#Working and Principle of Tablet Coating Machine

Explore tagged Tumblr posts

Text

Working and Principle of Tablet Coating Machine

Working and Principle of Tablet Coating Machine.

Working and Principle of Tablet Coating Machine: Tablet coating is a critical process in pharmaceutical manufacturing, enhancing the appearance, shelf life, and taste of tablets. The Working and Principle of Tablet Coating Machine are integral to this process. These machines apply a thin layer of coating material to tablets, which can serve various purposes, from masking the taste to controlling…

View On WordPress

0 notes

Text

The Fluid Bed Dryer Granulator: Your All-in-One Processing Solution

In the world of pharmaceutical, chemical, and food processing, efficiency and quality are paramount. Manufacturers are constantly seeking equipment that can streamline operations while delivering consistent, high-grade products. Enter the fluid bed dryer granulator – a versatile workhorse that offers a compelling solution to various processing needs.

What is a Fluid Bed Dryer Granulator (FBD)?

A fluid bed dryer granulator, often shortened to FBD fluid bed dryer, is a single piece of equipment that combines two essential processes: drying and granulation. It utilizes the principle of fluidization, where a bed of solid particles is suspended and agitated by an upward stream of heated air or gas. This creates a fluid-like state, ensuring efficient heat and mass transfer.

How Does it Work?

Drying: Wet granules, powders, or slurries are introduced into the fluid bed dryer.

Fluidization: Heated air is blown through the material from the bottom, causing the particles to lift and suspend, creating a fluidized bed.

Drying: The hot air efficiently removes moisture from the particles due to the increased surface area and intimate contact.

Granulation (Optional): For granulation, a binding solution is sprayed onto the fluidized particles. The particles collide and adhere, forming larger granules.

Drying (Continued): The newly formed granules are dried within the same chamber, ensuring a consistent final product.

Benefits of Using an FBD Fluid Bed Dryer

Efficiency: Combining drying and granulation in one unit saves time, labour, and floor space compared to using separate machines.

Uniformity: The fluidization process ensures uniform drying and granulation, resulting in consistent particle size and quality.

Improved Flowability: Granulation enhances the flow properties of powders, making them easier to handle and process.

Versatility: Fluid bed dryer granulators can handle a wide range of materials and particle sizes.

Control: Precise control over parameters like temperature, airflow, and spray rate allows for optimized processing conditions.

Reduced Contamination Risk: Closed processing minimizes the risk of product contamination and dust generation.

Applications of Fluid Bed Dryer Granulators

FBD fluid bed dryers are utilized in several industries, including:

Pharmaceuticals: Drying and granulating pharmaceutical powders for tablets, capsules, and other solid dosage forms.

Chemicals: Processing chemicals, fertilizers, and pesticides.

Food Industry: Drying and granulating food products like instant coffee, powdered milk, and flavourings.

Types of Fluid Bed Dryers

Several types of fluid bed dryers are available, each with unique features and applications:

Top-Spray Fluid Bed Dryer: The most common type, where the binding solution is sprayed from the top onto the fluidized bed.

Bottom-Spray Fluid Bed Dryer (Wurster Coater): Used for coating particles or granules with a precise layer of material.

Tangential-Spray Fluid Bed Dryer: Employs a horizontal spray pattern for efficient drying and granulation of fine powders.

Choosing the Right Fluid Bed Dryer

Selecting the appropriate fluid bed dryer granulator depends on several factors:

Material properties: Consider the particle size, density, and moisture content of your material.

Desired particle size and shape: Determine the required granule characteristics for your final product.

Production capacity: Choose a dryer with the appropriate batch size and throughput for your needs.

Process requirements: Consider specific needs like temperature control, automation, and containment.

Conclusion

The fluid bed dryer granulator is a versatile and efficient processing solution for a wide range of industries. By combining drying and granulation in a single unit, it offers significant advantages in terms of productivity, quality, and cost-effectiveness. When selecting an FBD, careful consideration of your specific material properties, process requirements, and production goals is crucial to ensure optimal performance and successful product development.

0 notes

Text

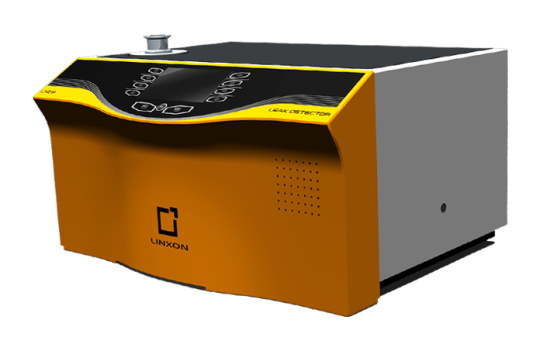

Exploring Advanced Vacuum and Helium Leak Detection Solutions

In industries ranging from manufacturing to research, vacuum systems play a pivotal role in ensuring operational efficiency and product quality. Among the various technologies available, rotary vane vacuum pumps, dry vacuum pumps, helium leak detectors, helium leak testing machines, and helium recovery systems have become essential tools. Let’s dive into the functionalities and applications of these systems to better understand their impact.

Rotary Vane Vacuum Pump: Reliable Performance in a Compact Design

The rotary vane vacuum pump is one of the most commonly used types of vacuum pumps. Its compact design, reliability, and versatility make it suitable for various applications. The pump operates by using vanes that rotate inside a cylindrical chamber, creating a vacuum by displacing air or other gases.

Applications:

Medical and Laboratory Equipment: Rotary vane vacuum pumps are used in medical applications such as vacuum-assisted wound closure systems and laboratory vacuum systems.

Packaging Industry: These pumps are integral to vacuum packaging machines, ensuring products remain fresh by eliminating air from packaging.

HVAC Systems: In heating, ventilation, and air conditioning systems, rotary vane pumps help in refrigerant recovery and evacuation processes.

Key benefits of rotary vane vacuum pumps include their durability, low noise operation, and ease of maintenance.

Dry Vacuum Pump: Oil-Free Efficiency for Sensitive Processes

Unlike rotary vane pumps, dry vacuum pump operate without the use of oil or any other sealing liquid. This makes them ideal for processes where contamination must be avoided.

Advantages of Dry Vacuum Pumps:

Clean Operation: With no oil involved, these pumps prevent contamination of the pumped gases or the environment.

Energy Efficiency: Many dry vacuum pumps are designed to consume less energy, reducing operational costs.

Low Maintenance: Without oil changes or sealing fluid replacement, maintenance requirements are minimal.

Common Applications:

Pharmaceutical Industry: Dry vacuum pumps are used in tablet coating and other sensitive pharmaceutical processes.

Semiconductor Manufacturing: These pumps play a critical role in processes like chemical vapor deposition and etching, where cleanliness is paramount.

Food Processing: Dry vacuum pumps are used in freeze-drying and vacuum cooling applications.

Helium Leak Detector: Precision in Leak Detection

Helium leak detector are essential tools for identifying and quantifying leaks in sealed systems. Helium is an ideal tracer gas due to its small molecular size and inert properties, making it capable of detecting even the tiniest leaks.

Working Principle:

A helium leak detector typically consists of a mass spectrometer that senses the presence of helium within a system. When helium is introduced into the system under test, the detector identifies any escaping helium, pinpointing leaks with high accuracy.

Key Applications:

Automotive Industry: Helium leak detectors are used to ensure the integrity of fuel systems, air conditioning systems, and exhaust systems.

Aerospace Sector: Ensuring leak-tight components in critical aerospace systems, such as fuel tanks and propulsion systems.

Medical Devices: Used in testing the hermeticity of medical implants and diagnostic equipment.

The precision and reliability of helium leak detectors make them indispensable for maintaining safety and quality standards.

Helium Leak Testing Machine: Comprehensive Leak Testing Solutions

A helium leak testing machine is a complete system that incorporates a helium leak detector, pumping systems, and control units to automate the leak testing process. These machines are tailored to meet the specific requirements of various industries.

