#assembly line systems

Explore tagged Tumblr posts

Text

Assembly Line Systems - Expert Technologies Group

Optimise Your Production with Expert Technologies Group’s Assembly Line Systems

In the dynamic landscape of manufacturing, where precision and efficiency are paramount, finding the right partner for your assembly line systems is crucial. Enter Expert Technologies Group, a beacon of excellence in the realm of production line solutions. Here’s why they stand out, making them the preferred choice for businesses seeking a transformative edge:

Technological Prowess: Expert Technologies Group is synonymous with cutting-edge technology. Their assembly line systems integrate the latest innovations, ensuring that your manufacturing processes are not just efficient but are ahead of the curve in terms of technological advancements.

Unparalleled Expertise: With a team of seasoned professionals, Expert Technologies Group brings a wealth of expertise to the table. Their engineers and specialists understand the intricacies of assembly line processes, guaranteeing solutions that address your unique challenges and goals.

Streamlined Workflows: Efficiency is at the core of Expert Technologies Group’s ethos. Their assembly line systems are meticulously crafted to streamline your workflows, resulting in reduced bottlenecks, improved throughput, and a more synchronised production process.

Elevate your assembly processes with Expert Technologies Group. It’s not just about upgrading systems; it’s about future-proofing your operations. Contact them today and embark on a journey towards a more efficient, precise, and technologically advanced assembly line systems.

0 notes

Note

I have come back am I allowed to ask about more WIPs from your list. I am so so curious about "Shen Yuan Gets Two Daemons", the intersection of daemons with transmigration is so interesting to me. (I may be back again later but I am trying once again to not do So Many Asks At Once)

omg thank u for the continued asks!!

for this fic, the concept is that when shen yuan transmigrates into shen qingqiu, he takes over the OGs body but not his soul. therefore ergo, shen qingqiu is gone, but his daemon is still there. shen yuan reluctantly makes a deal with the og scum villain's daemon—xiu ya won't turn him in for the body snatching if shen yuan works on finding a way to resurrect shen qingqiu. shen yuan's own soul is very excited to suddenly have a body of her own AND a bonus brother.

Shen Yuan returns to the world of the living with a scream. Not his own, as it turns out. He awakens laying in bed, something warm and soft and weighty laying in his chest. There’s a soft thump thump thump that beats in time with his heart. For a moment, he feels perfectly at peace—like the best ASMR ever, sending tingles through his whole body and making every muscle relax. That’s when the screaming starts. Shen Yuan shoots up and instantly regrets it. The weight on his chest goes flying off with a discontented noise, and the room spins around him. He’s caught between a need to get up, to find and soothe the source of the sound, and an arresting vertigo that steals the air from his lungs. The result is him flailing half way out of bed in a tangle of—silk? Two large, firm hands catch him around the shoulders. “Shidi, please, stay in bed. Everything will be alright. I’ve called for Mu Qingfang. A-Su is doing what she can. Just stay still.” Shen Yuan doesn’t recognize the latter name, but the former pings something in the back of his mind. He looks up blearily as those hands gently press him back into the mattress. The man leaning over him has a broad, handsome face that, combined with the dark eyes and gentle, worried crease to his brow, immediately puts Shen Yuan in mind of his older brothers. He allows this to be his excuse for folding right away, letting himself be manhandled back into bed even as half of his brain is clawing for him to move, to help. He looks over the man’s shoulder, searching for the source of the agonized screaming. It sounds like someone is being murdered. What he finds is a sight his mind can’t fully comprehend. There is a large dog in a corner of the room with its paw holding something down. The thing under its paw is a shifting mass, leaking strange golden dust. One moment there is fur, then feathers, then scales. It screams all the while. “What’s wrong with him?” Shen Yuan asks blankly. “I’m not sure,” the man says, “but we are going to fix it.” His eyes look sad. There is a little scrabbling noise, barely audible over the creature in the corner’s yelling. A fluffy white cat jumps onto the mattress and climbs up onto Shen Yuan’s chest. “Ah,” he says, and his hands instinctively come up around her. She must be what he accidentally flung away before. She makes a sleepy grumble and gets comfortable. Shen Yuan finds his energy and his ability to comprehend his surroundings fading rapidly, now that she is there, warm and solid in his arms. He bats away the human hand that reaches for his wrist absently. “Xiao Jiu, that—” The man next to the bed looks strangely horrified as he drifts off. Shen Yuan has no idea who he was talking to.

