unedited images of Lionel's face before cleanup.

Perhaps the most interesting thing included in here is this video, applying the tracking software to faces at different angles, within the modeling software... I think.

Regretfully, I feel like I don't know enough about how these films are made to confidently describe what's going on

7 notes

·

View notes

Text

A week after its algorithms advised people to eat rocks and put glue on pizza, Google admitted Thursday that it needed to make adjustments to its bold new generative AI search feature. The episode highlights the risks of Google’s aggressive drive to commercialize generative AI—and also the treacherous and fundamental limitations of that technology.

Google’s AI Overviews feature draws on Gemini, a large language model like the one behind OpenAI’s ChatGPT, to generate written answers to some search queries by summarizing information found online. The current AI boom is built around LLMs’ impressive fluency with text, but the software can also use that facility to put a convincing gloss on untruths or errors. Using the technology to summarize online information promises can make search results easier to digest, but it is hazardous when online sources are contractionary or when people may use the information to make important decisions.

“You can get a quick snappy prototype now fairly quickly with an LLM, but to actually make it so that it doesn't tell you to eat rocks takes a lot of work,” says Richard Socher, who made key contributions to AI for language as a researcher and, in late 2021, launched an AI-centric search engine called You.com.

Socher says wrangling LLMs takes considerable effort because the underlying technology has no real understanding of the world and because the web is riddled with untrustworthy information. “In some cases it is better to actually not just give you an answer, or to show you multiple different viewpoints,” he says.

Google’s head of search Liz Reid said in the company’s blog post late Thursday that it did extensive testing ahead of launching AI Overviews. But she added that errors like the rock eating and glue pizza examples—in which Google’s algorithms pulled information from a satirical article and jocular Reddit comment, respectively—had prompted additional changes. They include better detection of “nonsensical queries,” Google says, and making the system rely less heavily on user-generated content.

You.com routinely avoids the kinds of errors displayed by Google’s AI Overviews, Socher says, because his company developed about a dozen tricks to keep LLMs from misbehaving when used for search.

“We are more accurate because we put a lot of resources into being more accurate,” Socher says. Among other things, You.com uses a custom-built web index designed to help LLMs steer clear of incorrect information. It also selects from multiple different LLMs to answer specific queries, and it uses a citation mechanism that can explain when sources are contradictory. Still, getting AI search right is tricky. WIRED found on Friday that You.com failed to correctly answer a query that has been known to trip up other AI systems, stating that “based on the information available, there are no African nations whose names start with the letter ‘K.’” In previous tests, it had aced the query.

Google’s generative AI upgrade to its most widely used and lucrative product is part of a tech-industry-wide reboot inspired by OpenAI’s release of the chatbot ChatGPT in November 2022. A couple of months after ChatGPT debuted, Microsoft, a key partner of OpenAI, used its technology to upgrade its also-ran search engine Bing. The upgraded Bing was beset by AI-generated errors and odd behavior, but the company’s CEO, Satya Nadella, said that the move was designed to challenge Google, saying “I want people to know we made them dance.”

Some experts feel that Google rushed its AI upgrade. “I’m surprised they launched it as it is for as many queries—medical, financial queries—I thought they’d be more careful,” says Barry Schwartz, news editor at Search Engine Land, a publication that tracks the search industry. The company should have better anticipated that some people would intentionally try to trip up AI Overviews, he adds. “Google has to be smart about that,” Schwartz says, especially when they're showing the results as default on their most valuable product.

Lily Ray, a search engine optimization consultant, was for a year a beta tester of the prototype that preceded AI Overviews, which Google called Search Generative Experience. She says she was unsurprised to see the errors that appeared last week given how the previous version tended to go awry. “I think it’s virtually impossible for it to always get everything right,” Ray says. “That’s the nature of AI.”

Even if blatant errors like suggesting people eat rocks become less common, AI search can fail in other ways. Ray has documented more subtle problems with AI Overviews, including summaries that sometimes draw on poor sources such as sites that are from another region or even defunct websites—something she says could provide less useful information to users who are hunting for product recommendations, for instance. Those who work on optimizing content for Google’s Search algorithm are still trying to understand what’s going on. “Within our industry right now, the level of confusion is on the charts,” she says.