Features and Benefits:

Automation: Automated testing reduces human error and increases throughput.

Customizability: Machines can be designed for specific applications, such as testing automotive radiators, batteries, or high-pressure vessels.

High Sensitivity: These systems can detect leaks at the micro-level, ensuring the highest standards of quality control.

Industrial Applications:

Energy Sector: Used for testing high-pressure gas cylinders and pipelines.

Electronics Manufacturing: Ensures the integrity of sealed electronic components such as sensors and displays.

Vacuum Technology: Essential in testing vacuum chambers and components for scientific and industrial applications.

Helium Recovery System: Sustainability in Leak Detection

As the demand for helium increases and its availability decreases, helium recovery system have become a critical component of modern leak detection setups. These systems capture and recycle helium, reducing operational costs and environmental impact.

How Helium Recovery Systems Work:

Capture: Helium used in the testing process is captured from the test environment.

Purification: The captured helium is purified to remove contaminants.

Storage: The purified helium is stored for reuse in subsequent tests.

Advantages:

Cost Savings: Reducing the need for new helium purchases can significantly cut costs.

Environmental Benefits: Minimizing helium waste supports sustainable operations.

Enhanced Efficiency: Continuously recycled helium ensures a steady supply for testing operations.

Applications:

Manufacturing Plants: Ideal for large-scale operations where helium usage is high.

Research Facilities: Ensures a sustainable supply of helium for experiments and testing.

Aerospace Industry: Critical for testing and maintaining expensive and sensitive components.

The Future of Vacuum and Leak Detection Technologies

With advancements in technology, vacuum systems and helium leak detection solutions are evolving to meet the growing demands of precision, efficiency, and sustainability. Integration with IoT and smart systems enables real-time monitoring and diagnostics, reducing downtime and increasing productivity. Moreover, the push toward eco-friendly solutions is driving the adoption of oil-free and helium recovery systems.

Final Thoughts:

Whether it’s a rotary vane vacuum pump ensuring efficient vacuum creation, a dry vacuum pump delivering oil-free operation, or a helium leak detector safeguarding the integrity of critical systems, these technologies are indispensable. Helium leak testing machines and helium recovery systems further enhance efficiency and sustainability, making them vital in today’s industrial landscape.

By understanding and implementing these advanced systems, industries can achieve higher standards of quality, safety, and environmental responsibility.

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes

Text

Progress

He thought that the scientists had been born without compassion or mercy, and that had been a requirement in their field to achieve any real progress. Certainly the quest for new heights in science, medicine and other such fields had contributed to that chilling lack of qualities that many considered to be the essential mark of humanity. They could only go so far with predictions and tests, and only a little further still with animal experiences. They needed him, and he knew it.

Sometimes he could imagine them laughing, but it was a mechanical laugh, as if they couldn’t even appreciate the result of their lengthy work. That scared him – that they made progress for progress’s sake, and not for any personal desire or even any faint notions of propelling humanity to new levels of perfection.

He remembered to blink.

Soon they would come in their white coats and dead stares, with their syringes and tablets and charts. Although they had restrained him well, he knew that their strongmen would come also, if only to enforce obedience. He had no fear of physical pain and only dim thoughts of rebellion. How could he? Before and during the experiments they had tortured him psychologically, physically and mentally, and although they were cruel they knew his limits well - perhaps they knew because of their cruelty - and they had stopped short of breaking him entirely. Their aim, however, had been achieved – they had robbed him of hope through their systematic abuse.

He remembered to swallow.

Those thoughts of rebellion were disturbingly born from principle, as if the only reason for rebelling should be because it was his duty, or it was expected of him, and not because he genuinely objected to their treatment of him. That would have scared him deeply, but with each passing day he became more and more resigned to his fate, as those dim thoughts faded. Hope had left him – willpower followed it. He did not wish or hope to die, but he knew he would.

He was becoming less than human, and he screamed as he realised that it made him more like the scientists.

Even the scream lacked any will.

He remembered to breathe. They would not let him asphyxiate in any case.

The scream drew him, but they did not hurry. Perhaps the scientists had finally converted to machines – they were not human to begin with, and it would not have been difficult. He knew that he was not the only experiment in this place. One by one they entered his room, five in total including the strongman. They surrounded his table, those machines walking.

He blinked again. Their drug had torn the skill from him and relearning it was a struggle.

One carried a syringe. He recognised none of them, and in a rare flash of understanding he realised he hadn’t seen any of them before. Indeed, had he ever seen the same one twice? He couldn’t remember, but he didn’t think the drug affected his memory. The detail was simply not important – a familiarity with any of them disgusted him, even in his listless state, and it wouldn’t have helped in any case.

The syringe wielder lifted it and placed it against the intravenous port and ejected the drug into it.

This was their last experiment.

As his last automatic function stopped, he didn’t even scream.

Only humans screamed.

Credit to: Archfeared

0 notes

Text

Exploring the Intricacies of Pharmaceutics: From Ball Mills to Tablet Coating Machines

Pharmaceutics, the science of preparing and dispensing drugs, is a field that is constantly evolving with technological advancements. In this blog, we delve into three key aspects of pharmaceutics: the Any Maze software, ball mills, and tablet coating machines.

All Maze is a versatile software used in behavioral research. It’s designed to automate the process of tracking and analyzing the behavior of animals in experiments. The software is highly customizable, allowing researchers to tailor their experiments to their specific needs. It’s an invaluable tool in the field of pharmacology, where it’s often used to study the effects of drugs on animal behavior.

Moving from software to machinery, let’s discuss ball mill in pharmaceutics. A ball mill is a grinding machine popularly used in pharmaceutics for the size reduction of drugs. Size reduction is a crucial process in the production of pharmaceuticals as it improves the rate of absorption of drugs in the body. The ball mill works on the principle of impact and attrition: the drug particles are fed into a cylinder containing balls, and the rotation of the cylinder causes the balls to grind the drug into a fine powder.

Lastly, we turn our attention to tablet coating machines. These machines are used to coat the surface of tablets with a thin layer of coating material. Tablet coating serves several purposes: it can mask the taste of the drug, enhance its appearance, and control the release of the drug into the body. The coating process involves spraying the tablets with a coating solution while they are being rotated in a pan. The result is a uniformly coated tablet that is easier to swallow and more effective in delivering the drug.

In conclusion, the Any Maze software, ball mills, and tablet coating machines each play a unique role in the field of pharmaceutics. By understanding these tools, we can appreciate the complexity and precision involved in drug preparation and dispensing. As technology continues to advance, we can expect to see even more innovative tools and techniques in the field of pharmaceutics.

0 notes

Text

How does the high-speed rotary tablet press machine work?

In the world of pharmaceutical manufacturing, high-speed rotary tablet press machines play a crucial role in producing a vast array of tablets efficiently and accurately. These machines are designed to transform powdered or granulated materials into solid tablets of uniform size, shape, and weight. Behind their seemingly simple operation lies a complex interplay of mechanical, electrical, and hydraulic systems. In this blog post, WECAPS will delve into the working principle of high-speed rotary tablet press machines, exploring the intricate mechanisms that enable them to deliver high-quality tablets at an impressive production rate.

Overview of High-Speed Rotary Tablet Press Machines

High-speed rotary tablet press machines are advanced pharmaceutical equipment used for mass production of tablets. They consist of several key components, including a hopper, feeder, turret, punches and dies, compression rollers, and control systems. The process begins with the feeding of powdered or granulated materials into the hopper, which then delivers the material to the feeder. The feeder ensures a consistent flow of material into the die cavities located on the turret.

Working Principle of Automatic High-Speed Rotary Tablet Press Machine

1. Filling and Compression

Once the material is in the die cavities, the filling and compression stages take place. The turret rotates, bringing the die cavities under the punches. As the punches descend, they compress the material, forming it into a tablet. The compression force applied by the punches is carefully controlled to ensure uniform tablet hardness and thickness.

