#Integrating IoT

Explore tagged Tumblr posts

Text

IoT development solutions for hospitals in South Africa Revolutionize healthcare in South Africa with Mobiloitte's IoT Development Solutions tailored for hospitals. Our cutting-edge technology enhances patient care, streamlines operations, and improves resource management. Monitor equipment, ensure patient safety, and reduce costs with our user-friendly solutions. Embrace innovation and deliver world-class healthcare. Partner with Mobiloitte, your trusted South African IoT development experts.

#IoT Development Solutions#Integrating IoT#IoT Services#IoT & Emerging Technologies#IoT Solutions for Smart Applications#IoT Division#Product Development Channel#IoT Automation Solutions#IoT systems#IoT Solutions for Education#iot in gaming#iot in biotechnology#iot solutions for hotels#iot in hospitality industry#smart home iot solutions#iot solutions for transportation#blockchain iot app development company#blockchain iot software development company#IoT application development services

0 notes

Text

Azure IoT Central: Revolutionizing IoT Solutions for Manufacturing Industries

Azure IoT Central is a cutting-edge platform built on the foundation of Azure IoT, offering a model-based approach to empower businesses in constructing enterprise-grade IoT solutions. Designed with the aim of eliminating the need for cloud-solution development expertise, Azure IoT Central provides a comprehensive software as a service (SaaS) solution. With its built-in templates for various industries, device provisioning services, and feature-rich dashboards, it enables seamless monitoring of device health, connectivity, management, and communication.

Streamlining Manufacturing Operations with Azure IoT Central

In the realm of manufacturing, Azure IoT Central proves to be a game-changer by facilitating the seamless connection, management, and monitoring of industrial assets. By leveraging Azure IoT Central, manufacturing industries can effortlessly integrate data into their applications, enabling them to make data-driven decisions and unlock operational efficiencies. With its user-friendly interface and powerful capabilities, Azure IoT Central empowers manufacturers to gain valuable insights from their assets and drive productivity.

Key Features and Benefits

Template-based Solution: Azure IoT Central offers pre-built templates tailored for various industries, enabling businesses to quickly deploy IoT solutions without extensive customization. These templates encompass a wide range of applications, including asset tracking, predictive maintenance, and remote monitoring, among others.

Device Provisioning Services: Simplifying the process of onboarding devices, Azure IoT Central provides robust device provisioning services. This feature streamlines the connection and configuration of devices, ensuring seamless integration into the IoT ecosystem.

Comprehensive Dashboard: Azure IoT Central's intuitive dashboard empowers businesses to monitor and manage their IoT devices effectively. From tracking device health and connectivity to managing firmware updates and troubleshooting, the dashboard provides real-time insights and facilitates proactive maintenance.

Secure and Scalable: Built on the trusted Azure IoT platform, Azure IoT Central ensures top-notch security for sensitive data and device communications. Moreover, it offers scalability to accommodate growing business needs, allowing seamless expansion without compromising performance.

Integration Capabilities: Azure IoT Central seamlessly integrates with other Azure services, such as Azure Machine Learning and Azure Stream Analytics, enabling advanced analytics, machine learning capabilities, and seamless data integration across the Azure ecosystem.

Unlocking the Potential of IoT in Manufacturing

By harnessing the power of Azure IoT Central, manufacturing industries can revolutionize their operations and tap into the full potential of IoT. Here's how Azure IoT Central can benefit manufacturing businesses:

Enhanced Operational Efficiency: Real-time monitoring and analysis of industrial assets enable proactive maintenance, minimizing downtime and optimizing operations. Predictive maintenance and condition monitoring enable businesses to identify and address potential issues before they escalate.

Improved Product Quality: IoT-enabled sensors and devices collect data throughout the production process, ensuring quality control and adherence to standards. Businesses can gain valuable insights into product performance, identify defects, and take corrective measures promptly.

Cost Optimization: By leveraging Azure IoT Central, manufacturers can optimize resource allocation, reduce energy consumption, and streamline maintenance processes. Data-driven insights enable businesses to make informed decisions, resulting in cost savings and improved profitability.

Enhanced Safety and Compliance: IoT devices and sensors can monitor environmental conditions, ensuring a safe working environment for employees. Moreover, businesses can leverage IoT data to comply with industry regulations and maintain quality standards.

Get Started with Azure IoT Central Today

Take the first step toward transforming your manufacturing operations with Azure IoT Central. Leverage its advanced features, comprehensive templates, and user-friendly interface to build robust IoT solutions that propel your business forward. Embrace the power of data, streamline your operations, and unlock unparalleled insights with Azure IoT Central.

#Azure IoT Central#IoT solutions#Azure IoT solutions#Azure IoT cloud services#Azure IoT application development#Azure IoT cloud integration#Azure IoT analytics

2 notes

·

View notes

Text

How Custom AI-IoT Solutions Unlock Intelligent Automation and Real-Time Decisions

Custom AI and IoT solutions are revolutionizing industries by enabling real-time decision-making and intelligent automation. In this blog, Theta Technolabs explains how businesses can harness data-driven insights to boost efficiency, scalability, and innovation. Discover the impact of integrated AIoT systems across sectors like manufacturing, healthcare, logistics, and smart infrastructure.

