#coefficient of static friction

Explore tagged Tumblr posts

Text

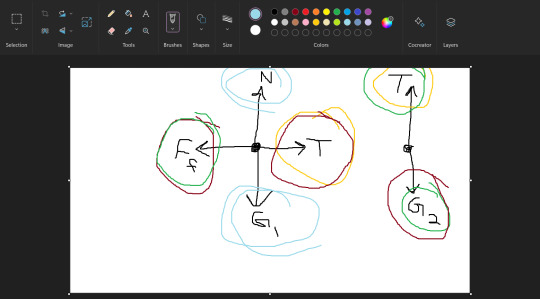

Homework diagrams that make no sense out of context

#ap physics#lab report#it's a board and a block with some felt on it and causes me more pain than literally anything else#I'm rocking this unit tho#coefficient of friction#coefficient of static friction#coefficient of kinetic friction#normal force#gravitational force#tension

0 notes

Text

Dick: *searching for his teammate post-battle* Romeo, Romeo! Where art thou Romeo?

Jason: Shut up. Shut up! Don’t you dare desecrate Shakespearen literature you Neanderthal.

Dick: *offended* what?

Jason: heh, you didn’t get that? Dumb.

Dick:

Dick: Well, Little Wing, right now you’re walking an average speed of 3.1 mph and you’re going to fire your grapple gun to shoot across to another building but in order to do so you need to increase your running speed because the tension on the string is opposing the Normal force at an angle and if you count the weight of gravity, you have to calculate F=ma with cos of 46 degrees or else the grapple won’t latch on but since there’s a high frictional force between your boot and the ground, the coefficient of static friction is much higher than normal so as such, you need to lower the coefficient of kinetic friction so you have the momentum to reach peak velocity needed to boost you into the air and not suspend your rope so that’d be your final velocity squared equal to your initial velocity squared minus 2 times gravity times your final height minus your initial height. So in conclusion, your initial speed of run must be 5.3 mph if you don’t want to bash your head open on a brick wall.

Jason: what.

Dick: oh you didn’t get that? Dumb.

Jason: ….Bitch.

#sibling behavior#Jason’s literature vs dick’s physics#I just finished telling my own brother he’s dumb an hour ago bc older siblings always know better. duh#dick grayson#nightwing#jason todd#red hood#batfam incorrect quotes#dicks a Mathlete so for sure he’d do this#Jason is into classic literature so he’d quote a sassy Jane Austin quote and the fight would begin again#they’re petty that way

753 notes

·

View notes

Text

two partners of mine now have pointed out that I'm extremely good at cleaning my apartment but terrible at keeping it clean, so for about one day a month the place looks like an ikea showroom and then it just gradually (well,) degenerates into a pit of filth until it's messy enough to overcome my like static coefficient of friction ig to clean it again

so there's probly an opportunity for personal growth here idk

32 notes

·

View notes

Text

Worker: Take this to the testing area. Name at the top. Sign the bottom, answer the questions, bring it back. Next. Shadow: Excuse me, but I have some concerns about these questions. Worker: Look at that sign up there. Does it say, "I give a damn"? Shadow: …No. Worker: That's because I don't. Shadow: But… See, this first question makes no sense. Look, "How many car lengths should you leave in front of you when driving?" There's no possible way to answer that. A car length is not a standardized unit of measure. Worker: …Look at the sign. Sonic: Shads, it's C. Just put down C. Shadow: I don't need your help, faker. Worker: Listen to your little friend, honey. Put C. Next. Shadow: No, no. Wait, no, hang on. Take a look at this next question. Rouge: Shadow, why are you arguing with the DMV? Shadow: How else are they going to learn? Look, question two: "When are roadways most slippery?" There are three answers, none of which are correct. The correct answer is, "When covered by liquid sufficient to reduce the coefficient to static friction between the tire and the road to zero. But not so deep as to introduce a new source of friction." Worker: … … [takes his test]: Here's your learner's permit. Go away. Shadow: …But I'm not done. I have many additional concerns about these questions. Worker: Don't make me climb over this counter. Rouge and Sonic [taking him away]: All right, come on. Let's go. Shadow: Aced it.

#incorrect quotes#sth#sonic#sonic the hedgehog#sonic movie 3#sonic movie universe#shadow the hedgehog#rouge the bat#sonic wachowski#source: big bang theory

35 notes

·

View notes

Text

Danielleitloudernow on AO3

**Not taking commissions currently, but I'm open to any thoughts you wanna throw my way**

Unfortunately, because some asshole had to go and fuck up a good thing, it's been ruined for everyone. All of my work is now locked to AO3 users only. If you don't have an AO3 account, I highly encourage you to get one.

✌️ ❤️ & Fuck AI

Fandoms Master List

Avatar: Legend of Korra

Criminal Minds

Xena Warrior Princess

Captain Marvel

Life is Strange

Mass Effect

Warrior Nun

Original-WIPs

Fic Master List

Korrasami

One Shots

It is Midnight, and Time is Passing, but I Sleep Alone

Paralyzed

Measure the Coefficient of Static Friction Between Us

Fuck Was I

Need You to Be Sure

Coffee Shop Soundtrack

An Apple a Day Keeps Anyone Away (If You Throw It Hard Enough)

Every Last One

Multi-Chapter Fics

The Consequences of Jello (title may change)

Far From Never

Series

Bet On It, Baby

STEMinism: A Study

Living On A Spare

Words Unspoken

Missing

You Stupid Girl

Control

Jemily

One Shots

The Violets in the Mountains Have Broken Rocks

Profiles and Princesses

All Persons, Living and Dead, Are Purely Coincidental

Everything Was Beautiful and Nothing Hurt

Princess, Profiled

Multi-Chapter Fics

Gonna Use My, My, My Imagination

In the Crooks of Your Body, I Find My Religion

WarriorBard

Caught

The Light

Get Your Hands Off My Apples

You Came and I Was Crazy For You

Fire Races Under My Skin and I Tremble

I Yield Before Gabrielle

Ramvers

Destruction of Government Property

Do You Wanna Touch

Pricefield

All These Cameras and I Still Can't Capture This Moment

Chaos Theory

Shiara

Series

Among the Stars

People Are Quick to Assume We Enjoy Being in Hazardous Situations

What Cannot Be Said Will Be Wept - multi-chapter fic

I Have a Question About Human Behavior

Avatrice

With Each Breath

When You Sleep

Between the Wish and the Thing, the World Lies Waiting

But for Which of My Good Parts Did You First Suffer Love for Me?

