#DC Pump

Explore tagged Tumblr posts

Text

Pumping [Well] Water Without Electricity:

For city-dwellers, this won't be an option and massive water storage and/or filtering/purification may be the only options when the public water is contaminated or not running.

For those with Well Water, the Well may not be dry but the electric pump could go on the fritz or the grid could go down. If the grid is down, a power generator is the easiest method to power the well pump but if the electric pump is on the fritz, or there is some other situation when electricity is not available to pump water; you may need water out of an existing well or to pump from a pond, creek, or some other outside water source. That's when It's good to have a manual (emergency hand pump) and, maybe a 12-volt/DC, backup plan.

You only have to go down below the highest level of the water in your well (Static Water Level). Regardless of how deep the well is the static water level may only be 25 feet from the top. Obviously, in a drought situation that could drop but it's not necessary to pull water from the bottom of the well, only from the static water level.

These resources may be of assistance to you: Options for Pumping Water Without Electricity Ram Pump Build Video 1

Ram Pump Build Video 2

Ram Pumps 4 Sale Indoor Pitcher Pump High-End Hand Pumps for an Existing (Deep) Well:

[Article 1] [Article 2]

[Simple Pumps]

[Bison Pumps] Inexpensive Pumps: [EZ Web Site] [EZ Video]

[Freedom Web Site] [Emergency Web Site] [Emergency Video] [Other Videos]

[Reference Link]

Related Resources: Have a Long-Term Water Storage Plan for Emergencies Methods to Purify Water

[11-Cs Basic Emergency Kit] [14-Point Emergency Preps Checklist] [Immediate Steps to Take When Disaster Strikes] [Learn to be More Self-Sufficient] [The Ultimate Preparation] [P4T Main Index]

NOTICE: Contents of this blog have been gathered from sources believed to be reliable but should not be considered authoritative. You are solely responsible for your own actions on how you use this information. Do your own research on topic(s) included.

This blog is partially funded by Affiliate Program Links, included on this page, and Private Donations. Thank you for your support.

#well water#well pump#hand water pump#hand pump#prepare4tomorrrow#prepper#survival#water#diy#DC pump

17 notes

·

View notes

Text

How do I know if an oil pump is bad?

If you’ve worked around machines long enough, you’ll know ��� when an oil pump starts acting up, you feel it. Maybe the flow slows down, maybe there’s weird noise, maybe the whole system just feels… off. That’s when you need to pay attention.

In industries like workshops, marine, fuel handling, or heavy machinery, these pumps move oil or lubricants from one place to another. And when they fail? Everything grinds to a halt — literally.

Let me walk you through how to spot when an oil pump’s not doing its job.

You Know Your Oil Pump’s in Trouble When…

The Flow Gets Weak

First sign? The oil’s not moving like it used to. You might notice slower transfer, spluttering, or uneven flow. Big red flag.

Weird Noises Start

Grinding, clanking, screeching… trust me, that’s not normal. Pumps are noisy by nature, but odd sounds usually mean internal parts are wearing down.

Oil Leaks Everywhere

Leaking oil around the pump, hoses, or fittings? Could be seals gone bad or cracks somewhere. Check it fast — leaks slow everything down and waste product.

The Pump Gets Hot

A pump that’s heating up more than usual means it’s working harder than it should. Might be internal damage, or maybe oil’s not flowing properly.

It Works… Then It Doesn’t

Intermittent pumping — stops, starts, sputters? That’s never a good sign. It could be electrical, mechanical, or just plain old wear and tear.

What Messes Up an Oil Pump?

Simple stuff adds up:

Using dirty oil or poor-quality fluids

Running the pump dry (no oil in the line)

Skipping maintenance checks

Letting seals, hoses, or fittings get old

Overloading the pump beyond its rated capacity

Seen it happen too many times — small problems grow fast when ignored.

What Should You Do?

First thing - shut it down if something feels off. Keep running it, you risk damaging more than just the pump.

