#integrated data systems

Explore tagged Tumblr posts

Text

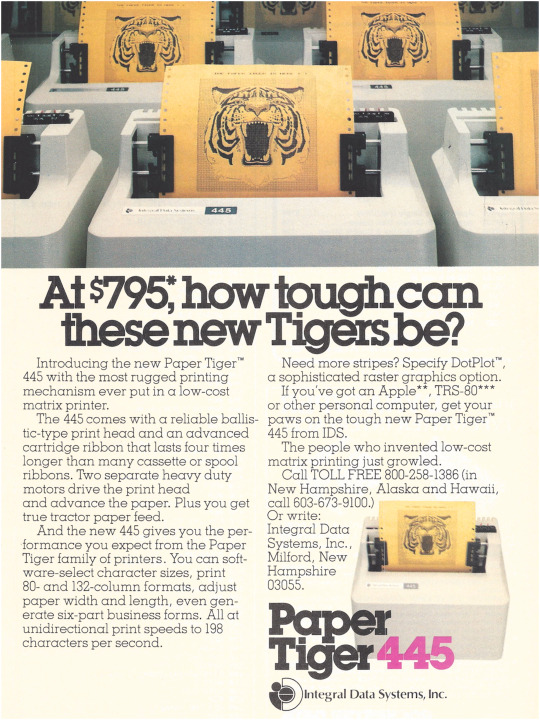

The Elusive Paper Tiger...

#1981#1980s#80s#eighties#80s ads#80s advertising#vintage ads#vintage advertising#80s tech#80s printers#state of technology#integrated data systems#paper tiger 445#interface age magazine

9 notes

·

View notes

Text

the neurologist i shadow is so funny bc she has a valley girl accent and yet she's the smartest person in the room. this woman was casually doing case consenus ab a man w frontotemporal dementia in the highest girliest voice imaginable. i want to be her i think

#case consensus is basically where several neurologists/doctors meet to decide what the patient's case actually is#im genuinely not sure why this medical center does it this way but they write down data on paper THEN input it into the digital system#which i have qualms w bc i feel like it wastes so much time#but literally my whole role at this internship is inputting this data into the system so i should probably be grateful they do it this way#but in that one meeting everyone was all over the place so this at the ending of the meeting this woman goes#“that... was frantic.”#in the most valley girl accent known to man#and ever since ive integrated this as my response to everything#youre right. that WAS frantic#she also was like “sorry im unfocused. need lunch rly bad” at one point during the meeting#this neurologist is just like the rest of us fr

240 notes

·

View notes

Text

oops all omnimon but like. fighter mode sage y'know?

#sonic#sage#sage the ai#sage sonic frontiers#sonic frontiers#purp doot#she would mangle other titans in it too and the minibosses and shit but my hand is tired man#like the base form has 2 of the red arms. and she can morph them at will#as long as she has been exposed to the data before and integrated it into her system#yeag. wahoog. get digimonized idiot

113 notes

·

View notes

Text

Being in a data governance class makes it so weird to watch the shit that tech giants are continuously pulling. I see them mass data scraping for AI training and I'm like. But Wait. What about GDPR??? Hello??? User privacy and right to access/correct/delete??? I know that's an EU thing but other places have their own data protection acts too!!! And they're pulling these moves that communicate such flagrant disrespect and irresponsibility for the handling of user data.

In the IT courses I've taken, they've taught us something that's really stuck with me: "Just because we can doesn't mean we should."

My data governance professor keeps emphasizing that as IT personnel, we will need to have a much higher sense of integrity than most other fields bc we have access to SO MUCH SHIT. IT and tech industries are so under-regulated bc of how relatively new it all is and how slow the law moves. But people in charge of handling user data should keep in mind that this is data about Real People, and capitalizing off of it is a violation of privacy.

But tech giants don't care. They'll keep poking and prodding, trying to capitalize off of users' data in order to earn as much money as they can. Data regulations like GDPR exist, but they don't cover everyone, and tech giants are more of "Do First, ask forgiveness later". Or in this case, pay the fines later. Bc if they violate GDPR, they Will be paying fines. And maybe they'll even change the way they handle the data... for EU citizens.

The rest of us are fucked tho. Tech giants really don't care. They just view us as assets to profit off of.

#speculation nation#just thinking. i kinda hope my data governance professor brings this up on Tuesday.#i want to hear her thoughts about it.#but yeah im entering into a field that will grant me so much power within my organization(s)#thats where the integrity really matters on a personal scale. bc im not gonna end up running any tech giants.#but i Will be one of the IT guys who can access like. everything? in a company.#maybe not everything everything. depending on how well the company has their data system structured.#access controls and what have you. hopefully an average IT person wont see like. highly classified data and whatever.#but in a lot of companies IT ppl can just do Whatever.#another thing she taught in my data governance class is how to spot warning signs for insider threats.#aka ur fellow IT workers. or even just normal employees who arent following safety protocol as they should.#aactually it's wild how much of data privacy rides on the integrity of those involved.#kinda scary. people behind the scenes in the tech world have way too much power.#and so many of them dont treat that with the care that it deserves.