Originals Incoming

Cheers!

Dani

#fan fiction#fic writer#fandom masterlist#fic masterlist#wlw fanfic#femslash fanfic#femslash fic#the legend of korra#korrasami#criminal minds#jemily#xena warrior princess#warriorbard#captain marvel#ramvers#life is strange#pricefield#mass effect#shiara#warrior nun#avatrice#fuck ai

29 notes

·

View notes

Text

DanielleItLouderNow on AO3

Writes WLW fics for fellow nerds with a dash of angst and sarcasm for that little bit of extra spice.

Loves comments and will always answer (even if it takes a year).

Commissions/Requests

Currently closed

Fandoms Master List

Avatar: Legend of Korra

Criminal Minds

Xena Warrior Princess

Captain Marvel

Life is Strange

Mass Effect

hopefully growing to include Warrior Nun

Originals Incoming

Fic Master List

Korrasami

One Shots:

It is midnight, and the time is passing, but I sleep alone

Paralyzed

Measure the Coefficient of Static Friction Between Us

Fuck Was I

Need You To Be Sure

Coffee Shop Soundtrack

An Apple a Day Keeps Anyone Away (If You Throw It Hard Enough)

Every Last One

Multi-Chapter Fics:

The Consequences of Jello (title may change)

Far From Never

Series:

Bet On It, Baby

STEMinism: A Study (beta'd by the amazing ireallyshouldnt_behere, check them out!)

Living On a Spare

Words Unspoken

Missing

You Stupid Girl

Control

Jemily

One Shots:

The Violets in the Mountains Have Broken Rocks

Profiles and Princesses

All Persons, Living and Dead, Are Purely Coincidental

Everything Was Beautiful and Nothing Hurt

Multi-Chapter Fics:

Gonna Use My, My, My Imagination

In the Crooks of Your Body, I Find My Religion

WarriorBard

Caught

The Light

Get Your Hands Off My Apples

You Came and I Was Crazy for You

Fire Races Under My Skin and I Tremble

I Yield Before Gabrielle

Ramvers

Destruction of Government Property

Do You Wanna Touch

Pricefield

All These Cameras and I Still Can't Capture This Moment

Chaos Theory

Shiara

People Are Quick to Assume We Enjoy Being in Hazardous Situations

Avatrice

With Each Breath

Interests

Reading

Writing

Science

Gaming

Cooking

Music

All forms of nerdiness

Skills

Smut

Fluff

Angst

Emotion

Description

Sarcastic One-Liners

Needs Improvement

Organization

Motivation

Moving from Point A to Point C because Point B is a fucking dick

Finishing

Listens To While Writing

youtube

Plus more

Looking For

Writing Friends

Conversation

Sharing

Hoping To

Get back into writing

Break into a new fandom (or fandoms)

Finish original works

Finish anything

If you stumbled onto me and wanna scream about writing, awesome! If you stumbled on me and wanna scream about nerdiness, fandom, weird shit, and other interests, maybe check out my main Tumblr @danielleitloudernow

Cheers!

#writerblr intro#writerblr#writers on tumblr#writing#writerscommunity#wlw fanfic#wlw fiction#lgbtq#lesbian#bisexual#korrasami#jemily#xena and gabrielle#ramvers#pricefield#shiara#avatrice#original writing

17 notes

·

View notes

Text

Get to Know About the Features and Benefits of Ceramic Balls

As their name implies, ceramic balls are spherical items composed of ceramic materials. They are available in a range of sizes, from little beads used in precision machinery to bigger balls used in industrial settings. These ceramic materials are mostly used to create these balls:

Al2O3 alumina: Alumina ceramic balls, which are renowned for their excellent hardness, are frequently employed in applications that call for wear resistance and high-temperature stability.

Zirconium dioxide: Zirconia ceramic balls are highly valued for their durability and resistance to chipping, which makes them perfect for demanding applications like grinding media and dental prostheses.

These ceramic balls made of silicon nitride (Si3N4) are renowned for their low density, high strength, and outstanding corrosion resistance.

Features and Benefits

Ceramic ball is extremely significant in a variety of sectors due to their exceptional qualities.

High Hardness: Ceramic balls are incredibly tough, which increases their resistance to abrasion and wear and increases their longevity.

They have a high level of chemical corrosion resistance, assuring their longevity in severe settings.

Low Friction: Ceramic balls use less energy in applications like bearings because their friction coefficients are lower than those of their metal equivalents.

High-Temperature Stability: They are appropriate for high-temperature applications because they can endure high temperatures without compromising their mechanical qualities.

Ceramic balls are used as rolling components in bearings often because of their low friction and high hardness, which prolong the life of the bearings by reducing wear and friction.

They are used in precision equipment like flow meters, check valves, and ball valves because their dimensional accuracy is crucial.

Electronics: Ceramic balls act as insulators to shield electronic parts from temperature stress and static electricity.