#daemon au#svsss#svsss fic#scum villain fanfic#qijiu#bingqiu#his dark materials#shen qingqiu#shen jiu#shen yuan#yue qingyuan#scum villains self saving system#scum villain#burywrites.pdf#buryspeaks.mp3#my fics#my writing#this one also doesnt have a title rip#also very little written of it bc sadly its lined up after some other fics on the assembly line at the moment rip#but its gonna get here eventually#unless? maybe i use this as my freeform prompt for the gotcha? we shall see

57 notes

·

View notes

Text

i am the number one fan of torturing Brennan Lee Mulligan, but it's honestly heartwarming to me how much Brennan suffers in episodes not designed around him, especially in the episodes he was a sub for. [spoilers through Game Changer 6.5]

for the first long stretch, Brennan was just very good at figuring out and adapting to a new game, and it was a bit less fun when he kept winning. where i'm from, when one student knows the answer every time, the teacher calls on them less. then there was Yes or No and Second Place, which knock specifically Brennan down, but these two wrongs don't necessarily make a right.

but then but then for Cool as a Cucumber and Bingo, the game was control your heart rate and be a funny person with a brand, two things you can't logic game your way out of. and Brennan just gets to play. and that's what it's all about. it's inspiring that we can play the same game with people of a range of natural ability and have the same fun. and by fun i sometimes mean torture.

#game changer#i don't wanna take the sam as teacher metaphor too far cause it gets weird fast but one lesson does apply:#if one kid has revealed your system of education as less a communal fostering of curiosity and more an assembly line of boxes to check#you may want to change your system rather than its relationship to that kid#dropout#analyzing the themes

38 notes

·

View notes

Text

#sick new world#music#system of a down#slipknot#a perfect circle#alice in chains#bring me the horizon#kittie#powerman 5000#static-x#dope#sevendust#lamb of god#combichrist#front line assembly

56 notes

·

View notes

Text

Kilolab equipment | Glass Pilot Plant | manufacturer & suppliers | Goel Scientific | Canada

We serve best Kilolab equipment, Kilolab equipment price, best glass pilot plant, glass pilot plant equipment price, Assemblies Over Glass Lined Reactor Manufacturers, in canada

#Buy Kilolab equipment#Kilolab equipment price#best glass pilot plant#glass pilot plant equipment price#Assemblies Over Glass Lined Reactor#Reaction Unit#Extraction Unit#Fractional Distillation#Metal Jacketed Glass Reactor#Mobile Mixing System#Multi Purpose Unit#Reaction Distillation#Simple Distillation Units#Distributors#Dealers#Suppliers#Wholesalers#Manufacturers#in canada#Goel Scientific Glass Works Ltd#Canada#Ontario#Toronto#Ottawa#British Columbia#Vancouver#Burnaby#Victory#Quebec#Montreal

2 notes

·

View notes

Text

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

⚙️ Tool Balancer Market Forecast to Reach $762.8 Million by 2035 Amid Growing Demand in Manufacturing & Automotive Sectors

The global Tool Balancer market is poised to grow from $358.7 million in 2024 to $762.8 million by 2035, reflecting a compound annual growth rate (CAGR) of 7.1% over the forecast period.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/tool-balancer-market-research-report

Tool balancers are vital in reducing operator fatigue and improving workflow efficiency across applications such as manufacturing assembly lines, automotive maintenance, warehouse operations, and biomedical equipment handling. The report explores market expansion across dimensions like Product Type, Application, Technology Integration, and Load Capacity.

🔍 Competitive Landscape & Industry Trends

The Tool Balancer market is highly competitive, with top players focusing on innovation, durability, and ergonomic safety. Leading companies include:

Ingersoll Rand

Carl Stahl

Gleason Reel (Hubbell)

Conductix-Wampfler

Tractel

Aero-Motive (Woodhead, A Molex Company)

Hangzhou Tangcheng

POWERMASTER

James Walker

Fasten Enterprises

NAC-InterCom

TE Connectivity

Key drivers fueling market expansion include the evolution of Industry 4.0, growing automation needs, and heightened emphasis on operator safety and fatigue reduction.

🌍 Global Outlook & Demand Hubs

Major growth opportunities lie in:

Rapid industrialization in emerging economies

Technological innovations in smart lifting systems

Strategic partnerships for equipment standardization

Demand is particularly strong in the U.S., Germany, China, Japan, and the UK, with Indonesia, Chile, and South Africa emerging as attractive markets for Total Addressable Market (TAM) expansion.

🔄 Supply Chain Evolution

With North America and Asia-Pacific leading in adoption, the Tool Balancer market’s supply chain—ranging from raw material procurement and precision manufacturing to global distribution—is expected to grow in complexity and resilience.

Challenges such as limited awareness in smaller markets and high upfront costs are being addressed through educational outreach, cost-competitive innovation, and after-sales support strategies.

🧠 About DataString Consulting

DataString Consulting delivers actionable market intelligence through tailored B2B and B2C research projects. With over 30 years of combined experience, our experts track and analyze fast-evolving segments across 15+ industries worldwide to help clients navigate strategic decisions with precision and confidence.