15 notes

·

View notes

Text

Aaron Parnas at The Parnas Perspective:

With that, we have alarming news this evening. According to the Washington Post, Elon Musk and DOGE are attempting to gain access to a highly-secure IRS system that contains sensitive financial data on every taxpayer, business, and nonprofit in the U.S. This has raised significant concerns within the IRS. The White House is reportedly pressuring the IRS to consider an agreement that would give DOGE officials broad access to IRS systems, including the Integrated Data Retrieval System (IDRS). The IDRS allows IRS employees to access detailed taxpayer information, including personal identification numbers and bank data, and even adjust transaction records. The access DOGE is requesting to this system is limited due to its sensitivity. If any taxpayer's information is disclosed or improperly accessed, they are legally entitled to compensation. This situation is alarming because it raises serious privacy concerns. The IDRS contains extremely sensitive data, and granting access to a private entity like DOGE could compromise taxpayer confidentiality and lead to potential misuse of information.

Elon Musk = threat to your data.

See Also:

Washington Post: Musk’s DOGE seeks access to personal taxpayer data, raising alarm at IRS

9 notes

·

View notes

Text

#IoT Testing#Internet of Things#Device Testing#Functional Testing#Performance Testing#Security Testing#Interoperability Testing#Usability Testing#Regression Testing#IoT Security#Smart Devices#Connected Systems#IoT Protocols#GQATTech#IoT Solutions#Data Privacy#System Integration#User Experience#IoT Performance#Compliance Testing#POS Testing#Point of Sale#Retail Technology#Transaction Processing#System Reliability#Customer Experience#Compatibility Testing#Retail Operations#Payment Systems#PCI DSS Compliance

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

We at Messung Industrial Automation are not just manufacturing PLC automation systems. We engineer intelligence. Smart PLC control is our ambition, and we aim to revolutionize the way AHU controllers operate, using a range of technologies, including Modbus, MQTT, compact PLCs, or IOT-enabled PLC.

What is a PLC-Based AHU Control System?

A PLC-based AHU control system is the ultimate HVAC master conductor. The flow, cooling, heating, and energy consumption of air are all controlled by real-time logic and precision through automation controllers.

Decision-making is the primary responsibility of a IoT enabled PLC (programmable logic controller), not just following instructions. Your AHU is designed to respond to data, adjust to changing surroundings, and function like a finely tuned machine with the help of intelligent controllers.

Whether it’s a mini PLC for a compact setup or a modular PLC for a multi-zone building, this IEC 61131-3 standard controller is the heartbeat of your air management system.

Core Functions of PLC Automation in AHU Controllers Applications

Sensor Integration

Temperature, humidity, CO2, and differential pressure are all sensors that your AHU controllers are equipped with. When it comes to Energy management systems, PLC control systems are necessary for reading, interpreting, and operating raw data.

Our intelligent PLCs work together with sensors to capture every detail of your indoor environment.

Data Analysis & Decision Making

After submitting the data, the PLC Automation magic begins. Our IEC 61131 based PLCs utilize advanced logic and maintain monitoring of variables such as:

Room occupancy

Outdoor air quality

Return air temperature

The intelligence in this scenario is not confined to automation alone it expands to the action of the PLC Control Systems.

Control Actions via Actuators

Now let's talk about the muscle of the operation. By utilizing PLC and Modbus TCP/IP, your automation controllers can dynamically control VFDs (Variable Frequency Drives) to regulate fan speeds while minimizing energy usage.

Actuated Dampers

Want zoned cooling in your building? Each damper is given precise guidance on when and where it should be opened or closed by our compact PLC, down to the second.

Valves

Our PLC automation system manages both hot and chilled water circuits, ensuring thermal comfort with accuracy.

Humidifiers & Dehumidifiers

System Overview: The NX-ERA JET Advantage

NX-ERA JET PLC is a digital command centre that is agile, adaptive, and always on alert as the AHU controllers. We have developed an intelligent and IEC 61131-3 standard PLC Control Systems that combine advanced logic, seamless connectivity, and flexible scalability. The NX-ERA JET is the key to ensuring that every component of your AHU system, including sensors and actuators, operates in perfect harmony.

Features of this IoT enabled PLC at a Glance

Modular PLC architecture is flexible and can be easily scaled for multi-zone management in large or changing infrastructure

The utilization of PLC with TCP/IP facilitates fast and secure communication between devices, including devices connected to remote systems

The integration of MODBUS RTU, Modbus TCP, and MQTT with BMS, SCADA, or cloud-based IoT platforms is facilitated by the native support provided by these protocols.

An integrated HMI that provides real-time, intuitive monitoring, diagnostics, and manual overrides.

Benefits of IoT enabled PLC for AHUs

In modern air handling, the focus isn’t just on moving air but moving it forward. Why? Integrating PLC control systems into AHUs can offer a transformative advantage in performance, sustainability, and adaptability for buildings. We should examine why PLC automation is the primary driving force behind intelligent HVAC solutions.

Improved Energy Efficiency

The value of energy is high, and PLC for energy systems with IEC 61131-3 standards optimizes every kilowatt. We can use our IoT enabled PLCs to save energy - up to 30% a time with intelligently controlled fan speeds, valve positions and damper angles that are real-time. Measurable reductions through these intelligent controllers help to reduce operational costs and greener footprints are not just numbers.