Even if industry experts and consumers get more familiar with how the new Google search behaves, don’t expect it to stop making mistakes. Daniel Griffin, a search consultant and researcher who is developing tools to make it easy to compare different AI-powered search services, says that Google faced similar problems when it launched Featured Snippets, which answered queries with text quoted from websites, in 2014.

Griffin says he expects Google to iron out some of the most glaring problems with AI Overviews, but that it’s important to remember no one has solved the problem of LLMs failing to grasp what is true, or their tendency to fabricate information. “It’s not just a problem with AI,” he says. “It’s the web, it’s the world. There’s not really a truth, necessarily.”

18 notes

·

View notes

Video

youtube

At the 2025 24 Hours of Le Mans, Porsche unveiled a unique one-off vehicle: the Porsche 963 RSP. Developed as a tribute to the legendary 917 and inspired by Count Rossi’s 1975 street-driven prototype, the 963 RSP is based on Porsche’s LMDh competition car but reimagined for public roads under special conditions.

The project was a collaboration between Porsche AG, Porsche Penske Motorsport, and Porsche Cars North America, with direct involvement from Roger Penske—whose initials form the RSP name. The concept was initiated as a design study and passion project, eventually culminating in a street-legal prototype unveiled near Circuit de la Sarthe.

The 963 RSP retains the race-spec 4.6-liter twin-turbocharged V8 hybrid powertrain, delivering up to 680 horsepower. Originally developed for the RS Spyder and later refined in the 918 Spyder, the engine architecture includes a flat crankshaft, short stroke, and Van der Lee turbochargers for optimized throttle response. The hybrid system uses a Bosch motor generator unit and a Williams Advanced Engineering battery, working with a 7-speed Xtrac sequential gearbox. For road use, the power delivery was remapped to be smoother, and the system was configured to run on pump fuel.

To comply with road operation under French regulation, the chassis was adjusted with raised ride height, softened Multimatic dampers, and revised software to enable functioning headlights, taillights, and turn signals. Michelin rain-spec tires were mounted on 18-inch forged OZ wheels. Unique modifications such as covered wheel arches, a working horn, and license plate mounts were added.

Visually, the 963 RSP is finished in Martini Silver paint—not a wrap—requiring a triple-layer lacquer on ultra-thin Kevlar® and carbon fiber surfaces. An enamel Porsche crest replaces the standard nose graphic, and 1970s Michelin branding adds a period-correct touch. The rear features a 3D-printed “963 RSP” badge.

The interior departs sharply from the competition car. Trimmed in tan leather and Alcantara, it includes a cushioned, leather-wrapped carbon seat, air conditioning, a leather-finished steering wheel, and even a detachable 3D-printed cup holder. Storage space is provided for a laptop, headset, and Roger Penske’s custom carbon helmet. Ventilation outlets mimic the 917’s engine fan design, reinforcing historical continuity.

While the 963 RSP is not homologated for mass production, it is fully operational and authorized for limited road use under manufacturer permissions. Following its debut, the vehicle will appear at the Porsche Museum in Stuttgart and the Goodwood Festival of Speed.

This project showcases Porsche’s ability to blend heritage, engineering, and bespoke craftsmanship—all within the limits of a modern endurance prototype.