#Tool Balancer Market Forecast#Industrial Tool Balancers#Manufacturing Line Optimization Tools#Automotive Assembly Equipment#Ergonomic Lifting Solutions#Load Handling Equipment#Industrial Safety Tools#Assembly Line Support Devices#Warehouse Equipment Market#Smart Balancing Systems#DataString Market Insights#Global Manufacturing Tools Trends

1 note

·

View note

Text

The Future of Industrial Automation: How Auto Bots Pvt. Ltd. is Leading the Way

The modern manufacturing industry relies heavily on industrial automation as its central structure. Companies achieve exceptional efficiency and productivity levels together with high accuracy through advanced technological implementations. The revolutionary sector finds one of its leading players in Auto Bots Pvt. Ltd. which operates as a prominent Pune-based organization. The company holds a prime position as the Assembly Line Machines Manufacturer in Pune and Automation Integrator Systems in Pune that has revolutionized the robotics and automation sector. The exploration of future industrial automation employs an analysis of Auto Bots Pvt. Ltd.’s leadership role in technological innovation.

0 notes

Text

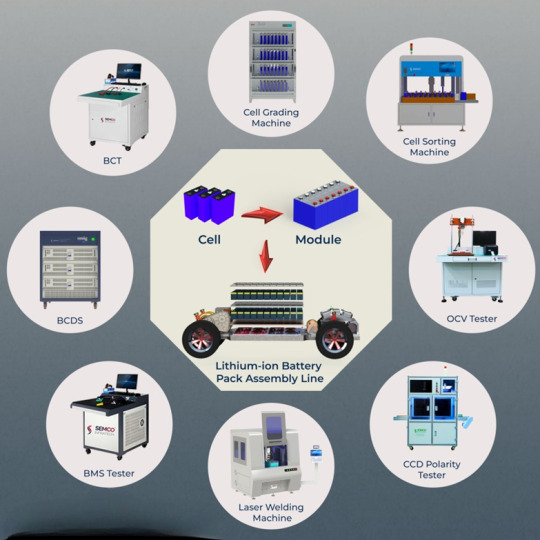

How a Lithium-ion Battery Assembly Line Works?

As the demand for electric vehicles (EVs) and energy storage solutions surges, the efficiency of lithium-ion battery assembly lines plays a crucial role in determining the success of battery manufacturers. A well-optimized assembly line ensures high precision, consistency, and cost-effectiveness. But how does the process work? Let’s dive into the key stages of a lithium-ion battery assembly line.

Cell Grading: The Foundation of Excellence

Cell grading is a crucial first step in the process when each battery cell is carefully examined to ascertain its performance parameters. To produce a thorough "report card" for every cell, capacity, and internal resistance are carefully examined. This methodical procedure guarantees uniformity and groups cells according to their performance attributes, establishing the groundwork for the best possible utilization of a battery pack.

Cell Sorting: Precision in Pairing

After grading, cells are sorted based on their specifications, optimizing the performance of the final battery pack. By ensuring that the batteries in a pack are precisely matched, this precision matching maximizes performance and prolongs battery life. To fully utilize each cell's potential within the battery pack's overall power, this phase must be carefully planned.

OCV Testing Machines

Open Circuit Voltage (OCV) testing machines measure the voltage of cells to ensure they meet the required standards before assembly.

CCD Polarity Tester

This equipment is used for precise alignment and assembly of battery components, enhancing the overall efficiency of the production process.

BMS Testing: The Guardian of Performance

At the heart of the battery pack lies the Battery Management System (BMS), serving as its vigilant guardian. Before integration, the BMS undergoes rigorous testing to validate its functionality and its ability to effectively communicate with the individual cells. This crucial step ensures that the BMS is equipped to monitor and regulate the health and performance of the battery pack with unwavering precision.

Cell Welding: Where Precision Meets Connectivity

As the testing cells await their transformation into a unified force, the delicate process of cell welding takes center stage. Automated robotic arms execute this task with precision, forging strong and reliable electrical connections between the cells. The seamless integration achieved through cell welding forms the foundational framework for the battery pack, ensuring its resilience and efficiency.

Battery Pack Testing or Aging: Trials of Endurance

The culmination of the assembly line journey leads to the final stage – rigorous testing of the complete battery pack. Depending on its intended application, this phase may encompass charging/discharging cycles to simulate real-world usage or accelerated aging tests to evaluate long-term performance and safety. Through these trials of endurance, the battery pack's resilience and reliability are put to the test, ensuring its readiness for the demands of modern life.

Battery Comprehensive Testing

Finally, comprehensive testing machines assess the battery packs' overall functionality, safety, and longevity before they are ready for deployment. The integration of these advanced machines not only streamlines the production process but also ensures that you deliver high-quality, reliable battery packs that power the future of transportation.