High Precision Control

AHU controllers equate performance with precision. Why? Our IEC 61131-3 compliant PLCs provide precise control over airflow, temperature and humidity. The result? Consistent comfort, efficient performance and strict environmental regulations.

Advanced Diagnostics

The use of intelligent PLCs with IoT systems means that problems can be prevented rather than delayed. With real-time monitoring and fault detection, teams can receive predictive maintenance insights to minimize downtime and maximize up time.

Scalability and Modularity

Our modular PLCs are designed to accommodate the growth of your building, offering compact systems and multi-zone installations. Do you require an immediate upgrade or expansion? These intelligent controllers can scale without complexity.

BMS Integration

Our PLC Control Systems with IEC 61131-3 standard integrates seamlessly with Building Management Systems, creating one intelligent ecosystem. Whether it’s HVAC, lighting, fire alarms, or access control—everything talks to everything for smoother operations.

In a world where data and efficiency are the primary drivers of change, PLC-controlled AHU controllers provide more than just automation; they also offer confidence. Our IoT enabled PLCs enable buildings to thrive rather than just functioning.

Intelligent PLC Control Systems for Smart Buildings

HMI with PLC Controllers - An HMI with PLC controller enables the observation of invisible areas. The entire package, including fan speed and filter life, is conveniently located at your fingertips.

MQTT based PLC and IoT Systems - The integration of IoT enabled PLC and MQTT support enables your AHU to communicate with the cloud, apps, and analytics platforms, simplifying the process of achieving predictive control and remote access.

Real-World Applications

Through PLC-based AHU control systems, we at Messung are changing the possibilities of environments from sterile labs to busy malls. With precision, adaptability, and unparalleled reliability, our intelligent automation controllers tackle the challenges associated with every application.

Pharma Cleanrooms - The precision of pharmaceutical products is essential in their application. The strict GMP standards are adhered to by our PLC control systems, which involve managing temperature, humidity, pressure differentials. The result? Zones that are sterile, upholding drug integrity and safety.

Commercial Buildings - Employee comfort drives efficiency. Our HVAC automation enables seamless climate management of all floors and departments. By utilizing intelligent design, efficient air circulation, and real-time monitoring, our IoT enabled PLCs enhance the productivity and satisfaction of customers in spaces.

Data Centers - Servers demand a stable climate 24/7. Even minor temperature fluctuations can compromise data. Our intelligent PLC Control Systems with IEC 61131-3 standard ensure uninterrupted cooling performance, reducing thermal risk and operational downtime.

Energy-Efficient Manufacturing - Today's manufacturers must strike a balance between sustainability and production. Without compromising comfort or compliance, our PLCs maximize AHU performance to reduce energy footprints, reduce emissions, and guarantee stable internal environments.

Wherever there's air to manage and performance to perfect, our Compact PLCs lead the way with intelligent control.

Messung’s Expertise in HVAC Automation

We at Messung lead the way in HVAC automation innovation for organizing smart air movement. Our legacy is created on trust, performance, and innovative control systems that transform indoor environments, not only on technology

Why Choose Messung PLC Automation?

We design smart automation systems rather than only selling PLC Control Systems. With more than four decades of engineering expertise, our PLCs are the favoured option of architects, MEP consultants, HVAC contractors, and facility managers across India and globally. Our internal R&D, field-tested dependability, and quick support system turn us into a progress partner rather than just a supplier.

Built on IEC 61131-3 Standard

To ensure every Messung programmable logic controller is consistent, dependable, and compatible with worldwide systems—today and tomorrow — our automation controllers follow this internationally recognized IEC 61131-3 standard.

Flexible Form Factors

Whether you are managing many air zones throughout a smart high-rise or automating a small rooftop AHU, our compact and modular PLCs meet every architectural and functional requirement.

Comfort, control, and conservation are not optional but rather vital in the quickly changing realm of smart infrastructure of today. Furthermore, realizing this potent triad calls for smart, adaptive control rather than just automation. That is what Messung's PLC-based AHU systems precisely provide. Our programmable logic controllers redefine air handling performance for buildings of all sizes with real-time responsiveness, easy BMS integration, IoT readiness, and IEC 61131-3 standard. Our intelligent controllers offer precision, dependability, and next-generation energy efficiency from sterile zones to skyscrapers. Should excellence be your goal, our IoT enabled PLC guarantees you lead rather than merely follow. Why settle for fundamentals when you may automate brilliance with our smart automation controllers?

FAQs

What makes a PLC suitable for AHU control?

Real-time processing, sensor compatibility, actuator control, and smooth BMS integration define good automation controllers. Messung's smart PLCs with IoT systems check every box

Can a modular PLC (Programmable logic controllers) handle multiple AHU zones?

Absolutely. Modular PLCs like Messung’s NX-ERA JET are great for big buildings since they can span levels and zones.

How does Messung's IoT enabled PLC enhance building performance?

Connecting to cloud systems and providing remote access help our IoT enabled PLCs to maximize energy efficiency and real-time maintenance cycles.

Why is Messung’s NX-ERA JET the ideal, affordable PLC choice for midscale operations compared to traditional compact or mini PLCs?

Messung’s NX-ERA JET offers advanced performance at an affordable price, making it perfect for midscale operations. It outperforms mini PLCs with better speed, scalability, and flexibility, without breaking the budget.