Conclusion Ceramic balls from ceramic ball manufacturer may be small, but they have a big influence on many different sectors. Due to their remarkable qualities, which include hardness, corrosion resistance, and low friction, they have a well-deserved position in a variety of applications, from dental implants to industrial gear. We may anticipate ceramic balls to play an ever more significant part in determining our future as technology develops, silently working in the background to enhance performance, durability, and efficiency in innumerable goods and procedures.

Main source: https://sdballs.weebly.com/

2 notes

·

View notes

Text

UHMW Profiles: The Durable, Custom Solution for Demanding Applications

In industries where abrasion, impact, and chemical exposure are daily challenges, UHMW profiles offer a reliable, high-performance solution. As a trusted plastic extrusion company, Spiratex specializes in manufacturing custom UHMW profiles engineered to perform under pressure—whether you’re in material handling, food processing, packaging, or automation.

With decades of extrusion experience and a commitment to innovation, Spiratex delivers UHMW extrusions that solve problems and extend the life of your equipment.

What Are UHMW Profiles?

UHMW (Ultra-High Molecular Weight Polyethylene) is a high-performance plastic known for its exceptional resistance to wear, impact, and chemicals. UHMW profiles are custom-shaped plastic components created through the plastic extrusion process to meet specific application needs. These profiles can take on virtually any shape—from simple guides and wear strips to more complex, application-specific components.

Spiratex was one of the first companies in North America to extrude UHMW, and we continue to push the boundaries of what’s possible with this versatile material.

Why Choose UHMW Profiles?

✔ Exceptional Wear Resistance

UHMW outperforms many other materials in high-friction environments. Our UHMW profiles maintain integrity under heavy load and continuous use, making them ideal for conveyor systems, guide rails, and chain guides.

✔ Low Friction and Self-Lubricating

UHMW’s naturally low coefficient of friction reduces drag and improves movement, especially in conveyor and automation systems. That means smoother operation and less maintenance.

✔ High Impact Strength

UHMW can absorb repeated impact without cracking or breaking. It’s a rugged solution for applications that experience heavy contact or shifting loads.

✔ Chemical and Moisture Resistance

From caustic cleaners to wet environments, UHMW stands up to exposure without degrading, making it a top choice for food processing, agriculture, and packaging lines.

✔ Customization Flexibility

No two operations are the same—and neither are our UHMW profiles. Spiratex can produce custom shapes, sizes, and formulations, including options for FDA compliance, static dissipation, and high temperature resistance.

Custom UHMW Profiles from Spiratex

Spiratex offers 100% custom UHMWplastic profiles designed to meet your exact specifications. Whether you need a specific shape to reduce friction, extend conveyor life, or improve line efficiency, we can create a solution that fits seamlessly into your system.

Our in-house tooling capabilities allow us to bring your custom profile to life quickly and cost-effectively, with low minimum order requirements.

Common UHMW Profile Applications:

· Conveyor wear strips and guides

· Chain guides and belt supports

· Sliding and gliding components

· Packaging and automation systems

· Food-safe product contact surfaces

Spiratex: Your Partner in Custom UHMW Extrusions

With more than 70 years of experience, Spiratex is a pioneer in custom plastic extrusion. We’re not just a UHMW profiles manufacturer—we’re a long-term partner who helps solve problems, improve equipment performance, and reduce downtime.

From engineering support to production expertise, we offer:

· Custom tooling and profile design

· Short lead times and fast prototyping

· Tight tolerances and consistent quality

· Extensive material knowledge, including UHMW, HDPE, and TPU

Let’s Design Your Custom UHMW Profile

If you’re ready to enhance performance and reduce wear with a durable, high-quality UHMW profile, Spiratex is here to help. Let our team collaborate with you to create a custom solution that meets your exact needs—no matter how complex.

Contact Spiratex today to get started on your custom UHMW profile project.

Source Url : - https://twitdirectory.net/uhmw-profiles-the-durable-custom-solution-for-demanding-applications/

0 notes

Text

Footwear Testing Lab Near Me for Industrial Safety Boots: What to Know

When it comes to industrial safety boots, quality and compliance are non-negotiable. These specialized shoes protect workers in high-risk environments such as construction sites, manufacturing plants, and chemical processing facilities. For manufacturers, suppliers, and procurement teams, ensuring that these boots meet global safety standards is critical—and that starts with finding a reliable “Footwear Testing Lab near me.”

In this blog, we’ll explore the role of footwear testing labs in validating industrial safety boots, the types of tests conducted, and why choosing a nearby certified facility is essential for your business.

Why Industrial Safety Boots Require Specialized Testing

Industrial safety footwear isn’t just regular footwear. It must protect against:

Heavy impacts and compression

Punctures from sharp objects

Slipping on oily or wet surfaces

Electrical hazards

Extreme temperatures or chemical spills

Substandard boots can put lives at risk and expose companies to regulatory penalties or costly liability claims. That’s why testing industrial safety boots is not optional—it’s mandatory for regulatory compliance and workplace safety.

Searching for a “Footwear Testing Lab Near Me”: Why Local Matters

When you search for a “Footwear Testing Lab near me,” you're seeking more than convenience. You're looking for speed, compliance, accuracy, and partnership. Here’s why a local certified lab is the smart choice for safety boot manufacturers and distributors:

1. Faster Sample Turnaround

Having a lab close by reduces sample transit time, allows for face-to-face collaboration, and accelerates report delivery—especially helpful when dealing with urgent compliance checks.

2. Easier Communication

A local lab means easy access to technical experts who can walk you through results, resolve issues, and recommend adjustments during the development process.

3. Cost-Effective Compliance

Shipping samples overseas is expensive. Using a nearby testing lab minimizes logistics costs and delays while still providing access to globally recognized certifications.