To achieve high-speed production, modern rotary tablet press machines employ a variety of mechanisms. One such mechanism is the pre-compression station, which applies a preliminary force to the material before the main compression stage. This pre-compression helps eliminate air and voids from the material, resulting in denser tablets.

2. Ejection and Collection

After compression, the tablets are ejected from the die cavities. This is typically achieved using a lower punch, which pushes the tablet out of the die. The ejected tablets then move along a conveyor system or chute for collection. To prevent sticking or damage, the tablets may undergo additional processes, such as polishing or coating, before they are ready for packaging.

3. Control Systems and Safety Features

High-speed rotary tablet press machines are equipped with advanced control systems to ensure precise operation and safety. These systems monitor various parameters, such as tablet weight, thickness, and hardness, and make real-time adjustments to maintain quality standards. Safety features, such as interlocks and sensors, are also incorporated to prevent accidents and protect operators.

4. Maintenance and Optimization

To ensure the longevity and optimal performance of a high-speed rotary tablet press machine, regular maintenance is essential. This includes cleaning, lubrication, and inspection of critical components. Additionally, periodic calibration and adjustment of the machine's settings are necessary to maintain tablet quality and production efficiency.

The working principle of high-speed rotary tablet press machines involves a sophisticated combination of mechanical, electrical, and hydraulic systems. From feeding and compression to ejection and collection, every step is carefully designed. In manufacturing industries such as pharmaceuticals or nutraceuticals, the high-speed presses enable rapid production while maintaining product integrity.

Related Products

WECAPS GZP620 Series High Speed Rotary Tablet Press

This machine is one kind of double side rotary tablet press machine, which can press granular materials into round shape tablet, irregular tablet or double-side engraved tablet. It is mainly used in pharmaceutical, chemistry, foodstuff, electronic industries.

1.High speed with large quantity punches, double press rollers, suitable for mass production.

2. Made of stainless steel, the housing is fully closed. The surface of the rotary turret is covered with a hardened layer so that the turret surface is wear resistant. The machine conforms to GMP requirements.

3. Perfect tableting system, twice compression forming, reasonable framework with proper space and big pressure roller, machine performance is reliable and no tablet weight difference.

4. Double impeller type force feeder, improve granules flow-ability and filling performance, ensure the filling precision.

5.Tooling track adopt double-side lifting structure, the punches are balanced stress and wear resistance.

6. High performance electrical control system, ensure each program processing precisely.

7.Automatic oil&grease central lubrication system, ensure the lubrication of pressure rollers, toolings and tracks, extending the working life of the machine.

8. Special oil proof, dust proof and noise proof design.

#rotary tablet press machine#high-speed rotary tablet press machine#automatic rotary tablet press machine#double rotary tablet press machine#pharmaceutical machine

0 notes

Text

Complete Guide of All Pharmaceutical R&D Equipment

Coating Machines

Efficient Small-Batch Tablet Coating Solution for Pharmaceutical R&D.

The Pharma R&D Tablet Coater is a groundbreaking, self-contained film coater designed for smaller trial batches of tablets and granules. Its sleek exterior is made of durable SS 304 stainless steel, and it features a precision-coating pan positioned at a tangential angle of 35° to 45°, ensuring efficient and uniform coating for pharmaceutical research and development.

pharmaceutical research and development – the R&D tablet coating machine.

The R&D Coater is a versatile and semi-automatic unit designed for pharmaceutical research and development. This integrated system comprises a stainless steel coating pan, a precision spraying system, a hot air blower, and an efficient exhaust system. It harnesses the rotary motion of the coating pan to gently tumble the tablets or granules contained within it. Inside the pan, strategically placed baffles tilt the contents to ensure uniform and efficient coating.

For film coating, a specialized spray gun is employed to disperse finely nebulized droplets of the coating solution onto the moving bed, ensuring consistent coverage across all tablets. To complete the process, a stream of hot air is directed onto the tablet bed, with the exhaust temperature ranging between 60°C and 80°C, enhancing overall performance.

The advanced control panel offers precise control over various settings, including temperature and rotation speeds, allowing for tailored adjustments to meet specific research needs. When introducing tablets or granules into the pan or retrieving them, a scoop should be used. The optimal parameters for coating should be determined through experimentation and trials, ensuring the highest quality results in pharmaceutical research and development.

Fluidized Bed Processor

The Fluidized Bed Processor is a versatile solution tailored for the research and development needs of various industries, including pharmaceuticals, chemicals, food production, and academic institutions like pharmacy colleges. Its primary functions involve coating and drying pellets, allowing for a wide range of applications, such as:

Color Modification: Altering the color of pellets for specific requirements.

Improved Taste: Enhancing the taste of pharmaceutical or food products.

Modified Release: Achieving controlled and modified release forms.

Moisture and Oxygen Protection: Safeguarding products from environmental factors.

Granulation Machine

A rapid mixer granulator is a pharmaceutical equipment designed for the efficient mixing and granulation of powders to produce uniform and high-quality granules. It plays a crucial role in the pharmaceutical industry, particularly in tablet manufacturing. The key components of a rapid mixer granulator include a cylindrical mixing bowl, an impeller, and chopper blades. The mixing bowl accommodates the dry powders or granules, and the impeller provides rotational movement, creating a vortex within the bowl. Simultaneously, the chopper blades introduce additional shearing forces, breaking down agglomerates and ensuring thorough mixing.

The working principle of a rapid mixer granulator involves a series of sequential steps to achieve optimal granulation. Initially, dry powders or granules are loaded into the mixing bowl. As the impeller and chopper blades rotate, they create a controlled and dynamic mixing environment. A liquid binder is then added to the rotating powder bed, leading to the formation of wet mass. The impeller and chopper blades work together to break down any lumps, disperse the liquid binder uniformly, and induce granulation. The resulting granules exhibit improved flow properties, uniform size distribution, and enhanced compressibility, making them ideal for subsequent tablet compression processes in pharmaceutical manufacturing.

Fluid Bed Top Coater

A fluid bed top coater is a pharmaceutical processing equipment designed for coating granules or particles with a thin layer of coating material. This coating process is commonly used in the pharmaceutical industry to enhance the properties of the granules, such as taste masking, controlled release, or protection of active ingredients. The equipment consists of a perforated bed through which air is blown, creating a fluidized bed of granules. The coating material is sprayed onto the fluidized granules, ensuring even distribution and uniform coating.

The working principle of a fluid bed top coater involves several steps. Initially, the granules to be coated are placed in the fluidized bed. Air is then introduced at a controlled rate, creating a fluidized state where the granules become suspended and behave like a fluid. This fluidized bed provides an ideal environment for uniform coating. The coating material, often in the form of a liquid solution or suspension, is sprayed onto the fluidized granules through a nozzle system. The fluidized state ensures that each granule receives an even and consistent coating. After coating, the granules are dried by continued airflow until the desired coating thickness is achieved. The fluid bed top coater's efficient and precise coating process is crucial for achieving the desired pharmaceutical product characteristics.

lab-scale fluid bed dryer

A lab-scale fluid bed dryer is a small-scale version of the industrial fluid bed dryer and is widely used in laboratory settings for drying, granulating, and coating small quantities of pharmaceutical or chemical materials. It operates on the principle of fluidization, where air is used to fluidize and suspend particles, creating an efficient drying or coating environment. The equipment typically consists of a drying chamber, a perforated bed, a fan system, and controls for temperature and airflow.

In its working process, the lab-scale fluid bed dryer first places the material to be dried or processed on the perforated bed within the drying chamber. Air is then forced through the bed from below, causing the particles to become suspended and behave like a fluidized mass. This fluidized state allows for efficient heat transfer, leading to rapid and uniform drying of the material. The temperature and airflow are controlled to achieve the desired drying conditions.

For coating applications, a liquid coating material can be sprayed onto the fluidized particles, ensuring a uniform and controlled coating thickness. The lab-scale fluid bed dryer is advantageous for research and development purposes, allowing scientists and researchers to experiment with different drying or coating parameters on a smaller scale before scaling up to industrial production.