Are MQTT based Programmable logic controllers better than traditional protocols?

MQTT-based PLCs offer faster, lighter, and more effective communication than conventional systems like MODBUS RTU for remote and IoT-intensive applications.

#messing 1st blog ahu link#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#AHU controllers#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#AHU controllers systems#NX-ERA JET#HVAC solutions#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#Pharma Cleanrooms#Commercial Buildings#Data Centers#smart automation systems#programmable logic controller#BMS integration#smart PLCs#Modular PLCs

0 notes

Text

Hybrid Small Modular Reactors (SMRs): Pioneering the Future of Energy and Connectivity

SolveForce is proud to announce the release of a groundbreaking new book, “Hybrid Small Modular Reactors (SMRs): From Design to Future Technologies,” co-authored by Ronald Joseph Legarski, Jr., President & CEO of SolveForce and Co-Founder of Adaptive Energy Systems. This publication stands at the convergence of next-generation nuclear energy, telecommunications infrastructure, and digital…

#Adaptive Energy Systems#AI in Energy#Cybersecurity#Data Center Energy Solutions#Digital twin#Energy and Telecom Integration#Energy Storage#Energy Sustainability#Fiber Optics#Fusion-Fission Hybrids#Grid Optimization#Hybrid SMRs#Hydrogen from SMRs#Lead-Cooled Reactor#Modular Energy#Next-Gen Reactors#Nuclear Book Release#Nuclear Energy#Nuclear Innovation#Reactor Safety#Recycled Nuclear Fuel#Ron Legarski#Small Modular Reactors#Smart Grid#smart infrastructure#SMR Deployment Strategies#SMR Design#SolveForce#Telecommunications#Yash Patel

0 notes

Text

Integrating legacy systems with modern technologies is critical for digital transformation and long-term business growth. This guide outlines practical steps to conduct a successful legacy system integration, including identifying challenges, choosing the right integration tools, and minimizing operational disruption. Learn how to align old infrastructure with new solutions to improve performance, enhance data flow, and future-proof your enterprise IT ecosystem.

0 notes

Text

The AIoT Revolution: How AI and IoT Convergence is Rewriting the Rules of Industry & Life

Imagine a world where factory machines predict their own breakdowns before they happen. Where city streets dynamically adjust traffic flow in real-time, slashing commute times. Where your morning coffee brews automatically as your smartwatch detects you waking. This isn’t science fiction—it’s the explosive reality of Artificial Intelligence of Things (AIoT), the merger of AI algorithms and IoT ecosystems. At widedevsolution.com, we engineer these intelligent futures daily.

Why AIoT Isn’t Just Buzzword Bingo: The Core Convergence

Artificial Intelligence of Things fuses the sensory nervous system of IoT devices (sensors, actuators, smart gadgets) with the cognitive brainpower of machine learning models and deep neural networks. Unlike traditional IoT—which drowns in raw data—AIoT delivers actionable intelligence.

As Sundar Pichai, CEO of Google, asserts:

“We are moving from a mobile-first to an AI-first world. The ability to apply AI and machine learning to massive datasets from connected devices is unlocking unprecedented solutions.”

The AIoT Trinity: Trends Reshaping Reality

1. Predictive Maintenance: The Death of Downtime Gone are days of scheduled check-ups. AI-driven predictive maintenance analyzes sensor data intelligence—vibrations, temperature, sound patterns—to forecast failures weeks in advance.

Real-world impact: Siemens reduced turbine failures by 30% using AI anomaly detection on industrial IoT applications.

Financial upside: McKinsey estimates predictive maintenance cuts costs by 20% and downtime by 50%.

2. Smart Cities: Urban Landscapes with a Brain Smart city solutions leverage edge computing and real-time analytics to optimize resources. Barcelona’s AIoT-powered streetlights cut energy use by 30%. Singapore uses AI traffic prediction to reduce congestion by 15%.

Core Tech Stack:

Distributed sensor networks monitoring air/water quality

Computer vision systems for public safety

AI-powered energy grids balancing supply/demand

3. Hyper-Personalized Experiences: The End of One-Size-Fits-All Personalized user experiences now anticipate needs. Think:

Retail: Nike’s IoT-enabled stores suggest shoes based on past purchases and gait analysis.

Healthcare: Remote patient monitoring with wearable IoT detects arrhythmias before symptoms appear.

Sectoral Shockwaves: Where AIoT is Moving the Needle

🏥 Healthcare: From Treatment to Prevention Healthcare IoT enables continuous monitoring. AI-driven diagnostics analyze data from pacemakers, glucose monitors, and smart inhalers. Results?

45% fewer hospital readmissions (Mayo Clinic study)

Early detection of sepsis 6+ hours faster (Johns Hopkins AIoT model)

🌾 Agriculture: Precision Farming at Scale Precision agriculture uses soil moisture sensors, drone imagery, and ML yield prediction to boost output sustainably.

Case Study: John Deere’s AIoT tractors reduced water usage by 40% while increasing crop yields by 15% via real-time field analytics.

🏭 Manufacturing: The Zero-Waste Factory Manufacturing efficiency soars with AI-powered quality control and autonomous supply chains.