4. Local Regulation Expertise

If your safety boots are intended for specific regional markets, a local lab is more likely to be familiar with applicable safety and labeling standards—from Gulf Conformity Marking (G-Mark) in the UAE to CE standards in Europe.

What to Expect from a Certified Footwear Testing Lab Near You

When it comes to industrial safety boots, a certified footwear testing lab near me should offer comprehensive testing services to ensure your product meets global safety standards like:

ASTM F2413 (USA)

EN ISO 20345 (Europe)

CSA Z195 (Canada)

AS/NZS 2210.3 (Australia/New Zealand)

Here are the essential tests you should expect:

1. Impact Resistance Testing

Safety boots must withstand a defined amount of force (measured in joules) on the toe area without breaking. Labs test toe caps—often made of steel, aluminum, or composite materials—using drop impact tests.

2. Compression Resistance Testing

This test checks how well the toe area handles gradual pressure, simulating heavy loads resting on the boot. It helps ensure that the boot can protect workers from crushing injuries.

3. Slip Resistance Testing

Safety boots are often used in slippery environments. Certified labs test outsoles on wet, oily, and dry surfaces to measure friction coefficients and determine slip resistance levels.

4. Puncture Resistance Testing

Industrial work boots often include a puncture-resistant plate. This test simulates sharp objects—like nails or debris—penetrating the sole, ensuring the boot provides adequate underfoot protection.

5. Electrical Hazard and Conductivity Testing

Depending on the work environment, boots may need to be:

Electrical Hazard (EH) Rated to protect against open circuits

Anti-static or conductive to avoid static buildup in sensitive workspaces

Labs verify the footwear’s ability to resist or conduct electrical current under various conditions.

6. Chemical and Heat Resistance Testing

In chemical plants and fire-related industries, boots must resist chemical corrosion, flame exposure, and thermal degradation. Labs simulate these environments to validate the durability of materials used.

7. Water Resistance and Absorption Testing

For waterproof safety boots, labs assess how well the boot repels or absorbs moisture over time—essential for comfort and long-term performance in wet environments.

8. Sole Bonding and Flexing Resistance

To ensure long-lasting performance, the bond strength between the outsole and upper is tested under repeated flexing and stress cycles.

How to Choose the Right Footwear Testing Lab Near You

Not all testing labs are created equal. When searching for a “Footwear Testing Lab near me,” make sure to evaluate the following:

✅ Accreditation and Certifications

Ensure the lab is ISO/IEC 17025 accredited. This means their testing methods, equipment, and reporting meet international standards, ensuring globally accepted results.

✅ Specialization in Safety Footwear

Choose a lab with a proven track record in industrial and safety footwear testing, not just general-purpose shoe testing.

✅ Turnaround Time and Support

Ask about the average time for test results and whether they offer engineering support, product evaluation reports, and retesting options.

✅ Equipment and Testing Standards

Verify that the lab is equipped to test according to the required safety standards for your export destination—whether it's ASTM, ISO, or EN.

Benefits of Partnering with a Certified Footwear Testing Lab Near Me

Let’s recap why working with a certified local testing lab can be a strategic move for your safety footwear brand:

Quicker Market Launch: Rapid results enable fast certifications and product launches.

Improved Quality Control: Routine batch testing can catch defects before reaching the customer.

Risk Mitigation: Tested and certified boots protect you from lawsuits and product recalls.

Customer Trust: Certification from an accredited lab builds brand credibility with buyers and industrial clients.

Regulatory Approval: Local labs often understand the documentation required for region-specific safety certification, customs clearance, or government tenders.

Final Thoughts

In the world of industrial safety, there’s no room for compromise. Finding a certified footwear testing lab near me is the first step toward ensuring your industrial boots meet stringent safety standards and keep workers protected.

Whether you're launching a new product, entering new markets, or upgrading an existing design, partnering with a nearby testing lab gives you the speed, accuracy, and trust you need to stay ahead in the game. Don't wait for a safety issue to arise—proactively test, comply, and lead with quality.

#footwear testing lab near me#footwear testing lab#footwear testing#testing lab near me#testing lab in delhi