Lab-Scale Extruder & Spheronizer Combo

Lab-Scale Extruder and Spheronizer Combo is a seamlessly integrated system poised to redefine granulation in formulation research and product development. The Extruder component, featuring four interchangeable heads, facilitates versatile low-pressure granulation techniques on a bench-top scale, accommodating batches as small as 200 grams. Its adaptability and indicative results make it a cost-effective and efficient solution for evaluating diverse formulations.

Complementing the Extruder, the Spheronizer component offers precise control over spheronization processes, featuring a substantial 230 mm diameter friction plate capable of producing spheres ranging from 0.5 mm to 10.0 mm. With user-friendly features such as easy disassembly, GMP design, variable plate speeds, and a dedicated stainless steel control panel, this dynamic duo empowers researchers and product developers to seamlessly progress from extrusion to spheronization, unlocking new possibilities for innovation in pharmaceuticals, chemicals, and the food industry. The Extruder and Spheronizer Combo stand as a cohesive and powerful platform, representing a significant leap forward in granulation technology.

Lab-Mini Screw Extruder: Tailored Solutions for Pharmaceutical Pelletization

A mini screw extruder is a compact and versatile piece of equipment used in laboratories or small-scale production settings for extruding and processing various materials. It operates on the principle of using a rotating screw to push, melt, and shape materials into a desired form. This equipment is commonly employed in the plastics, food, and pharmaceutical industries for tasks such as compounding, mixing, and forming different shapes.

In its working process, the mini screw extruder takes raw materials in solid or pellet form and feeds them into the extrusion chamber. The rotating screw applies heat and pressure, causing the material to soften and take on the desired shape as it passes through the die. The mini screw extruder's compact size and adaptability make it a valuable tool for small-scale experimentation and development of new formulations or processes.

Lab Mini Spheronizer

A Mini Spheronizer is a laboratory-scale equipment used in pharmaceutical and chemical industries for spheronization, a process that involves shaping and rounding extruded material into spherical pellets or beads. It operates by rotating a disc at high speeds, causing the extruded material to form spherical shapes through constant rolling and friction.

Hot Melt Extruder

A Hot Melt Extruder is a compact apparatus used for pharmaceutical and polymer processing. It employs heat to melt and extrude materials, facilitating the production of solid dispersions, implants, or controlled-release formulations. This equipment is particularly useful for processing thermolabile substances by minimizing exposure to high temperatures.

Die Roller Extruder

A Die Roller Extruder is a machine designed for the continuous extrusion of various materials, including plastics and pharmaceutical formulations. It consists of rollers that compress and shape the material as it passes through the die. This extrusion process is widely utilized in industries where continuous and uniform shaping of materials is essential, allowing for efficient production of consistent profiles or forms.

All-Purpose Mixing Machine

An all-purpose mixing machine in the pharmaceutical industry is a versatile piece of equipment designed to efficiently blend various ingredients, such as powders, granules, or liquids, to achieve a homogeneous mixture. It plays a crucial role in pharmaceutical manufacturing processes, contributing to the production of formulations like tablets, capsules, and suspensions. These mixing machines are adaptable to different batch sizes and offer flexibility in accommodating diverse formulations and production requirements.

The working principle of an all-purpose mixing machine involves the integration of a mixing vessel or bowl, agitators, and sometimes choppers or blades. The dry or liquid components are loaded into the mixing vessel, and the agitators create rotational or shearing forces to ensure uniform distribution of the ingredients. Choppers or blades may be employed to break down agglomerates and further enhance mixing. The speed and duration of the mixing process are controlled to achieve the desired level of homogeneity. The all-purpose mixing machine is crucial for maintaining product quality, consistency, and meeting regulatory standards in pharmaceutical manufacturing.

A Table Top Transdermal Patch Machine

A Table Top Transdermal Patch Machine in the pharmaceutical industry is a compact and specialized apparatus used for the production of transdermal patches. These patches are designed to deliver medication through the skin, providing a controlled and sustained release of the active pharmaceutical ingredient. The table-top version is typically smaller in scale, making it suitable for laboratory or research settings where small batches of transdermal patches can be developed and tested.

The working principle of a Table Top Transdermal Patch Machine involves the precise combination of drug-containing adhesive layers, backing materials, and protective liners. The machine applies pressure and heat to laminate these layers, ensuring a consistent and reliable transdermal patch. The compact design allows for ease of use in smaller-scale experiments, making it a valuable tool for researchers and formulation scientists.

Advanced TDP & ODF Machine Pilot Scale

An Advanced TDP & ODF Machine Pilot Scale is a sophisticated piece of equipment used for the development and production of transdermal patches and orally disintegrating films (ODFs) on a larger pilot scale. This machine integrates advanced features to handle increased production volumes and maintain precise control over the manufacturing process. It is crucial in the pharmaceutical industry for scaling up the production of transdermal patches and ODFs, both of which are innovative drug delivery systems.

In operation, the Advanced TDP & ODF Machine Pilot Scale follows a similar principle to the table-top version, involving the precise assembly of multiple layers and the application of pressure and heat to create transdermal patches or ODFs. The advanced features of this machine enhance efficiency, accuracy, and scalability, making it an integral part of the pharmaceutical manufacturing process for these specialized drug delivery systems.

Maze Master Software Interface and Digital Plethysmometer

Behavioral instruments such as the Maze Master Software interface and Digital Plethysmometer play crucial roles in experimental setups focused on assessing and quantifying animal behavior in research settings. The Maze Master Software interface is a tool designed for managing and analyzing data from behavioral experiments conducted in mazes. It provides a user-friendly platform to control maze environments, record animal movements, and analyze behavioral metrics. Researchers can customize experiments, track parameters, and obtain valuable insights into aspects like learning, memory, and spatial navigation.

The Digital Plethysmometer is an instrument used to measure changes in blood flow and volume in small animal extremities, often tails, for assessing peripheral perfusion. This device aids in studying vasomotor responses and is particularly valuable in cardiovascular and pharmacological research. The plethysmometer records changes in limb circumference or blood volume based on alterations in infrared light transmission. Researchers can use this data to understand vascular reactivity and evaluate the effects of various interventions on peripheral blood flow.

Both instruments contribute significantly to the field of behavioral and physiological research by providing accurate, reproducible, and quantifiable data essential for understanding various aspects of animal behavior and physiology.

Radial Arm Maze:

The Radial Arm Maze is a widely used behavioral test in neuroscience and pharmacology to assess spatial learning and memory in rodents. It typically consists of a central platform with multiple arms extending radially. Each arm is baited with a reward, and the subject, usually a rat or mouse, learns to navigate and remember which arms contain the rewards. The working principle involves the rodent relying on spatial cues to efficiently locate and retrieve the rewards while avoiding previously visited arms. Researchers analyze the choices made and the time taken, providing insights into cognitive functions, memory, and spatial navigation abilities.

Morris Water Maze:

The Morris Water Maze is a classic spatial memory and learning test for rodents, particularly mice and rats. It comprises a large pool of opaque water, with a hidden platform submerged just below the water's surface. Animals learn to locate the hidden platform using spatial cues around the room. The working mechanism involves the subjects forming a cognitive map of the environment and adjusting their strategies over trials. Researchers measure parameters like escape latency and path length, offering valuable data on spatial learning, memory consolidation, and cognitive flexibility. The Morris Water Maze is a versatile tool in neuroscience for studying various neurological conditions and the effects of pharmacological interventions.

Open Field Maze:

The Open Field Maze is a commonly used apparatus in behavioral research to assess general locomotor activity, exploration, and anxiety levels in rodents. It consists of a large, open arena with defined zones. The working principle involves placing the animal in the center and allowing it to explore the environment freely. Researchers observe and record behaviors such as distance traveled, time spent in the center versus the periphery, and grooming activities. The Open Field Maze provides insights into anxiety-related behaviors, locomotor activity, and the effects of pharmacological interventions on exploratory behavior in preclinical studies.