Data Point: Bosch’s AIoT factories achieve 99.9985% quality compliance and 25% faster production cycles through automated defect detection.

Navigating the Minefield: Challenges in Scaling AIoT

Even pioneers face hurdles:ChallengeSolutionData security in IoTEnd-to-end encryption + zero-trust architectureSystem interoperabilityAPI-first integration frameworksAI model driftContinuous MLOps monitoringEnergy constraintsTinyML algorithms for low-power devices

As Microsoft CEO Satya Nadella warns:

“Trust is the currency of the AIoT era. Without robust security and ethical governance, even the most brilliant systems will fail.”

How widedevsolution.com Engineers Tomorrow’s AIoT

At widedevsolution.com, we build scalable IoT systems that turn data deluge into profit. Our recent projects include:

A predictive maintenance platform for wind farms, cutting turbine repair costs by $2M/year.

An AI retail personalization engine boosting client sales conversions by 34%.

Smart city infrastructure reducing municipal energy waste by 28%.

We specialize in overcoming edge computing bottlenecks and designing cyber-physical systems with military-grade data security in IoT.

The Road Ahead: Your AIoT Action Plan

The AIoT market will hit $1.2T by 2030 (Statista). To lead, not follow:

Start small: Pilot sensor-driven process optimization in one workflow.

Prioritize security: Implement hardware-level encryption from day one.

Democratize data: Use low-code AI platforms to empower non-technical teams.

The Final Byte We stand at an inflection point. Artificial Intelligence of Things isn’t merely connecting devices—it’s weaving an intelligent fabric across our physical reality. From farms that whisper their needs to algorithms, to factories that self-heal, to cities that breathe efficiently, AIoT transforms data into wisdom.

The question isn’t if this revolution will impact your organization—it’s when. Companies leveraging AIoT integration today aren’t just future-proofing; they’re rewriting industry rulebooks. At widedevsolution.com, we turn convergence into competitive advantage. The machines are learning. The sensors are watching. The future is responding.

“The greatest achievement of AIoT won’t be smarter gadgets—it’ll be fundamentally reimagining how humanity solves its hardest problems.” — widedevsolution.com AI Lab

#artificial intelligence#predictive maintenance#smart city solutions#manufacturing efficiency#AI-powered quality control in manufacturing#edge computing for IoT security#scalable IoT systems for agriculture#AIoT integration#sensor data intelligence#ML yield prediction#cyber-physical#widedevsolution.com

0 notes

Text

Nichrome Data Over Internet: How Smart Packaging, IoT & Analytics Are Transforming Manufacturing

Packaging has never been more advanced. No more simple boxes and bottles. Smart packaging is where it's at today, and it's revolutionizing the packaging industry from inside out. At Nichrome, we are not just riding the wave of change—our path-breaking packaging automation solutions, backed by IoT, real-time data, and cloud-intelligent connectivity, are leading the charge.

Welcome to Nichrome Data Over Internet—or as we more commonly call it, N-DOIT. It's not a service, it's a packaging philosophy. A philosophy that puts data, analytics, and efficiency front and centre in every packaging machine that we design, install, and maintain.

From food packaging automation to agro automation, we're enabling Indian manufacturers to jumpstart their future. Through N-DOIT, we're enabling them to work smarter, faster, and more in control—all due to the powerful combination of cloud platforms, remote monitoring, and data-driven decision making.

Let us dive into how this change is shaping up.

What Is "Data Over Internet" in Packaging?

Just think how great it would be if your packaging machines talked. Better yet—what if they could listen, analyze, and predict? That is what Data Over Internet (DOI) makes a reality. At its essence, DOI is a real-time collection, transmission, and analysis of machine data across secure cloud platforms.

This isn't just fancy tech talk. It allows packagers to experience genuine real-time machine monitoring, instant insights, and greater visibility of their complete packaging automation system. From uptime, line downtime, energy usage, or product throughput, we enable you to view it all—anywhere, at any time.

This level of remote monitoring changes the game completely, especially for the packaging industry in India, where agility and efficiency are the need of the hour. With IoT solutions for the packaging industry in India, Nichrome offers unmatched transparency and control.

Smart Packaging Systems Enabled by IoT

This is where packaging and the future converge—Nichrome’s smart packaging solutions are transforming manufacturing through the capabilities of IoT (Internet of Things). Our integrated solutions surpass machines by introducing smart sensors and Internet of Things connected devices that track all performance aspects in real time.

Whether you have a pouch filling machine, sachet pack machine, or any food packing machine, our N-DOIT (Nichrome Data Over Internet Technology) patented technology makes your packaging process intelligent, cutting edge, and efficient.

Here is all that you can get with it:

Instant Deviation Alerts - Get notified the moment there's a sealing, filling accuracy, or temperature change.

Enhanced Machine Health Monitoring - Track the motor performance, pressure levels, and wear indicators to avoid breakdowns.

Environmental Controls - Monitor temperature and humidity levels required for sensitive products like pharmaceuticals or milk.

Data-Driven Decision Making – Analyze production data to maximize OEE (Overall Equipment Effectiveness) and minimize downtime.

Remote Accessibility – Remote access to machine data in real-time—greater visibility and control of operations.

