#flexible electronics

Explore tagged Tumblr posts

Text

Soft, stretchy 'jelly batteries' inspired by electric eels

Researchers have developed soft, stretchable 'jelly batteries' that could be used for wearable devices or soft robotics, or even implanted in the brain to deliver drugs or treat conditions such as epilepsy. The researchers, from the University of Cambridge, took their inspiration from electric eels, which stun their prey with modified muscle cells called electrocytes. Like electrocytes, the jelly-like materials developed by the Cambridge researchers have a layered structure, like sticky Lego, that makes them capable of delivering an electric current. The self-healing jelly batteries can stretch to over ten times their original length without affecting their conductivity—the first time that such stretchability and conductivity has been combined in a single material. The results are reported in the journal Science Advances.

Read more.

#Materials Science#Science#Batteries#Flexible electronics#Electronics#Self healing#Hydrogels#Polymers#University of Cambridge

125 notes

·

View notes

Text

Competitive Landscape in the Transparent Polyimide Films Industry

The transparent polyimide films industry has seen remarkable growth in recent years, driven by the rising adoption of flexible electronics, aerospace advancements, and innovations in optoelectronics. Transparent polyimide films, known for their superior thermal stability, flexibility, and optical clarity, play a critical role in applications such as foldable displays, solar cells, and high-temperature-resistant coatings. As demand for these films rises, companies are intensifying efforts in innovation, collaboration, and market expansion to stay ahead in the competitive landscape.

Key Players and Innovations Shaping the Market

Several major companies are at the forefront of the transparent polyimide films market, prioritizing R&D to create high-performance products that cater to the evolving needs of industries.

DuPont:DuPont is a recognized leader in the transparent polyimide films market, offering products tailored for cutting-edge applications. The company has introduced advanced transparent polyimide films with superior optical properties, making them ideal for foldable smartphones and flexible printed circuit boards. DuPont’s initiatives toward sustainable manufacturing practices further enhance its leadership position in the industry.

Kaneka Corporation:Kaneka has carved a niche with its high-temperature-resistant polyimide films. By expanding its product range to include ultra-thin, transparent films, the company meets the growing demand for flexible displays in the electronics sector. Kaneka’s focus on improving mechanical durability and flexibility has made it a go-to supplier for manufacturers developing foldable displays.

Kolon Industries:Kolon Industries stands out for its transparent polyimide films designed for flexible displays and solar cell applications. With proprietary manufacturing processes that deliver high clarity and strength, the company meets the stringent demands of the electronics and energy sectors. Collaborations with leading technology firms have further bolstered Kolon’s position in this competitive industry.

SKC Inc.:SKC has emerged as a pioneer in producing lightweight and durable transparent polyimide films. The company’s advanced coating technologies enhance the resistance of its films to environmental stressors such as UV radiation and humidity, making them ideal for aerospace and optoelectronic applications.

FlexEnable:Specializing in flexible electronics, FlexEnable has developed transparent polyimide films for wearable devices and flexible displays. Its expertise in roll-to-roll manufacturing has allowed for scalable production of cost-effective films that cater to diverse industries

Strategies Driving Market Leadership

To thrive in this highly competitive market, companies are leveraging multiple strategies such as collaborations, sustainability initiatives, and geographical expansion.

Collaborating with Consumer Electronics Companies

The surge in demand for foldable and flexible devices has led to partnerships between polyimide film manufacturers and major tech brands such as Samsung, LG, and Huawei. These collaborations provide material suppliers with stable, long-term revenue streams while enabling tech companies to push boundaries in product design.

Commitment to Sustainability

With growing environmental awareness, leading players like DuPont and Kolon Industries have adopted sustainable production practices. For example, introducing recyclable materials and eco-friendly manufacturing processes reduces waste and lowers carbon emissions, aligning their goals with global environmental standards.