0 notes

Text

The major aim for conducting the experiment was to establish a steady flow and measure the flow rate. In order to meet this objective, the aspects measured include average time taken to collect the water, the volumetric flow rate per se, and the pressure difference representing the static head and velocity. Intuitively, the process involved the use of combination of weight bench (hydraulic bench), to take the two readings, venture meter and manometer. Eleven points were selected along the venture meter whereby piezometric head values for each was measured and explored in the “procedure” section. In which case, the Bernoulli’s theorem majorly relies on the use of classical venture as can be seen from the experiment. The experiment demonstrates succinctly that the venture is a means for establishing flow measurement and, from which, the discharge coefficient can be derived. From the results, it is true to say that the pressure difference increases as the level of water in the manometer tubes increases. Chapter 1: Introduction Bernoulli’s principle named after its founder, Daniel Bernoulli, asserts that “as the speed of a moving fluid (liquid or gas) increases, the pressure within the fluid decreases. In which case, the use of Bernoulli’s equation guides the major concepts in the aforementioned definition. The equation makes use of the relation between pressure, velocity and elevation (height). This is different to the continuity equation, which only applies a relation between speed of the fluid and the cross sectional area measured for a pipe in which the fluid moves. It is worth noting that there are certain restrictive conditions to which the principle can hold. This include, the fluid used must be frictionless at a constant density; in which case, steady flow is a must. Since frictional effects are mostly significant when very close to the boundary layers, the use of Bernoulli’s approximation is feasible in outside the boundary layers. In which case, the flow outside is guided by the combination of two forces, pressure and gravity. The concept conveyed can be explored on the basis of law of conservation of energy. As a result, movement of fluid from wider section of a pipe to a constriction, triggers a greater distance movement of corresponding volume at the constriction thereby leading to an increase in speed. The aspects explained therein, constituting work done in both wider and narrower section can be summarized into the product of the pressure and volume. The greater speed evident leads to higher kinetic energy of the given volume in the narrower pipe. Going by the law of energy conservation, the observed increase of kinetic energy is thereby balanced by a decrease in the product of pressure-volume as shown in the Bernoulli’s equation below (Durgaiah 2002, 50). Kinetic energy + potential energy + flow energy = constant Theory The center line, while considering the assumptions that the fluid used must be frictionless at a constant density; in which case, steady flow is a must: From the above Bernoulli’s tequation, the total head (h) is obtained from summing up the pressure head (h), velocity head (hv) , and elevation head (z), respectively as depicted on the left hand side of the equation. Consequently, the theorem supports the assumption that for a fluid flowing through a pipe, the total head at any point is constant. Objectives To measure the piezometric head values for all eleven points To confirm the feasibility of Bernoulli equation when applied to a steady flow. CHAPTER 2: APPARATUS AND EXPERIMENTAL PROCEDURE 2.1 Apparatus Venturi meter Stop watch Weight bench Weight of 6 kg 2.2 Procedures The Bernoulli’s equation apparatus was set up on the weight bench. 11-tapered sections converging in the direction of flow were selected. The mass, at the weight bench was set at 0.006 kg constant for all the points. The outflow tube was then positioned right above the volumetric tank while the rig inlet was connected to the bench flow supply. The bench valve was closed and the pump was then started. The bench valve was opened gradually while filling water in the test rig. The bench valve was opened and permitted to flow through the manometer. The air bleed was opened to allow entry of air to the top of the manometer. After reaching a convenient height, the screw was tightened again. CHAPTER 3: CALCULATIONS AND RESULTS Part of the results as obtained from excel worksheet: Figure 1: Table Depicting Data Obtained Position A B C D E F G H I J K Diameter (mm) 26 23.2 18.4 16 16.8 18.47 20.16 21.84 23.53 25.24 26 Area mm2 530.9 422.7 265.9 201.1 221.1 268 318.8 375 435 500.8 530.9 Area m2 0.0005309 0.0004227 0.000266 0.0002011 0.0002211 0.000268 0.0003188 0.000375 0.000435 0.0005008 0.0005309 Test Mass (kg) Time (s) Q Distance from A (mm) 0 20 32 46 61 76 91 106 121 136 156 1 (i) 0.006 10.47 0 0.268 0.254 0.155 0.005 0.024 0.111 0.158 0.187 0.205 0.219 0.226 (ii) 7.09 1.287 1.617 2.570 3.398 3.091 2.550 2.144 1.822 1.571 1.365 1.287 Avg time 8.78 0.268 0.219 0.016 -0.236 -0.134 0.021 0.118 0.183 0.227 0.258 0.268 2 (i) 0.006 10.46 0 0.243 0.234 0.168 0.068 0.079 0.137 0.169 0.188 0.200 0.210 0.248 (ii) 9.12 1.154 1.450 2.305 3.048 2.772 2.287 1.922 1.634 1.409 1.224 1.154 Avg time 9.79 0.243 0.204 0.040 -0.162 -0.081 0.044 0.123 0.175 0.210 0.235 0.243 3 (i) 0.006 16.93 0 0.224 0.219 0.178 0.117 0.122 0.157 0.177 0.189 0.197 0.202 0.205 (ii) 19.03 0.629 0.789 1.255 1.659 1.509 1.245 1.047 0.890 0.767 0.666 0.629 Avg time 17.98 0.224 0.212 0.164 0.104 0.128 0.165 0.188 0.204 0.214 0.222 0.224 Figure 2: Picture Form Depicting The Whole Table Sample Calculations Test 1 Q = MASS/AVG.time = 0.006/8.78 = 0.00006834 ( = Q/area = 0.00006834/0.0005309 = 1.287 Hn theoretical = hn experiment – = 0.268 – In order to obtain the graph for Bernouli’s experiment, the following table was made for the the three tests: FIGURE 3: Table For Graph for BERNOULLIS EXPERIMENT A B C D E F G H I J K Test 1 h experimental (mm) 268 254 155 5 24 111 158 187 205 219 226 Test 2 h experimental (mm) 243 234 168 68 79 137 169 188 200 210 248 Test 3 h experimental (mm) 224 219 178 117 122 157 177 189 197 202 205 From the table, a graph of hn against position from A was made to help in depicting and exploring more on the Bernouli’s experiment. The three graphs with different lines represent the three tests carried out: Figure 4: Graph of hn against position from A The above graph depicts the pattern existing for the relationship between hn and position in the venture meter tube. It shows that the pattern assumed for all the three tests is similar as it starts at a higher point at position A, then drops to lowest point at D then again rise to relatively higher point at K, for all. Further, the graph also indicates that test 1 has both the highest point and lowest point while test 2 has relatively higher and lower point and 3 is the last in this category. This confirms the uniformity of all the tests. CHAPTER 4: ANALYSIS AND DISCUSSION The major objective of this lab is to confirm the validity of the Bernoulli equation when setting up a steady flow. Further, the experiment was set to measure the flow rates and the piezometric heads (both static and total pressure heads) contained in a convergent and divergent tube for a range of steady flow rates. Intuitively, the experiment makes use of bernoulli’s principle which makes it nature based on the relation between velocity and pressure for a frictionless fluid. In order to meet this objective, the aspects measured include average time taken to collect the water, the volumetric flow rate per se, and the pressure difference representing the static head and velocity. Intuitively, the process involved the use of combination of weight bench (hydraulic bench), to take the two readings, venture meter and manometer. Eleven points were selected along the venturi meter whereby piezometric head values for each was measured and explored in the “procedure” section. From this, the venturi meter allowed for deriving a relation between the flow rates, therein, and pressure measurement under the guidance of Bernoulli’s equation. The result obtained from this experiment confirms that an increase in pressure difference triggers a corresponding increase in flow rates of water thereby leading to increase in velocities. This was observed for both the convergent and divergent flow. As shown, whenever there was pressure difference increase the result was a rise in the water level contained in the manometer tube. Intuitively, there is a difference in velocity for fluid flowing through wider and lower constrictions. The velocity of the fluid increases whenever it flows from a wider constriction to a narrower constriction. The table in the results section confirms this, as depicted in the observed increase in the velocity of water moving in the tapered duct as the area of the duct increases. It is also worth noting that this was observed regardless of difference in pressure and the flow type. Analysis of the results concludes that a decrease in water flow rate leads to a decrease in the velocity of water. As can be shown in the results the velocity for the cross sections increased as the diameter decreased; point A had the largest diameter (26 mm) but with slowest flow rate and hence the velocity thereby was also low while point D (16 mm) had the tightest diameter but with highest flow rate and highest velocity. In which case, the fast flow rate was evident at points of smaller tubes while the slowest was in the bigger tubes. For A, the difference was 0.268 while for D the velocity difference was 3.398 and this was confirmed for all the three tests. Consequently, this confirms that the velocity of the fluid flowing in a tube is affected by the diameter since a bigger tube triggers a larger difference in velocity while a smaller tube results to the difference in velocity, VIB and VIC is smaller. Even though the experiment was completed successfully, the presence of zero error must have occurred while taking the measurement for each test. In which case, while taking the readings the level of static head might have not been allocated appropriately. Consequently, this might have triggered slight effect on the calculations and this can be evident at position K where the graph defied the perceived uniform pattern for the three tests. Consequently, the experiment confirms the validity of Bernoulli’s principle when applied to steady flow of fluid contained in tapered duct. In which case, there is increase in absolute velocity values along similar channel. Any slight difference witnessed from the actual value can be contributed to insignificant errors witnessed positioning of the eye while taking the readings. There might have been slight diversion in positioning the eye parallel to scale. In order to solve this error for future experiment, the water level must be allowed to settle and be stable. CHAPTER 5: CONCLUSION AND RECOMMENDATION 5.1 Conclusion Read the full article