From food packaging lines to sachet fillers, our IoT-enabled packaging technology transforms your production line into a lean, clean, and hyper-efficient one.

Welcome to a world where smart packaging doesn't merely respond—it anticipates, avoids, and acts.

Predictive Maintenance with Analytics

Why wait for a breakdown when you can anticipate it first? That is the benefit of predictive maintenance—and Nichrome leads the charge. Our automatic packaging machines feature intelligent diagnostics that utilize data analytics and machine learning to continuously watch and detect early warning signs of failure.

This is how our predictive maintenance is a game-changer for your packaging operations:

Scheduled maintenance, real-time machine monitoring, rather than repair in response

Enhanced OEE (Overall Equipment Effectiveness) because of reduced unplanned downtime

Improved productivity and consistent performance between shifts

Remote diagnostics for faster decision-making and assistance

Integrated sensors and real-time performance monitoring analytics

This isn't tweaking a little—it's a complete redesign in how you manage your production floor. With Nichrome's smart packaging automation solutions, you enjoy control, productivity, and uptime your competition can only dream of.

Real-Time Machine Monitoring for Efficiency

Knowledge is power today, and real-time knowledge is a superpower. With our N-DOIT service, manufacturers have the authority to conduct real-time remote machine monitoring anywhere in the world.

From the factory floor to the aircraft, you can monitor machine dashboards, make adjustments, and monitor performance metrics on our cloud-connected packaging machines. Remote operation, real-time data, and actionable insights? That's what we call next-generation packaging technology.

This degree of remote monitoring facilitates quicker decision-making, energy conservation, and greater accountability between shifts and locations. Guesswork no more—straight performance.

Nichrome's Role in India's Smart Packaging Revolution

At Nichrome Packaging Solutions, we are thrilled to be spearheading India's packaging revolution. With a history of more than four decades, we are not just packaging machine manufacturers—we are innovation facilitators. Our packaging solutions are smart, scalable, affordable, and are designed to address the evolving requirements of Indian industries.

India-specific: Whether it is agro automation and pharma packaging or FMCG and dairy, all of our solutions are India-specific.

Smart yet Robust: Our packaging machines are engineered to be rugged for the floor, yet intelligent on the cloud, combining durability with data-driven efficiency.

For Every Stage of Business: Whether you are a start-up looking to grow or an established brand looking to go digital, we have flexible solutions that grow with you.

Smart Manufacturing Ready: With real-time monitoring, cloud analytics, and IoT, our solutions future-proof your packaging operations.

Nichrome is your trusted ally in leading India's smart packaging drive.

Benefits of Smart Automation for Manufacturers

Let's talk about results. Because while innovation is exciting, it's the results that matter. That's what our innovative packaging solutions offer:

Enhanced speed and accuracy on the packaging lines

Smart automation reduces human error and accelerates operations with precision. Pouch filling or blister packaging, operations are carried out faster, with precise accuracy, accelerating throughput and product quality.

Reduced packaging waste and improved utilization of packaging material

Advanced sensors and control systems provide precise fill weights, minimize spillage, and ensure precise sealing. Not only is material wastage saved, but production costs are also lowered, making your company more efficient and sustainable.

Seamless integration with other smart factory devices and systems

Nichrome's solutions seamlessly integrate with ERP systems, MES systems, and IoT-based monitoring systems. The result? A networked packaging ecosystem that converses in real-time and responds dynamically to production demands.

Whether you're equipping food, pharma, or agro packaging plants, our industrial packaging machines simplify operations, make them smarter, and more profitable. It's no surprise the advantages of automation in packaging have more people talking than ever.

Our packaging systems are cleverly engineered, from the smallest food packaging machine to the most advanced industrial packaging line.

The Future of Smart Manufacturing & IoT Data-Driven

The best part? This is just the beginning. We're not talking sci-fi anymore—smart manufacturing is here, it's growing, and it's transforming the packaging industry like never before. That's what the future looks like:

Machine Learning Takes the Lead - With AI-based systems, packaging lines will be intelligent. Expect machines to self-adjust for material changes, optimize sealing or filling settings, and even schedule preventive maintenance—all autonomously.

Tailored Packaging on Demand - Want to change package size, branding or shape on the fly? No problem. With consumer behaviour data at its core, dynamic packaging design is a breeze—tailored, creative, and competitive.

Sustainability- Our smart packaging solutions ensure efficient energy usage, lower material wastage and reduced carbon footprint. That’s eco-smart packaging with a purpose.

Real-Time, Cloud-Connected Control - Thanks to cloud platforms and remote monitoring, performance metrics are accessible anytime, anywhere—making decision-making smarter and faster.

From packaging automation systems to IoT solutions for the packaging industry in India, Nichrome is already building this future. The future isn’t coming—it’s here. Let’s package it smartly. Let’s package it together.

Conclusion

The packaging world has changed, and with Nichrome’s smart packaging systems, the shift isn’t just noticeable, it’s measurable.

With N-DOIT, we're offering Indian manufacturers a roadmap to future-ready operations. From real-time machine monitoring and predictive maintenance to remote monitoring and cloud-connected packaging machines, Nichrome’s solutions are designed to deliver performance with punch.