Expanding Presence in Emerging Markets

Asia-Pacific has emerged as a hotbed of growth for the transparent polyimide films market, largely due to its booming electronics and renewable energy sectors. Recognizing this, companies are bolstering their operations in countries like China, South Korea, and India by setting up manufacturing units and enhancing supply chain capabilities.

Advances in Manufacturing Technologies

Continuous innovations in manufacturing processes, including roll-to-roll deposition and plasma-enhanced chemical vapor deposition (PECVD), enable the production of thinner, more durable, and optically superior films. These advancements cater to high-tech industries such as aerospace, automotive, and healthcare, opening new growth opportunities.

Tailored Solutions for Specialized Applications

Industries such as aerospace and optoelectronics demand materials with highly specialized properties. Companies are addressing this need by offering custom-made transparent polyimide films designed to withstand extreme conditions, such as high temperatures and radiation, further expanding their market reach.

Download the detailed PDF brochure to explore further insights.

The transparent polyimide films market is on track for robust growth as the demand for flexible displays, wearable devices, and solar technologies continues to rise. Innovations in material science and manufacturing are expected to propel the market forward, enabling the integration of these films into next-generation applications such as augmented reality (AR) and virtual reality (VR) devices.

As the competition heats up, success in the industry will depend on a company’s ability to balance innovation with sustainability while forming strategic alliances. The market’s dynamic nature and potential to transform high-tech industries make it one to watch in the years ahead.

#transparent polyimide films#flexible electronics#foldable displays#solar cells#optoelectronics#aerospace advancements

0 notes

Text

How Printable Electronic Inks Are Shaping the Future of Flexible Electronics

Discover how printable electronic inks are transforming flexible electronics. From wearable technology to smart packaging, explore their benefits, applications, and future trends. Take your innovations to the next level with A-Gas Electronic Materials. Visit our website today to learn more.

#printable electronic inks UK#flexible electronics#electronic circuits#inkjet printing#screen printing#lightweight electronics UK#automotive electronics UK#advanced printable inks UK#UK electronic materials#A-Gas Electronic Materials#electronics innovation UK#eco-friendly electronics UK

0 notes

Text

0 notes

Text

Flexible Electronics Market To Witness A Pronounce Growth During 2024 To 2030

Introduction Acumen Research and Consulting is proud to announce the release of its latest market research report titled “Flexible Electronics Market Size and Forecast Till 2030.” This report provides an exhaustive analysis of the flexible electronics market, focusing on key trends, growth drivers, challenges, and future projections. As industries increasingly shift towards lightweight and…

0 notes

Text

New substrate material for flexible electronics could help combat e-waste

New Post has been published on https://thedigitalinsider.com/new-substrate-material-for-flexible-electronics-could-help-combat-e-waste/

New substrate material for flexible electronics could help combat e-waste

Electronic waste, or e-waste, is a rapidly growing global problem, and it’s expected to worsen with the production of new kinds of flexible electronics for robotics, wearable devices, health monitors, and other new applications, including single-use devices.

A new kind of flexible substrate material developed at MIT, the University of Utah, and Meta has the potential to enable not only the recycling of materials and components at the end of a device’s useful life, but also the scalable manufacture of more complex multilayered circuits than existing substrates provide.

The development of this new material is described this week in the journal RSC: Applied Polymers, in a paper by MIT Professor Thomas J. Wallin, University of Utah Professor Chen Wang, and seven others.

“We recognize that electronic waste is an ongoing global crisis that’s only going to get worse as we continue to build more devices for the internet of things, and as the rest of the world develops,” says Wallin, an assistant professor in MIT’s Department of Materials Science and Engineering. To date, much academic research on this front has aimed at developing alternatives to conventional substrates for flexible electronics, which primarily use a polymer called Kapton, a trade name for polyimide.

Most such research has focused on entirely different polymer materials, but “that really ignores the commercial side of it, as to why people chose the materials they did to begin with,” Wallin says. Kapton has many advantages, including excellent thermal and insulating properties and ready availability of source materials.