Conclusion: Precision, Innovation, and Reliability

From the meticulous grading of individual cells to the comprehensive testing of the assembled battery pack, the cell-to-battery assembly line embodies a fusion of precision, innovation, and reliability. Each step in this intricate process plays a pivotal role in shaping the quality, safety, and performance of the batteries that power our modern world. Behind every seamless charge and every enduring power source lies a journey of expertise and dedication, culminating in the creation of batteries that stand as pillars of energy in our technologically driven lives.

#Lithium-ion battery assembly line#Lithium-ion battery manufacturing process#Battery cell assembly#Lithium-ion battery production#Battery manufacturing equipment#Battery cell grading process#Battery cell sorting techniques#Battery management system testing#Cell welding in battery manufacturing#Battery pack aging tests#Comprehensive battery testing procedures

0 notes

Text

anyone know of good examples of mechanical body horror in prose? Ideally the kind of discomfort that comes from like, idk, watching videos of eye surgery. But fully mechanical. Needed for reasons.

#watching videos of people assembling animatronics and like#There's something about the uncanny valley there that gets across visually that I feel like i am struggling to capture in words#and it is harshing my vibes for a thing i'm writing that Needs that discomfort#but I don't know examples off the top of my head that do it without mixing biological systems in?#like 'oh this is disconcerting bc we're blurring the line between flesh and machine and that make my flesh feel bad' is not what i want#'this is disconcerting because this mechanical thing evokes a process that makes my flesh feel bad' is closer#maybe i need to put some effort into generating squickier metaphor#complaining

1 note

·

View note

Text

Automated Press Assembly Station Manufacturer & Supplier in Pune India

Discover Hytech Didactic's Automated Press Assembly Station Manufacturer and Supplier in Pune. Perfect for mechatronics training, PLC HMI training, and automated assembly training solutions.

#automated press assembly station Pune#assembly line manufacturer in pune#press assembly station Pune#mechatronics training Pune#mechatronics training cell Pune#Hytech mechatronics Pune#PLC HMI training Pune#automated assembly training Pune#industrial automation training Pune#press assembly automation Pune#automated press system Pune

0 notes

Text

Airbus Nearing Decision on H125 Helicopter Assembly Site in India

Airbus Helicopters is close to finalizing the location for its new final assembly line (FAL) in India, intended for the H125 helicopter. Eight potential sites are currently under evaluation, according to top Airbus Helicopters officials.

Expansion Plans in India

The proposed FAL, a collaboration between Airbus Helicopters and Tata Advanced Systems Limited (TASL), aims to meet the growing demand in India and South Asia. The decision on the location is expected soon, with the groundbreaking ceremony planned for late 2024 and the first H125 helicopter rolling out by 2026.

Olivier Michalon, Executive Vice President Global Business of Airbus Helicopters, emphasized that the final decision will consider factors like employee attractiveness, industrial activity, logistics, and regulations. “We are still in the final assessment stage but stay tuned, we should be in a position to announce shortly,” Michalon told reporters at Airbus Helicopters’ headquarters in Marignane, near Marseille.

Strategic Partnership

This FAL will be the first in the private sector in India, marking a significant milestone for Airbus and TASL. It follows the announcement made on India’s Republic Day during the French President Emmanuel Macron’s state visit to India. This is the second aircraft FAL by Airbus and TASL, with the first being the C295 military aircraft FAL in Vadodara.

Production Capacity and Future Prospects

Initially, the India FAL will have an annual production capacity of 10 H125 helicopters. Currently, the H125 is manufactured at Airbus Helicopters’ headquarters in Marignane, as well as in the US and Brazil. Although starting with a modest production capacity, Michalon mentioned the potential for significant expansion based on market demand. “Starting from scratch, it is not negligible. It could very well be 20, 30, or 50 in some years,” he noted.

Market Potential in India

India’s civil helicopter market, while currently small, holds immense potential due to its large population and economic growth. Airbus anticipates that producing the H125 in India will boost the usage of helicopters across various sectors.

Sunny Guglani, Head of Airbus Helicopters South Asia, highlighted the flexibility to ramp up production in response to demand. He cited a projected demand for 500 H125 class helicopters in India and neighboring countries over the next 20 years. “We have approximately 140 Airbus Helicopters in the region, with 100 in India alone,” Guglani stated, noting Airbus’s 40% market share in civil and para-public helicopters in the region.

Broader Implications

Michalon described the current market as “embryonic” but ripe for expansion. He pointed out that India’s growing middle and upper classes will drive demand for various services, including emergency medical services, law enforcement, firefighting, and disaster management. “We had two possibilities: either we wait for the sky to fully open, or we demonstrate our trust and the recognition of the potential of India and be ready to invest,” Michalon explained.