#intelligent automation#IoT solutions#smart automation systems#IoT integration#IoT development company#AI in manufacturing#custom AI development#IoT in healthcare#AI-powered systems

0 notes

Text

Discover Real-World IoT Device Examples for Industrial Use

Want to see real IoT devices examples in action? At Aknitech, we implement IoT device monitoring, PLC integration, and access control IoT devices across various industries. Empower your systems with the next generation of automation solutions. Tags: iot devices examples, iot device monitoring, plc integration, access control iot devices, iot examples

0 notes

Text

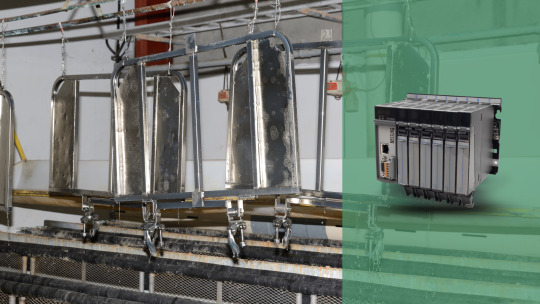

Smarter Surface Protection – PLC Automation in Autophoretic Coating Plants

In modern manufacturing, surface coating is not just cosmetic—it’s essential for durability, corrosion resistance, and performance. Autophoretic coating (also known as A-coating) has emerged as a water-based, eco-friendly alternative to electro-coating. When combined with PLC-based automation, it becomes a powerful, scalable solution for high-quality, uniform metal finishing.

Because let’s face it—metal without proper protection is like a knight without armour. In today’s industrial world, that armour comes in the form of surface coating. And when it comes to smart, sustainable, and scalable coating, autophoretic coating is the unsung hero.

But wait, here’s where it gets exciting. Pair this eco-warrior coating with PLC automation, and what you get is nothing short of magic. At Messung Industrial Automation, we believe that the perfect coat is not just about shine—it's about smarts, speed, and sustainability.Let’s dive into the world where chemistry meets code, and surface protection meets the future.

What is Autophoretic Coating?

Autophoretic coating, also known as A-coating, is a process where metal parts are dipped in a reactive water-based solution. The result? A self-depositing layer forms on the surface, without any electric current. Unlike traditional methods that zap the surface with electricity, A-coating lets chemistry take the wheel.

Why Are Industries Making the Switch?

Industries are coating their bets on it because it avoids the need for heavy electric setups and provides uniform coverage even in complex geometries. Since it is water-based, it is also very environmentally friendly.

Where Is It Being Used?

From under-the-hood car parts to refrigerator frames, autophoretic coating is making waves in:

Automotive parts

Appliance components

Agricultural and construction machinery

General industrial structures

In an age where efficiency, sustainability, and performance go hand in hand, autophoretic coating emerges as a transformative solution. Its simplicity belies its power, ushering in a cleaner, smarter way to protect surfaces without compromising on quality or cost. As industries across the board continue to embrace greener practices, A-coating, powered by automation and intelligence, is painting the future—one seamless coat at a time.

Role of PLC in the Coating Plant

In the realm of autophoretic coating, precision isn't a luxury—it's a necessity, and that precision begins with the silent genius of automation: the Programmable Logic Controller (PLC). Think of the PLC as the central nervous system of your coating plant—connecting, communicating, and commanding every mechanical muscle with machines. Here is how PLCs turn a basic coating line into a harmonious dance of efficiency and intelligence.

Precision Process Automation

A modern autophoretic coating plant runs smoothly like a well-coordinated team, and the PLC (Programmable Logic Controller) is in charge. It doesn’t just control the machines—it helps everything work perfectly together. From:

Tank temperature

Solution pressure & pH levels

Cycle timing for each dip and rise

...every step is monitored and controlled by PLC automation.

Material Handling Magic

Using intelligent material handling controllers, our PLC guides parts through multiple stages:

Degreasing

Surface conditioning

Coating dip

Rinsing & curing

Like a choreographer directing a ballet of metal.

Circulation & Filtration Mastery

Good coating = Consistent flow. Our process controllers and PLC control systems manage:

Fluid circulation

Filtration cycles

Solution replacement timing

Synchronisation with Process Controllers

Through seamless synchronisation with motion control systems, everything moves with precision. No drips, no downtime.

In an industry where milliseconds matter and uniformity is sacred, PLC automation elevates the autophoretic coating plant from functional to phenomenal. It enables not just control, but clarity—ensuring that every part, every dip, and every process flows with intelligent intent.

NX-ERA JET PLC System Architecture

Our flagship—NX-ERA JET PLC—is a robust, real-time, and rugged automation genius. It’s compact, reliable, and battle-tested in industrial heat.

Talk the Talk: MODBUS & TCP/IP

Built-in PLC communication protocols like:

MODBUS TCP/IP

MODBUS RTU

Make it plug-and-play with SCADA and automation systems. Yes, it speaks fluent-machine.

Ethernet-Based Controllers for High-Speed Sync

Using Ethernet-based controllers, data flows like molten metal. Zero lag, maximum productivity.

HMI with PLC Controllers

With user-friendly HMIs with PLC controllers, even a non-techie can operate complex coating sequences. Tap, drag, drop—and coat!