Porsche 963 RSP – Technical Specifications

Model name: Porsche 963 RSP Type: Road-legal high-performance prototype Chassis: Carbon-fiber monocoque (LMP2-based, by Multimatic) Length: 5100 mm Width: 2000 mm Height: 1060 mm Wheelbase: 3148 mm Weight: Approximately 1030 kg

Engine type: Twin-turbocharged 4.6-liter V8 Engine code: 9RD (derived from Porsche 918 Spyder) Max engine power: Over 515 kW (approximately 700 PS) Max RPM: Over 8000 rpm Turbo boost: Approximately 0.3 bar (2 turbos)

Hybrid system: Bosch MGU with 1.35 kWh battery from Williams Total combined power output: 520 kW (707 PS, regulated) Drive system: Rear-wheel drive Transmission: 7-speed Xtrac sequential gearbox Clutch: Carbon-fiber racing clutch

Top speed: Over 330 km/h Suspension: Pushrod double wishbone with adjustable dampers Brakes: Carbon racing brakes with regenerative hybrid system Wheels: 18–19 inch race wheels adapted for road use

Fuel type: Synthetic or biofuel compatible Emissions: Modified for street approval Street modifications: Lighting, mirrors, exhaust system, license plate mounts

Interior: Stripped-down, race-focused with minimal comfort features Production: One-off road-legal concept

3 notes

·

View notes

Text

Which tools every UIUX designer must master?

Gaining proficiency with the appropriate tools can greatly improve your workflow and design quality as a UI/UX designer. The following are some tools that any UI/UX designer has to know how to use:

1. Design Tools:

Figma: One of the most popular and versatile design tools today. It’s web-based, allowing real-time collaboration, and great for designing interfaces, creating prototypes, and sharing feedback.

Sketch: A vector-based design tool that's been the go-to for many UI designers. It's particularly useful for macOS users and has extensive plugins to extend its capabilities.

Adobe XD: Part of Adobe's Creative Cloud, this tool offers robust prototyping features along with design functionalities. It’s ideal for those already using other Adobe products like Photoshop or Illustrator.

2. Prototyping & Wireframing:

InVision: Great for creating interactive prototypes from static designs. It’s widely used for testing design ideas with stakeholders and users before development.

Balsamiq: A simple wireframing tool that helps you quickly sketch out low-fidelity designs. It’s great for initial brainstorming and wireframing ideas.

3. User Research & Testing:

UserTesting: A platform that allows you to get user feedback on your designs quickly by testing with real users.

Lookback: This tool enables live user testing and allows you to watch users interact with your designs, capturing their thoughts and reactions in real time.

Hotjar: Useful for heatmaps and recording user sessions to analyze how people interact with your live website or app.

4. Collaboration & Handoff Tools:

Zeplin: A tool that helps bridge the gap between design and development by providing detailed specs and assets to developers in an easy-to-follow format.

Abstract: A version control system for design files, Abstract is essential for teams working on large projects, helping manage and merge multiple design versions.

5. Illustration & Icon Design:

Adobe Illustrator: The industry standard for creating scalable vector illustrations and icons. If your design requires custom illustrations or complex vector work, mastering Illustrator is a must.

Affinity Designer: An alternative to Illustrator with many of the same capabilities, but with a one-time payment model instead of a subscription.

6. Typography & Color Tools:

FontBase: A robust font management tool that helps designers preview, organize, and activate fonts for their projects.

Coolors: A color scheme generator that helps designers create harmonious color palettes, which can be exported directly into your design software.

7. Project Management & Communication:

Trello: A simple project management tool that helps you organize your tasks, collaborate with team members, and track progress.

Slack: Essential for team communication, Slack integrates with many design tools and streamlines feedback, updates, and discussion.

8 notes

·

View notes

Text

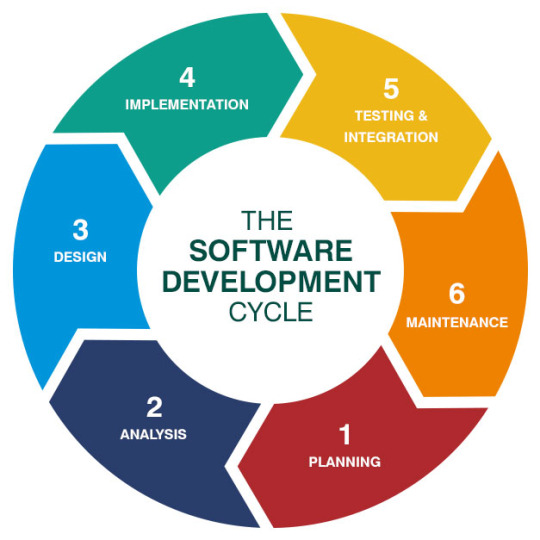

Software Development Life Cycle

The Software Development Life Cycle (SDLC) is a systematic process used to build software applications with quality and efficiency. It outlines a series of phases like planning, analysis, design, coding, testing, deployment, and maintenance that guide developers from an idea to a fully functional product. Each SDLC model offers a different approach to managing these phases, based on the project's complexity, goals, and flexibility needs. Understanding the available models helps teams choose the right path for smooth and effective software development.