The polyimide business is projected to be a $4 billion global market by 2030. “It’s everywhere, in every electronic device basically,” including parts such as the flexible cables that interconnect different components inside your cellphone or laptop, Wang explains. It’s also widely used in aerospace applications because of its high heat tolerance. “It’s a classic material, but it has not been updated for three or four decades,” he says.

However, it’s also virtually impossible to melt or dissolve Kapton, so it can’t be reprocessed. The same properties also make it harder to manufacture the circuits into advanced architectures, such as multilayered electronics. The traditional way of making Kapton involves heating the material to anywhere from 200 to 300 degrees Celsius. “It’s a rather slow process. It takes hours,” Wang says.

The alternative material that the team developed, which is itself a form of polyimide and therefore should be easily compatible with existing manufacturing infrastructure, is a light-cured polymer similar to those now used by dentists to create tough, durable fillings that cure in a few seconds with ultraviolet light. Not only is this method of hardening the material comparatively fast, it can operate at room temperature.

The new material could serve as the substrate for multilayered circuits, which provides a way of greatly increasing the number of components that can be packed into a small form factor. Previously, since the Kapton substrate doesn’t melt easily, the layers had to be glued together, which adds steps and costs to the process. The fact that the new material can be processed at low-temperature while also hardening very quickly on demand could open up possibilities for new multilayer devices, Wang says.

As for recyclability, the team introduced subunits into the polymer backbone that can be rapidly dissolved away by an alcohol and catalyst solution. Then, precious metals used in the circuits, as well as entire microchips, can be recovered from the solution and reused for new devices.

“We designed the polymer with ester groups in the backbone,” unlike traditional Kapton, Wang explains. These ester groups can be easily broken apart by a fairly mild solution that removes the substrate while leaving the rest of the device unharmed. Wang notes that the University of Utah team has co-founded a company to commercialize the technology.

“We break the polymer back into its original small molecules. Then we can collect the expensive electronic components and reuse them,” Wallin adds. “We all know about the supply chain shortage with chips and some materials. The rare earth minerals that are in those components are highly valuable. And so we think that there’s a huge economic incentive now, as well as an environmental one, to make these processes for the recapture of these components.”

The research team included Caleb Reese and Grant Musgrave at the University of Utah, and Jenn Wong, Wenyang Pan, John Uehlin, Mason Zadan and Omar Awartani at Meta’s Reality Labs in Redmond, Washington. The work was supported by a startup fund at the Price College of Engineering at the University of Utah.

#aerospace#alcohol#applications#billion#Business#cables#catalyst#chips#college#development#devices#DMSE#e-waste#earth#economic#electronic#electronic waste#Electronics#engineering#Environmental#factor#flexible electronics#form#Global#Health#Heat#heating#Infrastructure#Internet#Internet of Things

0 notes

Text

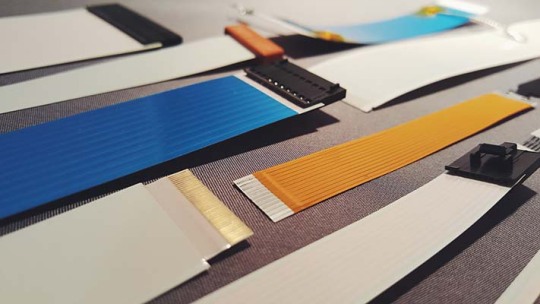

#Semiconductors#Flat Flex Cable#Flexible Electronics#Electrical Connectors#Electronics Manufacturing#High Density Interconnects#Flat Flex Cable Market

0 notes

Text

ೃ༄ੈ✩‧₊˚

#electronics#circuit#circuit board#flexible circuit board#ccd sensor#ccd cable#canon a85#cyber#cybercore#cyberpunk#orange#flickr#oldweb#old web#2008

183 notes

·

View notes

Text

PCB layout--MakerPCB

PCB or PCB assembly quickly offer, feel free email to [email protected]

https://www.linkedin.com/in/marcia-liu-0566a11b1/

#electronic#uav#pcb assembly#pcb#pcb manufacturer#flexible pcb board#flex pcb#electrical design#engineering#electrical#electricity

3 notes

·

View notes

Text

Flux AI is an advanced AI platform that automates and optimize the process of circuit design. LEAR MORE IN THIS ARTICLE.....