Elevated Plus Maze:

The Elevated Plus Maze is a well-established test for evaluating anxiety-like behavior in rodents. The maze features two enclosed arms and two open arms elevated above the ground, creating an approach-avoidance conflict. Animals, typically rodents, are placed on the central platform and can choose between the open and enclosed arms. The working mechanism involves the innate tendency of rodents to explore novel environments while balancing the fear of open spaces. Researchers measure parameters such as time spent in open and closed arms, entries into each arm type, and overall exploration behavior. The Elevated Plus Maze is valuable for studying anxiety-related disorders and assessing the anxiolytic or anxiogenic effects of pharmaceutical compounds.

T-Maze:

The T-Maze is a classic apparatus used in behavioral neuroscience to investigate spatial learning and memory in rodents. Its structure resembles the letter "T," with a stem and two arms forming the crossbar. During a trial, an animal, often a rat or mouse, is placed at the base of the stem and given the choice to turn left or right. One arm is typically baited with a reward, while the other remains unrewarded. The working principle involves the rodent using spatial cues to remember and choose the correct arm containing the reward. Researchers analyze the animal's choices, latency to make a decision, and memory retention, providing valuable insights into spatial cognition and memory processes.

Y-Maze:

The Y-Maze is another widely used apparatus for assessing spatial working memory and spontaneous alternation behavior in rodents. It consists of three arms forming the shape of the letter "Y," and animals are allowed to explore the maze freely. The working mechanism involves the innate tendency of rodents to alternate between the arms during successive entries. Researchers record the sequence of arm entries and analyze the percentage of spontaneous alternations as an indicator of spatial working memory. The Y-Maze is particularly useful in preclinical studies to investigate the effects of drugs or genetic manipulations on short-term memory and spatial cognition.

Zero Maze:

The Zero Maze is a specialized apparatus used in behavioral research to assess anxiety-like behavior in rodents. It consists of a circular platform elevated above the ground with two enclosed areas and two open areas. The circular design aims to create a conflict between the natural exploratory behavior of rodents and their aversion to open spaces. The enclosed areas offer a sense of security, while the open areas induce anxiety. The working principle involves placing the animal in the center of the maze and monitoring its preference for exploring the enclosed or open sections. Researchers analyze parameters such as time spent in open and closed areas, entries into each zone, and the overall anxiety-related behavior. The Zero Maze is valuable for studying anxiolytic or anxiogenic effects of drugs and understanding the neural mechanisms underlying anxiety.

Light/Dark Box:

The Light/Dark Box is a widely used apparatus in behavioral neuroscience to assess anxiety-like behavior in rodents, primarily mice and rats. It consists of two compartments: one brightly illuminated (light compartment) and the other dark and enclosed (dark compartment), connected by an opening. The working mechanism leverages the rodents' natural aversion to brightly lit and open spaces. Animals are placed in the dark compartment and given the choice to explore the light area. Researchers monitor behaviors such as time spent in each compartment, entries, and latency to enter the light area. The Light/Dark Box provides insights into an animal's response to conflicting motivations of exploration and aversion, making it a valuable tool for studying anxiety-related behaviors and evaluating the effects of pharmacological interventions.

Aesthesiometer

An aesthesiometer is a medical instrument designed to measure an individual's sensitivity to tactile stimuli, providing quantitative assessments of their sensory perception. It is commonly used in neurological examinations to evaluate the integrity of sensory pathways and detect abnormalities in touch sensitivity. The instrument typically consists of a calibrated rod or filament with a controlled diameter, which is applied to the skin at varying pressure levels. The examiner adjusts the force applied by the aesthesiometer until the individual being tested perceives the sensation. This threshold of perception is then recorded, allowing clinicians to assess and monitor changes in sensory function, particularly in patients with neurological disorders or peripheral neuropathies.

The working principle of the aesthesiometer involves systematically applying the calibrated filament to specific areas of the skin, such as the fingertips or toes, while gradually increasing the force. The individual undergoing the test provides feedback when they first sense the touch, and the corresponding force or pressure required to elicit the sensation is measured. The aesthesiometer allows for precise and reproducible assessments of tactile sensitivity, aiding in the diagnosis and monitoring of conditions affecting the sensory pathways. Clinicians use this information to evaluate the severity of sensory deficits, track changes over time, and tailor appropriate interventions for patients with sensory impairments.

0 notes

Text

The Future of Pharmaceutical Drying and Coating: FBD Fluid Bed Dryer, Tablet Coater, Water Maze

Introduction:

In the ever-evolving world of pharmaceutical manufacturing, the need for efficient and precise processes has never been greater. Pharmaceutical companies are constantly seeking ways to improve their production methods, ensuring the safety and efficacy of their products while optimizing costs and resources. One significant advancement in this quest for excellence is the integration of cutting-edge equipment, such as the FBD Fluid Bed Dryer, Tablet Coater, and Water Maze system. In this blog post, we will delve into these technologies, exploring their functions and the ways they are shaping the future of pharmaceutical drying and coating.

Understanding the FBD Fluid Bed Dryer

What is an FBD Fluid Bed Dryer?

The FBD Fluid Bed Dryer, or Fluidized Bed Dryer, is a pivotal piece of equipment in pharmaceutical manufacturing. It is widely used to dry granules, powders, and particles, creating a uniform and consistent product quality. This technology relies on the principle of fluidization, which involves passing hot air through a layer of granules, making them behave like a fluid.

How does the FBD Fluid Bed Dryer work?

The FBD Fluid Bed Dryer works by suspending particles in a chamber using a controlled airflow. When hot air is introduced into the chamber, it passes through the layer of particles, leading to fluidization. This process allows for efficient and uniform drying of the pharmaceutical materials. The key features of FBD Fluid Bed Dryer are:

Efficient heat and mass transfer

Short drying times

Enhanced product uniformity

Reduced risk of product degradation

Advantages of using FBD Fluid Bed Dryer in pharmaceutical drying

The use of FBD Fluid Bed Dryer offers several advantages in pharmaceutical drying processes:

Uniform and consistent product quality

Reduced drying time

Energy-efficient operation

Enhanced heat and mass transfer

Precise temperature control

Minimal risk of product degradation

The Future of Pharmaceutical Drying with FBD Fluid Bed Dryer

As pharmaceutical manufacturing continues to evolve, the FBD Fluid Bed Dryer plays a crucial role in achieving higher efficiency, product quality, and cost-effectiveness. We'll likely see further innovations in FBD technology, with even more advanced features and automation, making it an indispensable tool for the future of pharmaceutical drying.

Tablet Coating: Revolutionizing Pharmaceutical Manufacturing

What is a Tablet Coater?

Tablet coating is a vital step in the pharmaceutical manufacturing process, serving multiple purposes, including masking the taste of the tablet, enhancing its appearance, and protecting it from environmental factors. A Tablet coat is a machine designed to apply a thin, uniform layer of coating material to tablets, capsules, or pellets.

How does a Tablet Coater work?

Tablet Coaters work by placing the tablets in a rotating drum and then spraying the coating material onto them. The rotation of the drum ensures that the coating is distributed evenly, resulting in a uniform and glossy finish. The key features of a Tablet Coater are:

Accurate control over coating thickness

Even the distribution of the coating material

Reduces the risk of overcoating or undercoating

Minimizes batch-to-batch variations

Advantages of using a Tablet Coater in pharmaceutical manufacturing

The use of a Tablet Coater offers several advantages in pharmaceutical tablet coating processes:

Enhanced tablet appearance and patient acceptability

Protection of tablets from environmental factors

Improved taste masking

Precise control over the coating process

Reduced batch-to-batch variations

The Future of Pharmaceutical Coating with Tablet Coater

The future of pharmaceutical manufacturing is driven by the need for more efficient and precise processes. Tablet Coaters are becoming increasingly sophisticated, with innovations such as real-time monitoring and automation. These advancements ensure higher quality products and more cost-effective production. In the coming years, we can expect to see even more advanced Tablet Coaters that streamline the coating process and minimize human intervention.