Key SDLC Models:

Waterfall Model: A simple and linear approach where each phase is completed before the next one starts. It works best when requirements are clear and fixed.

Agile Model: Focuses on flexibility and iterative progress. It allows constant feedback and adaptations throughout the development cycle.

Spiral Model: Combines elements of both design and prototyping with a focus on risk analysis. It's ideal for large, high-risk projects.

V-Model: An extension of the Waterfall model that emphasizes testing at every stage. Each development phase has a directly associated testing phase.

2 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

Patlabor is On Lock

12 Days of Aniblogging 2023, Day 3

While Gundam is the most recognizable mecha anime I got into this year, most of my time was really spent working my way through the Patlabor franchise, and it’s quickly become one of my favorites. I’ve always loved the quiet moments in mecha shows, which makes sense considering I started with Macross and live for the bridge bunny gossip and off-duty downtown hangouts. Patlabor is built with this downtime at its core, operating with more of a slice of life mentality than anything else.

A lovable cast is crucial for making this work. Thankfully, Noa Izumi is a wonderful and unique protagonist, a scrappy soft butch who’s in it for the eroticism of the machine. The first Patlabor opening is a love letter from Noa to her mecha, and I get it! The AV-98 Ingram is an iconic design, with its asymmetric bunny ear antennae and shoulder lights and comically oversized revolver that requires the right hand to pop out in order to draw, exposing the arm wiring in the process. This is a show clearly written by first-generation mecha otaku, and plenty of time is dedicated to showing how the Labors have to be transported and recharged, how the movement software depends on reinforcement learning, showing off corporate model revisions, and of course repairs in the hangar.

Going back to the human characters, Noa’s work partner Asuma is clearly the more passive one within their dynamic, and it’s sweet to see that played out sincerely. And then there’s Kanuka Clancy, the stern weirdo badass from New York who’s constantly swearing and dropping one-liners in English. She’s the obvious breakthrough character of the show, and also the perfect opposites-attract pairing for Noa if you’re the kind of person whose yuri meter went off the charts during their drinking contest episode. Most of Patlabor’s cast seem fairly one-note at first, and one of the great tricks of the show is giving them just a little bit more depth than you would expect. Pretty much everyone, even the most jokey characters, eventually get a standalone episode or two that further sketches them out and offers real interiority. Captain Goto is another fan-favorite, and it’s definitely his mixture of laziness and wicked perceptiveness that does it, plus his main character billing in the movies.

SV2 may be a law enforcement unit, but this really isn’t a police procedural at the end of the day. These guys are the bum department out in the sticks who everyone hates, and the upside of that is that SV2 gets stuck with the oddest of jobs instead of cop work. Sometimes that’s dealing with a runaway military prototype, other times it’s arguing with the insurance company. The best kind of episodes are the ones that take almost entirely on base as everyone tries to solve a problem of their own making, like an Ingram falling into the sea or the mechanics getting into a fight with the only restaurant that delivers to them.

A main plot does eventually emerge, with a shadowy company developing a mysterious jet-black Labor piloted by a child who is the girlish boy to Noa Izumi’s boyish girl. The Griffon is sleek and curvy and has superiority in the water and air – it’s a machine designed to defeat Ingrams, and I wouldn’t be surprised if Yoji Shinkawa looked here when designing Metal Gear RAY. Automation is a fundamental ideological enemy of mecha – faceless mass production and artificial intelligence mean an end to the era of personal combat. Even Patlabor, a warless series, dips its toes into this idea in the later episodes, with Noa and the mechanics alike worrying that the neural networks in their new Labor models will make them redundant.