Check for:

Oil levels and condition

Visible leaks

Clogged lines or filters

Electrical issues (if it’s motor-driven)

If it’s beyond a quick fix? Time to call your supplier or maintenance team. Sometimes it’s cheaper to swap the pump than patch problems over and over.

Final Word

In this line of work, equipment downtime costs money. An oil pump that’s failing slows you down, wastes oil, and risks damaging your machines.

Trust your gut - when the pump sounds weird, leaks, or flow gets weak, deal with it. Regular checks and sticking with decent suppliers help avoid bigger breakdowns.

0 notes

Text

one last late entry for superbat week :D day 2: accommodation mishaps! inspired by that time they had to share a bed in superman/batman annual vol 1 (2006)

#superbat#superman#batman#bruce wayne#clark kent#dc#dc comics#dcu#my art#mine#superbat week 2024#YEEHAWWWW#can't believe i actually finished another entry but superbat really has me so so pumped to draw

13K notes

·

View notes

Text

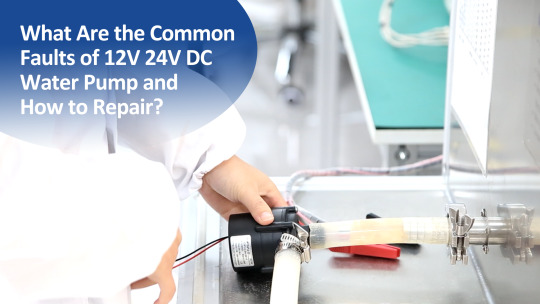

What Are the Common Faults of 12V 24V DC Water Pump and How to Repair?

12V 24V DC water pumps are essential components in various applications, from automotive systems to water circulation in industrial equipment. However, like all mechanical devices, they can encounter issues that affect their performance over time. To avoid operational disruptions and potential economic losses, it's essential for operators to become adept at diagnosing and addressing common pump problems. Here's a comprehensive guide to understanding common problems and how to address them:

No Water Flow From the Outlet:

Causes: Insufficient water in the pump chamber, leaks in the suction pipe or pump head, low speed leading to excessive mechanical seal leakage.

Solutions: Fill the pump chamber with water, fix air leaks, inspect and repair pipe connections, increase voltage to raise speed, and replace the mechanical seal.

Low Water Flow From the Outlet:

Causes: Blockages in the impeller flow channel or suction pipe, severe impeller wear, insufficient power resulting in low speed.

Solutions: Remove obstructions, replace the impeller, and adjust the speed to the rated level.

Pump Overheating:

Causes: Blocked inlet or outlet, insufficient cooling, or motor issues.

Solutions: Clear any obstructions, improve cooling, or check and replace faulty components.

Excessive Noise and Vibration:

Cause: Unstable installation support or worn pump bearings, poor rotor dynamic balance, eccentric bearing.

Solutions: Adjust support feet, replace bearings, and correct alignment.

Liquid Leakage:

Causes: Loose nut connecting the pump head and body, damaged sealing ring leading to mechanical seal damage.

Solution: Tighten the nut and replace the mechanical seal.

Pump Fails to Start:

Causes: Overly tight packing or debris jamming the impeller and pump body, debris blocking the pump shaft or bearing, severely bent pump shaft.

Solutions: Disassemble the pump body to remove debris or rust, correct or replace the pump shaft.

Interruptions in Water Pumping:

Causes: Blocked inlet or pipeline, loose pump shaft, falling water level at the inlet, suction of the inlet hose.

Solutions: Clear blockages, clean the water diversion pipe, reinforce the impeller, adjust installation position of 12V 24V dc water pump or wait for the water level to rise.

Insufficient Water Flow After Startup:

Causes: Low power machine speed leading to slow pump rotation, inadequate pump head, partially blocked pipeline or impeller, or impeller damage, minor water outlet pipe leakage.

Solutions: Restore the rated speed, seal any leaks, remove blockages, replace the impeller, or address minor leaks.