From seamless communication to intuitive control, the NX-ERA JET PLC is more than just a controller—it's the central nervous system of your autophoretic coating plant. With its advanced architecture, lightning-fast data sync, and plug-and-play compatibility, it transforms complexity into clarity. Whether you're scaling up or starting smart, this system offers the flexibility, durability, and intelligence your operations demand.In a world where precision meets pressure, the NX-ERA JET PLC ensures your plant doesn’t just perform—it excels.

Advanced PLC Automation for Smart Manufacturing

In the age of Industry 4.0, surface coating is no longer just about chemistry—it's about intelligence, precision, and adaptability. That’s where advanced PLC automation steps in as the invisible powerhouse behind your plant’s performance. Whether you're scaling up operations or streamlining a compact facility, smart automation is the lever that elevates your process from ordinary to outstanding.

Let’s uncover how Messung’s cutting-edge PLC technology is revolutionising autophoretic coating plants with flexible, responsive, and future-ready control systems.

Modular, Compact & Ready to Go - Whether it’s a big plant or a small-scale setup, our Modular PLC, Compact PLC, and Smart PLC configurations give you tailor-made flexibility.

Motion Control with Millisecond Precision - Our motion control systems enable synchronised movement, avoiding delays or overlaps in the coating sequence.

Material Handling - Our embedded material handling controllers do the heavy lifting—literally—without breaking a sweat.

This isn't just automation. This is smart automation that thinks ahead, moves with purpose, and adapts to demand. With Messung’s PLC-powered intelligence, your coating plant doesn’t just run—it evolves.

Because in the world of advanced manufacturing, it’s not just about staying ahead—it's about setting the pace.

Smart. Sustainable. Secure: The Evolution of PLC Automation in Coating Plants

In the era of Industry 4.0, coating plants need more than just control—they need intelligence, integration, and intention. Here’s how Messung’s PLC automation is redefining autophoretic coating systems:

Built for Harsh Industrial Realities – Our Industrial PLCs endure dust, moisture, heat, and vibration. Conformal-coated PLCs protect against corrosive chemicals in A-coating zones and provide long-lasting performance in extreme environments.

Safety Meets Smarts - PLCs are integrated for emergency stops, controlled shutdowns, and real-time fault alerts with logs, making them smart, secure, and always in control.

Welcome to Industry 4.0-Based Controllers

PLC with IoT for remote monitoring and real-time plant access.

MQTT-based PLCs for cloud-friendly, lightweight data communication.

Full PLC system integration with BMS, SCADA & more—ensuring a harmonious automation ecosystem.

Green Gains: Eco-Friendly A-Coating Automation

Water-based chemistry reduces VOCs and emissions.

Smart PLCs optimize dosing & disposal—minimising waste, maximising results.

Cleaner air, cleaner conscience, smarter coatings.

With Messung’s intelligent PLC, you don’t just automate—you evolve. Sustainable, scalable, and secure—this is the new face of PLC-based automation solutions in A-coating.

Business Benefits of PLC-Based Automation Solutions

In today’s hyper-competitive manufacturing world, success isn’t just about innovation—it’s about consistency, efficiency, and scalability. This is where PLC-based automation doesn’t just support your coating process—it transforms it. Let’s explore how Messung’s smart automation systems turn operational goals into tangible business advantages.

Uniformity Every Time - When every product must meet the same high standard, there’s no room for guesswork. Thanks to PLC control systems, your coating process is even, repeatable, and of high quality.

Never any Downtime - Time is money, and downtime is a thief. With real-time monitoring and intelligent automation controllers, potential issues are detected and resolved before they affect production. Fewer breakdowns. More uptime. Happier bottom line.

Easy to Maintain & Scale - Growth shouldn’t be a gamble. With built-in PLC maintenance alerts, you get proactive notifications that prevent surprises. Want to expand operations? Simply plug and play with modular I/O modules. You’re ready for tomorrow—today.

In essence, PLC automation is not just a control system—it’s a business strategy. It safeguards quality, boosts efficiency, and equips your coating plant with the agility to evolve. Because when your process is smart, your performance is unstoppable.

Conclusion: The Final Coat

A surface is only as strong as the system behind it. In the era of smart manufacturing, Messung’s PLC automation solutions empower autophoretic coating plants with unmatched precision, efficiency, and sustainability. From real-time monitoring and advanced PLC control systems to seamless IoT integration and predictive maintenance, our technology ensures optimal surface protection with minimal waste. Whether it’s modular PLCs, industrial automation controllers, or motion control systems, Messung delivers the complete package. So why let inefficiencies corrode your bottom line? Upgrade your coat. Upgrade your process. Upgrade with Messung PLCs—where intelligent automation meets perfect protection.

FAQs

How does PLC contribute to energy efficiency in coating plants?

By optimizing process timings, reducing idle machine hours, and enabling intelligent power management, PLCs help cut down energy consumption and operational costs.

Can PLC automation reduce coating defects?

Absolutely. With real-time monitoring, precision control, and error alerts, PLC automation ensures consistent quality.

How easy is it to integrate Messung PLCs in existing lines?

Very! Our modular PLC systems and versatile PLC communication protocols like MODBUS and TCP/IP allow seamless integration.

Are conformal-coated PLCs necessary?

Yes, especially in chemically aggressive environments like coating plants. They extend the life and reliability of your Programmable Logic Controller.

What industries benefit most from PLC with IoT?

Automotive, general manufacturing, and any industry embracing Industry 4.0-based controllers and smart factory setups.