So if you’re looking to go beyond the ordinary, it’s time to partner with Nichrome, where packaging automation, IoT, and analytics come together to create intelligent, integrated, and inspiring packaging solutions.

Let’s reimagine what packaging can do. Let’s N-DOIT.

FAQs

Q1: What makes Nichrome's N-DOIT different from other packaging systems? A1: N-DOIT isn’t just about machines—it’s about real-time data, predictive analytics, and smart connectivity that empowers manufacturers to optimise efficiency and reduce downtime.

Q2: Can these smart systems be customised for specific industries like food or agrochemicals? A2: Absolutely. Our solutions are scalable and industry-specific, with smart sensors tailored for food-grade compliance, agrochemical precision, and everything in between.

Q3: How do smart machines improve packaging efficiency? A3: With real-time monitoring, predictive alerts, and automatic adjustments, smart machines significantly enhance speed, accuracy, and consistency, reducing waste and boosting quality.

Q4: What support does Nichrome offer for Indian packaging markets? A4: We provide cost-effective, scalable automation with IoT support, training, and maintenance services tailored for India’s dynamic industries.

Q5: Is cloud connectivity secure and reliable for my factory setup? A5: Our cloud platform is highly secure, ensuring encrypted data transfers, consistent uptime, and seamless integration with your existing infrastructure.

#Smart packaging#Nichrome Data Over Internet#food packaging automation#packaging machines#Data Over Internet (DOI)#packaging automation system#smart packaging solutions#IoT (Internet of Things).#Our integrated solutions#a pouch filling machine#N-DOIT (Nichrome Data Over Internet Technology)#food packaging lines#automatic packaging machines#Nichrome Packaging Solutions#innovative packaging solutions#cloud-connected packaging machines

0 notes

Text

IPaaS for Cloud-Based Integration: Transforming Data Integration across IT Systems

Connect your applications and accelerate your digital transformation and business development initiatives with Integration connectivity as service capabilities provided by the Smarter Integration Platform. Integration Connectivity as a Service (ICaaS) is a low-code, cloud-based digital integration solution. Our integration experts have created the Smarter Integration platform to harness this cutting-edge technology and give our clients the quickest, most reliable, and cost-effective route of Integration available. Smarter Integration represents the next generation of enterprise integration for the digital age.

Cloud-Based Integration

Cloud-based Integration, in particular, presents a whole host of opportunities for improving internal efficiencies and is the natural next step for public sector organizations looking to get on top of this mass of data. With the faster deployment of the integration layer, organizations can turn their attention to what matters – using data to empower employees, enable cross-departmental collaboration, and drive efficiency and cost savings. Regarding how private sector businesses manage and share their data, legacy tech, such as the on-premise data warehouse, is disappearing in favor of cloud technology.

Data Integration

Data integration combines multiple sources across an organization to provide a complete, accurate, and up-to-date dataset for BI, data analysis, and other applications and business processes. It includes data replication, ingestion, and transformation to combine different data types into standardized formats to be stored in a target repository such as a data warehouse, data lake, or data lake house.

Integrated IT systems

In an IT context, Integration refers to the result of a process that aims to combine different, often disparate, subsystems so that the data contained in each becomes part of a larger, more comprehensive system that, ideally, quickly and easily shares data when needed. Integrated IT systems refer to interconnected software, hardware, and network components that work together seamlessly to streamline operations, enhance data sharing, and improve efficiency across an organization.

IPaaS

iPaaS, which stands for "Integration Platform as a Service," is a cloud-based platform that allows your organization to build integrations between applications, processes, and data, whether in the cloud or on-premises. iPaaS can help businesses streamline processes, automate workflows, and share data.

0 notes

Text

How to Use n8n and AI to Build an Automation System

Automation is changing how we work every day. It helps save time, reduce mistakes, and get more done with less effort. If you want to automate your tasks but don’t know where to start, this guide is for you. In this post, you will learn how to use n8n — a free, open-source automation tool — combined with AI to build smart workflows that do work for you. What Is n8n? n8n (pronounced…

#AI automation#AI integration#AI workflow#AI-powered workflows#API integration#artificial intelligence tools#automate emails#automate tasks#automation platform#automation software#automation system#automation tips#business automation#chatbot automation#data processing automation#email automation#intelligent automation#low-code automation#n8n automation#no-code automation#open source automation#productivity tools#smart automation#time-saving tools#workflow automation#workflow builder

0 notes

Text

Streamline Your Operations with Salesforce Inventory Management Solutions

Looking to gain better control over your stock and supply chain? Our customized Salesforce inventory management solutions help businesses efficiently track, manage, and optimize inventory—all within the Salesforce platform. Whether you're a retailer, wholesaler, or manufacturer, our team can design a tailored solution that fits your operational needs. With features like real-time stock tracking, automated reorder alerts, warehouse integration, and detailed reporting, you can make smarter decisions and reduce manual errors. Our certified Salesforce experts ensure seamless integration with your existing CRM, sales, and service processes to provide a unified view of your inventory lifecycle. From initial setup to ongoing support, we offer end-to-end services that grow with your business. Contact us today for a free consultation and see how our Salesforce inventory management solutions can improve accuracy, efficiency, and profitability across your operations.