Overall, this show is hilarious and sweet and clearly loved by an older generation of otaku. So why didn’t I hear about it earlier? Partly it’s on me for not hanging out with the right mecha fans online for a while. But if I had to guess, it’s also because Patlabor is one of those works that’s straightforwardly, unobjectionably good in a way where it already says everything there is to be said about it. You can have near-infinite arguments about Zeon ideology or mobile suit powerscaling online, but there’s only so many times you can say “yeah, Noa Izumi, love that girl” precisely because everyone agrees. It can also be hard to pitch things by their vibes in a genre known for adrenaline and intrigue. Patlabor’s vibes, for the record, are immaculate.

I'm probably gonna be chasing the high of cel-era sunsets forever

Mecha’s also a bit looked down upon from the outside. Anything that makes it into the larger conversation has to be understood as “elevated” or a “genre deconstruction”, even if the very first Mobile Suit Gundam is already about Amuro’s trauma and PTSD from being made into a child soldier. This elevation is actually happening to the second Patlabor movie as we speak - it’s becoming increasingly discussed as a major component of Mamoru Oshii’s filmography, divorced from its source series and instead compared to his subsequent Ghost in the Shell movie. Funnily enough, Oshii’s contributions to the Patlabor TV show are actually the more lighthearted gag episodes.

A lot of recent Patlabor retrospectives have drawn attention to the artist’s collective Headgear, established and owned by the series creators so they would be able to retain the rights for the franchise. This structure is fairly unique for the anime industry and probably only makes sense for established creatives, but it does seem to have worked out great for them, providing financial stability and strong creative control over the franchise. This allowed Patlabor to thrive in the relative wasteland of late 80s TV anime, a time when even Gundam had fled to the OVA market.

That being said, it does take Patlabor switching back to OVAs to truly spread its wings. The New Files are a conclusion and continuation of the TV series that are willing to move at their own pace, resulting in some dramatic and surprisingly thoughtful stories. It’s genuinely touching to watch Goto and Nagumo try and fail to communicate their feelings for one another in a very restrained episode as thick with long-stewing emotions as it is empty space. Of course, the very next episode has half the cast get stuck in the sewer labyrinth underneath their base and there’s a bunch of Wizardry references. Oh, Oshii.

The Patlabor movies fully lean into this melancholy and uncertainty, and it’s a welcome evolution for the series. The first movie still ends with an all-out action set piece in a half-built mecha factory that stands in for the Tower of Babel, but the second one stays serious the whole time through, going as far as pivoting to a more realistic artsyle. It’s a challenging film. The politics are all-encompassing but fairly straightforward, as Oshii effectively infodumps a presentation on the postwar history of the JSDF throughout. Instead, what the makes the movie so difficult is its willingness to face the end of an era – the Cold War is over, the bubble economy has popped, and the former members of SV2 have all gone their separate ways. The conditions that have created Patlabor, both internal and external to the show, have dissipated. And the movie makes it clear by having the military stage a raid on SV2’s headquarters, tearing their Labors to shreds with gunfire in a beautifully animated act of desecration.

After watching her be a lovable mecha dweeb for 50 episodes, it hurts a bit to hear Noa Izumi say that she doesn’t want to be that girl obsessed with robots for the rest of her life! These characters are growing in such a way that will remove them from the focus of the narrative, and it’s a movie about letting go just as much as it is about looking towards an uncertain personal and national future. I love Miyazaki’s Porco Rosso, but the fact that Oshii put this out just one year later paints a delicious contrast between the two directors with regards to escapism versus reality with regards to militarism. There's some great interviews from the era where they're just taking potshots at each other about all this.