#Autophoretic coating#Messung Industrial Automation#PLC automation#Programmable Logic Controller (PLC)#material handling controllers#motion control systems#NX-ERA JET PLC#HMI with PLC Controllers#advanced PLC automation#Modular PLC#Compact PLC#Smart PLC#Industrial PLCs#Smart PLCs#PLC-based automation solutions#PLC control systems#PLC automation solutions#IoT integration#industrial automation controllers#Industry 4.0-based controllers

0 notes

Text

Boost Device Performance with Professional Firmware Testing at GQAT Tech

What is Firmware Testing & Why It’s Crucial for Smart Devices

In today's connected world, everything you use from your smartwatch to your smart TV runs on firmware; firmware is low-level software that operates hardware. So what happens when the firmware does not perform as it should? Devices crash, user experience drops, and businesses suffer—this is why firmware testing has become such a significant component of the quality assurance (QA) process.

At GQAT Tech, we perform firmware testing with intelligence using a combination of real hardware environments and automation to verify that every device operates exactly as intended. In this article, we will explore firmware testing, why it matters, and how GQAT Tech empowers you to deliver bug-free, top-performing smart products.

What is Firmware?

Firmware is a class of software that is permanently burned into a hardware item to complete the basic function and potentially further functions of that hardware item.

You’ll find firmware in:

Smartphones

IoT devices

Printers

Wearables

Routers

Smart home appliances

Firmware is unlike software in that it is not intended for frequent updates. Because of that, if there is a bug or unsafe code in the firmware, it may impact the firmware's intent or may compromise the entire device.

What is Firmware Testing?

Firmware testing is the validation and verification to check that the firmware behaves correctly when interacting with hardware and the other components in the system.

The key areas of testing firmware will include:

Functionality – Does the firmware do what it is intended to do?

Stability – Does it crash?

Performance – Is it efficient? Is it quick?

Security – Is it safe? Does it protect itself from unauthorized use or firmware-level attacks?

Testing firmware is more complicated than testing a software product due to the integration of hardware and software, so it's where GQAT Tech can provide its value here.

Why Firmware Testing is Important

Here’s why skipping firmware testing can lead to serious problems:

Device Failures – Bugs in firmware can crash your entire device.

Security Risks – Weak firmware can open doors to hackers.

Unstable Performance – Devices may freeze, restart, or act unexpectedly.

Poor User Experience – Customers won’t tolerate devices that don’t work properly.

Costly Product Recalls – Fixing bugs after launch can cost millions.

With firmware embedded in critical devices, testing before release is not optional—it’s necessary.

Why GQAT Tech?

Full-Service QA Team: Specialists in firmware and embedded testing.

Testing on Real Hardware: Hardware testing—not just simulators.

Custom Test Plans: Plans tailored to the specifics of your hardware, product goals, and release schedule.

Detailed Reporting: Bug reporting and test case coverage are clear and easy to understand.

Time-to-Market Speed: Find and fix firmware bugs earlier in the development cycle.

GQAT Tech will not only test your product, but it provide the assurance of reliability, scalability, and safety.

Conclusion

In a digital world, where the devices must "just work," firmware quality is critically important. Whether you're developing smart home, wearable, or industrial IoT devices, validating firmware will give you confidence that your product will deliver a zero-fail experience.

💬 Are you ready to approach firmware testing with confidence?

👉 Explore Firmware Testing Services at GQAT Tech

#Firmware Testing#Embedded Software Testing#Hardware Testing#IoT Device Testing#Quality Assurance#Low-Level Software Testing#Device-Level Testing#Embedded QA#Hardware Compatibility#Regression Testing#Automated Firmware Testing#GQAT Tech Testing Services#Tech QA#Software-Hardware Integration#Product Validation Testing

0 notes

Text

Exploring the Vision Behind the Book "Comprehensive Technology Solutions Offered by SolveForce and Partners"

In a world increasingly driven by digital infrastructure, the need for comprehensive, scalable, and future-ready telecommunications and technology solutions has never been more pressing. The newly released book Comprehensive Technology Solutions Offered by SolveForce and Partners arrives at a pivotal moment in that evolution. Authored by industry leaders Ron Legarski, Steve Sramek, and Bryan…

#AI-powered security#Cloud Services#DSL#fiber#Fixed Wireless#IoT#IoT Integration#Mobility#MPLS#SASE#SD-WAN#SIP Trunking#VPN

0 notes

Text

The AIoT Revolution: How AI and IoT Convergence is Rewriting the Rules of Industry & Life

Imagine a world where factory machines predict their own breakdowns before they happen. Where city streets dynamically adjust traffic flow in real-time, slashing commute times. Where your morning coffee brews automatically as your smartwatch detects you waking. This isn’t science fiction—it’s the explosive reality of Artificial Intelligence of Things (AIoT), the merger of AI algorithms and IoT ecosystems. At widedevsolution.com, we engineer these intelligent futures daily.

Why AIoT Isn’t Just Buzzword Bingo: The Core Convergence

Artificial Intelligence of Things fuses the sensory nervous system of IoT devices (sensors, actuators, smart gadgets) with the cognitive brainpower of machine learning models and deep neural networks. Unlike traditional IoT—which drowns in raw data—AIoT delivers actionable intelligence.

As Sundar Pichai, CEO of Google, asserts:

“We are moving from a mobile-first to an AI-first world. The ability to apply AI and machine learning to massive datasets from connected devices is unlocking unprecedented solutions.”