#salesforce system integration#salesforce inventory management#salesforce ticketing system#salesforce data integration platform

0 notes

Text

it weekend now so i cant continue fiddling around with it (and most likely i wont have much time for fancy projects next week) but i was so excited to install a usb sniffer on the windows computer and see what the traffic to the spectrometer looks like. and then the stupid driver issue happened!!

#tütensuppe#also slightly worrying that the singular person ive talked to about this project#(one of the spectrometer users. not fluent in control system or the more techy stuff)#seems very convinced that this is going to work. which i am very much not im just playing around at this point#i can retrieve usb identification info (like serial number connection speed device model etc)#but the attempts at functional communication a) returned numbers i cant parse b) im not even sure what i DID there#i replugged it this morning but ran what i thought was an initializing command before#and it started audibly moving something inside so i think i was accessing the slits/shutter instead#in the long run it WOULD be preferable to integrate it into the control system but my skills are questionable...#aside from the driver issue it would also help w the work bc you can make properties record the history#rn apparently they have to manually record what settings they use when and if someone forgets you can throw out the data.#plus: less clunky remote control and easy integration into their data acquisition tool#it would be SO COOL but its harder than expected weh weh

0 notes

Text

Distribution Transformer Monitoring

https://www.cmsgp.com/distribution-transformer-monitoring.php

Welcome to CMSGP, the most trusted and reputed distribution transformer monitoring manufacturer

At CMSGP, we are proud to be recognized as one of the most reliable names in Distribution Transformer Monitoring solutions. With over 20 years of proven expertise, we have become a key player in the industrial automation space. Known for our innovation and quality-driven approach, we are the preferred partner for top industries across India, delivering advanced monitoring technologies and exceptional service.

Distribution Transformer Monitoring System

Distribution Transformer Monitoring plays a critical role in enhancing grid efficiency and ensuring the long-term performance of transformers. These systems offer real-time insights into crucial metrics such as load conditions, temperature, oil levels, and overall power quality. By integrating IoT sensors with advanced data analytics, these monitoring solutions allow utilities to detect potential faults early, extend asset life, and reduce unexpected downtime. The result is a smarter, more efficient power distribution network with lower maintenance costs and increased reliability.

Our Product Portfolio

CMSGP provides an extensive array of industrial communication and monitoring solutions tailored for the energy and automation sectors. Our offerings include meter interface modems, data concentrator units, industrial 4G routers, RTUs, edge gateways, and integrated gateways. Every product is rigorously tested to meet stringent performance and safety standards. We also offer custom engineering to ensure our devices align precisely with your operational and infrastructure needs.

Delivering Quality Products

Quality is at the heart of everything we do. As a trusted provider of Distribution Transformer Monitoring systems, CMSGP is committed to excellence at every phase from design to deployment. Our manufacturing processes follow strict quality control protocols to ensure that each product delivers long-term durability and optimal performance. This dedication to superior product quality helps us eliminate inefficiencies and consistently exceed client expectations.

Constant Innovation

Innovation fuels our progress. Our commitment to continuous improvement enables us to develop Distribution Transformer Monitoring systems that set new benchmarks for reliability and performance. By minimizing downtime and enhancing the resilience of grid infrastructure, our solutions empower businesses to stay ahead in a competitive energy market. We constantly invest in R&D to provide smarter, more adaptive systems that elevate operational excellence.

State-of-the-Art Production and Scalable Operations

We utilize the latest manufacturing technologies to deliver scalable and precise Distribution Transformer Monitoring systems. Our production capabilities are built to handle both small-scale custom projects and large infrastructure deployments with ease. By blending automation with accuracy, we ensure product reliability and high throughput. Our scalable operations support esteemed clients like Honeywell, JSW, L&T, BHEL, ABB, KPTCL, and Crompton Greaves.

Bespoke Monitoring and Automation Solutions

Leveraging years of domain experience, CMSGP designs customized Distribution Transformer Monitoring and automation systems tailored to client-specific goals. Our solutions integrate IoT sensors, real-time analytics, and remote-control functions to provide end-to-end grid visibility and control. Whether it’s fault detection, power quality analysis, or remote asset management, we deliver adaptable systems that enhance operational performance while maintaining compliance with industry standards.

Strong Supply Network

Our reliable supply chain infrastructure ensures seamless product delivery and implementation. We maintain strong relationships with our suppliers and partners to source premium components that meet the requirements of advanced Distribution Transformer Monitoring applications. With streamlined logistics and efficient inventory control, we’re able to deliver solutions quickly, reduce lead times, and keep projects on track year-round.

Our Commitment

CMSGP’s leadership in Distribution Transformer Monitoring is driven by our customer-centric philosophy. We believe in building lasting relationships through transparency, innovation, and excellence. Our goal is to create collaborative, sustainable solutions that drive value for all stakeholders and support the long-term growth of the power sector.

Applications

Remote telemetry systems

Security and surveillance integration

CNC machinery monitoring

Smart lighting management

Support for legacy serial interface printers

Address: No. 300-B, 5th Main, 4th Phase, Peenya Industrial Area, Bangalore, Karnataka 560058.

Call: +91-98450-49177 or Email: [email protected]

#Industrial IoT Gateway Devices#IoT Platform Providers in India#Meter Data Acquisition System#Integration of IoT with Cloud computing

0 notes