Water Maze: Sustainable Pharmaceutical Wastewater Treatment

What is a Water Maze?

Pharmaceutical manufacturing involves a significant amount of water usage, leading to the generation of wastewater containing various contaminants. A Water Maze, also known as a wastewater treatment system, is an innovative solution that addresses the challenge of pharmaceutical wastewater treatment. It is designed to treat and purify wastewater, making it environmentally safe for disposal.

How does a Water Maze work?

A Water Maze system employs a combination of physical, chemical, and biological treatment processes to purify pharmaceutical wastewater. The primary steps involved in a Water Maze system are:

Screening and solids removal

Chemical treatment to neutralize and precipitate contaminants

Biological treatment using microbes to break down organic compounds

Final clarification and disinfection

The key features of a Water Maze system include:

Sustainable wastewater treatment

Compliance with environmental regulations

Reduced environmental impact

Safe disposal of pharmaceutical wastewater

Advantages of using a Water Maze in pharmaceutical wastewater treatment

The use of a Water Maze system offers several advantages in pharmaceutical wastewater treatment:

Environmental sustainability

Regulatory compliance

Cost-effective wastewater treatment

Reduced environmental impact

The Future of Pharmaceutical Wastewater Treatment with Water Maze

With increasing environmental concerns and stringent regulations, the pharmaceutical industry is constantly searching for more sustainable ways to manage wastewater. The Water Maze system represents the future of pharmaceutical wastewater treatment, with advancements in technology and automation that make it even more efficient and eco-friendly. Pharmaceutical companies are likely to invest in cutting-edge wastewater treatment solutions like Water Maze to minimize their environmental footprint.

Conclusion:

In the pharmaceutical industry, where precision and efficiency are of utmost importance, the FBD Fluid Bed Dryer, Tablet Coater, and Water Maze system are shaping the future of pharmaceutical drying, coating, and wastewater treatment. These advanced technologies not only enhance product quality but also contribute to sustainability and cost-effectiveness.

As pharmaceutical manufacturing continues to evolve, we can expect to see even more innovations in these areas, making them indispensable tools for the future of pharmaceutical production. With the integration of FBD Fluid Bed Dryer, Tablet Coater, and Water Maze, the pharmaceutical industry is well-positioned to meet the demands of a rapidly evolving world.

0 notes

Text

What is Rubber Machinery?

Machinery used to manufacture various rubber products such as tires, including general rubber machinery, tire machinery and other rubber product machinery 3 categories.

Rubber machinery in general “Machinery for preparing rubber or semi-finished products, including raw material processing machinery, rubber mixing machines, extruders, calenders, curtain canvas pre-treatment devices and cutting machines.

Rubber mixing machines are divided into two types: open type and closed type.

Open rubber mixing machine: It is mainly used for hot mixing, tablet pressing, rubber breaking, plasticizing and rubber mixing. It consists of rollers, roller bearings, roller pitch adjustment device, emergency brake device, frame, machine base, transmission device, and heating and cooling system.

The working principle of the open rubber mixer is: raw rubber or rubber material is fed into the nip by friction between two rollers rotating at different speeds and subjected to strong shearing and compression to increase the degree of plasticity. This double roller open rubber mixing mill began to be used in production in 1826. Its structure is relatively simple and it is still commonly used in modern times.

Closed Rubber Mixing Machine: It is mainly used for plasticizing and mixing rubber. It has one more mixing chamber than the open mixer. After the raw rubber and compounding agent are loaded into the mixing chamber from the feed hopper, the material door is closed, the upper bolt of the pressing device is pressed down, and the two rotors of the mixing chamber mixture rotate in opposite directions at different or the same speed.

The charged rubber material is subjected to constant agitation, rolling and strong kneading between the rotors, between the rotors and the mixing chamber, which leads to oxidation and chain scission, which increases plasticity. At the same time, the rubber material is evenly dispersed and mixed due to shearing, so as to achieve the purpose of mixing the rubber.

Since the invention of the elliptical rotor enclosed rubber mixer in 1916, the enclosed rubber mixer has developed rapidly in the rubber industry. Subsequently closed rubber mixers with other types of rotors appeared. The mixing cycle of a modern closed rubber mixer is 2.5-3 minutes and the maximum capacity of the mixing chamber is 650 litres.

The extruder is used to extrude treads, inner tubes, hoses and various rubber strips, and is also used to coat cables and wire products. The most common is the screw extruder. Its working principle is: the rubber material is stirred, mixed, plasticized and compacted in the barrel by rotating the extrusion screw, and then it moves in the direction of the machine head and finally extrudes a product of a certain shape. From the mouth Depending on the needs of the product, various machines can be used for compound extrusion of a variety of rubber materials.

Screw extruders are divided into two types: hot feed and cold feed. Hot feed extruders generally feed strips that have been preheated by an open rubber mill. The rubber material fed by the cold feed extruder does not melt with heat, so the hot melt equipment can be omitted.

The calender is mainly used for pasting or rubbing curtain canvas, rubber material pressing, laminating, pressing and embossing. The main working part of the calender is the roller, and the number of rollers is usually 3 or more. When rubber material with a certain temperature and plasticity is fed into the gap of counter-rotating rollers, it is strongly squeezed and stretched under the action of friction to form the required product. The first calender was made and used in production in 1857, and it has been continually improved thereafter.

Especially since the 1950s, the development of the plastics industry has strongly promoted the improvement of high-precision and high-speed calenders. In order to obtain calendered products with a uniform thickness, new calenders are generally equipped with roll deflection compensation devices. The thickness of the calendered semi-finished product is measured with special equipment, and some calenders are also equipped with an automatic thickness adjustment system controlled by an electronic computer.

Tire Machinery

This type of machinery includes tire building machines, tire displacement machinery, tire molding vulcanizers, bladder vulcanizers, cushion belt vulcanizers, tube splicers and tube vulcanizers, as well as tire machinery, retreading machinery tires and recovered rubber production machinery. More than 60% of the world's rubber is used to make tires, so tire machinery occupies an important place in rubber machinery. Figure 2 is a flowchart of tire production.

The tire making machine is used to roll and process various components such as rubber cord, wire cord, and tread into a green tire. According to the purpose, it is divided into two categories: ordinary tire making machines and radial tire making machines.

The cords of the cords of the common tire carcass intersect at a certain angle. When forming, the cord tube is first placed in the building drum, and then wire loops are placed on both sides, and the cushioning layer and tread rubber are covered in the middle to form the shape. The green tire becomes cylindrical.

The main difference in the structure between radial tires and ordinary tires is that the cords of the cushion layer and the axis of the carcass are 90° 75° (almost orthogonal), so the diameter of the cushion layer does not it can be changed significantly after molding, so the carcass is made. After that you need to expand to the rough final shape and then attach the damping layer. Therefore, the structure of the radial tire making machine is also different from that of the ordinary tire making machine.

A molding machine completes the entire radial tire building process, which is called the one-time molding method. The carcass is made by a modified ordinary tire making machine, and then formed on the radial tire making machine, which is called the two-stage forming method.

Continuous Vulcanizing Ovens

Microwave Rubber Vulcanization

0 notes

Text

Types of Tablet Coating Equipment

Coating Pan Machine Models are available in a variety of sizes, including 30", 36", 42", 48", 60", and 72". The coating pan is equipped with a motor, MS cladding, a standard gearbox, an air filter, and a hot air blowing system with an SS pan on the interior, allowing the outer covering to be readily cleaned. To avoid foundation, the machine is mounted on dyna mounts, and the coating machine 30", 36", 42", or 48" features a variable-speed hot air blowing system. With a step pulley and no hot air blowing mechanism, a 60" or 72" coating machine is available in two speeds. The cilt coating machine features an interlocked circuit that can only be operated when the blowers are 'ON' to avoid heartburn.