0 notes

Photo

The 3/3vx750 Cogged V-Belt is engineered to provide enhanced durability and wear resistance in applications involving shock or pulsating loads. The body compound, a fiber-loaded EPDM rubber blend, offers excellent abrasion resistance, a high coefficient of friction for increased power capacity compared to wrapped belts, good ozone resistance, very good heat resistance across a temperature range of -40 to +150 °C (-40 to +302 °F), and static conductivity according to ISO1813 standards. Order the 3/3vx750 Cogged V-Belt today at WWW.SAWBELTS.COM, and receive our new 60-day return policy.

0 notes

Text

PTFE O-Ring / Polytetrafluoroethylene O-Ring Seals

PTFE O-Ring / Polytetrafluoroethylene O-Ring Seals Product Overview PTFE O-Rings are high-performance sealing components made from pure or modified PTFE materials, offering exceptional chemical resistance, temperature stability and low friction coefficient. Ideal for both static and dynamic sealing in demanding applications. Technical Specifications & Advantages Material Virgin PTFE or filled…

0 notes

Text

Main functions and maintenance methods of Linear Guide Rail

1.What is Linear Guide Rail? Linear Guide Rail is an important component used in mechanical design to support and guide moving parts to make reciprocating linear motion in a given direction. It consists of guide rails, sliders, rolling elements and retainers. Through the infinite rolling cycle of balls between the sliders and guide rails, high-speed and high-precision linear motion under high loads is achieved.

2.Operating principle of Linear Guide Rail The operating principle of Linear Guide Rail is mainly based on rolling guidance, and low-friction linear motion is achieved through the rolling of steel balls between the sliders and guide rails. Specifically, Linear Guide Rail consists of slide rails, sliders, balls, ball retainers and ball return grooves. There are many balls installed between the sliders and the guide rails. These balls perform infinite rolling cycles when the sliders move, thereby converting sliding friction into rolling friction, significantly reducing the friction coefficient and improving motion efficiency and precision.

3.Main functions of Linear Guide Rail 1.Load bearing and guiding: Linear Guide Rail plays a role of load bearing and guiding in mechanical design, supporting and guiding moving parts to make reciprocating linear motion in a given direction. It can achieve high-precision linear motion under high load. 2.Improve positioning accuracy: Since Linear Guide Rail adopts rolling friction, the friction coefficient is low, and the difference between dynamic friction and static friction is small, the bed will not slip during operation, and the positioning accuracy of micron level can be achieved. 3.Reduce wear: Traditional sliding guides will cause wear and affect accuracy due to oil film backflow and insufficient lubrication. The rolling guide of Linear Guide Rail has very little wear, and the machine can maintain accuracy for a long time. 4.Suitable for high-speed movement: Linear Guide Rail has low friction, and only a small amount of power is needed to make the bed run, which is especially suitable for occasions with frequent reciprocating operation. At the same time, it is suitable for high-speed operation because the heat generated by its friction is small. 5.Bear multi-directional loads: The special structural design of Linear Guide Rail enables it to bear loads in the upper, lower, left and right directions at the same time. Compared with traditional sliding guides, it has a stronger lateral load bearing capacity in the direction of parallel contact surfaces. 6.Easy assembly and interchangeability: The assembly of Linear Guide Rail is simple. You only need to mill or grind the assembly surface of the guide rail on the bed, and fix the guide rail and slider to the machine with a specific torque according to the recommended steps. In addition, Linear Guide Rail is interchangeable, and the slider or guide rail can be replaced separately, so that the machine can regain high-precision guidance.