Gradual Decrease in Water Flow:

Cause: Accumulation of debris in the filter screen or bell mouth, lowering of the inlet water level.

Solutions: Remove debris and increase the inlet depth.

Regular maintenance and prompt problem-solving will help ensure the longevity and efficiency of your 12V 24V DC water pump, allowing it to continue serving your needs effectively. By understanding these common faults and knowing how to diagnose and repair them, you can extend the lifespan of your pumps, reduce downtime, and ensure consistent functionality. Remember that safety precautions should always be observed when handling and maintaining water pumps.

youtube

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Official Web: http://www.topsflo.com/

Key Words: 24v dc water pump,24v water pump, 12v dc pump,dc pump, brushless dc pump, dc brushless pump, 12v brushless pump, brushless 12V pump, 12v water pump, small water pump, dc water pump, dc motor pump, bldc water pump, 24v brushless dc pump,mini water pump, 12v mini water pump, 12v dc water pump , micro dc pump, Solar DC Water Pump,Solar DC Pump,hot water dispenser pump,EV charger pump,smart toilet pump,water heater pump,car circulation pump,car water pump,car preheater pump, server electronics cooling pump, server cooling pump, rack server cooling pump,water cooling pump, liquid cooling pump

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#water pump#dc pump#liquidcooling#bldcwaterpump#24vbrushlessdcpump#microdcpumps#microdcwaterpump#Youtube

0 notes

Text

orange is done. im free !!! (to finally do yellow)

#im so pumped for yellow and green actually ehehe#koriand'r#starfire#teen titans#bart allen#impulse#well not actually#im tagging him anyway#impulse 1000000#impulse one million#squirrel girl#doreen green#marvel rivals#aquaman#arthur curry#justice league#young justice#oh also#hermes#hades game#dc fanart#marvel fanart#rainbow challenge#ash.art

349 notes

·

View notes

Text

All these people on Twitter sharing Red Hood art with the captions like ‘it’s okay to punch Nazis’ while I appreciate the sentiment, he would not fucking say that. He would kill them. Guys cmon

#he is pumping lead into them without remorse like cmon let’s be real here#Red Hood#Jason Todd#batfam#batfamily#dc#Gotham

363 notes

·

View notes

Text

some kind of guy

#my art#dc comics#green lantern#guy gardner#drew this while listening to a mr plinkett review#one of these days i’ll be able to pump out a guy in 5 min lol help me

140 notes

·

View notes

Text

Spooky Month Supernatural AU

I watched three seasons of supernatural and of course I had to do this au.

extra info: Jack tried killing John when they first met. But yaoi happens lol

Patty isn’t pictured cause she is used as a vessel from Moloch. She will get freed but not rn.

skid and pump help the hunting community through finding info in old books, and through Hope.

Ross and Robert have specific psychic abilities:

Ross: Telepathy, Empathy, Clairvoyance , Mediumship

Robert: Telekinesis, Empathy, Precognition , Animal connection

#spooky month#spooky month ross#aus#spooky month robert#art#spooky month roy#non dc au#spooky month au#spooky month hatzgang#spooky month kevin#spooky month art#Spooky month jack#Spooky month susie#Spooky month pump#Spooky month john#spooky month hope#spooky month lila#spooky month jaune#spooky month rick#spooky month patty#spooky month radford#spooky month fan art#Spooky month skid#Spooky month ignacio#Spooky month moloch#spn#spnfandom

132 notes

·

View notes

Text

I headcanon that Tim's caffeine problem functions like my friends caffeine problem. In that he actually hates caffeine but he'll chug 3 red bulls when he needs to lock in. He's going to stay up regardless of the caffeine thanks to the insomnia. But without it he's not going to brain very much. He likes coffee less but it's an acceptant substitute of energy drinks are not available. He'll drink the energy drink over like a really sweet frappaccino because it's the only thing guaranteed to keep him alert and at peak mental condition. He doesn't drink it as often as people think he does but when he does drink energy drinks, he'll consume and ungodly amount in one sitting. Then he'll crash at like 5 in the morning and complain when he has to wake up 3 hours later.