#fluxai#flexible circuit board#electronic#ai#gadgets#automation#artificial intelligence#hardware#techinnovation

2 notes

·

View notes

Text

Harnessing nature's fractals for flexible electronics: Biomimetic fabrication technique uses leaf skeletons as templates

By using leaf skeletons as templates, researchers harnessed nature's intrinsic hierarchical fractal structures to improve the performance of flexible electronic devices. Wearable sensors and electronic skins are examples of flexible electronics. A research team at the University of Turku, Finland, has developed an innovative approach to replicating bioinspired microstructures found in plant leaf skeletons, eliminating the need for conventional cleanroom technologies. The work is published in the journal npj Flexible Electronics. Fractal patterns are self-replicating structures in which the same shape repeats at increasingly smaller scales. They can be created mathematically and also occur in nature. For example, tree branches, leaf veins, vascular networks, and many floral patterns, such as cauliflower, follow a fractal structure.

Read more.

26 notes

·

View notes

Text

okay i decided to order the refurbed laptop. my plan is to make sure it runs acceptably (i'm guessing it's probably a "user turned it on once or twice and disliked the screen" situation tbh), see if the touch display it has is any worse than my current display, and then decide if i want to replace the display myself or not lol

#nadia rambles#if it's worse than my current display i'll definitely replace it. if it's the same i will probably have to think about it...#i'd LIKE to upgrade to 100% srgb and those displays are only $200 ish instead of $500 but if it's acceptable enough... we'll see#2025 is my year of buying refurbished normally expensive electronics for a third the price lmao#w/ intent for some amount of longevity and flexibility instead of relying on cheaper less durable tech#coincidentally we also switched to almost entirely ceramic plates and bowls recently in an attempt to lessen our plastic use#partly for health reasons since obv that plastic is already made and being presumably tossed out but...

1 note

·

View note

Text

Advanced Packaging Solutions with UV-Curable Adhesive Photoresist

Discover how UV-curable adhesive photoresists revolutionise advanced packaging in the electronics industry. Benefit from high resolution, strong adhesion, fast curing times, and environmental advantages. Contact A-Gas Electronic Materials for expert advice and high-quality solutions to optimise your packaging processes.

#UV-curable adhesive photoresist#advanced packaging UK#semiconductor packaging UK#wafer-level packaging UK#flip chip bonding#TSV technology UK#flexible electronics#high-resolution photoresist UK#A-Gas Electronic Materials#electronic manufacturing UK

0 notes

Text

Dynamic Looms | Weaving Machine Manufactures in Gujarat, India

Dynamic Autolooms India Pvt. Ltd. was established in 1976 itself as a pioneer in the weaving industry, serving both domestic and international markets. The company specializes in advanced rapier looms and shuttle looms, catering to fabric manufacturers across diverse sectors such as apparel, technical textiles, and industrial textiles. Known for integrating decades of experience with cutting-edge technologies, Dynamic Autolooms delivers innovative, high-quality solutions for its customers, ensuring that quality outshines cost.

With over 1,50,000 weaving machines installed globally and a trusted clientele of more than 3,000 companies, Dynamic Autolooms has revolutionized fabric manufacturing with its modernized looms. From high-speed rapier looms to specialized technical fabric looms, the company’s engineering excellence has set industry benchmarks for innovation and reliability.

Products:

Dynamic Autolooms provides advanced textile machinery, including:

Rapier Looms: Precision looms with modern technologies, approved under the Government’s TUF subsidy scheme.