The AIoT Trinity: Trends Reshaping Reality

1. Predictive Maintenance: The Death of Downtime Gone are days of scheduled check-ups. AI-driven predictive maintenance analyzes sensor data intelligence—vibrations, temperature, sound patterns—to forecast failures weeks in advance.

Real-world impact: Siemens reduced turbine failures by 30% using AI anomaly detection on industrial IoT applications.

Financial upside: McKinsey estimates predictive maintenance cuts costs by 20% and downtime by 50%.

2. Smart Cities: Urban Landscapes with a Brain Smart city solutions leverage edge computing and real-time analytics to optimize resources. Barcelona’s AIoT-powered streetlights cut energy use by 30%. Singapore uses AI traffic prediction to reduce congestion by 15%.

Core Tech Stack:

Distributed sensor networks monitoring air/water quality

Computer vision systems for public safety

AI-powered energy grids balancing supply/demand

3. Hyper-Personalized Experiences: The End of One-Size-Fits-All Personalized user experiences now anticipate needs. Think:

Retail: Nike’s IoT-enabled stores suggest shoes based on past purchases and gait analysis.

Healthcare: Remote patient monitoring with wearable IoT detects arrhythmias before symptoms appear.

Sectoral Shockwaves: Where AIoT is Moving the Needle

🏥 Healthcare: From Treatment to Prevention Healthcare IoT enables continuous monitoring. AI-driven diagnostics analyze data from pacemakers, glucose monitors, and smart inhalers. Results?

45% fewer hospital readmissions (Mayo Clinic study)

Early detection of sepsis 6+ hours faster (Johns Hopkins AIoT model)

🌾 Agriculture: Precision Farming at Scale Precision agriculture uses soil moisture sensors, drone imagery, and ML yield prediction to boost output sustainably.

Case Study: John Deere’s AIoT tractors reduced water usage by 40% while increasing crop yields by 15% via real-time field analytics.

🏭 Manufacturing: The Zero-Waste Factory Manufacturing efficiency soars with AI-powered quality control and autonomous supply chains.

Data Point: Bosch’s AIoT factories achieve 99.9985% quality compliance and 25% faster production cycles through automated defect detection.

Navigating the Minefield: Challenges in Scaling AIoT

Even pioneers face hurdles:ChallengeSolutionData security in IoTEnd-to-end encryption + zero-trust architectureSystem interoperabilityAPI-first integration frameworksAI model driftContinuous MLOps monitoringEnergy constraintsTinyML algorithms for low-power devices

As Microsoft CEO Satya Nadella warns:

“Trust is the currency of the AIoT era. Without robust security and ethical governance, even the most brilliant systems will fail.”

How widedevsolution.com Engineers Tomorrow’s AIoT

At widedevsolution.com, we build scalable IoT systems that turn data deluge into profit. Our recent projects include:

A predictive maintenance platform for wind farms, cutting turbine repair costs by $2M/year.

An AI retail personalization engine boosting client sales conversions by 34%.

Smart city infrastructure reducing municipal energy waste by 28%.

We specialize in overcoming edge computing bottlenecks and designing cyber-physical systems with military-grade data security in IoT.

The Road Ahead: Your AIoT Action Plan

The AIoT market will hit $1.2T by 2030 (Statista). To lead, not follow:

Start small: Pilot sensor-driven process optimization in one workflow.

Prioritize security: Implement hardware-level encryption from day one.

Democratize data: Use low-code AI platforms to empower non-technical teams.

The Final Byte We stand at an inflection point. Artificial Intelligence of Things isn’t merely connecting devices—it’s weaving an intelligent fabric across our physical reality. From farms that whisper their needs to algorithms, to factories that self-heal, to cities that breathe efficiently, AIoT transforms data into wisdom.

The question isn’t if this revolution will impact your organization—it’s when. Companies leveraging AIoT integration today aren’t just future-proofing; they’re rewriting industry rulebooks. At widedevsolution.com, we turn convergence into competitive advantage. The machines are learning. The sensors are watching. The future is responding.

“The greatest achievement of AIoT won’t be smarter gadgets—it’ll be fundamentally reimagining how humanity solves its hardest problems.” — widedevsolution.com AI Lab

#artificial intelligence#predictive maintenance#smart city solutions#manufacturing efficiency#AI-powered quality control in manufacturing#edge computing for IoT security#scalable IoT systems for agriculture#AIoT integration#sensor data intelligence#ML yield prediction#cyber-physical#widedevsolution.com

0 notes

Text

Streamlining Business Operations with JDE Orchestrator

Introduction: Brief overview of JD Edwards EnterpriseOne and the role of JDE Orchestrator in modernizing business processes.

Key Features:

Automation of Repetitive Tasks: Discuss how JDE Orchestrator automates routine tasks, reducing manual intervention and errors.

Integration with IoT Devices: Explain the integration capabilities with Internet of Things (IoT) devices for real-time data collection.

API Connectivity: Highlight the ability to connect with third-party applications through APIs.

Benefits:

Enhanced Efficiency: Showcase how automation leads to faster decision-making and reduced operational costs.

Improved Accuracy: Emphasize the reduction in human errors and data inconsistencies.

Scalability: Discuss how businesses can scale operations seamlessly with JDE Orchestrator.