#idk i love coffe addict tim#but reluctant caffeine issues tim is so much funnier#as a side note#i headcanon that tim likes sweet things as much as dick#and will get the most godawful calorie loaded drinks with like 10 pumps of syrup#because this boy grew up with very limited adult supervision#there's no one to limit his sugar intake#lena speaks#batman#dc comics#tim drake#robin#red robin dc#tim drake's coffee addiction#tim drake headcanon#also idk how my friend can hate caffeine as much as she does and still consume as much as she does#girl get help

66 notes

·

View notes

Text

Peter SO excited he can ask Dick about health issues on his side of the family, because he wasn't ever able to do that before

#your honor itd literally be so cute#“so lile what issues run on your side?” (secretly SO pumped to get an answer)#peter finding out hes predisposed to addiction#*eyeing dick in college#peter parker in gotham#spiderman in gotham#spiderman#peter parker#batman#batfam#dc#dc x marvel#dick grayson is the multiversal equivalent to peter's dad#dick grayson is richard parker#dick gray and richard parker are the same person

138 notes

·

View notes

Text

whenever i think about the constant slog of world-changing, massive events that writers keep pumping into detective comics comics i think about miyazaki and his mastery of portraying ma in his films — breathing space amidst action and movement. nothing feels important if everything is important. there are no stakes when the world is ending every other week. those quiet moments between tragedy and loss — trainsurfing, eating lunch together, sitting quietly on page while the world isn’t on fire — feel smaller and smaller each year. let moments pause long enough to mean something

#something something accelerationism#also this has ALWAYS been a problem but i think looking at the events dc is pumping out now things have gotten worse#knight terrors and beast world in a calendar year of each other….. Bad#dc comics#spokes

148 notes

·

View notes

Text

What is a diesel flow meter?

Where diesel fuel is mission-critical, in transportation, construction, logistics, and agriculture, there is a serious need to accurately measure consumption. A diesel flow meter is a measurement meter to measure the quantity or rate of diesel fuel in transit or consumed. From fuel consumption measurement by fleets to fuel storage tank measurement, the meter plays a significant role in saving money, making it more efficient, and accurate billing or stock control.

In this article, we’ll explore what a diesel flow meter is, how it works, its types, and the benefits it offers across various industries.

Understanding the Diesel Flow Meter

The diesel flow meter is an electric or mechanical gauge that provides a reading of the quantity of diesel flowing through a fuel dispensing device, hose, or pipe. They are utilized in trying to operate equipment such as boats, gas pumps, diesel generators, tankers, and machinery.

The primary application of a diesel flow meter is the delivery of accurate measurement of diesel fuel in fuel consumption optimization, fuel consumption monitoring, and fuel consumption control. It is utilized most effectively in cost saving, environmental conservation, and business efficiency improvement.

How Does a Diesel Flow Meter Work?

Principle behind diesel flow meter operation will be based on what type of flow meter it is, but the principle remains the same—calculates flow rate by knowing how much fuel passes through a chamber.

Examples of diesel flow meters most often utilized are:

1. Mechanical (Positive Displacement) Flow Meters

These meters use floating internal parts such as pistons or gears to measure fluid. They take one turn to gauge a nominal volume of liquid. They are highly accurate and precise, particularly in the case of constant flow.

2. Turbine Flow Meters

Turbine meters have a revolving turbine blade located in the diesel flow path. The rotation is directly proportional to diesel speed, and the flow rate is read by sensors.

3. Digital or Electronic Flow Meters

Digital flow meters utilize LCD or LED displays and typically consist of features like flow rate, total quantity, temperature compensation, and recording. They are also utilized in commercial fuel dispensers and next-generation industrial installations.

Applications of Diesel Flow Meters

Diesel flow meters find applications in industries and applications as:

Fleet Management: Monitor diesel fuel consumption of trucks and buses to make them fuel efficient.