Shuttle Looms: High-speed looms for durable, quality fabric production.

Electronic Jacquards: Configurations from 640 to 5,376 hooks for intricate weaving.

Specialized Equipment:

Electronic Let-off and Take-up Systems

Truck-in Devices

Custom technical developments for specific fabrics.

Industries Served:

Dynamic Autolooms provides solutions across various textile sectors:

Apparel Textiles:

Sarees: Fine cotton and silk fabrics with intricate patterns.

Light Denim: Fashionable, high-speed woven denim.

Corduroy: High-density fabrics with superior texture.

Ethnic Wear: Precision-woven sherwanis, dupattas, and salwars.

Household Textiles:

Furnishing: Premium fabrics for curtains, shawls, and blankets.

Bed Sheets: Soft, durable materials for homes and businesses.

Technical Textiles:

Glass Fiber: Specialized looms for industrial applications.

Filtration Materials: High-performance fabrics for filtration.

Packaging: HDPE and HTPP heavy-duty fabrics.

Certifications:

ISO 9001:2008 Certification: First Indian weaving machinery manufacturer to achieve this milestone.

Member of:

Ahmedabad Textile Industry’s Research Association (ATIRA)

Textile Machinery Manufacturers Association (TMMA)

Engineering Export Promotion Council (EEPC)

Indian Textile Accessories & Machinery Manufacturers Association (ITAMMA)

Ahmedabad Engineering Manufacturers Association (AEMA)

Gujarat Chamber of Commerce and Industry (GCCI)

Indian Technical Textile Association (ITTA)

Micro, Small & Medium Enterprises (MSME)

National Small Industries Corporation (NSIC)

Infrastructure: Dynamic Autolooms operates a 1,50,000 sq. ft. facility on a 2,60,000 sq. ft. plot in Ahmedabad, Gujarat, featuring cutting-edge technologies for precision manufacturing. Key features include induction furnaces for casting, CNC and VMC machines for machining, and Mitsubishi EX laser cutting for accuracy. The in-house foundry, active since 1984, supports internal and external casting needs. Advanced design software like Solid Edge ST4 aids the R&D team in driving innovation and maintaining industrial standards.

Quality Assurance: Dynamic Autolooms ensures quality at every stage of production with stringent ISO-compliant processes. From material sourcing to final assembly, the company uses advanced manufacturing technologies, backed by dedicated quality control and R&D teams, to deliver durable and reliable products.

Customer-Centric Approach: Dynamic Autolooms places the customer at the core of its operations. The company is dedicated to understanding and fulfilling customer needs, offering tailored solutions and robust after-sales support. Ensuring clarity in all customer interactions, Providing high-quality products backed by dependable services, Fostering long-term relationships by exceeding customer expectations.

Technological Innovations: Dynamic Autolooms thrives on innovation, with a focus on continuous research and development. With Velvet Looms, Electric Jacquards and Infinity-I Sample Loom.

As a leading weaving machinery manufacturer in India, Dynamic Autolooms continues to provide the best weaving solutions for fabric manufacturers, setting industry benchmarks in quality and innovation.

#Dynamic Looms#Dynamic Production in Gujarat#Electronic Jacquard#Rapier Loom#Shuttle Loom#Power Loom#Jacquard Rapier Loom#Looms for Technical Textiles#Wire Weaving looms#Shuttleless Rapier Loom#Rapier Weaving Machine#Electronic Let-off Mechanism#Flexible Rapier Loom#Trendy Rapier Weaving Machine#High Speed Shuttle Loom#Heavy Duty Flexible Rapier Loom#Semi Automatic Drop Box Shuttle Looms#Largest Rapier Loom Manufacturer#Electronic Jacquard in Gujarat#Looms Factory#Automatic Shuttle Loom#Automatic Shuttle Loom Suppliers#Rapier Loom Manufacturer#Power Loom Machine Manufacturers in India#Looms Company#Loom India#Automatic Shuttle Loom in India#Rapier Loom Manufacturers in India#Textile Weaving Machine Manufacturer in India#Best Weaving Solutions

1 note

·

View note

Text

Important Ohm’s Law Problems for Competitive Exams

A circuit has a resistance of 10 Ω and a current of 2 A. What is the voltage across the circuit?