Real-World Applications:

Manufacturing: Example of automating production line processes.

Supply Chain Management: Streamlining inventory management and order processing.

Summarize the transformative impact of JDE Orchestrator on business operations.

Empower your JD Edwards system today by embracing the advanced automation capabilities of jde orchestrator.

#JD Edwards automation#business process orchestration#ERP integration#real-time data processing#IoT-enabled ERP#API-driven workflows.

0 notes

Text

Mobiloitte’ IoT Application Development Services in South Africa Empower homes across South Africa with the future of smart living through Mobiloitte's IoT application development services. Our experts utilize IoT technologies like MQTT, IoT protocols, and cloud integration to create intuitive, energy-efficient, and secure smart home solutions. Experience heightened comfort, convenience, and energy savings. Choose Mobiloitte for cutting-edge IoT applications that enhance lifestyles across the nation.

#IoT Development Solutions#Integrating IoT#IoT Services#IoT & Emerging Technologies#IoT Solutions for Smart Applications#IoT Division#Product Development Channel#IoT Automation Solutions#IoT systems#IoT Solutions for Education#iot in gaming#iot in biotechnology#iot solutions for hotels#iot in hospitality industry#smart home iot solutions#iot solutions for transportation#blockchain iot app development company#blockchain iot software development company#IoT application development services

0 notes

Text

How Dynamics 365 & IoT Optimize Field Service Operations

Learn how Dynamics 365 Field Service and IoT integration enhance proactive maintenance, reduce downtime, and automate work orders for seamless field operations.

0 notes

Text

Nichrome Data Over Internet: How Smart Packaging, IoT & Analytics Are Transforming Manufacturing

Packaging has never been more advanced. No more simple boxes and bottles. Smart packaging is where it's at today, and it's revolutionizing the packaging industry from inside out. At Nichrome, we are not just riding the wave of change—our path-breaking packaging automation solutions, backed by IoT, real-time data, and cloud-intelligent connectivity, are leading the charge.

Welcome to Nichrome Data Over Internet—or as we more commonly call it, N-DOIT. It's not a service, it's a packaging philosophy. A philosophy that puts data, analytics, and efficiency front and centre in every packaging machine that we design, install, and maintain.

From food packaging automation to agro automation, we're enabling Indian manufacturers to jumpstart their future. Through N-DOIT, we're enabling them to work smarter, faster, and more in control—all due to the powerful combination of cloud platforms, remote monitoring, and data-driven decision making.

Let us dive into how this change is shaping up.

What Is "Data Over Internet" in Packaging?

Just think how great it would be if your packaging machines talked. Better yet—what if they could listen, analyze, and predict? That is what Data Over Internet (DOI) makes a reality. At its essence, DOI is a real-time collection, transmission, and analysis of machine data across secure cloud platforms.

This isn't just fancy tech talk. It allows packagers to experience genuine real-time machine monitoring, instant insights, and greater visibility of their complete packaging automation system. From uptime, line downtime, energy usage, or product throughput, we enable you to view it all—anywhere, at any time.

This level of remote monitoring changes the game completely, especially for the packaging industry in India, where agility and efficiency are the need of the hour. With IoT solutions for the packaging industry in India, Nichrome offers unmatched transparency and control.

Smart Packaging Systems Enabled by IoT

This is where packaging and the future converge—Nichrome’s smart packaging solutions are transforming manufacturing through the capabilities of IoT (Internet of Things). Our integrated solutions surpass machines by introducing smart sensors and Internet of Things connected devices that track all performance aspects in real time.

Whether you have a pouch filling machine, sachet pack machine, or any food packing machine, our N-DOIT (Nichrome Data Over Internet Technology) patented technology makes your packaging process intelligent, cutting edge, and efficient.

Here is all that you can get with it:

Instant Deviation Alerts - Get notified the moment there's a sealing, filling accuracy, or temperature change.

Enhanced Machine Health Monitoring - Track the motor performance, pressure levels, and wear indicators to avoid breakdowns.

Environmental Controls - Monitor temperature and humidity levels required for sensitive products like pharmaceuticals or milk.

Data-Driven Decision Making – Analyze production data to maximize OEE (Overall Equipment Effectiveness) and minimize downtime.

Remote Accessibility – Remote access to machine data in real-time—greater visibility and control of operations.

From food packaging lines to sachet fillers, our IoT-enabled packaging technology transforms your production line into a lean, clean, and hyper-efficient one.

Welcome to a world where smart packaging doesn't merely respond—it anticipates, avoids, and acts.

Predictive Maintenance with Analytics

Why wait for a breakdown when you can anticipate it first? That is the benefit of predictive maintenance—and Nichrome leads the charge. Our automatic packaging machines feature intelligent diagnostics that utilize data analytics and machine learning to continuously watch and detect early warning signs of failure.

This is how our predictive maintenance is a game-changer for your packaging operations:

Scheduled maintenance, real-time machine monitoring, rather than repair in response

Enhanced OEE (Overall Equipment Effectiveness) because of reduced unplanned downtime

Improved productivity and consistent performance between shifts

Remote diagnostics for faster decision-making and assistance

Integrated sensors and real-time performance monitoring analytics

This isn't tweaking a little—it's a complete redesign in how you manage your production floor. With Nichrome's smart packaging automation solutions, you enjoy control, productivity, and uptime your competition can only dream of.