The H125, known for its versatility in missions like emergency medical services, law enforcement, and aerial work, is well-suited to meet India’s diverse needs. With around 7,200 H125 helicopters in operation worldwide, it is one of Airbus Helicopters’ most popular models.

Looking Ahead

Although smaller in scale, the H125 FAL in India will adhere to the same processes and standards as Airbus’s flagship facility in Marignane. The helicopters produced will carry the European Union Aviation Safety Agency (EASA) certification and will be competitively priced. Airbus is confident that this strategic move will enhance its global footprint and address the growing demand in the South Asian region.

In conclusion, Airbus’s decision to establish an H125 FAL in India is a testament to the country’s potential as a major hub for helicopter manufacturing and use. Stay tuned for the official announcement of the site location, which promises to be a significant development in the aerospace industry.

#Airbus Helicopters#H125 Helicopter#India Assembly Line#Tata Advanced Systems Limited#Aerospace Industry

0 notes

Text

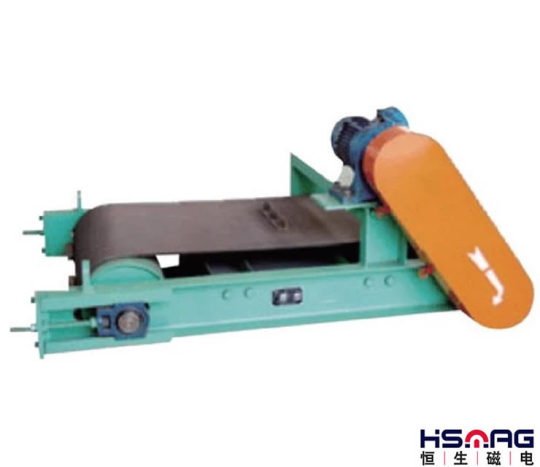

Magnetic Separator Conveyor Belts Types

Magnetic Separator Conveyor Belts Types Mgnetic separator conveyor belts move things from one place to another in factories. Some conveyor belts have magnets. The magnets take away pieces of metal that shouldn’t be there. This makes the product cleaner. It also stops metal from breaking machines further down the line. There are a few types of these magnetic separator conveyor belts. Each one…

View On WordPress

#Belt Drum Separator#Drum separators#hump magnets#In-line Magnets#industrial application#Industrial Magnetic Assemblies#industrial magnetic equipment#Magnet Design#magnetic attraction#Magnetic belts#Magnetic Circuits#magnetic components#Magnetic device#Magnetic drum separators#MAGNETIC field#magnetic field attraction#Magnetic Filters#Magnetic Filtration#magnetic filtration system#Magnetic Liquid traps#magnetic permeable sheets#Magnetic pulley separator#Magnetic Pulleys#Magnetic Separation#magnetic separation assemblies#magnetic separation equipment#magnetic separation systems#Magnetic Separator#Magnetic Separator Conveyors#Permanent magnet types

1 note

·

View note

Text

"Sodium-ion batteries for electric vehicles and energy storage are moving toward the mainstream. Wider use of these batteries could lead to lower costs, less fire risk and less need for lithium, cobalt and nickel.

On Nov. 18, CATL, the world’s largest battery manufacturer, announced its second-generation sodium-ion battery, mass production of which would begin in 2027. The China-based company said the new battery has an energy density of 200 watt-hours per kilogram, which is an increase from 160 watt-hours per kilogram for the previous generation that launched in 2021. Higher energy density in an EV battery translates into more driving range.

On Nov. 21, a consortium of seven U.S. national laboratories announced a new initiative in which they would spend $50 million to foster collaboration to accelerate the development of sodium-ion batteries. The partnership is led by Argonne National Laboratory in the Chicago area.

The two announcements are part of a larger shift as governments, researchers and companies look for alternatives to lithium-ion batteries, the dominant technology for EVs and energy storage.

For now, there are no passenger cars or trucks sold in the United States that use sodium-ion batteries. Some sodium-ion models are available in China and countries that import vehicles from China.

“The reason we’re pursuing this is very simple,” said Venkat Srinivasan, a battery scientist at Argonne and the director of the new collaboration. “It’s because the huge demand in lithium-ion batteries has meant that we have a supply-chain constraint.

“We have a problem with cobalt. We have a problem with nickel,” he said, naming two of the metals often used in lithium-ion batteries.

Cobalt, nickel and lithium carry a variety of concerns, including the environmental damage of mining. [Note: Which is massive, and so are the human rights issues associated with lithium mining, which involves horrible conditions and is exacerbating conflict and civil wars in the Democratic Republic of Congo.] ...

In contrast, a sodium-ion battery relies on an element—sodium—that you can find in table salt and ocean water...

Also, a sodium-ion battery has much lower risk of fire. When lithium-ion batteries sustain damage, it can lead to “thermal runaway,” which triggers a dangerous and toxic fire.