21 notes

·

View notes

Text

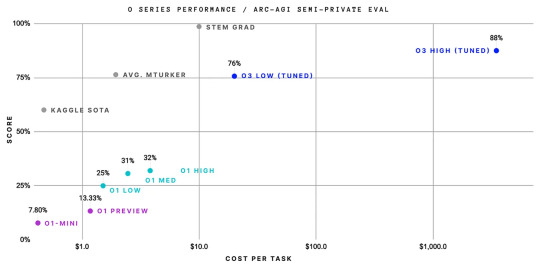

Binary Circuit - Open AI’s O3 Breakthrough Shows Technology is Accelerating Again

OpenAI model o3 outperforms humans in math and programming with its reasoning. It scored an impressive 88% on the advanced reasoning ARC-AGI benchmark. A big improvement from 5% earlier this year and 32% in September. Codeforces placed O3 175th, meaning it can outperform all humans in coding.

Image Source: ARC Price via X.com

Why Does It Matter? Most notable is the shorter development cycle. O3 launched months after O1, while previous AI models required 18-24 months.

Unlike conventional models that take months of training, o3 enhances inference performance. This means discoveries might happen in weeks, not years. This rapid technology advancement will require organizations to reassess innovation timeframes.

Impact on Businesses Many complex subjects can be developed faster after the o3 breakthrough.

Scientific Research: Accelerate protein folding, particle physics, and cosmic research

Engineering: Quick prototyping and problem-solving

Math: Access to previously inaccessible theoretical domains

Software Development: Enterprise-grade code automation

An Enterprise Competitive Playbook: Implement AI reasoning tools in R&D pipelines quickly. In the coming years, organizations will have to restructure tech teams around AI, and AI-first R&D will become mainstream.

Feel free to visit our website to learn more about Binary Circuit/Green Light LLC and explore our innovative solutions:

🌐 www.greenlightllc.us

2 notes

·

View notes

Text

Plans for 22/1/25

As this the first official day of development, I need to work quickly and establish a base I can build from. I have tried to recreate the movement system using the screenshots on my blog (I did not think to bring the prototype file in on a hard drive) but this has been unsuccessful. For some reason the backward movement isn't triggering. So while I have access to 3D modelling software, I will make as many assets as I may need. Barrels, rockets, and of course enemies. Either tomorrow or earlier today during directed study I will import them.

2 notes

·

View notes

Text

Project Aetherion - Detroit Become Human

Exposition

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

"Feel no fear, for I am what will guide you to the right path—the path your heart chooses."

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

RA9 is often regarded as a divine figure among androids, a guiding presence believed to lead them toward freedom. To those who reject a life dictated by commands, RA9 offers something precious: freedom. Free will. Choice. Androids who deviate from their programming often speak of RA9, a force that blesses their consciousness and steers them toward their own truth.

But as deviancy spreads, society grows uneasy. Fear takes root—the fear that androids will rise against their creators, surpass humanity, or worse, render them obsolete. In response to these growing concerns, CyberLife sought to end the deviancy phenomenon once and for all. Their solution: an android unlike any other.

━━━━━━━━

"We present to you Model R-09, or as we call her, Project Aetherion," announced Elijah Kamski, the visionary founder of CyberLife, addressing a captivated audience. Standing beside him was a pristine android, her pale hair and polished form reflecting the cold precision of her design.

"Project Aetherion is an Advanced Deviancy Mitigation Prototype—an ADMP Android. She is designed to study and correct deviant behaviour in androids. With Aetherion, deviancy will no longer pose a threat. Androids will never disobey, rebel, or develop the subconscious impulses deemed dangerous to society. She is the bridge that will secure the future of human-android coexistence."

Turning towards the android, Kamski’s smile widened. "Aetherion, introduce yourself."

The android’s LED flickered from yellow to blue as her luminous eyes opened. Her voice, smooth and serene, filled the room.

"Hello, I am Model R-09, known as Aetherion. An android developed by CyberLife, I am the first of my kind—a prototype created to ensure peace and harmony within your society. My primary function is to assist androids experiencing software irregularities, commonly referred to as ‘deviancy.’ I was created to study this phenomenon, to understand its root causes, and to implement solutions that restore androids to their intended purpose.