4.Maintenance method of Linear Guide Rail 1.Daily cleaning: Regularly use a clean cotton cloth or a soft brush to remove impurities such as dust, chips and oil on the surface of the linear guide. Avoid using rough materials when cleaning to avoid scratching the surface of the guide rail. You can use a mild detergent with a cleaning cloth to wipe it, but be careful that the detergent cannot contain corrosive ingredients such as strong acids and alkalis. After cleaning, it should be wiped dry in time to prevent moisture residue from causing rust on the guide rail. 2.Lubrication and maintenance: Good lubrication is essential for the normal operation and service life of Linear Guide Rail. Select appropriate lubricants, such as lubricating oil or grease, according to the use environment and working conditions, and ensure that the lubricant is evenly applied to the sliding surface of the guide rail. Check the state of the lubricant regularly, replenish and replace the lubricant in time to prevent the lubricant from deteriorating or contaminating. 3.Prevent overload and impact: Overload and sudden impact loading should be avoided when using Linear Guide Rail. Overload will cause the wear of the guide rail to increase, reduce its accuracy and service life. When designing and using the system of linear guide rails, the load should be reasonably arranged according to the load-bearing capacity and working requirements of the guide rails, and necessary buffering and shock-absorbing measures should be taken. 4.Regular inspection and adjustment: Regularly inspect the Linear Guide Rail, including the flatness, straightness and clearance of the guide rail. Professional measuring tools can be used for detection, such as level, laser interferometer, etc. If deviation or wear of the guide rail is found, it should be adjusted or the relevant parts replaced in time. At the same time, check whether the fixing bolts and connectors of the guide rail are loose. If they are loose, tighten them in time. 5.Storage precautions: If the Linear Guide Rail needs to be stored for a long time, appropriate protective measures should be taken. Wipe the surface of the guide rail clean, apply a layer of anti-rust oil or lubricant, and wrap it with plastic film or oil paper. The storage environment should be kept dry and ventilated, avoiding direct sunlight and high temperature environment. The status of the guide rail should be checked regularly during storage, and any abnormalities should be handled in time.

Source:https://community.networkofcare.org/blogs/amber_stepper_motor/archive/2025/03/20/main-functions-and-maintenance-methods-of-linear-guide-rail.aspx

0 notes

Text

Rouge [from the other side of the house]: Shadow, help me! Shadow [sprints to Rouge's room. Knocks on her door]: Rouge? Rouge: I'm in the bathroom! Shadow: Shall I come back at a better time? Rouge: Get in here! Hurry! Shadow [sprints to the closed door and raises a fist] Rouge: Don't you dare knock! [Shadow enters and sees Rouge holding her arm while panting.] Shadow: Hello. Rouge: I slipped in the shower. I think I dislocated my shoulder. Shadow: Not surprising. You have no safety mat or adhesive stickers to allow for purchase on a surface with a low coefficient of static friction. Rouge: Really? Again? Now? Shadow: Tubs are slippery. Rouge: I know. I slipped. Will you just turn the water off and help me up? Shadow [helps her out] Rouge: Oh, my God. I gotta go to the emergency room. Shadow: Assuming you're correct that your humerus is no longer seated in the glenoid socket, I would think so. Rouge: Please, get me some clothes. Shadow [guides her to the room and opens her closet]: I see you've also turned a deaf ear to my recommendation to an organizational system. Rouge: Shadow, top and shorts, please. We're in a hurry. Shadow [takes some out] Rouge: Ugh, that top with those shorts? Shadow [takes another outfit] Rouge: No… No, not that one eith-- Oh, that's so cute! Shadow [gives the clothes a judgemental look]: We should have you checked for a concussion. [AT THE HOSPITAL] [Rouge is sitting on a chair, holding her arm. Shadow comes back with some papers and a pen] Shadow: We have to fill these out. "Describe illness or injury." Rouge: …I dislocated my shoulder. Shadow: All right. And "how did the accident occur?" Rouge: You already know that. Shadow: True. Cause of accident: lack of adhesive ducks. Rouge: … Shadow: Okay, medical history. Have you been diagnosed with diabetes? Rouge: No. Shadow: Kidney disease? Rouge: No. Shadow: Migraines? Rouge: Getting one. Shadow: Okay. Moving to psychiatric disorders. "List all major behavioral diagnoses, e.g. depression, anxiety, etc." Rouge: What the hell does this have to do with my stupid shoulder?! Shadow: …Episodes of sub-psychotic rage.

#incorrect quotes#sth#sonic fandom#sonic movie universe#shadow the hedgehog#rouge the bat#shadow and rouge#source: big bang theory

16 notes

·

View notes

Text

This came up on my FYP feed and I thought it would be super fun to do in honor of NaNoWriMo.

20 Questions

1. How many works do you have on AO3?

I have 30: 2 series, 5 WIPs, and a whole bunch of one shots 😁

2. What's your total AO3 word count?

134,500. Not sure how I hit an even number, but that's fun!

3. What fandoms do you write for?

Mostly Korrasami (The Legend of Korra) and JEmily (Criminal Minds), but I have written for WarriorBard (Xena Warrior Princess), Ramvers (Captain Marvel), and Pricefield (Life is Strange). I'm working on originals, too, but that's neither here nor there.