The process of manufacturing sodium-ion batteries is similar to that of lithium-ion batteries, or at least similar enough that companies can shift existing assembly lines without having to spend heavily on retooling.

But sodium-ion batteries have some disadvantages. The big one is low energy density compared to lithium-ion. As a result, an EV running on a sodium-ion battery will go fewer miles per charge than a lithium-ion battery of the same size...

The national labs’ initiative has a five-year timeline, with a goal of developing sodium-ion batteries with energy densities that match or exceed those of today’s iron phosphate-based lithium-ion batteries. Researchers would do this by finding various efficiencies in design and materials.

The project is happening alongside the labs’ ongoing work to develop and improve other kinds of batteries.

Lithium-ion batteries dominate today’s market...

However, sodium-ion battery production is growing, and is projected to reach 140 gigawatt-hours by 2030, about 13 times its current level, according to Benchmark. Lithium-ion production also is projected to nearly triple by 2030.

“The key market driver for sodium-ion batteries is their potential to be cost competitive with lithium-ion batteries,” said Catherine Peake, an analyst for Benchmark...

Most of the push by battery companies to build sodium-ion systems is happening in China, but some of it is happening in other markets, including a plan by California-based Natron Energy to open its first large plant in Rocky Mount, North Carolina. Natron made its announcement about the $1.4 billion project in August and has not given a timeline for when the plant would be online.

Meanwhile, researchers and companies continue working on other battery technologies.

I asked Srinivasan how sodium-ion batteries fit into this larger picture. He said sodium-ion will likely gain market share over the next few years as an alternative to lithium-ion batteries.

Near the end of the decade, solid-state batteries will begin to become available, which would allow for higher energy densities and longer driving ranges. Solid-state batteries use a solid electrolyte instead of a liquid or gel. The electrolyte is the substance through which ions move as they go from side to side during charging and discharging.

The technologies can coexist in the market, Srinivasan said.

He thinks solid-state batteries will initially be most common in high-end models and popular with people who want the longest possible ranges.

He expects that sodium-ion batteries will be more common in low-cost EVs for people who live in cities or suburbs and don’t place a high premium on driving range.

“It will not be a fringe player,” he said, about sodium-ion. “It will actually be a fast-growing segment.”"

-via Inside Climate News, December 6, 2024

#ev#electric vehicles#sodium ion#lithium#lithium battery#lithium ion batteries#lithium mining#mining#cars#good news#hope

819 notes

·

View notes

Text

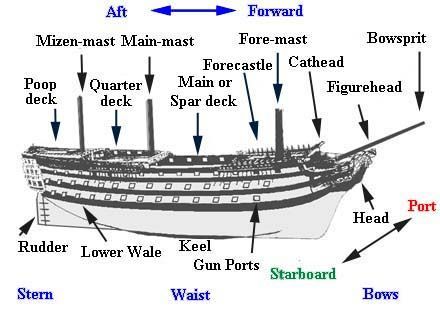

Glossary of Nautical Terms - as used in the late 18th and early 19th centuries

Aft: at or towards the stern or after part of a ship, the opposite of bow.

Aloft: overhead, or above.

Athwart: across.

Bank: a rising ground in the sea, differing from a shoal, because not rocky but composed of sand, mud or gravel.

Becalmed: to halt through lack of wind.

Bow: the foremost end or part of a ship, the opposite of stern.

Bowsprit: a large mast or piece of timber which stands out from the bow of a ship.

Burthen: the older term used to express a ship's tonnage or carrying capacity. It was based on the number of tuns of wine that a ship could carry in her holds, the total number giving her burthen.

Chase, to: to pursue a vessel in wartime with the aim of capturing, acquiring information from her, or destroying.

Colours: the name by which the national flag flown by a ship at sea is known, used to determine nationality.

Dead reckoning: a system of navigation where the position of a ship is calculated without the use of any astronomical observation whatever.

Fair wind: a wind favourable to the direction a ship is sailing.

Fathom: a measure of six feet, used to divide the lead (or sounding) lines in measuring the depth of water; and to calculate in the length of cables, rigging, etc.

Fore: the forward part.

Hail, to: to call to another ship.

Helm: the instrument by which the ship is steered, and includes both the wheel and the tiller, as one general term.

Jib: a triangular sail set by sailing ships on the boom which runs out from the bowsprit.

Jury-mast: a temporary makeshift mast erected to replace a mast that has been disabled or carried away.

Jury-rudder: a makeshift arrangement to give a ship the ability to to steer when she has lost her rudder.

Keel: the lowest and principal timber of a wooden ship - the single strongest member of the ship's frame.

Knot: the nautical measure of speed, one knot being a speed of one nautical mile (6,080 feet) per hour. As a measure of speed the term is always knots, and never knots an hour.

Landfall: the discovery of the land.