V= I × R = 2A × 10Ω = 20V

A 24V battery is connected to a resistor of 6 Ω. Find the current flowing through the circuit.

youtube

GET MORE FREE SOLUTION 👈.

#digital learning#online education#online courses#online tutoring#online learning#hesi a2 test#hesi a2 test prep#hesi online classes#electronics manufacturing#electronics industry#electronics components#electronics store#electronics design#vlsi design#electronics#materials#connectivity#computing#ohm's law#flexible circuit board#flex circuit pcb#circuit breaker#electric switch#Youtube

0 notes

Text

450 Million-Year-Old Organism Finds New Life in Softbotics - Technology Org

New Post has been published on https://thedigitalinsider.com/450-million-year-old-organism-finds-new-life-in-softbotics-technology-org/

450 Million-Year-Old Organism Finds New Life in Softbotics - Technology Org

In collaboration with palaeontologists from Spain and Poland, researchers at Carnegie Mellon University used fossil evidence to engineer a soft robotic replica of a pleurocystitid. This marine organism existed nearly 450 million years ago and is believed to be one of the first echinoderms capable of movement using a muscular stem.

Pleurocystitid fossil and pleurocystitid robot replica. Image Credit: Carnegie Mellon University

Published in Proceedings of the National Academy of Sciences, the U.S. National Science Foundation-supported research seeks to broaden modern perspective of animal design and movement by introducing a new a field of study — paleobionics — aimed at using Softbotics, robotics with flexible electronics and soft materials, to understand the biomechanical factors that drove evolution using extinct organisms.

“Softbotics is another approach to inform science using soft materials to construct flexible robot limbs and appendages,” said Carmel Majidi, the lead author of the study. “Many fundamental principles of biology and nature can only fully be explained if we look back at the evolutionary timeline of how animals evolved. We are building robot analogues to study how locomotion has changed.”

[embedded content]

With humans’ time on earth representing only 0.007% of the planet’s history, the modern-day animal kingdom that influences understanding of evolution and inspires today’s mechanical systems is only a fraction of all creatures that have ever existed.

Image credit: CMU

Using fossil evidence to guide their design and a combination of 3D-printed elements and polymers to mimic the flexible columnar structure of the moving appendage, the team demonstrated that pleurocystitids were likely able to move over the sea bottom using a muscular stem to push themselves forward.

Despite the absence of a current day equivalent, — echinoderms have since evolved to include modern day starfish and sea urchins — pleurocystitids have been of interest to paleontologists due to their pivotal role in echinoderm evolution.

Image credit: CMU

The researchers determined that wide sweeping movements were likely the most effective motion and that increasing the length of the stem significantly increased the animals’ speed without forcing it to exert more energy.

Now that the researchers have demonstrated that they can use Softbotics to engineer extinct organisms, they hope to explore other animals, like the first organism that could travel from sea to land — something that can’t be studied in the same way using conventional robot hardware.

“Bringing a new life to something that existed nearly 500 million years ago is exciting in and of itself,” said mechanical engineer and study co-author Phil LeDuc. “But we aren’t just looking at fossils in the ground, we are trying to better understand life through working with paleontologists.”

Source: NSF

#3d#Animals#approach#Biology#Building#Carnegie Mellon University#Chemistry & materials science news#Collaboration#Design#earth#Electronics#energy#Engineer#Evolution#Explained#Featured video#flexible electronics#fossil#Fossils#Foundation#Fraction#Fundamental#Hardware#History#how#humans#Ideas#it#life#limbs

0 notes