Coating Pan is also known as the R&D Coating Pan since it is used in laboratories for research and development. Due to its small and compact size, it is also known as Mini Coating Pan, Small Coating Pan, and Compact Coating Pan.

The Coating SS Pan Mouth Ring's rim hollow helps to keep debris and tainted drugs out. Siemens and L&T have developed a cilt standard machine that includes a Redicon gearbox, NGEF or Siemens motor, and all electrical components. For economic reasons, the thermostat control Gear Box and electrical, including motors, are also offered on demand by the customer.

We are interested in offering a quality range of Manual Nitrogen Flashing that is used to pack all types of spices. We are one of the prominent firms operating in this sector. When making this nitrogen flashing, we only employ the highest quality components and cutting-edge technologies. The given nitrogen flashing is well-liked in the market because to its various excellent attributes. Aside from that, clients may get this nitrogen flashing at competitive costs from us.

An Ellipsoidal pan is mounted on a suitable stand and powered by a motor through the right gearbox in a coating pan machine. The pan is composed of stainless steel 316 and includes welded baffles. This baffle aids in the rotational tumbling of the tablets/material into the pan. A three-step pulley or a variable-speed drive in the control panel can adjust the speed. It includes a hot air blower, a coating pan with a heater assembly, and a flexible stainless steel tubing that inserts into the pan to dry the tablets/material after coating. A control panel aids in the provision of a starter or variable speed drive, as well as a digital temperature controller.

A spraying system for film coating/sugar coating into the coated pan's tablets/material with the pan coating. It comprises of a pressurised vessel with sufficient volume and spray guns set on a platform. The liquid in the container is sprayed into the coating pan on the coated item under pressure. A peristaltic pump aids in the flow of fluid into the spray cannon, which is then dispersed around the pan.

For expelling fumes generated by liquid spraying into the coating pan's tablets/material, we supply an exhaust blower as an alternative.

A wet scrubber aids in the neutralisation of exhaust emissions before they reach the open air.

I'd like to demonstrate how to select a new tablet coating equipment.

I understand that it is one of the most challenging processes, particularly for newcomers to the pharmaceutical industry.

I'll simplify the procedure by taking a whole different strategy.

That is, all existing tablet coating equipment must be classified based on its functioning principle and coating process/technique.

This manner, you'll be able to figure out what kind of tablet coater machine is best for your specific needs.

All extant tablet coating machines can be classified into the following categories based on their working principle:

· Coating Pan, Standard

· Coating Pan with Perforations

· Coater for Fluidized Beds

Every sort of tablet coating machine has a different working principle, as you'll see later in this text.

Essentially, this means that the structural design will be different as well.

I am confident that, armed with this knowledge, you will be able to select an appropriate tablet coater based on your personal requirements.

0 notes

Text

Touch Screen Technology Application and Classification

With the development of computer technology, the input method of the computer has gone from the original paper tape input to the keyboard input, to the mouse input, and then to the touch input, which has gone through four stages. This process is a process from professional to popularization. Touch screen technology allows more people to use the computer.

A touch screen is an interactive input device. The user only needs to touch a certain position on the screen with a finger or a light pen to control the operation of the computer. Therefore, the touch screen technology has the characteristics of simple operation and flexible use.

Touch screen is also called touch panel. When the graphic buttons on the screen are touched, the haptic feedback system on the screen can drive various linking devices according to a pre-programmed program, which can be used to replace the mechanical button panel and create a dynamic audio-visual effect by the LCD. Simply put, it is an inductive display device that can be connected to input signals such as contacts.

The application scenarios and terminals of touch screens are very extensive, and they can be divided into 7 categories from the perspective of scene types:

Type 1: Portable Equipment

Including Mobile phone, Pocket PC, E-book, Web Pad, Translator, Tablet PC, etc.

Type 2: Public Information Equipment

Including ATM, Public Inquiry Machine (Kiosk), Ticket Vending Machine, Digital Photo Printing System, etc.

Type 3: Communication Equipment

Including Video Phone, SmartPhone, Internet TV, Set-top box, GPS, etc.

Type 4: Office Automation Equipment

Including Copier, Punch Card Machine, Word Processor, Electronic Touch Whiteboard, etc.

Type 5: Information Collection Equipment

Including POI, POS Information Inquiry Machine, etc.

Type 6: Information Appliances

Including Refrigerator, Microwave, Coffee Maker, Washing Machine, LCD TV, etc.

Type 7: Entertainment Devices

Including Gaming Machine, Gambling Machine, Slot machine, Roulette machine, etc.

According to the type of sensor, touch screens are roughly divided into five types: infrared, resistive, surface acoustic wave(SAW), capacitive touch screens, and electromagnetic touch screens.

Infrared technology touch screens are inexpensive, but the outer frame is fragile, which is prone to light interference and distortion in curved surfaces. The design of capacitive technology touch screens is reasonable, but it is difficult to solve the problem of image distortion. The positioning of resistive technology touch screens is accurate, but its The price is quite high, and it is afraid of scratching; the surface acoustic wave touch screen solves the various defects of the previous touch screen, and it is not easy to be damaged. It is suitable for various occasions. The disadvantage is that if there are water droplets and dust on the screen surface, the touch screen will become dull It doesn't even work; electromagnetic technology touch requires a professional stylus, which is inconvenient to use.

1.Infrared touch screen

The principle of the infrared touch screen is very simple, just add the frame frame of the light spot distance on the display, without adding a coating or connecting the controller to the surface of the screen. Infrared emitting tubes and receiving tubes are arranged on the four sides of the frame from the light spot to form an infrared network on the screen surface. When the user touches a certain point on the screen with his finger, the two infrared rays passing through the position are blocked, and the computer can immediately calculate the position of the touched point. Because the infrared touch screen is not affected by current, voltage and static electricity, it is suitable for some harsh environmental conditions. Its main advantages are low cost, easy installation, no need for cards or any other controllers, and it can be used on computers of all grades. However, since the frame is only added to the ordinary screen, the infrared emitting tube and the receiving tube around the frame are easily damaged during use.

2.Resistive touch screen

The surface touched by the finger is a hard coating to protect the underlying PET layer. The PET layer is a thin elastic PET film that bends downward when the surface is touched, and allows the two underlying ITO coatings to contact each other and connect the circuit at that point. Between the two ITO layers is a separation fulcrum about one thousandth of an inch thick that separates the two layers. At the bottom is a transparent hard bottom layer to support the above structure, usually glass or plastic.

3.Surface Acoustic Wave(SAW) touch screen

A surface acoustic wave is a mechanical wave that propagates along the surface of a medium. The touch screen is composed of a touch screen, a sound wave generator, a reflector and a sound wave receiver. The sound wave generator can send a high frequency sound wave across the surface of the screen. When a finger touches the screen, the sound wave on the contact point is blocked Determine the coordinate position. The surface acoustic wave touch screen is not affected by environmental factors such as temperature and humidity. It has extremely high resolution, excellent scratch resistance, and long life (50 million times without failure); high light transmittance (92%), which can maintain clear and translucent Image quality; no drift, only need to be corrected once during installation; there is a third axis (ie pressure axis) response, which is most suitable for use in public places.

4.Electromagnetic touch screen

The basic principle of the electromagnetic induction touch screen is to judge by the magnetic field generated by the sensor under the panel during the operation of the electromagnetic pen. The electromagnetic pen is the signal transmitter, and the antenna board is the signal receiver. When a change occurs, the position point is defined by the operation.

5.Capacitive touch screen

Capacitive touch screens are divided into surface capacitive touch screens and projected capacitive touch screens.

(1) Surface Capacitive Technology:

The surface capacitive touch screen uses only a single layer of ITO, and long and narrow electrodes are plated on all four sides of the touch screen to form a low-voltage AC electric field within the conductor. When a finger touches the screen surface, a coupling capacitance is formed between the finger and the conductor layer, and a certain amount of charge is transferred to the human body. In order to recover these charge losses, the charge is replenished from the four corners of the screen, and the amount of charge replenished in all directions is proportional to the distance of the touch point, from which we can calculate the position of the touch point.