Agriculture: Monitor tractors, harvesters, and irrigation pumps' diesel fuel usage.

Construction: Monitor heavy equipment fuel consumption of bulldozers and excavators.

Fuel Distribution: Monitor retail stations and bulk dispensing of diesel fuel properly.

Marine & Aviation: Monitor boats and ground support equipment's fuel usage.

Benefits of Having a Diesel Flow Meter

There are many benefits of buying a diesel flow meter:

Precise Fuel Monitoring: Avoids under- and over-dispensing of diesel.

Fuel Sparing: Saves fuel and prevents wasteful consumption of fuel.

Inventory Monitoring: Tracks fuel inventory and refilling cycle.

Efficiency in Operation: Maximizes industrial equipment and generator fuel usage.

Prevents Fuel Theft: Ideally suited for fuel sensing and fuel theft.

Conclusion

A diesel flow meter is an effective device for any organization that consumes huge quantities of diesel fuel. Whether it is a fuel depot, fleet, or heavy equipment company, this meter provides real-time information, accuracy, and control over fuel consumption.

With all the models and technology available which you can implement, you will need to select the most suitable type of flow meter that will best suit the level of operation and conditions that you want to achieve. Not only is this less expensive in terms of saving fuel cost, but this will also allow you to have better control over your fuel management system.

0 notes

Text

Someone give me the DC/DP crossover where the Lazarus Pits are ectoplasm but instead of fixing Jason, Danny makes him worse

#oh dude you’ve got a ton of contaminated ectoplasm#let me fix that for you#Jason - now with ghost powers and unbridled rage - I’m going to go commit so many murders#I just think maybe pumping a traumatized teenager full of afterlife goo should have some consequences#bonus:#Danny watching Jason rip the head off a pimp with his bare hands#*I want him so fucking bad*#DC/DP#jason todd#danny fenton#danny phantom#red hood

24 notes

·

View notes

Text

Ok I change my mind starlight express is not that bad

#checked it out a few months ago when I was listening to cats and i thought it was sooo bad#decided to give the soundtrack(s) another listen yesterday#original and the 2024 revival versions#and it’s not as bad as I remember. some of the songs are good even. i see the vision.#starlight express#still don’t really understand the plot tee bee haitch#Wikipedia synopsis is confusing to me. and I don’t really care to bootleg it.#but I like pumping iron#i like the fact they made greaseball a woman in the 2024 version I think it works great w the character. but wish they kept the Elvis thing.#also ac/dc from the ocr is really good#the red and blue costume? w the mohawk? cunt.#also why isn’t call me rusty on 2024 isn’t that like. the song that introduces the main character ?#tragic that they took out the insane guy as well#but I like the ballads on 2024 a lot more. not a big fan of love ballads anymore but they’re good here#also poppas/mommas blues has the funniest lyrics ever actually so iconic#i maintain that the show overall does not fuck as hard as it should#but it’s got it’s moments I see it now#also I’ve always had great respect for the outfits but I simply did not like them. but watching some clips…. they r growing on me.#fuck it maybe I will bootleg it sometime

27 notes

·

View notes

Text

erm

#i just keep pumping out aus. it's my curse. for everything i ever fixate on#my art#scott pilgrim#spto#spto au#dc comics#wallace wells#ramona flowers#knives chau#neil nordegraf#stephen stills#(he's batman)#the joker#harley quinn#batman#starfire#robin#scollace#scollace but worse tbh#I'M NOT SHIPPING KNIVES AND NEIL ALSO I SHOULD MAKE THAT CLEAR

201 notes

·

View notes

Text

wawa night shift worker: where are your parents

robin, just trying to buy some stakeout snacks: 🙁

#batman#dc#dcu#robin#dc comics#batfamily#i drafted this 4 months ago#tim drake#dick grayson#jason todd#also in nj u don’t pump ur own gas#wawa worker pumping the bat mobile like 😧😧

40 notes

·

View notes