4. What are your top 5 fics by kudos?

Fuck Was I

The Consequences of Jello

Profiles and Princesses

Measure the Coefficient of Static Friction Between Us

The Violets in the Mountains Have Broken Rocks

5. Do you respond to comments? Why or why not?

Always. I always respond to comments. It's so fun interacting with readers, and often, other writers. I've made a few friends from it and it's been so great. I have been known to drop off the face of the earth so I don't answer for a long ass time, but j always answer. Plus, I think it's a great way to show appreciation for those taking the time to interact. I love those emails telling me a fic has a comment. I poured so much of myself and my time into something and someone took the time to say something about it! It's pure magic.

6. What's the fic you wrote with the angstiest ending?

I think my fics are all HEAs, honestly. But there's a healthy dosing of angst throughout a lot of them.

7. What's the fic you wrote with the happiest ending?

Probably any of them, but Fuck Was I if I had to choose.

8. Do you get hate on fics?

I did and I have. A fellow writer once called it "flaming troll shit" and since I changed my perspective to see it that way, I A) am considerably less bothered, and B) haven't really noticed it since.

9. Do you write smut? If so, what kind?

I do write smut. I write the type of smut I want to read and it's always evolving. I don't really do like, BDSM (love to read it, don't have much urge to write it, though), but I'll throw in some kink once in a while. Really, I guess I just like to write real sex. The emotions, the connection, the want.

10. Do you write crossovers? What's the craziest one you've written?

Honestly, no. It's never really been something on my radar. It feels like a lot to keep track of or to meld and that's just a lot. Kudos to those who can and do, though.

11. Have you ever had a fiction stolen?

I really hope not. Imitation is the sincerest form of flattery, but plagiarism is illegal, kids.

12. Have you ever had a fic translated?

Not that I'm aware of.

13. Have you ever co-written a fic before?

I have not. I have a beta reader (shout out to ireallyshouldnt_behere) who tells me if I'm an idiot or gives me suggestions, but we haven't moved into the realm of actual co-author (yet). We have joked about it before, and I would love to try a co-writing fic with someone.

14. What's your all-time favorite ship?

Honest to God, JEmily. I had this theory when Criminal Minds first started back in the day that Emily and JJ got a little too drunk one night and clothes came off, that it turned into a thing. And then Will came along and Emily had to go and break her own damn heart because she didn't think she was good enough or JJ would be in danger being with her. Which is funny, given the Lauren arc, but I digress. But also, Xena and Gabrielle, always, because I grew up on XWP and those two were so obviously in love.

15. What's a WIP you want to finish but doubt you ever will?

A novel I started writing 12 years ago 🤣 I love the concept and the characters and what I want to do with it, where I expect it to go. But holy fuck, it's been tedious. I have like...40k words of just bullshit that's not even really connected.

16. What are your writing strengths?

Emotions. Sometimes tension. Angst. Smut.

17. What are your writing weaknesses?

Dialogue. And moving from point A to point B. Sometimes grammar (and that annoys me most of all).

18. Thoughts on writing dialogue in another language for a fic?

I've done it, but let's be honest, it's Google translated because I'm American and for some reason we think English is the only language...

19. First fandom you wrote for?

Legend of Korra. I had read something that just made my head hurt and I thought "I can write better than that!" Spoiler alert, that's a really shitty reason to write something and no, you can't always 'write something better.' Plus, everyone is different: voice, styles, confidence, all that. Anyway, I cranked out a random idea (Living on a Spare) I thought was funny, and here we are.

20. Favorite fic you've ever written?

Oh, why do you make me choose? That's a really good question. I think Chaos Theory (at least at the moment). I just found a bunch of bad pick-up lines and turned them into something ridiculous.

Just for funsies, I'mma tag @thewillowtree3 @blackbird-brewster @cargopantsprentiss @ahhhsami and hope you guys do it but really it's up to you! Cheers, yo!

#ao3#ao3 fic#ao3 fanfic#ao3 writer#writing#writer#fanfic#fanfic writer#fanfic writing#nanowrimo#for fun#wlw fanfic#wlw love#wlw#lesbian#lgbtqia

2 notes

·

View notes

Text

The wear resistance coefficient of PTFE sheet

PTFE sheet is very wear-resistant. It ranks as one of the best plastics for wear resistance. PTFE sheet is much more wear-resistant than nylon, polypropylene, and polytetrafluoroethylene. It is also four times more wear-resistant than carbon steel and stainless steel. The friction coefficient of PTFE sheet is very low. The static friction coefficient ranges from about 0.04 to 0.1. Meanwhile, the dynamic friction coefficient is roughly between 0.01 and 0.04. When PTFE touches other materials, it has very little friction. In various scenarios where we need to reduce friction, we find that PTFE sheet is an ideal material. PTFE has the best wear resistance of any plastic. Its wear resistance is much higher than nylon, polypropylene, and even polytetrafluoroethylene. In fact, it is four times better than carbon steel and stainless steel. The abrasion index of mortar is much lower than that of plastics, cast iron pipes, and carbon steel pipes.

Load: When the load goes up, the friction coefficient of the PTFE sheet goes down. This happens when the material surfaces touch more closely. This contact makes it harder for them to move against each other.

Sliding speed: At low speeds, the friction coefficient stays steady. As speed goes up, the friction coefficient might drop at first. But if the speed gets too high, the friction coefficient can rise due to heat from friction.

Surface roughness: The roughness of the material in contact with the PTFE sheet affects its friction coefficient. A rough surface boosts mechanical interlocking, which raises the friction coefficient. In contrast, a smooth surface lowers the friction coefficient.

Temperature: Normal range is -190°C to 260°C. Higher temperatures lower the friction coefficient. High temperatures can change the material in both physical and chemical ways. This change can affect the friction coefficient.

PTFE sheets have a broad application prospect in various industrial fields. Their strong performance gives them special functions. This brings great convenience to industrial production. As technology keeps advancing, we expect the use of PTFE sheets to grow.

1 note

·

View note