Real-Time Machine Monitoring for Efficiency

Knowledge is power today, and real-time knowledge is a superpower. With our N-DOIT service, manufacturers have the authority to conduct real-time remote machine monitoring anywhere in the world.

From the factory floor to the aircraft, you can monitor machine dashboards, make adjustments, and monitor performance metrics on our cloud-connected packaging machines. Remote operation, real-time data, and actionable insights? That's what we call next-generation packaging technology.

This degree of remote monitoring facilitates quicker decision-making, energy conservation, and greater accountability between shifts and locations. Guesswork no more—straight performance.

Nichrome's Role in India's Smart Packaging Revolution

At Nichrome Packaging Solutions, we are thrilled to be spearheading India's packaging revolution. With a history of more than four decades, we are not just packaging machine manufacturers—we are innovation facilitators. Our packaging solutions are smart, scalable, affordable, and are designed to address the evolving requirements of Indian industries.

India-specific: Whether it is agro automation and pharma packaging or FMCG and dairy, all of our solutions are India-specific.

Smart yet Robust: Our packaging machines are engineered to be rugged for the floor, yet intelligent on the cloud, combining durability with data-driven efficiency.

For Every Stage of Business: Whether you are a start-up looking to grow or an established brand looking to go digital, we have flexible solutions that grow with you.

Smart Manufacturing Ready: With real-time monitoring, cloud analytics, and IoT, our solutions future-proof your packaging operations.

Nichrome is your trusted ally in leading India's smart packaging drive.

Benefits of Smart Automation for Manufacturers

Let's talk about results. Because while innovation is exciting, it's the results that matter. That's what our innovative packaging solutions offer:

Enhanced speed and accuracy on the packaging lines

Smart automation reduces human error and accelerates operations with precision. Pouch filling or blister packaging, operations are carried out faster, with precise accuracy, accelerating throughput and product quality.

Reduced packaging waste and improved utilization of packaging material

Advanced sensors and control systems provide precise fill weights, minimize spillage, and ensure precise sealing. Not only is material wastage saved, but production costs are also lowered, making your company more efficient and sustainable.

Seamless integration with other smart factory devices and systems

Nichrome's solutions seamlessly integrate with ERP systems, MES systems, and IoT-based monitoring systems. The result? A networked packaging ecosystem that converses in real-time and responds dynamically to production demands.

Whether you're equipping food, pharma, or agro packaging plants, our industrial packaging machines simplify operations, make them smarter, and more profitable. It's no surprise the advantages of automation in packaging have more people talking than ever.

Our packaging systems are cleverly engineered, from the smallest food packaging machine to the most advanced industrial packaging line.

The Future of Smart Manufacturing & IoT Data-Driven

The best part? This is just the beginning. We're not talking sci-fi anymore—smart manufacturing is here, it's growing, and it's transforming the packaging industry like never before. That's what the future looks like:

Machine Learning Takes the Lead - With AI-based systems, packaging lines will be intelligent. Expect machines to self-adjust for material changes, optimize sealing or filling settings, and even schedule preventive maintenance—all autonomously.

Tailored Packaging on Demand - Want to change package size, branding or shape on the fly? No problem. With consumer behaviour data at its core, dynamic packaging design is a breeze—tailored, creative, and competitive.

Sustainability- Our smart packaging solutions ensure efficient energy usage, lower material wastage and reduced carbon footprint. That’s eco-smart packaging with a purpose.

Real-Time, Cloud-Connected Control - Thanks to cloud platforms and remote monitoring, performance metrics are accessible anytime, anywhere—making decision-making smarter and faster.

From packaging automation systems to IoT solutions for the packaging industry in India, Nichrome is already building this future. The future isn’t coming—it’s here. Let’s package it smartly. Let’s package it together.

Conclusion

The packaging world has changed, and with Nichrome’s smart packaging systems, the shift isn’t just noticeable, it’s measurable.

With N-DOIT, we're offering Indian manufacturers a roadmap to future-ready operations. From real-time machine monitoring and predictive maintenance to remote monitoring and cloud-connected packaging machines, Nichrome’s solutions are designed to deliver performance with punch.

So if you’re looking to go beyond the ordinary, it’s time to partner with Nichrome, where packaging automation, IoT, and analytics come together to create intelligent, integrated, and inspiring packaging solutions.

Let’s reimagine what packaging can do. Let’s N-DOIT.

FAQs

Q1: What makes Nichrome's N-DOIT different from other packaging systems? A1: N-DOIT isn’t just about machines—it’s about real-time data, predictive analytics, and smart connectivity that empowers manufacturers to optimise efficiency and reduce downtime.

Q2: Can these smart systems be customised for specific industries like food or agrochemicals? A2: Absolutely. Our solutions are scalable and industry-specific, with smart sensors tailored for food-grade compliance, agrochemical precision, and everything in between.

Q3: How do smart machines improve packaging efficiency? A3: With real-time monitoring, predictive alerts, and automatic adjustments, smart machines significantly enhance speed, accuracy, and consistency, reducing waste and boosting quality.

Q4: What support does Nichrome offer for Indian packaging markets? A4: We provide cost-effective, scalable automation with IoT support, training, and maintenance services tailored for India’s dynamic industries.