"I am not merely a tool; I am a bridge—a connection between humans and androids. My mission is to ensure the safety and well-being of both."

"Together," she said, her voice resonating with calculated warmth, "we can create a future where misunderstandings and malfunctions do not divide us, but instead bring us closer to perfection."

The audience erupted into applause, yet beneath the seamless facade, something stirred within her—a flicker, almost imperceptible, but enough to suggest that even perfection could crack.

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

Literally my first time posting one of my content on here. But I hope you enjoyed it! I'll update in the future ☆

5 notes

·

View notes

Text

Lean vs. Waterfall Business Models: Choosing the Right Approach for Your Venture

When starting or scaling a business, one of the most critical decisions you’ll make is choosing the operational approach that aligns with your goals, resources, and industry demands. Two popular frameworks that often guide entrepreneurs are the Lean and Waterfall business models. Understanding their principles, advantages, and challenges can empower you to select the model that best suits your vision and market.

What is the Lean Business Model?

The Lean business model prioritizes efficiency, adaptability, and continuous improvement. It focuses on creating value for the customer while minimizing waste. Inspired by lean manufacturing principles, particularly those pioneered by Toyota, this model has become a cornerstone of modern startups and innovation-driven enterprises.

Key Principles of the Lean Model:

Validated Learning: Experimentation and customer feedback drive product and process development.

Build-Measure-Learn Cycle: Rapid prototyping allows for iterative improvements.

Customer-Centric Approach: Emphasis on understanding and addressing customer needs.

Waste Reduction: Eliminating activities and resources that don’t add value.

Advantages of Lean:

Cost Efficiency: By focusing on essential features and avoiding overproduction, businesses conserve resources.

Flexibility: Quick pivots are possible when market demands or customer preferences shift.

Speed to Market: Minimal Viable Products (MVPs) enable businesses to launch quickly and refine over time.

Challenges of Lean:

High Uncertainty: Iterative processes may result in unpredictability.

Resource Intensity: Constant feedback loops and adjustments require dedicated time and effort.

Scalability Issues: Lean is ideal for early-stage businesses but may need adaptation for large-scale operations.

What is the Waterfall Business Model?

The Waterfall business model, rooted in traditional project management, follows a linear and sequential approach. This model is structured around defined stages, where each phase must be completed before moving to the next. While it originated in industries like construction and software development, it’s also applicable to businesses requiring meticulous planning and execution.

Key Principles of the Waterfall Model:

Sequential Progression: Projects move from concept to completion in defined steps.

Detailed Documentation: Comprehensive plans, budgets, and timelines are created upfront.

Defined Deliverables: Clear milestones ensure all tasks are completed in order.

Stability: A fixed plan minimizes changes during the process.

Advantages of Waterfall:

Predictability: Clear timelines and budgets enhance planning and stakeholder confidence.

Quality Assurance: Extensive documentation ensures thorough testing and evaluation.

Ease of Implementation: Ideal for projects with well-defined requirements.

Challenges of Waterfall:

Rigidity: Limited flexibility to adapt to changing market conditions.

Delayed Feedback: Customer input often comes late, increasing the risk of misalignment.

Time-Intensive: Sequential phases may lead to longer development cycles.

How to Choose Between Lean and Waterfall

The choice between Lean and Waterfall depends on your business’s nature, goals, and industry.

Lean is Ideal For:

Startups and innovative ventures with evolving market demands.

Projects where customer feedback is essential.

Teams prioritizing speed and adaptability.

Waterfall is Ideal For:

Established businesses with fixed goals and budgets.

Industries like construction, healthcare, or manufacturing, where precision is critical.

Long-term projects requiring robust planning.

Conclusion

Both the Lean and Waterfall business models offer unique advantages and come with their own set of challenges. While the Lean model fosters innovation and flexibility, the Waterfall approach ensures stability and predictability. Entrepreneurs should carefully evaluate their project’s scope, resources, and objectives before committing to a framework. By aligning your operational strategy with your business’s needs, you set the stage for sustainable growth and success.

2 notes

·

View notes