Land-locked: sheltered all round by the land, so that there is no view of the sea.

Lead: an instrument for discovering the depth of water, attached to a lead-line, which is marked at certain distances to measure the fathoms.

Lee: the side of a ship, promontory, or other object away from the wind; that side sheltered from the wind. It is the opposite side to windward.

Lee shore: a coastline on to which the wind blows directly - consequently it can be dangerous as the wind tends to force the sailing ship down on it.

Leeward: with the wind; towards the point to which the wind blows.

Letter of Marque: a commission issued in Britain by the Lord High Admiral or Commissioners of the Admiralty authorizing the commander of a privately owned ship to cruise in search of enemy merchant vessels. The letter of marque described the ship, her owners and officers, the amount of surety which had been deposited and stressed the necessity of having all prize vessels or goods seized condemned and valued at a Vice Admiralty Court for the payment of 'prize money'.

Lie-to: to prevent a vessel from making progress through the water - achieved by reducing sail in a gale. The objective is to keep the vessel in such a position, with the wind on the bow, as to ensure that heavy seas do not break aboard.

The Line (or 'Crossing the Line') Sailing across the Equator. Nautical tradition where seamen celebrate the crossing of the equator by dressing up and acting out a visit by King Neptune. Those who have not previously crossed the line are summoned to the court of Neptune for trial, followed by a ritual ducking (in a bathing tub of seawater) and sometimes lathered and roughly shaved.

Mainsail: the principal sail of a sailing vessel.

Mizzen (or mizen): the name for the third, aftermost, mast of a square-rigged sailing ship or of a three-masted schooner.

Muster: to assemble the crew of a ship on deck and call through the list of names to establish who is present and accounted for.

Muster-book: the book kept on board a vessel in which was entered the names of all men serving in the ship, with the dates of their entry and final discharge from the crew. It was the basis on which victuals were issued and payment made for services performed on board.

Pintle: a vertical metal pin attached to the leading edge of the rudder; it is fitted into the metal ring or 'gudgeon' bolted to the sternpost of a vessel. This provides the means for hinging the rudder on the sternpost and allows a rudder to be swung or turned as desired (by use of the tiller); where necessary (ie. when the rudder needs to be removed or repaired) the pintles can be unshipped quickly and the rudder detached.

Port: the left-hand side of a vessel as seen from the stern; also a harbour or haven.

Privateer: a privately owned vessel armed with guns which operated in time of war against the trading vessels of an enemy nation. Each privateer was given a a 'letter of marque' which was regarded as a commission to seize any enemy shipping as a 'prize'. The name 'privateer' has come to refer to both the ship and the men who sailed in her.

Prize: name used to describe an enemy vessel captured at sea by a ship of war or a privateer; also used to describe a contraband cargo taken from a merchant ship. A 'prize court' would then determine the validity of capture of ships and goods and authorize their disposal. 'Prize' in British naval history always acted as considerable incentive to recruitment with many men tempted to join the navy in anticipation of quick riches.

Prize Court: Captured ships were to be brought before prize courts where it was decided whether the vessel was legal prize; if so, the whole value was divided among the owners and the crew of the ship.

Prize Money: the net proceeds of the sale of enemy shipping and property captured at sea - these proceeds were distributed to the captors on a sliding scale from highest rank to lowest seaman.

Road or Roadstead: a stretch of sheltered water near land where ships may ride at anchor in all but very heavy weather; often rendered as 'roads', and does not refer to the streets of a particular port city but rather its anchorage, as in 'St Helens Roads', the designated anchorage for shipping located between St. Helens (Isle of Wight) and Portsmouth, or 'Funchal Roads' at the island of Madeira. (see Elizabeth Macquarie's 1809 Journal).

Quarter: (1)the direction from which the wind was blowing, particularly if it looked like remaining there for some time; (2)the two after parts of the ship - strictly speaking a ship's port or starbord quarter was a bearing 45° from the stern.

Ship: from the Old English scip, the generic name for sea-going vessels (as opposed to boats). Originally ships were personified as masculine but by the sixteenth century almost universally expressed as as feminine.

Shoal: a bank or reef, an area of shallow water dangerous to navigation. Sounding: the of operation of determioning the depth of the sea, and the quality of the ground, by means of a lead and line, sunk from the ship to the bottom, where some of the sediment or sand adheres to the tallow in the hollow base of the lead.

Sound: (1) to try the depth of the water; (2) a deep bay.

Sounding: ascertaining the depth of the sea by means of a lead and line, sunk from a ship to the bottom.

Soundings: those parts of the ocean not far from the shore where the depth is about 80 to 100 fathoms.

Spar: a general term for any wooden support used in the rigging of a ship - includes all masts, yards, booms, gaffs etc.

Squall: a sudden gust of wind of considerable strength.