(2) Projected Capacitive Technology:

Compared with surface capacitive touch screens, projected capacitive touch screens can penetrate a thicker cover layer and do not require correction. Inductive capacitive etching of different ITO modules on two layers of ITO coating requires consideration of factors such as the total impedance of the module, the impedance of the connecting line between the modules, and the parasitic capacitance generated at the intersection of the two layers of ITO modules.

Which of the five touch screens do you like best? And which one is the best choice?Please follow our next article to learn more!

0 notes

Text

In-Depth Guide to Ball Mill Machine, Tablet Coater, & Double Cone Blender in Manufacturing

The modern manufacturing industry relies heavily on advanced machinery to streamline production processes and ensure the highest quality output. Among the key players in this landscape are the Ball Mill Machine, Tablet Coater, and Double Cone Blender. In this comprehensive guide, we will delve deep into these three pivotal pieces of equipment, exploring their working principles, applications, and advantages in the world of manufacturing.

1.Ball Mill Machine

1.1 Working Principle

The Ball Mill Machine is a versatile workhorse in various industries, including pharmaceuticals, chemicals, and mining. At its core, the ball mill operates on a fundamental principle – that of impact and attrition. A cylindrical shell, mounted horizontally, houses the material to be ground along with the grinding medium, typically steel balls. As the shell rotates, the balls cascade within, impacting and grinding the material, ultimately reducing it to a fine powder.

1.2 Applications

Pharmaceutical Industry: Ball mill machines are indispensable for pharmaceutical manufacturers. They are used to create finely powdered medicines, ensuring consistent particle size and product quality. In pharmaceuticals, precision is paramount, and ball mills provide the necessary particle size control.

Chemical Industry: Chemical processes often begin with the mixing or reduction of materials into finer particles. Ball mills are crucial in this regard, facilitating the initial stages of various chemical reactions.

Mining Industry: In the mining sector, ball mills are employed to grind ores into a fine slurry. These slurries are then processed further, extracting valuable minerals. The efficiency of this grinding process directly impacts the overall mining operation.

1.3 Advantages

Precision in Particle Size Control: Ball mills allow manufacturers to achieve precise control over the size of particles, ensuring product consistency.

Versatility: These machines are capable of handling a wide range of materials, from minerals to pharmaceutical powders.

High Production Capacity: Ball mills are known for their high throughput, making them suitable for large-scale production.

Low Maintenance Requirements: With proper care, ball mills require minimal maintenance, which is crucial for minimizing production downtime.

2.Tablet Coater

2.1 Coating Process

Tablet Coater are a fundamental piece of equipment in the pharmaceutical industry, responsible for applying coatings to tablets. These coatings serve various purposes, including taste masking, protection from moisture, and controlled drug release. The tablet coating process involves placing tablets into a rotating drum. A coating solution is sprayed onto the tablets while they are in motion, ensuring an even and consistent coating. Subsequently, the coating solution is dried to create a solid, protective layer.

2.2 Applications

Pharmaceutical Industry: Tablet coaters are essential for pharmaceutical manufacturers to produce tablets with desirable characteristics. These characteristics may include extended-release formulations, improved palatability, or the ability to protect the drug from environmental factors such as moisture.

2.3 Advantages

Enhanced Drug Stability and Shelf Life: The coatings applied by tablet coaters improve the stability and shelf life of pharmaceutical products.

Improved Patient Compliance: Coatings can make tablets more palatable and easier to swallow, which enhances patient compliance with medication regimens.

Controlled Drug Release: Some tablets require a specific release profile. Tablet coaters enable manufacturers to control the rate at which the active ingredient is released within the body.

3.Double Cone Blender

3.1 Working Principle

The Double Cone Blender is a versatile blending and mixing machine primarily used for dry powders and granules. The blender consists of two conical-shaped vessels joined at their bases. The powders or granules to be mixed are loaded into the blender, and the vessel is set in motion, causing the materials to move and mix.

3.2 Applications

Pharmaceutical Industry: Double cone blenders are extensively used for homogenously mixing various pharmaceutical powders and granules. In pharmaceutical manufacturing, it's crucial to ensure that the active ingredients are uniformly distributed in the final product.

Food Industry: The food processing industry also benefits from double cone blenders. These machines are employed to blend various ingredients, ensuring consistent taste and quality in the final product.

3.3 Advantages

Gentle Mixing: Double cone blenders use a gentle mixing process, minimizing the risk of damaging sensitive particles.

Quick and Uniform Mixing: These blenders achieve quick and uniform mixing, critical for ensuring product consistency.

Easy Maintenance: Double cone blenders are relatively easy to clean and maintain, contributing to overall efficiency.

Importance of These Machines in Manufacturing

The significance of ball mill machines, tablet coaters, and double cone blenders in manufacturing cannot be overstated. These machines provide the precision, efficiency, and versatility needed to meet high-quality standards and maintain consistent product output. Whether it's the production of pharmaceutical formulations, blending ingredients in the food industry, or processing ores in mining, these machines play an integral role in enhancing productivity and ensuring quality.

Conclusion

In the ever-evolving world of manufacturing, the Ball Mill Machine, Tablet Coater, and Double Cone Blender stand as stalwart allies in achieving precision and efficiency. Understanding how these machines operate and their applications is essential for professionals in pharmaceuticals, chemicals, and other related industries. These machines empower manufacturers to optimize their processes, produce top-notch products, and remain at the forefront of their respective fields.

This comprehensive guide has explored the fundamental aspects of ball mill machines, tablet coaters, and double cone blenders, shedding light on their working principles, applications, and advantages. As you navigate the complex world of manufacturing, remember that these machines are your trusted companions in the quest for excellence and efficiency. For further insights into specific aspects of these machines or their roles in various industries, don't hesitate to explore our blog for in-depth articles on each of these remarkable manufacturing tools.

0 notes

Text

A tablet coating machine is a piece of systemic machinery that coats an external surface of a tablet using a thin material coating material.

Visit https://www.chitramechtech.com/working-principle-of-automatic-tablet-coating-machine/ to know more.

0 notes

Text

Peristaltic Pumps Market by Type (Peristaltic Tube Pumps, Peristaltic Hose Pumps), Discharge Capacity (Up To 30 Psi, 30-50 Psi, 50-100 Psi, 100-200 Psi and Above 200 Psi) End-Use Industry, and Region - Global Forecast to 2025 published on

https://www.sandlerresearch.org/peristaltic-pumps-market-by-type-peristaltic-tube-pumps-peristaltic-hose-pumps-discharge-capacity-up-to-30-psi-30-50-psi-50-100-psi-100-200-psi-and-above-200-psi-end-use-industry-and-region.html

Peristaltic Pumps Market by Type (Peristaltic Tube Pumps, Peristaltic Hose Pumps), Discharge Capacity (Up To 30 Psi, 30-50 Psi, 50-100 Psi, 100-200 Psi and Above 200 Psi) End-Use Industry, and Region - Global Forecast to 2025

“Peristaltic pumps market expected to register CAGR of 6.4% during the forecast period.”

The peristaltic pumps market is estimated to be USD 1.2 billion in 2020and is projected to reach USD 1.8 billion by 2025, at a CAGR of 6.4%, between 2020 to 2025.The peristaltic pumps market is of two types; peristaltic tube pumps and peristaltic hose pumps. The rising investments in the expansion of water & wastewater treatment plants worldwide and increasing production of pharmaceutical products across the globe are expected to drive the global peristaltic pumps market during the forecast period. Frequent replacement of hoses or tubes and the pulsed flow characteristics of peristaltic pumps are the major restraints in the peristaltic pumps market.

“Peristaltic tube pumps are the fastest-growing type of peristaltic pumps.”