Q5: Is cloud connectivity secure and reliable for my factory setup? A5: Our cloud platform is highly secure, ensuring encrypted data transfers, consistent uptime, and seamless integration with your existing infrastructure.

#Smart packaging#Nichrome Data Over Internet#food packaging automation#packaging machines#Data Over Internet (DOI)#packaging automation system#smart packaging solutions#IoT (Internet of Things).#Our integrated solutions#a pouch filling machine#N-DOIT (Nichrome Data Over Internet Technology)#food packaging lines#automatic packaging machines#Nichrome Packaging Solutions#innovative packaging solutions#cloud-connected packaging machines

0 notes

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

https://gqattech.com/compatibility-testing/

https://gqattech.com/firmware-testing/

#Compatibility Testing#Cross-Browser Testing#Cross-Platform Testing#Software Quality Assurance#Mobile App Testing#Web App Testing#Device Compatibility#OS Compatibility#Functional Testing#QA Testing Services#User Experience Testing#Responsive Design Testing#Testing on Real Devices#Software Testing#GQAT Tech QA Services#Firmware Testing#Embedded Software Testing#Hardware Testing#IoT Device Testing#Quality Assurance#Low-Level Software Testing#Device-Level Testing#Embedded QA#Hardware Compatibility#Regression Testing#Automated Firmware Testing#GQAT Tech Testing Services#Tech QA#Software-Hardware Integration#Product Validation Testing

0 notes

Text

The Future of IoT and AI Integration 2025

In 2025, the fusion of IoT and AI integration is reshaping how machines communicate, businesses operate, and societies thrive. The convergence of the Internet of Things (IoT) with Artificial Intelligence (AI) is no longer futuristic — it's already here, driving smart cities, industrial automation, and intelligent consumer ecosystems. As IoT and AI integration 2025 takes center stage, industries are leveraging this synergy to optimize operations, reduce human error, and unlock real-time decision-making.

What is IoT and AI Integration?

IoT refers to the network of interconnected devices that collect and share data, while AI enables these devices to analyze, learn, and make autonomous decisions. The integration of IoT and AI brings intelligent automation to devices, enhancing their ability to adapt, predict, and evolve.

How IoT and AI Integration Is Changing the Game in 2025

From healthcare to agriculture, the powerful duo of IoT and AI is revolutionizing how industries function. Here are the top sectors experiencing a transformation:

1. Smart Manufacturing (Industry 4.0)

• Predictive maintenance using AI-driven insights from IoT sensors • Robotics and automation for precision and safety • Real-time production monitoring with automated alerts

2. Healthcare

• Wearables collecting patient vitals with AI diagnosing anomalies • Smart hospitals with automated inventory and energy management • Remote surgery support powered by edge AI and IoT connectivity

3. Smart Cities

• AI-enabled traffic management based on IoT camera feeds • Automated waste management systems • Smart street lighting and energy optimization

4. Agriculture

• AI-driven precision farming based on IoT soil and weather sensors • Livestock monitoring using smart tags • Water and nutrient automation for crops

5. Retail & Supply Chain

• Inventory forecasting using IoT + AI analytics • AI-powered demand prediction • Cold chain monitoring for perishables

Benefits of AI and IoT Integration

• Enhanced Efficiency: Real-time decision-making reduces delays and boosts productivity • Cost Savings: Predictive analytics cuts down maintenance and resource waste • Improved Safety: AI monitors risk parameters from IoT devices to prevent accidents • Better Customer Experience: Personalized services powered by AI insights from IoT data

Challenges in 2025

Despite the rapid growth, there are some hurdles:

• Data Privacy & Security: As more devices connect, vulnerability increases • Infrastructure Requirements: High-speed connectivity and edge computing are necessary • Standardization: Interoperability remains a concern across different ecosystems

The Role of 5G and Edge AI

2025 is witnessing mass adoption of 5G and edge computing, allowing faster, low-latency processing of IoT data. Instead of sending data to the cloud, AI can process information on the edge device itself. This is crucial for time-sensitive applications like autonomous vehicles, smart grids, and medical devices.

Real-World Examples in 2025

• Tata Power uses IoT-AI for grid monitoring and predictive energy distribution. • Apollo Hospitals deploys wearable AI-integrated IoT devices for chronic disease monitoring. • Mahindra Agritech is implementing AI-IoT systems to automate irrigation based on real-time soil data.

The Road Ahead: What to Expect Beyond 2025

As both technologies evolve, we can expect:

• Increased adoption of digital twins • More autonomous decision-making devices • Broader use of generative AI models integrated with IoT for real-time content or data generation

Final Thoughts

IoT and AI integration 2025 is proving to be more than a buzzword—it’s a technological alliance with the power to redefine industries, enhance human capabilities, and create a more efficient and intelligent world. Businesses investing in this synergy today are setting themselves up for long-term success.

As connectivity expands and AI models become more robust, the line between the digital and physical world continues to blur, opening new possibilities for innovation, automation, and sustainability.

In the coming years, the winners in this space will be those who not only adopt the technology but adapt their strategies to leverage it fully.

#tagbin#writers on tumblr#artificial intelligence#technology#tagbin ai solutions#ai trends 2025#Future of IoT and AI Integration 2025#AI and IoT future trends#IoT AI convergence 2025#AI in Internet of Things 2025#Smart devices AI 2025#AI IoT use cases 2025#Artificial intelligence and IoT in business#Tagbin

0 notes