Starboard: the right-hand side of a vessel as seen from the stern.

Stern: after-part of a ship or boat.

Tack: the nautical manouevre of bringing a sailing vessel on to another bearing by bringing the wind round the bow; during this manouevre the vessel is said to be 'coming about'.

Tide of Flood: the flow of the tidal stream as it rises from the ending of the period of slack water at low tide to the start of the period of slack water at high tide; its period is approximately six hours.

Trade Winds: steady regular winds that blow in a belt approximately 30 N. and 30 S of the equator. In the North Atlantic the trades blow consistently all year round, from the north-east; in the South Atlantic they blow from the south-east, converging just north of the equator. The meeting of the trade winds just north of the equator created the infamous 'doldrums', where sailing ships could be becalmed for days or weeks waiting for a wind to carry them back into the trades.They were known as trade winds because of their regularity, thereby assisting sailing vessels in reaching their markets to carry out trade.

Under way: the description of a ship as soon as she begins to move under canvas power after her anchor has been raised from the bottom; also written as 'under weigh.'

Voyage: a journey by sea. It usually includes the outward and homeward trips, which are called passages.

Watch: (1) one of the seven divisions of the nautical day; (2) one of two divisions of the seamen forming the ship's company.

Wear: the nautical manouevre of bringing a sailing vessel on to another tack by bringing the wind around the stern.

Weather: in a nautical sense (rather than a meteorological) this is the phrase used by seamen to describe anything that lies to windward. Consequently, a coastline that lies to windward of a ship is a weather shore; the side of a ship that faces the wind when it is under way is said to be the weather side a ship, etc.

Weigh: to haul up.

Weigh anchor: the raising of the anchor so that the ship is no longer secured to the sea or river bottom.

Windward: the weather side, or that direction from which the wind blows. It is the opposite side to leeward.

Yard: (1) a large wooden spar crossing the masts of a sailing ship horizontally or diagonally, from which a sail is set. (2) a shortened form of the word 'dockyard, in which vessels are built or repaired.

Sources: JEANS, Peter D. Ship to Shore: a dictionary of everyday words and phrases derived from the sea. Santa Barbara: ABC-Clio, 1993.

The Oxford Companion to Ships & the Sea. (ed.) Peter Kemp. Oxford: Oxford University Press, 1976.

#naval history#naval artifacts#ship terms#not from me#sources below#18th century#19th century#age of sail#infos

2K notes

·

View notes

Text

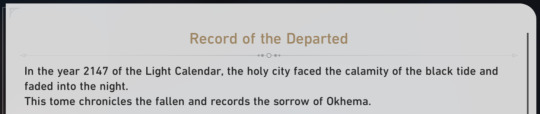

I know it's super popular to say that Mydei spent a year fighting the Black Tide in Castrum Kremnos because of these two lines:

But, though it might make me a stick in the mud to point it out, the time and date systems in Amphoreus seem to actually be completely arbitrary, with random skips, chronological overlaps, and insertions (and removals) of time gaps that actually make no sense at all.

For example, in 3.2, Cerces states that Anaxa has only 14 days to live following the attack on the Grove that led to them being fused. At the time Anaxa came to Okhema after the Grove disaster in 3.1, Mydei was still in Okhema.

As of 3.3, we're told explicitly that the Citizen's Assembly, which took place on Anaxa's 14th day, has "just wrapped up."

So somehow Mydei has achieved Schrödinger's War, simultaneously fighting for a couple weeks and a whole change of the calendar year at the same time. 😂

In the very same patch that Hyacine claims it is Year 4932 (3.3), we're also told that Okhema fell to the Black Tide in Year 2147...

Nearly 2800 years off from the other supposed dates.

Originally I thought we had perhaps gotten our hands on a document from a previous cycle, but that doesn't make sense because A) the Trailblazer adds more names to this sheet as you encounter more "ghosts" and B) A new cycle would restart the year numbering.

In short, I wouldn't trust a single time, day, or year given to us inside Amphoreus--nor would I trust a single Amphorean character's experiences with time itself.

Clearly both actual time and the characters' perceptions of time's passage are being extremely warped by the technology at play in Amphoreus, to the point that I think we're supposed to see it as almost eerie: None of the Amphorean cast seems to be able to recognize the inconsistencies of the time and space around them, nor do they ever seem capable of truly reflecting on the inconsistencies of their memories even when they acknowledge that there are inconsistencies.

We're in the Black Mirror, my dudes, and none of the "people" around us even recognize their own unreality.

Amphoreus is a horror story, for real for real.

#honkai star rail#amphoreus#amphoreus meta#3.3 spoilers#hsr spoilers#mydei#hyacine#I guess I don't need to tag for spoilers anymore but#if you haven't finished 3.3 that readable is a big one lol

336 notes

·

View notes